The recycling of sodium borohydride poses a huge challenge to the drive towards a hydrogen economy. Mechano-chemical, thermo-chemical and electrochemical are the only reported methods of recycling sodium metaborate into sodium borohydride. Much attention have been devoted towards the mechano-chemical and thermo-chemical methods of reduction, little focus is devoted to electrochemical methods. This research describes the electrochemical behaviour of borohydride (BH4ˉ) and metaborate (BO2ˉ) anion in alkaline solutions. The electrochemical characteristics of BH4ˉ is controlled by the alkaline concentration, the concentration of the BH4ˉ and the type of electrode material. The attempts to electro-reduce the BO2ˉ into BH4ˉ is reviewed and the challenges, suggestions and future outlook of electro-reduction to recycle the BO2ˉ into BH4ˉ is highlighted.

1. Introduction

Sodium borohydride (NaBH

4) is a hydrogen carrier with a high theoretical hydrogen storage capacity of around 10.8% w/w. In addition, the safe storage and fast kinetics of the release of gaseous hydrogen when in contact with water offers the storage and transport of hydrogen in solid form, which precludes the use of heavy high-pressurized gas storage containers and gas transport pipelines. The release of gaseous hydrogen at room temperature and pressure are described in the following equation:

The release of hydrogen from concentrated alkaline solutions of NaBH

4 necessitates the utilisation of NaBH

4 as the active electrochemical reductant in direct borohydride fuel cell (DBFC):

In both cases, the release of molecular hydrogen (Equation (1)) and the utilisation of the BH4− in DBFC (Equation (2)) release the sodium metaborate NaBO2 as the by-product. Therefore, successfully recycling the NaBO2 by-product into NaBH4 is the key for the utilisation of NaBH4 as a solid hydrogen storage material and as the electroactive reductant in DBFC.

The industrial production of NaBH

4 developed in the 1950s, known as the Brown—Schlesinger process

[1], which is highly inefficient, requires high temperatures, typically around 250 °C, and expensive chemical precursors, as given in the following equation:

Until now, there has not been much progress in increasing the efficiency of the production of NaBH4.

Another industrial process, known as the Bayer process, utilises the mineral borax (Na

2B

4O

7·10H

2O) in powder form but reacted with sodium metal and hydrogen gas with the presence of silica, as given in the equation below:

The Bayer process also possesses low conversion efficiency in the production of NaBH

4, in addition to being an energy-intensive process with operational temperatures of more than 400 °C

[2].

All these factors render NaBH

4 an expensive chemical to be utilised even in DBFC and as a hydrogen carrier material. One solution is to recycle the NaBO

2 by-product into NaBH

4. Among the methods for the recycling of NaBO

2 by-product into NaBH

4 are thermochemical

[3][4][5][6][7][8], which involves the reaction of NaBO

2 in the presence of hydrogen gas at high pressures, and metallic Mg as the reducing agent at temperatures more than 500 °C.

Another method for the recycling of the NaBO

2 by-product into NaBH

4 is by mechano-chemical means, or by ball-milling powder of the NaBO

2 in a reactor in the presence of reductants, in the presence of steel balls, to facilitate the mechanical knocking process

[9][10][11][12][13][14][15][16][17][18][19].

The electrochemical process, on the other hand, involves the electrochemical reduction of NaBO

2 into NaBH

4 with the passage of a reduction current. As mentioned in a recent review by Helder X. Nunes et al., 2021

[20], since the year 2000, the number of papers utilising electrochemical reduction for the recycling of NaBO

2 into NaBH

4 only constitutes around 18% of the total number of papers investigating the regeneration of NaBH

4, whereas the bulk are dedicated to mechano-chemical (50%) and thermo-chemical (32%) methods of recycling. This research focuses on the electrochemical behaviour of NaBO

2 and NaBH

4 in aqueous solution, the electrolytic reduction of NaBO

2, and finally, the challenges and future outlook of the process.

