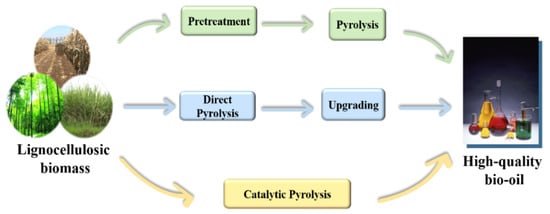

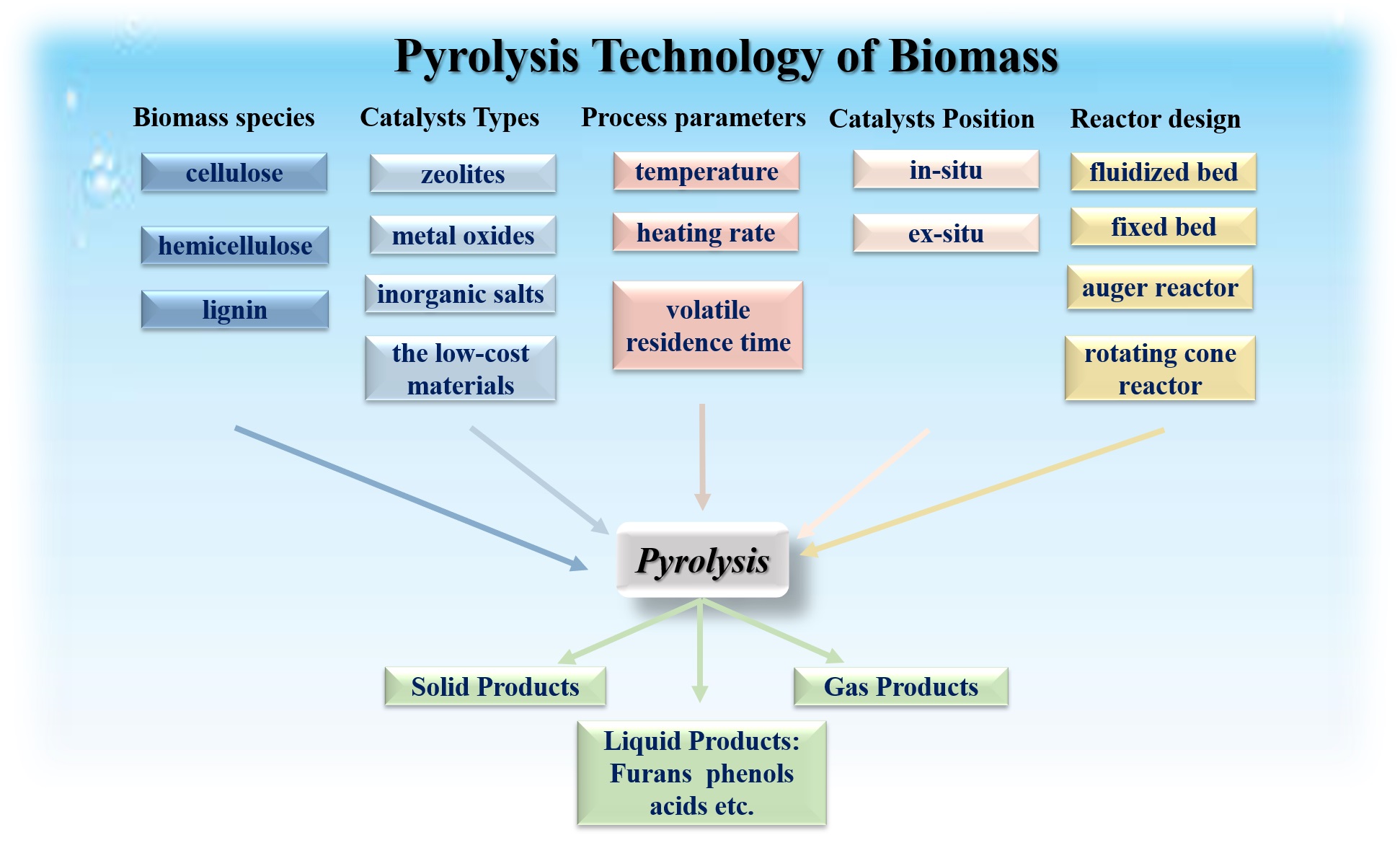

Lignocellulosic biomass is an excellent alternative of fossil source because it is low-cost, plentiful and environmentally friendly, and it can be transformed into biogas, bio-oil and biochar through pyrolysis; thereby, the three types of pyrolytic products can be upgraded or improved to satisfy the standard of biofuel, chemicals and energy materials for industries. The bio-oil derived from direct pyrolysis shows some disadvantages: high contents of oxygenates, water and acids, easy-aging and so forth, which restrict the large-scale application and commercialization of bio-oil. Catalytic pyrolysis favors the refinement of bio-oil through deoxygenation, cracking, decarboxylation, decarbonylation reactions and so on, which could occur on the specified reaction sites. Therefore, the catalytic pyrolysis of lignocellulosic biomass is a promising approach for the production of high quality and renewable biofuels. This review gives information about the factors which might determine the catalytic pyrolysis output, including the properties of biomass, operational parameters of catalytic pyrolysis and different types of pyrolysis equipment. Catalysts used in recent research studies aiming to explore the catalytic pyrolysis conversion of biomass to high quality biooil or chemicals are discussed, and the current challenges and future perspectives for biomass catalytic pyrolysis are highlighted for further comprehension.

- biomass

- catalysts

- pyrolysis

- biofuel

1. Introduction

Figure 6. The factors that affecting the pyrolysis of lignocellulosic biomass.

3. Challenges and Future Perspectives

Catalytic pyrolysis of lignocellulosic biomass is a promising technology for the generation of biofuels, and it is still in the initial stage, which is far from commercialization. Although huge progress in catalyst modification and catalytic pyrolysis has been made, the yield and quality of fuel-grade bio-oil still faces significant challenges. The following should be investigated, in order of priority.

(1) Since lignocellulosic biomass varies in composition and structure in terms of species, it is necessary to develop analytical methods and technology to characterize raw biomass or its single component at the molecular level. Then, these biomass species can be classified into particular categories, which is beneficial to design oriented catalysts, thereby obtaining the high conversion rate of biomass and high-quality biofuels. For example, for the efficient conversion of woody biomass species, one catalytic system might be designed and developed, while for algae, it is needed to develop another one. Furthermore, it should be estimated whether the raw biomass or the isolated component from biomass is more conductive to catalytic pyrolysis for desirable products, achieving the effective conversion and utilization of biomass to the greatest extent.

