Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Construction & Building Technology

Lead–zinc tailings are the typical solid wastes in mines with high yield and low utilization rates in some countries at present. They are mainly stockpiled in tailings reservoirs, occupying massive land resources and threatening the health of the environment.

- cement

- concrete

- geopolymer

1. Introduction

Lead–zinc tailings are the residual solid waste of lead–zinc ore after crushing and flotation [1]. China has a wide distribution of Pb–Zn minerals, and the production of Pb and Zn ranks first in the world [2]. However, with many lean ores, few rich ores, and complex mineral composition, most lead–zinc ores are highly difficult to beneficiate [3,4]. Therefore, with the continuous development of mineral resources, the number of tailings has increased dramatically [5,6]. According to the latest data in the Annual Report on Comprehensive Utilization of Resources in China, by the end of 2021, the total annual production of tailings in China was 16.49 billion tons, while the total utilization of tailings was only 312 million tons, with a comprehensive utilization rate of only 18.9% [7]. Western developed countries have started the comprehensive development and utilization of mineral resources since the first and middle of the 20th century and now have achieved waste-free and slag-free production in some mines [8]. China, on the other hand, started late, and the comprehensive utilization rate of tailings still has a big gap compared with European and American countries. Such a large number of tailings has serious safety hazards [9,10], which will not only pollute the environment and occupy land resources but also affect the healthy development of human society [11,12,13].

In response to this problem, the National Development and Reform Commission of China pointed out that it should make the best efforts to carry out the comprehensive utilization of resources and promote the green, efficient, high quality, high value, and large-scale utilization of solid waste. At present, the utilization of lead–zinc tailings in building materials provides the advantages of less pollution, high economic benefits, and sustainable development, and it is a highly promising and valuable method for the resource utilization of tailings [14]. Promoting the research and exploration of using lead–zinc tailings in building materials is of great significance to carry out comprehensive utilization of solid waste resources.

2. Characteristics and Hazards of Lead–Zinc Tailings

2.1. Characteristics of Lead–Zinc Tailings

Lead–zinc tailings are a kind of composite minerals with a complex chemical composition [15,16,17]. There are obvious differences in the composition of lead–zinc tailings from different mines due to the differences in the beneficiation process, as shown in Table 1. However, there are also some similarities among these lead–zinc tailings in terms of composition; that is, the metal content is generally low, and the main compositions are oxides of Si, Al, Fe, Ca, and Mg [18,19]. The low content of valuable metals makes lead–zinc tailings lose some recovery value, but the high content of silica–alumina oxides gives them reuse value. By comparing the chemical composition of lead–zinc tailings with clay, it can be found that the composition of both is very similar, and the content of SiO2, Fe2O3, and Al2O3 in some lead–zinc tailings is close to that in clay. In addition, the main minerals of lead–zinc tailings include quartz, feldspar, and clay, which are very close to natural sand minerals [3]. Therefore, lead–zinc tailings can be used as raw materials to produce cement or other construction materials in place of clay or sand. In summary, although the composition of lead–zinc tailings is complex and the valuable metals are difficult to recover, lead–zinc tailings still have high potential value in the production of building materials [20].

Table 1. Chemical composition of different lead–zinc tailings (wt.%).

| References | Types | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | Na2O | SO3 | K2O | LOI |

|---|---|---|---|---|---|---|---|---|---|---|

| Wang et al. (2017) [21] | Lead–zinc tailings | 66.23 | 7.67 | 2.45 | 8.51 | 1.78 | 0.54 | - | 0.65 | 3.83 |

| Zhang et al. (2015) [22] | 69.92 | 10.41 | 1.89 | 2.19 | 1.39 | 0.51 | 0.55 | 2.17 | 3.68 | |

| Argane et al. (2015) [23] | 68.44 | 9.380 | 2.200 | 1.99 | 0.48 | 0.7 | 0.449 | 5.46 | - | |

| Jankovic et al. (2017) [24] | 43.26 | 11.11 | 15.57 | 20.01 | 4.31 | 0.92 | 0.32 | 1.00 | 5.61 | |

| Shen et al. (2013) [25] | 49.43 | 17.23 | 8.23 | 5.88 | 9.02 | 0.41 | 1.43 | 4.59 | - | |

| Shen et al. (2013) [25] | 26.97 | 5.17 | 4.36 | 33.84 | 15.48 | 0.16 | 0.55 | 1.57 | 9.53 | |

| Wei et al. (2021) [26] | Clay | 61.37 | 14.32 | 4.74 | 12.40 | 2.36 | 1.03 | 0.03 | 2.59 | - |

2.2. Hazards of Lead–Zinc Tailings

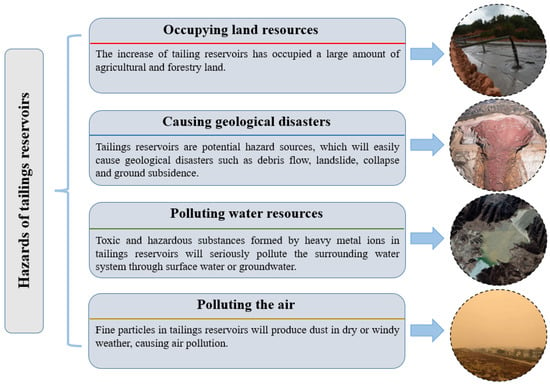

Stockpiling in tailings reservoirs is currently the most direct disposal method for lead–zinc tailings. According to the Work Plan for Preventing and Resolving Safety Risks of Tailings Reservoirs in 2020, there are nearly 8000 tailings reservoirs in China, ranking first in the world [27]. A total of 64 types of minerals are involved, of which the minerals with the largest stockpile of tailings contain Zn and Pb [28]. These tailings reservoirs not only occupy a large amount of national land area but also have certain security risks [29,30], and they are also harmful to the environment [31,32,33], as shown in Figure 1. At present, most tailings reservoirs are a dangerous source with high potential energy formed by the accumulation of tailings, which are easily disturbed to form disasters such as debris flow, resulting in major casualties and property losses [34,35,36].

Figure 1. Adverse effects of tailings reservoirs on environment and human society.

In addition, the problem of environmental pollution caused by the stockpiling of lead–zinc tailings should not be underestimated [37,38,39]. Kan et al. [40] assessed the pollution of As, Cd, Cr, Cu, Hg, Ni, Pb, and Zn by analyzing their concentration data in lead–zinc tailings reservoirs in China and found that the average concentrations of all these heavy metals in soil have exceeded the corresponding background values [41]. Under the combined effect of internal and external factors, the lead–zinc tailings in the tailings reservoirs will leach out a large amount of heavy metal liquid [42], which will seriously pollute the water resources in the nearby area after infiltrating with rainwater. Mine soil is also the major carrier of heavy metal pollution [16,17]. The contaminated soil not only affects the growth of local plants and animals but also causes food safety and leads to the entry of heavy metal elements such as Pb, Zn, and Cd into people’s bodies along the food chain [43]. Moreover, the large number of fine particles in tailings reservoirs can also cause serious dust pollution [44,45].

This entry is adapted from the peer-reviewed paper 10.3390/buildings13010150

This entry is offline, you can click here to edit this entry!