Much information regarding the thermodynamics of the competing reactions against the electroreduction of BO

2− (Equation (2)) is available in the literature. The electroreduction of BO

2− should be performed in concentrated alkaline solutions, as the BH

4− is stabilized with the presence of the OH

− in high concentrations. In concentrated alkaline solutions, there are few reactions which are competing reactions and are more thermodynamically favourable compared to Equation (2), which makes the electroreduction of BO

2− difficult in alkaline solutions. Among them are the hydrogen evolution reaction (HER) and reductions involving dissolved oxygen.

The presence of dissolved oxygen presents an avenue for the reduction of molecular oxygen into various ionic species in alkaline solution.

The reason for the thermodynamic feasibility of these reactions compared to Equation (2), is that these involve uncharged water and molecular oxygen in alkaline solutions, compared to the eight-electron reduction of a negatively charged BO2− anion.

2. Electrolysis of BO2− into BH4−

A few patents describe the electro-reduction of BO

2− into BH

4− in an aqueous medium

[21][22][23], but later reports

[24] did not verify any viable conversion of BO

2− into BH

4− in an aqueous medium, although the current efficiencies of the conversion, 20–25%, were reported in those patents

[21][22][23]. This could be due to the iodometric titration, which yields higher NaBH

4 formation, which was adopted by the patents

[24].

McLafferty et al.

[25] also performed experiments to verify several patents

[25][26][27] that claim the successful electrochemical reduction of BO

2− into BH

4−. They performed electrolysis of boric acid on mercury pool cathode in a divided electrolysis cell with cationic exchange membrane with sulfuric acid as the anolyte and BO

2− in 2 M NaOH as the catholyte. Since mercury has high overpotential for the hydrogen evolution reaction (HER), it was selected as the cathode in this study, and the potential of the mercury cathode was maintained between −2.16 and −2.60 V (vs. Hg/HgO). The authors found no presence of the BH

4− using cyclic voltammetry of alkaline solution even after two days of electrolysis. The same results were obtained with the hydrolysis of BO

2− in the catholyte at gold and Cu electrodes, to reproduce the work of Jiang et al.

[28], but no traces of the BH

4− were detected using CV of the catholyte after electrolysis. Gold cathode was used again in pulsed potential electrolysis and there was no presence of any BH

4− detected using CV. Titanium, Ag and Pb, which possess high overpotentials of HER, also did not show any conversion into BH

4− in the alkaline reduction of the BO

2− in the divided electrolysis cell. The authors used tetraalkylammonium hydroxide (TAAH) to increase the overpotential of the HER. All experiments concluded that the TAA

+ cation was ineffective in absorbing at the cathode surface due to the replacement of water molecules at higher negative potentials, which promoted the HER. The authors also tried to modify the cathode surface using a chelating compound or a cationic polyelectrolyte to coat the gold electrode surface, forming a self-assembled monolayer (SAM), which promotes the attraction of the BO

2− at small distances from the gold electrode surface. The chelating agent utilised for this purpose was 1-thioglycerol, which consists of a thiol group, which strongly bounds to the gold surface, and a diol group, which could bind with the BO

2−, while a quaternized poly(4-vinylpyridine) was selected as the cationic polyelectrolyte. The electrolysis was repeated as with the high overpotential metal cathode, but no presence of the BH

4− ion was detected in the CV.

Sanli et al.

[29] carried out electrolyses in 1 M NaOH + 0.1 M NaBO

2 at 0.5 V for 24 h and 48 h with Ag gauze cathode at room temperature and atmospheric pressure in an undivided electrochemical cell. The authors performed iodometric titration for the determination of the conversion efficiency of sodium metaborate into sodium borohydride. It was observed that there was 10% conversion after 24 h of electrolysis, reaching 17% (by iodometric titration) after 48 h. It was obvious that the low conversion efficiency was due to the HER at the cathode, which is a strong competing reaction with the electro-reduction of metaborate into borohydride.

The hydrogen is produced in situ at the cathode:

which was used to reduce the borate into borohydride:

The authors performed cyclic voltammetry of NaBO2 in 1 M NaOH and found that the electro-reduction of BO2− occurred at 0.5 V (vs. SCE) and the corresponding electro-oxidation of BH4− into the BO2− at 0.1 V (vs. SCE). They also reported that gold electrode is the most effective for the reduction of BO2− compared to Pt, Pd and Ni electrodes.

