| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Lilong Chai | -- | 3020 | 2022-11-23 04:40:24 | | | |

| 2 | Lindsay Dong | Meta information modification | 3020 | 2022-11-23 09:47:27 | | |

Video Upload Options

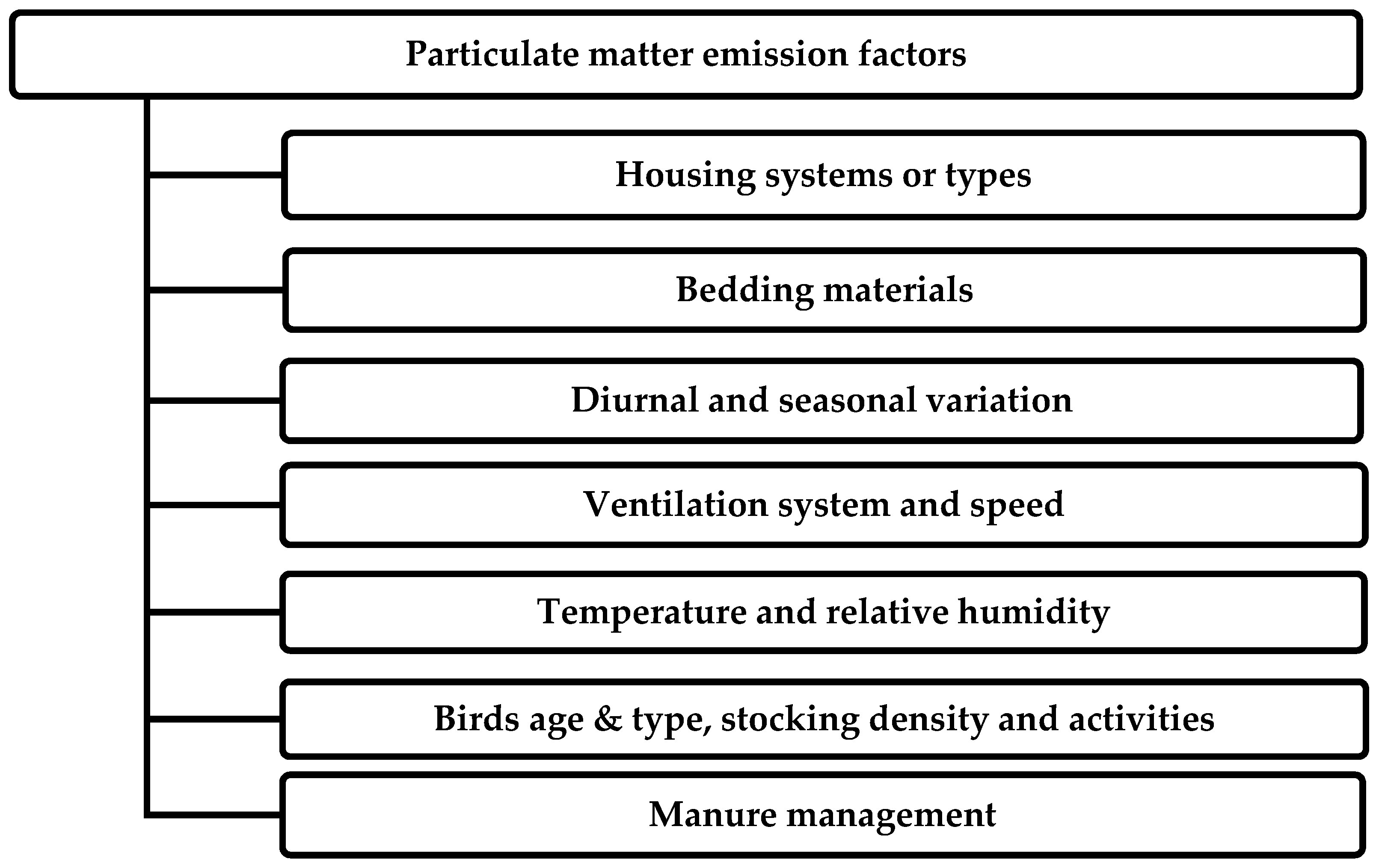

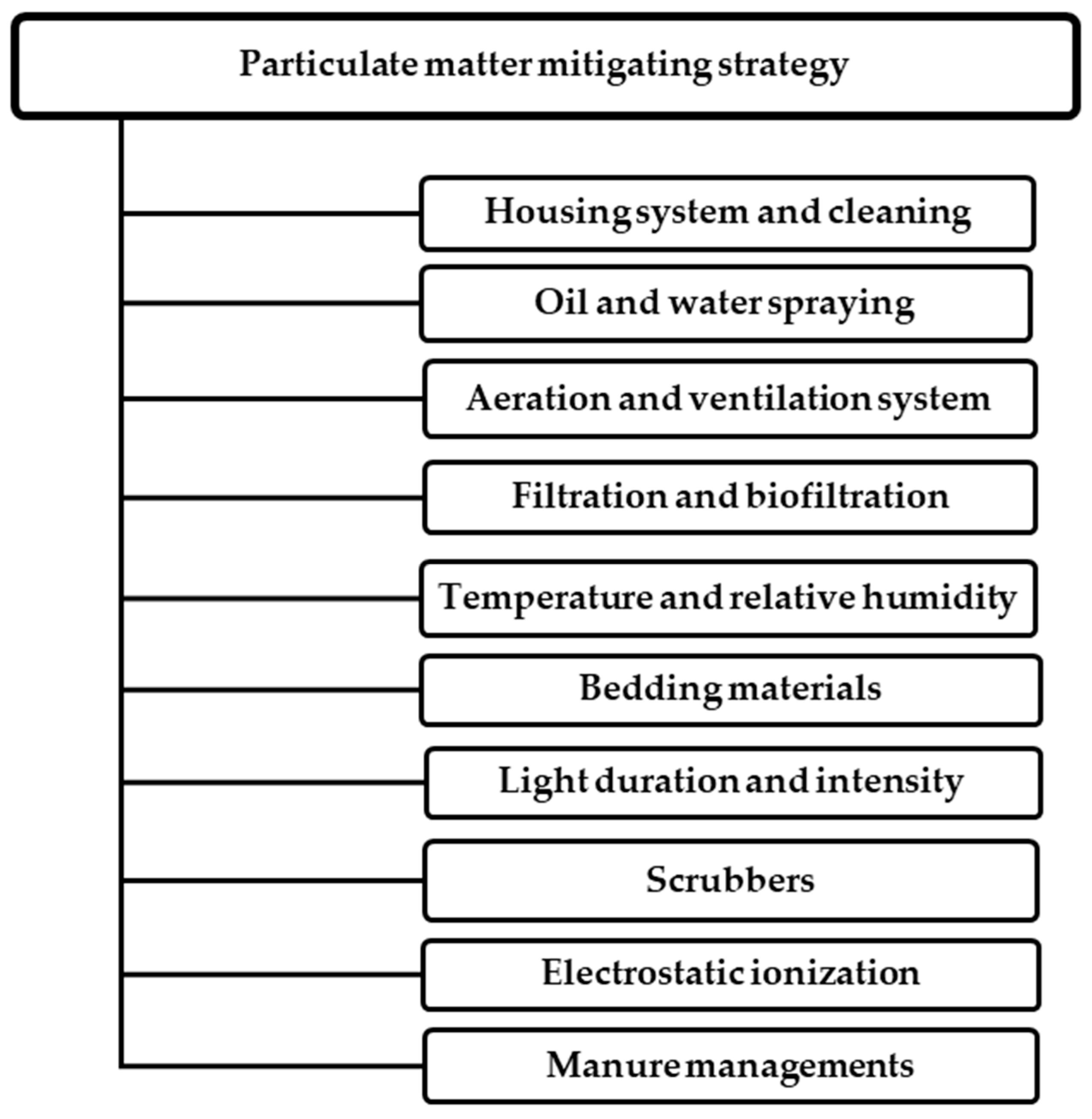

Poultry farming plays a key role in agricultural air emissions. Particulate matter (PM) level tends to be high in broiler and cage-free layer houses, that may impair health and welfare of animals and their caretakers. To protect public health and welfare, the occupational exposure limit for PM10 and PM2.5 (i.e., PM diameters that are generally ≤10 and 2.5 μm, respectively) are suggested not to exceed 150 µg m−3 and 35 µg m−3, respectively, based on 24-h concentrations thresholds as suggested by US. EPA. However, the levels of PM10 and PM2.5 in poultry houses could be 100 times higher than that limit. Generally, PM emissions are affected by various factors, including housing types, seasonal and diurnal variation, manure management, bedding materials, ventilation rates, and birds’ activities. High PM concentrations in poultry houses impair birds’ and caretakers’ liver, kidneys, and respiratory systems. Effective mitigation strategies include frequent house cleaning, optimum light intensity, liquid spraying, bedding management, and air filtration systems. However, mitigation strategies can be cost-prohibitive and have side effects. Therefore, poultry farms should select mitigation strategies based on farm location, climate conditions, environmental policies, and available resources (government assistance programs).

