| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Changwei Hu | -- | 1599 | 2022-12-07 15:40:23 | | | |

| 2 | Changwei Hu | -277 word(s) | 1322 | 2022-12-12 15:07:39 | | |

Video Upload Options

Lignocellulosic biomass is an excellent alternative of fossil source owing to the fact that it is low-cost, plentiful and environmentally friendly. Through pyrolysis, lignocellulosic biomass can be converted into the potential precusor of liquid fuel or platform chemicals. Therefore, the detailed knowledge and mechanism about biomass conversion should be overviewed and concluded. We have reviewed several factors which impact the conversion of biomass, including the properties of biomass, operational parameters of catalytic pyrolysis and different types of pyrolysis equipment. Meantime, some perspectives for future development have been proposed in the end.

1. Introduction

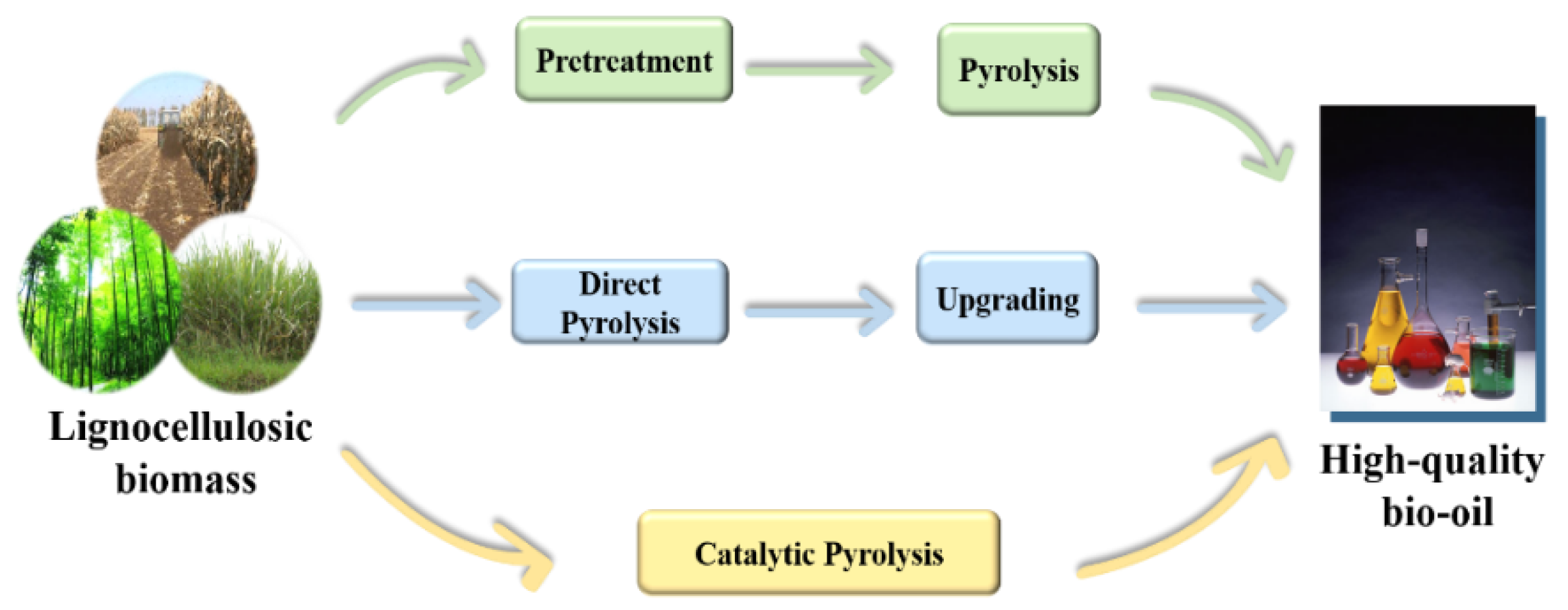

During the past several decades, research studies have mainly focused on three strategies for the optimal harnessing of biomass from pyrolysis, as shown in Figure 1. The first one is the pretreatment of raw biomass. It is reported that the characteristics of biomass can be influenced by different kinds of pretreatment methods [1][2][3], such as grinding, torrefaction, chemical or biological pretreatment. Therefore, the pretreated biomass may yield high quality bio-oil. Secondly, refinement of bio-oil is another choice for further utilization [4][5]. After the liquid products are obtained from direct pyrolysis of biomass, some oriented catalysts can be used to improve the quality. Or some separation and purification approaches can be applied to obtain the single chemicals. Thirdly, catalysts are introduced to the pyrolysis process to change the distribution of chemicals in bio-oil products directly [6][7][8]. Compared to the former two methods, catalytic pyrolysis outstands as the form of one-pot reaction, which simplifies significantly the technological process, especially avoiding the cooling and reheating of the obtained liquid products.