Santos et al.

[30] performed controlled potential (1.8 V) bulk electrolysis for the electroreduction of 2 M NaBO

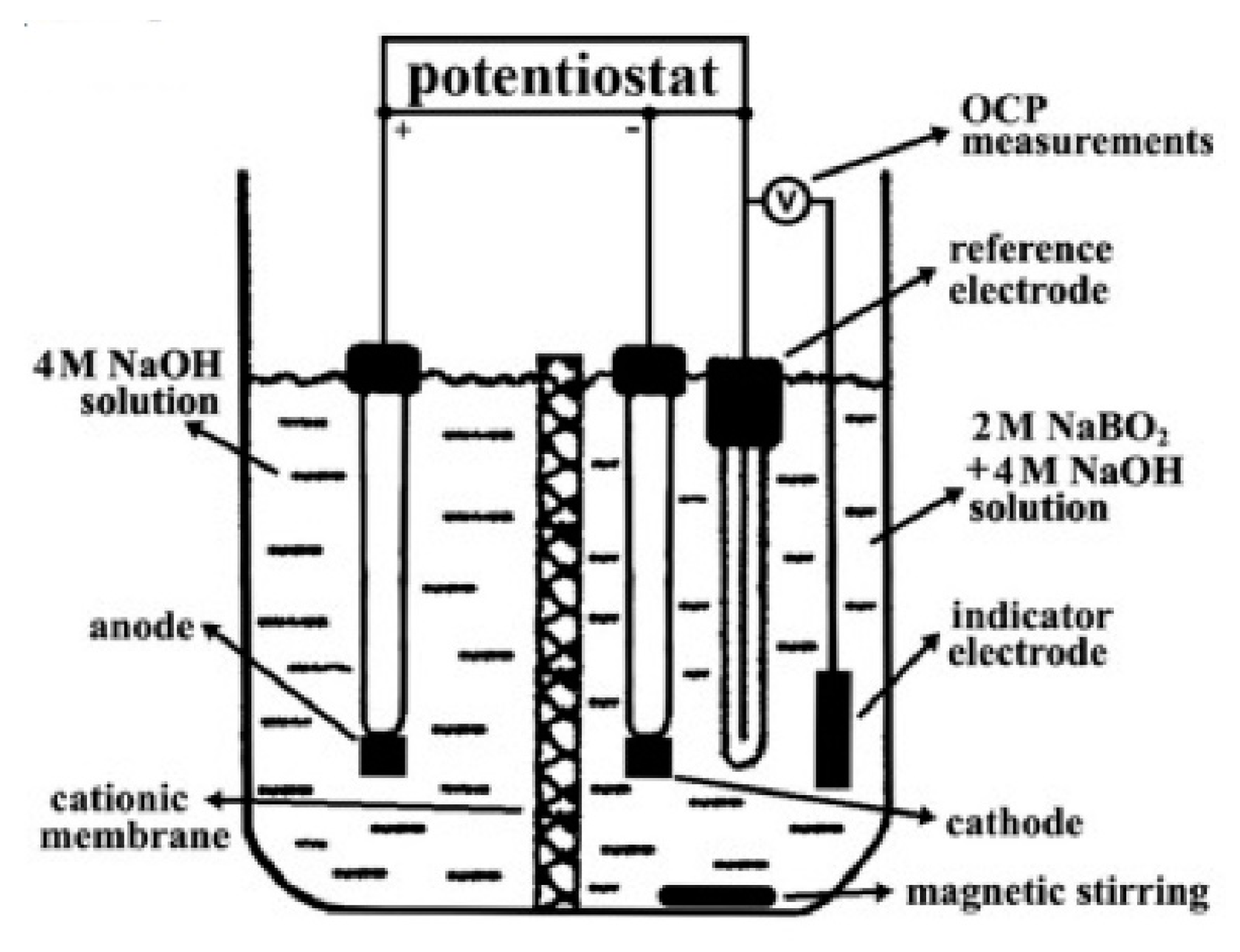

2 at cadmium cathode in 4 M NaOH in a divided electrochemical cell with a cationic exchange membrane (CEM), as shown in