1. Introduction

2. Dust Composition and Mixture

3. Factors Affecting Dust Generations

3.1. Effect of Housing Systems on PM

3.2. Effect of Bedding Materials on PM Levels

3.3. Effect of Lighting and Seasonal Variations on PM Levels

3.4. Effect of Ventilation System

3.5. Effect of Indoor Temperature and Relative Humidity

3.6. Other Factors

Poultry manure management plays an important role in dust emissions because manure contributes about 50% of total dust emissions in most housing systems with a raised floor [18]. Several studies show that floor-raised houses (broilers or layers) where manure gets deposited on the floor over time possess potentially higher PM concentrations than other poultry housing [17][37].

4. Impacts of PM on the Health and Welfare of Chickens and Farm Workers

High levels of PM can negatively impact the health and welfare of animals and their caretakers. According to Zhao et al. (2016), PM acts as a major carrier for airborne bacteria and endotoxin, which, once inhaled, might cause harmful effects on the respiratory systems of animals and caretakers [57]. When toxins carried by PM10 (particle size less than 10 µm) reach the bloodstream after inhalation, they can harm the respiratory system, liver, kidneys, and nervous system [12][14][58]. On the other hand, PM is more harmful to humans and birds with pre-existing cardiac diseases like asthma, making breathing difficult [59]. A low level of ventilation rate within the animal house was linked to long-term lung function impairment in animals [20]. Higher PM10 levels can increase the risk of chronic bronchitis, cardiovascular illness, pneumonia lesions, asthma-like symptoms, and lung cancer in farmers and animals [21][22].

High PM concentrations have been linked to higher avian mortality rates [60]. Particulate matters contain various airborne bacteria and endotoxin, which negatively impact health and welfare issues of birds. When birds inhale dust particles with dust-borne pathogens (especially Mycoplasma species) damage occurs to mucosal surface cilia present in the trachea [61]. Particulate matter of size PM2.5 was found to have lots of harmful microorganisms and endotoxins [62]. Long-term exposure to PM2.5 has been linked to impaired lung function, and fraction size up to PM10 has increased mortality risk [59].

Particulate matter in poultry houses can pollute the air and affect caretaker health. Poultry caretakers are at high risk due to occupational exposure to PM, leading to more respiratory hazards at work than in other work environments. Similarly, male poultry workers who smoke showed a substantially higher prevalence of chronic cough, chronic phlegm, and chronic bronchitis than nonsmokers [63]. The most common symptoms caused by PM in poultry workers are characterized by cough, phlegm, eye irritation, dyspnea, chest tightness, weariness, nasal congestion, wheezing, sneezing, nasal discharge, headache, throat irritation, and fever [12][19][20][21][22][59].

5. Mitigation Strategies Suppressing PM Levels in Poultry Houses

6. Particulate Matter Emission Mitigating Strategies

7. Summary

References

- Chai, L.; Kröbel, R.; Janzen, H.H.; Beauchemin, K.A.; McGinn, S.M.; Bittman, S.; Atia, A.; Edeogu, I.; MacDonald, D.; Dong, R. A Regional Mass Balance Model Based on Total Ammoniacal Nitrogen for Estimating Ammonia Emissions from Beef Cattle in Alberta Canada. Atmos. Environ. 2014, 92, 292–302.

- Chai, L.; Kröbel, R.; MacDonald, D.; Bittman, S.; Beauchemin, K.A.; Janzen, H.H.; McGinn, S.M.; Vanderzaag, A. An Ecoregion-Specific Ammonia Emissions Inventory of Ontario Dairy Farming: Mitigation Potential of Diet and Manure Management Practices. Atmos. Environ. 2016, 126, 1–14.

