| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Collins Ngoe Elangwe | -- | 2479 | 2022-12-09 08:44:58 | | | |

| 2 | Beatrix Zheng | + 1 word(s) | 2480 | 2022-12-12 02:14:53 | | |

Video Upload Options

Wound management remains a challenging issue around the world, although a lot of wound dressing materials have been produced for the treatment of chronic and acute wounds. Wound healing is a highly dynamic and complex regulatory process that involves four principal integrated phases, including hemostasis, inflammation, proliferation, and remodeling. Chronic non-healing wounds are wounds that heal significantly more slowly, fail to progress to all the phases of the normal wound healing process, and are usually stalled at the inflammatory phase. These wounds cause a lot of challenges to patients, such as severe emotional and physical stress and generate a considerable financial burden on patients and the general public healthcare system. It has been reported that about 1–2% of the global population suffers from chronic non-healing wounds during their lifetime in developed nations. Traditional wound dressings are dry, and therefore cannot provide moist environment for wound healing and do not possess antibacterial properties. Wound dressings that are currently used consist of bandages, films, foams, patches and hydrogels. Currently, hydrogels are gaining much attention as a result of their water-holding capacity, providing a moist wound-healing milieu.

1. Introduction

2. Types of Wounds

3. Hydrogels as Biomaterials

3.1. Gelatin

3.2. Cellulose

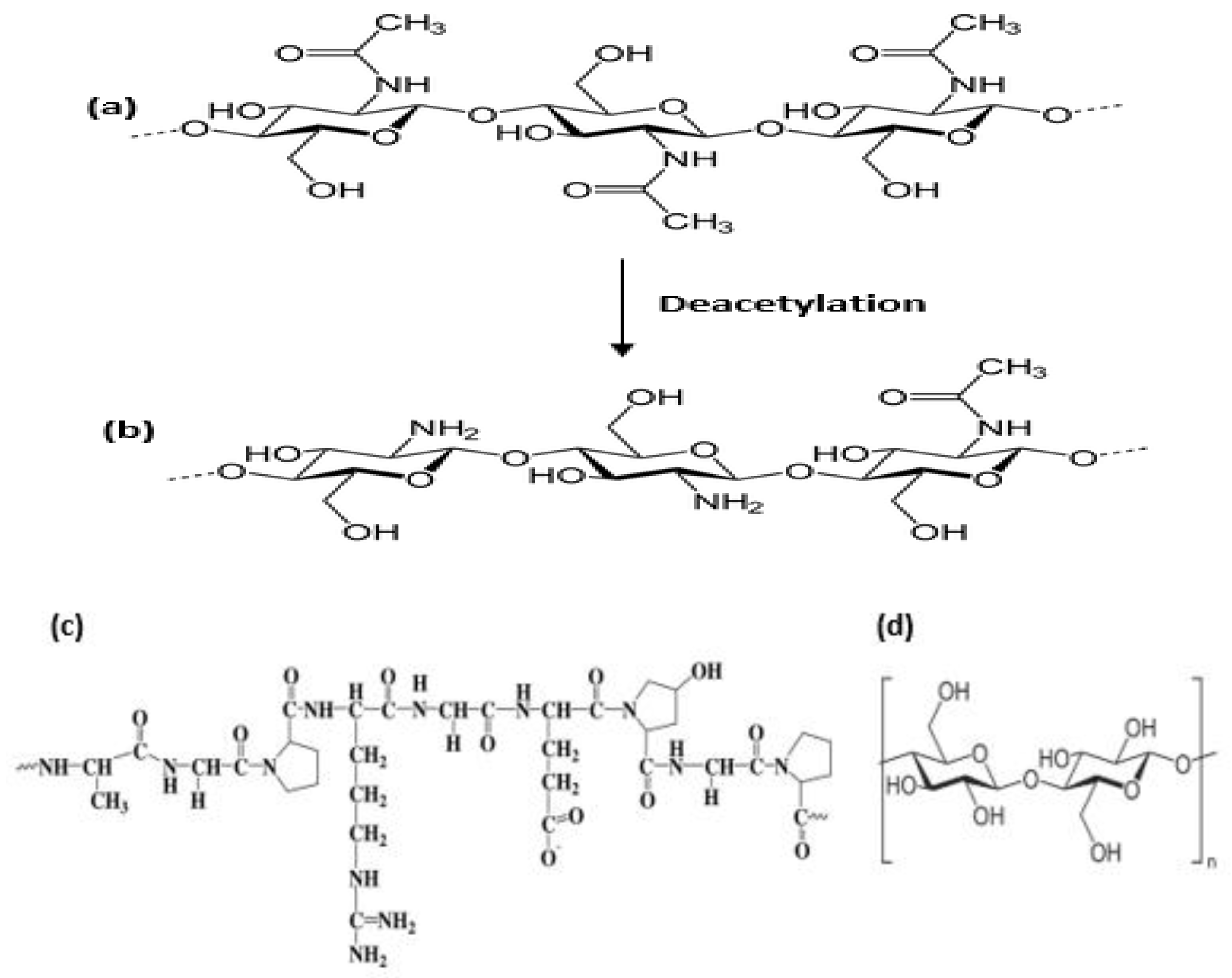

3.3. Chitosan

| Modification | Properties |

|---|---|

| Carboxymethyl chitosan |

Improved solubility in water. The commonly explored derivative of chitosan; it is amphoteric in nature and its solubility depends on pH, when the pH is >7 it is water soluble. |

| Thiolated urea derivatives |

Thiourea chitosan boost the antibacterial properties. |

| Carbohydrate branched chitosan |

Water soluble. Carbohydrate can be grafted on the chitosan backbone at the C2 position by reductive alkylation. They could be used for wound dressing and drug targeting. |