Figure 1. The cathodic compartment consists of an indicator electrode connected to a high impedance voltmeter for the potentiometric monitoring of the concentration of the sodium borohydride. However, the authors did not report any conversion efficiency for this electrochemical method. Upon completion of electro-reduction, the NaBH

4 can be isolated from aqueous solution by freeze-drying to eliminate water, leaving the NaBO

2, NaOH and NaBH

4. Then, the solid free water is dissolved in tetraglyme. The NaBH

4 is only solubilised in tetraglyme, leaving the NaBO

2 and NaOH undissolved. Tetraglyme is removed by thermal evaporation, leaving the NaBH

4, tetraglyme (C

10H

22O

5) is also known as tetraethylene glycol dimethyl ether, butyl diglyme (C

12H

26O

3) or diethylene glycol dibutyl ether.

Figure 1. Electrochemical cell for bulk electrolysis of NaBO2 and open circuit potential (OCP) measurements in alkaline solution at 25 °C. The NaBO2 is reduced at the cadmium cathode while a high impedance voltmeter prevents current to flow into the circuit between the indicator and reference electrodes for the OCP monitoring.

Shen Y. et al.

[31] carried the desulfurization of dibenzothiophene with a potential difference 3.5 V and an electrolytic time 4 h in 0.025 M NaOH using Pb cathode in an undivided cell for the regeneration of the NaBH

4. Pb cathode was selected due to the large overpotential for the HER, which could not have interfered with the electroreduction of BO

2− to BH

4−. The authors reported that the desulfurization efficiency was increased with the amount of added NaBO

2, due to the increased regeneration of the BH

4− with the presence of BO

2−; however, no efficiency conversion of the BO

2− into BH

4− was reported in this study.

Zhu et al.

[32] performed cyclic voltammetry at Cu cathode and Ni counter electrode (CE) and reported that the cathodic peak at 1.2 V (vs. SCE) was due to the formation of the BH

4−. In addition, they reported a conversion efficiency of 15% from electrolysis using an undivided electrolysis cell, with a potential difference of 1.7 V, in 1 M NaOH as the catholyte, at Cu cathode.

Chenhua et al.

[33] used NaBH

4 for the de-sulfurization of fuel and regenerated the NaBH

4 through electroreduction of the NaBO

2. The NaBO

2 was converted into sodium borohydride (NaBH

4) through electroreduction on boron doped diamond (BDD) cathode. The authors used a divided cell, using a cationic exchange membrane (CEM) to separate the CE from the WE and RE and used a pulsed current for the electro-reduction of the BO

2− into BH

4−. The negatively charged BO

2− experiences repulsion at the cathode. Thus, a pulse cycle of positive followed by negative potential facilitated the electro-reduction of the BO