Figure 1. The three strategies for biomass pyrolytic conversion

2. Factors Affecting the Catalytic Pyrolysis of Biomass

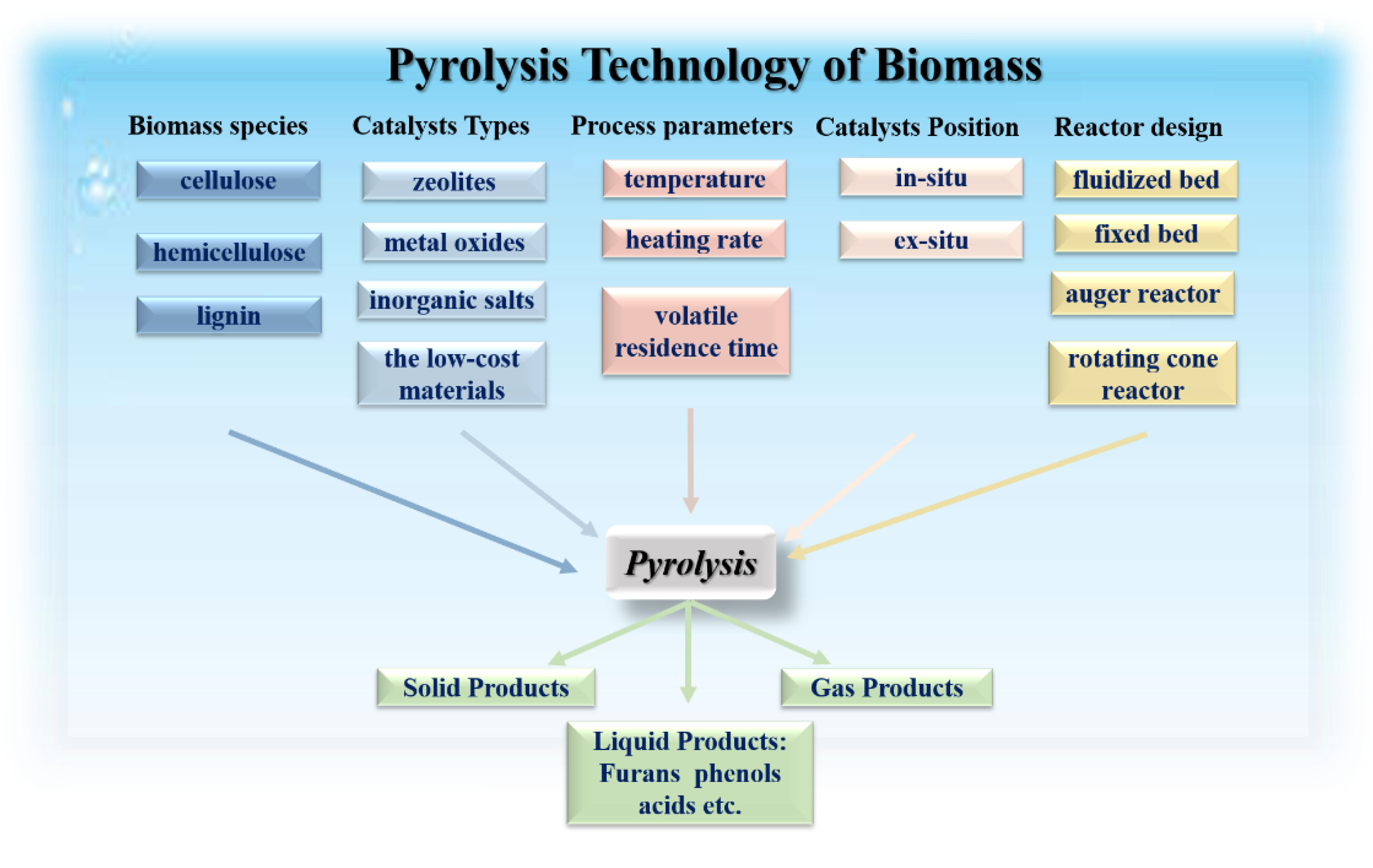

There are some key factors for catalytic pyrolysis of biomass, including biomass species, categories of reactor and catalyst as shown in Figure.6 .