| Sugar derivatives | N-Succinyl chitosan is an amphoteric polymer consisting of amine, hydroxyl, and carbonyl groups. It has excellent physical, chemical, and biological properties as required in biomedical applications. |

| Alkylation chitosan | It is an essential amphiphilic polymer based on polysaccharides. Improves the stability of the interfacial films, promotes its solubility. |

References

- Kamoun, E.A.; Kenawy, E.-R.S.; Chen, X. A review on polymeric hydrogel membranes for wound dressing applications: PVA-based hydrogel dressings. J. Adv. Res. 2017, 8, 217–233.

- Robson, M.; Steed, D.; Franz, M. Wound healing: Biological features and approaches to maximize healing trajectories. Curr. Probl. Surg. 2001, 38, 72–140.

- Dhivya, S.; Padma, V.V.; Santhini, E. Wound dressings—A review. BioMedicine 2015, 5, 22–28.

- Su, J.; Li, J.; Liang, J.; Zhang, K.; Li, J. Hydrogel Preparation Methods and Biomaterials for Wound Dressing. Life 2021, 11, 1016.

- Wang, W.; Wang, A. Nanocomposite of carboxymethyl cellulose and attapulgite as a novel pH-sensitive superabsorbent: Synthesis, characterization and properties. Carbohydr. Polym. 2010, 82, 83–91.

- Ooi, S.Y.; Ahmad, I.; Amin, M.C.I.M. Cellulose nanocrystals extracted from rice husks as a reinforcing material in gelatin hydrogels for use in controlled drug delivery systems. Ind. Crops Prod. 2016, 93, 227–234.

- Dufresne, A. Interfacial phenomena in nanocomposites based on polysaccharide nanocrystals. Compos. Interfaces 2003, 10, 369–387.

- Iqbal, M.S.; Akbar, J.; Saghir, S.; Karim, A.; Koschella, A.; Heinze, T.; Sher, M. Thermal studies of plant carbohydrate polymer hydrogels. Carbohydr. Polym. 2011, 86, 1775–1783.

- Fang, X.; Wang, C.; Zhou, S.; Cui, P.; Hu, H.; Ni, X.; Jiang, P.; Wang, J. Hydrogels for Antitumor and Antibacterial Therapy. Gels 2022, 8, 315.

- Lima, L.P.T.; Passos, M.F. Skin wounds, the healing process, and hydrogel-based wound dressings: A short review. J. Biomater. Sci. Polym. Ed. 2021, 32, 1910–1925.