(2) How to fully exert the role of solid catalysts to solid biomass is another tough task. When the solid catalyst is mixed with biomass evenly, the pyrolytic volatiles can arrive at the active sites on catalyst quickly for the following secondary reactions towards aromatic hydrocarbons or deoxygenated compounds. However, the solid catalysts only have an impact on the secondary reactions, while the initial thermal decomposition stage of biomass is not affected. The introduction of soluble salts might be a promising approach, which can be mixed evenly with biomass and attached to the biomass surface, thereby changing the intrinsic structure and boosting the thermal conversion rate of biomass. Nevertheless, soluble salts as catalysts are accompanied with the introduction of anions, such as Cl−, SO42−, NO3−, CO32− and other organic acid ions. These anions pose a threat on the safety and stability of bio-products. For example, it can be difficult to remove the SxOy, NxOy or other undesirable gas products from pyrolytic gas, and some toxic chemicals might be generated during the pyrolysis of biomass, such as chlorinated hydrocarbons and dioxins.

(3) The accurate analytical technology for the reaction intermediates in pyrolysis needs to be urgently developed. These intermediates could not be identified clearly and the information about the real catalytic pyrolysis process is still scarce. Therefore, the development of analytical technology that holds the ability to qualify and quantify the large-molecular weight fragments in-situ is quite promising for the overall comprehension of the reaction mechanism. Only when the structure and properties of pyrolytic volatiles or reaction intermediates are understood clearly, could the oriented catalysts be conceived and developed. Furthermore, the comprehensive analysis and characterization of bio-oil derived from catalytic pyrolysis is of great importance. Precisely figuring out the chemical composition of the liquid phase is the prerequisite of further upgrading and utilization.

(4) The stability and reutilization of catalyst is another significant issue for catalytic pyrolysis technique feasibility and economy, and it is vital to develop the ability of coke resistance. To achieve this goal, the first step is to clarify the detailed catalytic conversion mechanism of pyrolysis vapor that occurred on the active site of the surface or channels of catalysts. On the other hand, the design of pyrolysis reactor that allows for the in-situ regeneration of catalysts may help reduce the capital invested in the technique routes of biomass pyrolysis.