Figure 6. The factors that affecting the pyrolysis of lignocellulosic biomass.

Lignocellulosic biomass: different kinds of biomass feedstocks contain different amounts of cellulose, hemicellulose and lignin, and the interactions between the three major components also varies. In addition, the polymer structure, cross-linkages, density, thermal conductivity, airflow permeability or specific heat capacity of different biomass also have large differences, which may lead to different pyrolysis performance [9].

Diversity of reactor: miscellaneous reactors have been used and explored for catalytic pyrolysis in a small scale, such as fluidized bed, circulating fluidized bed, fixed bed, ablative, rotative, auger, vacuum and microwave reactors.

Process parameters (temperature, heating rate, and volatiles residence time): Taking these pyrolysis parameters into consideration, low temperature, low heating rate and long VRT are conducive to the formation of biochar; high temperature, high heating rate and long VRT are beneficial for the generation of gas products; and medium temperature, high heating rate and short VRT favor the production of bio-oil with a higher yield.

Position of catalysts: Compared with the ex-situ, the cost of in-situ mode is comparatively low, and the catalysts loaded not only participate in the catalytic process but also act as heat carriers. In addition, it is much more direct and quick for pyrolytic volatiles to undergo the further reaction. However, the coke formation and difficulties in catalyst recovery make the in-situ mode less competitive. Ex-situ is beneficial to control the secondary upgrading process flexibly, including catalyst species, reaction temperature, reaction gas atmosphere and so on. Before the catalytic pyrolysis technique is determined or improved, all aspects, for instance, the cost of device and catalysts, are needed to be taken into consideration.

The type of catalysts: Zeolites, metal oxide catalysts, soluble inorganic salts, and other low-cost materials.

3. Challenges and Future Perspectives

References

- Zhou, S.; Xue, Y.; Cai, J.; Cui, C.; Ni, Z.; Zhou, Z. An understanding for improved biomass pyrolysis: Toward a systematic comparison of different acid pretreatments. Chem. Eng. J. 2021, 411, 128513.

- Chen, Z.; Wang, M.; Jiang, E.; Wang, D.; Zhang, K.; Ren, Y.; Jiang, Y. Pyrolysis of Torrefied Biomass. Trends Biotechnol. 2018, 36, 1287–1298.

- Chen, D.; Mei, J.; Li, H.; Li, Y.; Lu, M.; Ma, T.; Ma, Z. Combined pretreatment with torrefaction and washing using torrefaction liquid products to yield upgraded biomass and pyrolysis products. Bioresour. Technol. 2017, 228, 62–68.

- Han, Y.; Gholizadeh, M.; Tran, C.-C.; Kaliaguine, S.; Li, C.-Z.; Olarte, M.; Garcia-Perez, M. Hydrotreatment of pyrolysis bio-oil: A review. Fuel Process. Technol. 2019, 195, 106140.

- Tabassum, N.; Pothu, R.; Pattnaik, A.; Boddula, R.; Balla, P.; Gundeboyina, R.; Challa, P.; Rajesh, R.; Perugopu, V.; Mameda, N.; et al. Heterogeneous Catalysts for Conversion of Biodiesel-Waste Glycerol into High-Added-Value Chemicals. Catalysts 2022, 12, 767.

- Wang, Y.; Akbarzadeh, A.; Chong, L.; Du, J.; Tahir, N.; Awasthi, M.K. Catalytic pyrolysis of lignocellulosic biomass for bio-oil production: A review. Chemosphere 2022, 297, 134181.

- Qiu, B.; Tao, X.; Wang, J.; Liu, Y.; Li, S.; Chu, H. Research progress in the preparation of high-quality liquid fuels and chemicals by catalytic pyrolysis of biomass: A review. Energy Convers. Manag. 2022, 261, 115647.

- Liu, R.; Sarker, M.; Rahman, M.M.; Li, C.; Chai, M.; Nishu; Cotillon, R.; Scott, N.R. Multi-scale complexities of solid acid catalysts in the catalytic fast pyrolysis of biomass for bio-oil production—A review. Prog. Energy Combust. Sci. 2020, 80, 100852.

- Pasangulapati, V.; Ramachandriya, K.D.; Kumar, A.; Wilkins, M.R.; Jones, C.L.; Huhnke, R.L. Effects of cellulose, hemicellulose and lignin on thermochemical conversion characteristics of the selected biomass. Bioresour. Technol. 2012, 114, 663–669.