- Vashist, A.; Vashist, A.; Gupta, Y.K.; Ahmad, S. Recent Advances in Hydrogel Based Drug Delivery Systems for the Human Body. J. Mater. Chem. B 2014, 2, 147–166.

- Xu, Q.; Ji, Y.; Sun, Q.; Fu, Y.; Xu, Y.; Jin, L. Fabrication of Cellulose Nanocrystal/Chitosan Hydrogel for Controlled Drug Release. Nanomaterials 2019, 9, 253.

- Alizadehgiashi, M.; Nemr, R.C.; Chekini, M.; Ramos, P.D.; Mittal, N.; Ahmed, U.S.; Khuu, N.; Kelley, O.S.; Kumacheva, E. Multifunctional 3D-Printed Wound Dressings. ACS Nano 2021, 15, 12375–12387.

- Gojgini, S.; Tokatlian, T.; Segura, T. Utilizing cell–matrix interactions to modulate gene transfer to stem cells inside hyaluronic acid hydrogels. Mol. Pharm. 2011, 8, 1582–1591.

- Youngblood, L.R.; Truong, F.N.; Segura, T.; Shea, D.L. Review: It’s All in the Delivery: Designing Hydrogels for Cell and Non-viral Gene Therapies. Mol. Ther. 2018, 26, 2087–2106.

- Spicer, C.D. Review: Hydrogel scaffolds for tissue engineering: The importance of polymer choice. Polym. Chem. 2020, 11, 184–219.

- Hou, Y.; Schoener, C.A.; Regan, K.R.; Munoz-Pinto, D.; Hahn, M.S.; Grunlan, M.A. Photo-cross-linked PDMSstar-PEG hydrogels: Synthesis, characterization, and potential application for tissue engineering scaffolds. Biomacromolecules 2010, 11, 648–656.

- Tavakoli, J.; Tang, Y. Review: Hydrogel Based Sensors for Biomedical Applications. Polymers 2017, 9, 364.

- Tavakoli, S.; Klar, S.A. Review: Advanced Hydrogels as Wound Dressings. Biomolecules 2020, 10, 1169.

- Metelmann, H.R.; Woedtke, T.V.; Weltmann, K.D. Comprehensive Clinical Plasma Medicine, Cold Physical Plasma for Medical Application; Springer: Berlin/Heidelberg, Germany, 2018; ISBN 978-3-319-67627-2.

- Tsegay, F.; Elsherif, M.; Butt, H. Smart 3D Printed Hydrogel Skin Wound Bandages: A Review. Polymers 2022, 14, 1012.

- Agale, S.V. Chronic leg ulcers: Epidemiology, aetiopathogenesis, and management. Ulcers 2013, 2013, 1–9.

- Misic, A.M.; Gardner, S.E.; Grice, E.A. The wound microbiome: Modern approached to examining the role of microorganisms in impaired chronic wound healing. Adv. Wound Care 2014, 3, 502–510.

- Comino-Sanz, I.M.; López-Franco, M.D.; Castro, B.; Pancorbo-Hidalgo, P.L. The Role of Antioxidants on Wound Healing: A Review of the Current Evidence. J. Clin. Med. 2021, 10, 3558.

- Cano, S.M.; Lancel, S.; Boulanger, E.; Neviere, R. Targeting Oxidative Stress and Mitochondrial Dysfunction in the Treatment of Impaired Wound Healing: A Systematic Review. Antioxidants 2018, 7, 98.

- Mehtani, D.; Seth, A.; Sharma, P.; Maheshwari, N.; Kapoor, D.; Shrivastava, K.S.; Tekade, K.R. Chapter 4: Biomaterials for Sustained and Controlled Delivery of Small Drug Molecules. In Biomaterials and Bionanotechnology Advances in Pharmaceutical Product Development and Research; Academic Press: Cambridge, MA, USA, 2019; pp. 89–152.

- Naomi, R.; Bahari, H.; Ridzuan, P.M.; Othman, F. Natural-Based Biomaterial for Skin Wound Healing (Gelatin vs. Collagen): Expert Review. Polymers 2021, 13, 2319.