2−. When the WE was charged positive, the BO

2− was attracted to the WE surface, and reduced into the BH

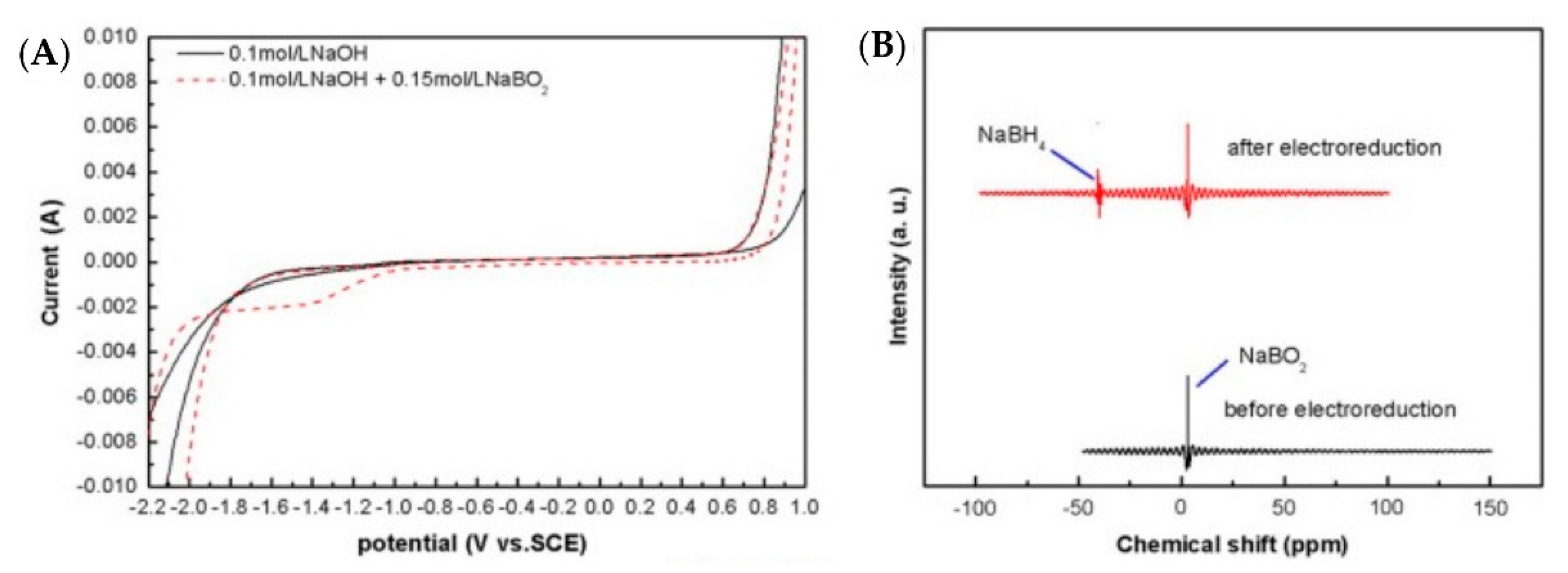

4−, as the potential was pulsed into the negative potential. The BDD showed the onset potential for the HER is at −1.8 V (vs. SCE), while the onset potential for the oxygen evolution reaction (OER) is around +0.6 V (vs. SCE), as shown in

Figure 2. The negative pulse is more positive than −1.8 V to avoid the HER but more negative than 0.6 V to avoid the OER. The electro-reduction of BO

2− into BH

4− showed a peak at −1.4 V (vs. SCE). The authors did not report any conversion efficiency for the electro-reduction of the BO

2− into borohydride BH

4−. The BH

4− was used as an intermediate for the desulfurization by supplying hydrogen for the reductive de-sulfurization of the gasoline samples. Upon reductive desulfurization, the BH

4− is oxidized into BO

2−.

Figure 2. (

A) Cyclic voltammogram of a BDD electrode in 0.1 M NaOH and 0.1 M NaOH + 0.15 M NaBO

2 at 0.100 V s

−1; and (

B) 11 boron NMR spectrogram of electrolytes before and after electroreduction, reaction conditions: 1.5 V forward pulse voltage, 0.3 V reverse pulse voltage, 1.5 s forward pulse duration, 0.5 s reverse pulse duration, 0.15 M NaBO

2 concentration, 0.1 M NaOH, 1.5 h of electrolytic time. Reproduced from ref.

[33] with permission from the publisher.