(5) The cost or investment of catalyst determines the overall economics of the biomass pyrolysis process, so it is necessary to exert techno-economic analysis and life cycle analysis of the selected catalyst. Furthermore, whether the corresponding technique route is suitable for the environment, or allowed with national policies, should be taken into account first before scaling up.

(6) Industrialization of biomass catalytic pyrolysis technology still faces many challenges. Firstly, the mixing of catalysts and biomass particles is tough to be guaranteed in large scale, which makes catalysts invalid; at the same time, the recovery of the used catalysts could not be easily realized, which increases the cost. Secondly, the heat and mass transfer become significantly difficult owing to the properties of lignocellulosic biomass, so large amounts of energy need to be supplied to the large-scale pyrolysis device. Last but not least, the diversity of biomass species and wide distribution of biomass both make the biomass pyrolysis industry tough to develop towards a large scale.

This entry is adapted from the peer-reviewed paper 10.3390/catal12121524

References

- Feng, Y.; Long, S.; Tang, X.; Sun, Y.; Luque, R.; Zeng, X.; Lin, L. Earth-abundant 3d-transition-metal catalysts for lignocellulosic biomass conversion. Chem. Soc. Rev. 2021, 50, 6042–6093.

- Liang, J.; Shan, G.; Sun, Y. Catalytic fast pyrolysis of lignocellulosic biomass: Critical role of zeolite catalysts. Renew. Sustain. Energy Rev. 2021, 139, 110707.

- Vikram, S.; Rosha, P.; Kumar, S. Recent Modeling Approaches to Biomass Pyrolysis: A Review. Energy Fuels 2021, 35, 7406–7433.

- Zakzeski, J.; Bruijnincx, P.C.A.; Jongerius, A.L.; Weckhuysen, B.M. The Catalytic Valorization of Lignin for the Production of Renewable Chemicals. Chem. Rev. 2010, 110, 3552–3599.

- Tian, X.; Wang, Y.; Zeng, Z.; Dai, L.; Xu, J.; Cobb, K.; Ke, L.; Zou, R.; Liu, Y.; Ruan, R. Research progress on the role of common metal catalysts in biomass pyrolysis: A state-of-the-art review. Green Chem. 2022, 24, 3922–3942.

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46.

- Garg, R.; Anand, N.; Kumar, D. Pyrolysis of babool seeds (Acacia nilotica) in a fixed bed reactor and bio-oil characterization. Renew. Energy 2016, 96, 167–171.

- Kollman, M.S.; Jiang, X.; Sun, R.; Zhang, X.; Li, W.; Chang, H.-M.; Jameel, H. Towards jet fuel from technical lignins: Feedstock-catalyst-product interactions revealed during catalytic hydrogenolysis. Chem. Eng. J. 2023, 451, 138464.

- Hoang, A.T.; Ong, H.C.; Fattah, I.M.R.; Chong, C.T.; Cheng, C.K.; Sakthivel, R.; Ok, Y.S. Progress on the lignocellulosic biomass pyrolysis for biofuel production toward environmental sustainability. Fuel Process. Technol. 2021, 223, 106997.

- Bhoi, P.R.; Ouedraogo, A.S.; Soloiu, V.; Quirino, R. Recent advances on catalysts for improving hydrocarbon compounds in bio-oil of biomass catalytic pyrolysis. Renew. Sustain. Energy Rev. 2020, 121, 109676.

- Oh, Y.K.; Hwang, K.R.; Kim, C.; Kim, J.R.; Lee, J.S. Recent developments and key barriers to advanced biofuels: A short review. Bioresour. Technol. 2018, 257, 320–333.

- Imran, A.; Bramer, E.A.; Seshan, K.; Brem, G. High quality bio-oil from catalytic flash pyrolysis of lignocellulosic biomass over alumina-supported sodium carbonate. Fuel Process. Technol. 2014, 127, 72–79.

- Zhou, S.; Xue, Y.; Cai, J.; Cui, C.; Ni, Z.; Zhou, Z. An understanding for improved biomass pyrolysis: Toward a systematic comparison of different acid pretreatments. Chem. Eng. J. 2021, 411, 128513.

- Chen, Z.; Wang, M.; Jiang, E.; Wang, D.; Zhang, K.; Ren, Y.; Jiang, Y. Pyrolysis of Torrefied Biomass. Trends Biotechnol. 2018, 36, 1287–1298.