- Neves, N.M.; Reis, R.L. (Eds.) Biomaterials from Nature for Advanced Devices and Therapies. In Chapter 3: Gelatin-Based Biomaterials for Tissue Engineering and Stem Cell Bioengineering; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 37–62.

- Dash, R.; Foston, M.; Ragauskas, A.J. Improving the mechanical and thermal properties of gelatin hydrogels cross-linked by cellulose nanowhiskers. Carbohydr. Polym. 2013, 91, 638–645.

- Kim, S.; Park, K. Tailor-Made Hydrogels for Tumor Delivery, Drug Delivery in Oncology; Wiley-VCH Verlag GmbH & Co. KGaA.: Weinheim, Germany, 2011; pp. 1071–1097.

- Shojaeiarania, J.; Bajwaa, D.; Shirzadifar, A. A review on cellulose nanocrystals as promising biocompounds for the synthesis of nanocomposite hydrogels. Carbohydr. Polym. 2019, 216, 247–259.

- Liu, S.; Qamar, A.S.; Qamar, M.; Basharat, K.; Bilal, M. Review: Engineered nanocellulose-based hydrogels for smart drug delivery applications. Int. J. Biol. Macromol. 2021, 181, 275–290.

- Liu, Y.; Song, S.; Liu, S.; Zhu, X.; Wang, P. Application of Nanomaterial in Hydrogels Related to Wound Healing. A review. J. Nanomater. 2022, 2022, 4656037.

- Zhou, Y.; Saito, T.; Bergström, L.; Isogai, A. Acid-Free Preparation of Cellulose Nanocrystals by TEMPO Oxidation and Subsequent Cavitation. Biomacromolecules 2018, 19, 633–639.

- Wegrzynowska-Drzymalska, K.; Mlynarczyk, D.T.; Chelminiak-Dudkiewicz, D.; Kaczmarek, H.; Goslinski, T.; Ziegler-Borowska, M. Chitosan-Gelatin Films Cross-Linked with Dialdehyde Cellulose Nanocrystals as Potential Materials for Wound Dressings. Int. J. Mol. Sci. 2022, 23, 9700.

- Lu, F.-F.; Yu, H.-Y.; Zhou, Y.; Yao, J.-M. Spherical and rod-like dialdehyde cellulose nanocrystals by sodium periodate oxidation: Optimization with double response surface model and templates for silver nanoparticles. Express. Polym. Lett. 2016, 10, 965–976.

- Zhang, P.; Chen, L.; Zhang, Q.S.; Hong, F.F. Using in situ dynamic cultures to rapidly biofabricate fabric-reinforced composites of chitosan/bacterial nanocellulose for antibacterial wound dressings. Front. Microbiol. 2016, 7, 260.

- Güiza-Argüello, V.R.; Solarte-David, V.A.; Pinzón-Mora, A.V.; Ávila-Quiroga, J.E.; Becerra-Bayona, S.M. Current Advances in the Development of Hydrogel-Based Wound Dressings for Diabetic Foot Ulcer Treatment. Polymers 2022, 14, 2764.

- Gupta, A.; Kowalczuk, M.; Heaselgrave, W.; Britland, S.T.; Martin, C.; Radecka, I. The Production and Application of Hydrogels for Wound Management: A Review. Eur. Polym. J. 2019, 111, 134–151.

- Alven, S.; Aderibigbe, B.A. Chitosan and Cellulose-Based Hydrogels for Wound Management. Int. J. Mol. Sci. 2020, 21, 9656.

- Hamedi, H.; Moradi, S.; Hudson, S.M.; Tonelli, A.E. Chitosan based hydrogels and their applications for drug delivery in wound dressings: A review. Carbohydr. Polym. 2018, 199, 445–460.

- Liu, H.; Wang, C.; Li, C.; Qin, Y.; Wang, Z.; Yang, F.; Li, Z.; Wang, J. A functional chitosan-based hydrogel as a wound dressing and drug delivery system in the treatment of wound healing. RSC Adv. 2018, 8, 7533–7549.