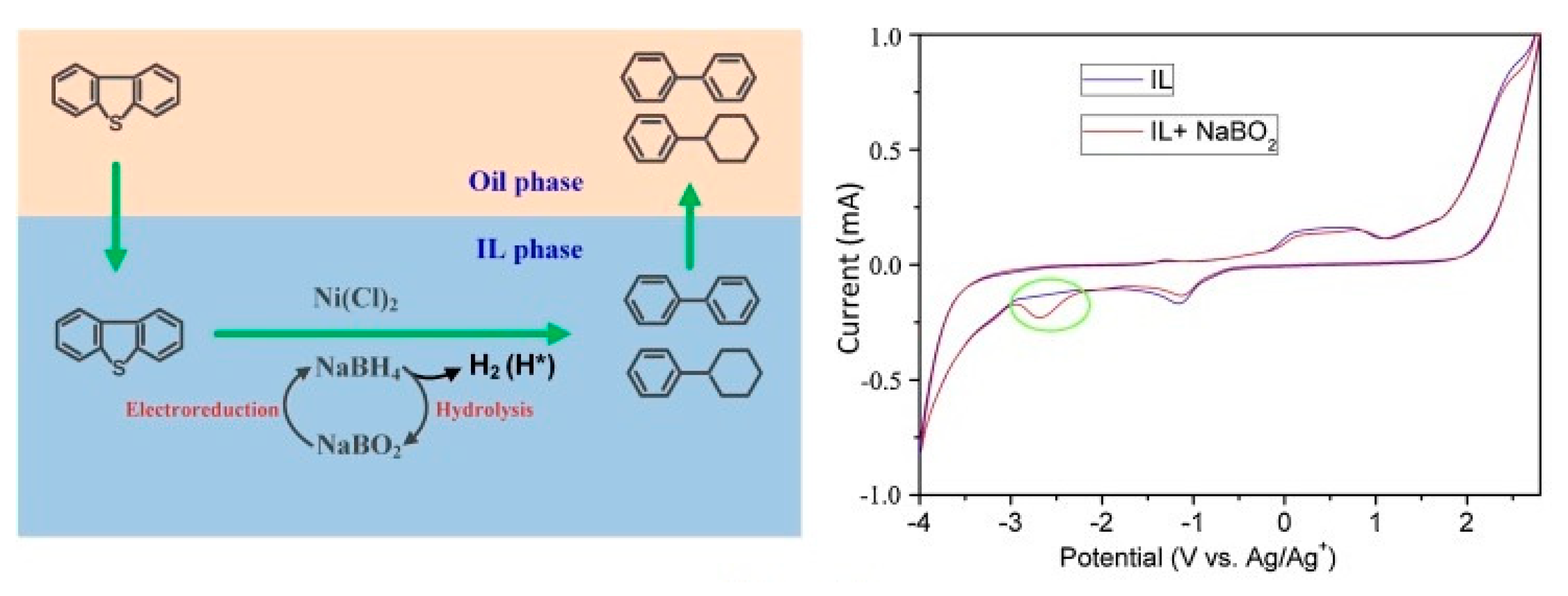

The same authors also used the same method of pulsed potential to re-generate BH

4− from BO

2− but applied a larger negative pulse potential (−2–2 V to −3.0 V) compared to the positive pulse potential (0.1 V to 0.9 V)

[34]. From the CV in ionic liquids (IL), the reduction of the BO

2− occurred at −2.5 V vs. Ag/Ag

+ using glassy carbon electrode (GCE) as the WE, where the HER was ineffective in providing competition against the electroreduction of the BO

2− as it occurred beyond −3 V vs. Ag/Ag

+, is shown in

Figure 3. The whole regeneration of BH

4− from BO

2− and desulfurization of a model fuel oil was carried out in an IL, 1-ethyl-3-methylimidazolium bis (trifluoromethanesulfonyl) imide (EMI[TFSI]) in an undivided electrochemical cell. A higher reverse pulse towards the positive potential was avoided due to the effect of oxygen evolution reaction (OER) and the oxidation into borax (sodium tetraborate). The time duration for the negative and positive pulse increased (0.1 s to 1.0 s) the desulfurization efficiency of the model oil; however, the conversion efficiency of the BO

2− into BH

4− was not calculated.

Figure 3. Left: The schematic diagram of the novel desulfurization process.

Right: Cyclic voltammogram of IL and IL + NaBO

2 on a glassy carbon electrode at 0.100 V s

−1. The green arrows show the movement of the molecule. Reproduced from ref.

[34] with permission from the publisher.

Hydrogen carrier electrode materials are also hydrogen release materials, as seen in rechargeable nickel metal hydride battery electrodes, such as NiMH and Ni(OH)

2 in alkaline solutions.

Both forward reactions are discharge reactions at the anode (-ve electrode) and cathode (+ve electrode) which takes place in rechargeable NiMH batteries in highly alkaline solutions.