- Chen, D.; Mei, J.; Li, H.; Li, Y.; Lu, M.; Ma, T.; Ma, Z. Combined pretreatment with torrefaction and washing using torrefaction liquid products to yield upgraded biomass and pyrolysis products. Bioresour. Technol. 2017, 228, 62–68.

- Han, Y.; Gholizadeh, M.; Tran, C.-C.; Kaliaguine, S.; Li, C.-Z.; Olarte, M.; Garcia-Perez, M. Hydrotreatment of pyrolysis bio-oil: A review. Fuel Process. Technol. 2019, 195, 106140.

- Tabassum, N.; Pothu, R.; Pattnaik, A.; Boddula, R.; Balla, P.; Gundeboyina, R.; Challa, P.; Rajesh, R.; Perugopu, V.; Mameda, N.; et al. Heterogeneous Catalysts for Conversion of Biodiesel-Waste Glycerol into High-Added-Value Chemicals. Catalysts 2022, 12, 767.

- Wang, Y.; Akbarzadeh, A.; Chong, L.; Du, J.; Tahir, N.; Awasthi, M.K. Catalytic pyrolysis of lignocellulosic biomass for bio-oil production: A review. Chemosphere 2022, 297, 134181.

- Qiu, B.; Tao, X.; Wang, J.; Liu, Y.; Li, S.; Chu, H. Research progress in the preparation of high-quality liquid fuels and chemicals by catalytic pyrolysis of biomass: A review. Energy Convers. Manag. 2022, 261, 115647.

- Liu, R.; Sarker, M.; Rahman, M.M.; Li, C.; Chai, M.; Nishu; Cotillon, R.; Scott, N.R. Multi-scale complexities of solid acid catalysts in the catalytic fast pyrolysis of biomass for bio-oil production—A review. Prog. Energy Combust. Sci. 2020, 80, 100852.

- Djakaria, K.; Tang, Z.; Shao, J.; Chen, X.; Xiao, H.; Smith, J.; Yang, H.; Chen, H. Improving the production of furfural from cellulose catalytic pyrolysis using WO3/γ-Al2O3 composite oxides. J. Anal. Appl. Pyrolysis 2022, 167, 105648.

- Zhang, W.; Xia, H.; Deng, Y.; Zhang, Q.; Xin, C. Slow pyrolysis of waste navel orange peels with metal oxide catalysts to produce high-grade bio-oil. Green Process. Synth. 2022, 11, 218–228.

- Zhang, C.; Zhang, L.; Li, Q.; Wang, Y.; Liu, Q.; Wei, T.; Dong, D.; Salavati, S.; Gholizadeh, M.; Hu, X. Catalytic pyrolysis of poplar wood over transition metal oxides: Correlation of catalytic behaviors with physiochemical properties of the oxides. Biomass Bioenergy 2019, 124, 125–141.

- Wang, W.; Liu, Y.; Wang, Y.; Liu, L.; Hu, C. Effect of Ni(NO3)2 Pretreatment on the Pyrolysis of Organsolv Lignin Derived from Corncob Residue. Processes 2020, 9, 23.

- Liu, Y.; Wang, Y.; Wang, W.; Liu, L.; Hu, C. Effects of MgCl2 Solution Pretreatment at Room Temperature on the Pyrolytic Behavior of Pubescens and the Properties of Bio-oil Obtained. Energy Fuels 2020, 34, 12665–12677.

- Wang, J.; Zhang, B.; Shujaa Aldeen, A.; Mwenya, S.; Cheng, H.; Xu, Z.; Zhang, H. Enhancing production of hydrocarbon-rich bio-oil from biomass via catalytic fast pyrolysis coupled with advanced oxidation process pretreatment. Bioresour. Technol. 2022, 359, 127450.

- Su, J.; Miao, K.; Zhao, Y.; Li, T.; Zhao, Z.; Luo, G.; Wang, K. Production of gasoline components from biomass catalytic hydropyrolysis using zeolite-based bifunctional catalysts. Biomass Convers. Biorefin. 2022, 1–13.

- Wu, L.; Xin, J.; Xia, D.; Sun, J.; Liang, J. Enhanced production of hydrocarbons from the catalytic pyrolysis of maize straw over hierarchical ZSM-11 zeolites. Appl. Catal. B 2022, 317, 121775.

- Rahman, M.M.; Liu, R.; Cai, J. Catalytic fast pyrolysis of biomass over zeolites for high quality bio-oil—A review. Fuel Process. Technol. 2018, 180, 32–46.