- Zhao, Y.; Shepherd, T.A.; Li, H.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part I: Monitoring System and Indoor Air Quality. Poult. Sci. 2015, 94, 518–533.

- Ni, J.-Q.; Diehl, C.A.; Chai, L.; Chen, Y.; Heber, A.J.; Lim, T.-T.; Bogan, B.W. Factors and Characteristics of Ammonia, Hydrogen Sulfide, Carbon Dioxide, and Particulate Matter Emissions from Two Manure-Belt Layer Hen Houses. Atmos. Environ. 2017, 156, 113–124.

- Ni, J.-Q.; Liu, S.; Diehl, C.A.; Lim, T.-T.; Bogan, B.W.; Chen, L.; Chai, L.; Wang, K.; Heber, A.J. Emission Factors and Characteristics of Ammonia, Hydrogen Sulfide, Carbon Dioxide, and Particulate Matter at Two High-Rise Layer Hen Houses. Atmos. Environ. 2017, 154, 260–273.

- NRC (National Research Council). Air Emissions from Animal Feeding Operations: Current Knowledge, Future Needs; National Academies Press: Washington, DC, USA, 2003.

- EPA National Emission Inventory. Ammonia Emissions from Animal Husbandry Operations; EPA National Emission Inventory: Washington, DC, USA, 2004; Volume 131. Available online: https://www3.epa.gov/ttnchie1/ap42/ch09/related/nh3inventorydraft_jan2004.pdf (accessed on 30 September 2022).

- Ritz, C.; Mitchell, B.; Fairchild, B.; Czarick III, M.; Worley, J. Improving In-House Air Quality in Broiler Production Facilities Using an Electrostatic Space Charge System. J. Appl. Poult. Res. 2006, 15, 333–340.

- Chai, L.; Ni, J.-Q.; Diehl, C.A.; Kilic, I.; Heber, A.; Chen, Y.; Cortus, E.; Bogan, B.; Lim, T.; Ramirez-Dorronsoro, J.-C. Ventilation Rates in Large Commercial Layer Hen Houses with Two-Year Continuous Monitoring. Br. Poult. Sci. 2012, 53, 19–31.

- Wang, K.; Li, Q.; Wang-Li, L.; Cortus, E.; Bogan, B.W.; Kilic, I.; Liang, W.-Z.; Xiao, C.-H.; Chai, L.-L.; Ni, J.-Q. The National Air Emissions Monitoring Study′s Southeast Layer Site: Part V. Hydrogen Sulfide and Volatile Organic Compounds. Trans. ASABE 2016, 59, 681–693.

- WHO (World Health Organization). Ambient (Outdoor) Air Pollution. Available online: https://www.who.int/news-room/fact-sheets/detail/ambient-(outdoor)-air-quality-and-health (accessed on 30 September 2022).

- US EPA. Health and Environmental Effects of Particulate Matter (PM). Available online: https://www.epa.gov/pm-pollution/health-and-environmental-effects-particulate-matter-pm (accessed on 30 September 2022).

- US EPA. NAAQS Table. Available online: https://www.epa.gov/criteria-air-pollutants/naaqs-table (accessed on 30 September 2022).

- US EPA. Particulate Matter (PM) Basics. Available online: https://www.epa.gov/pm-pollution/particulate-matter-pm-basics (accessed on 30 September 2022).

- EEA Group 10: Agriculture—European Environment Agency. Available online: https://www.eea.europa.eu/publications/EMEPCORINAIR5/page019.html (accessed on 30 September 2022).

- Wicklin, G.; Czarick, M. Particulate Emissions from Poultry Housing. In Proceedings of the ASAE Annual International Meeting, Minneapolis Convention Center, Minneapolis, MN, USA, 10–14 August 1997; pp. 10–14.

- Cambra-López, M.; Hermosilla, T.; Lai, H.T.; Aarnink, A.J.A.; Ogink, N. Particulate Matter Emitted from Poultry and Pig Houses: Source Identification and Quantification. Trans. ASABE 2011, 54, 629–642.

- Ahaduzzaman, M.; Milan, L.; Morton, C.L.; Gerber, P.F.; Walkden-Brown, S.W. Characterization of Poultry House Dust Using Chemometrics and Scanning Electron Microscopy Imaging. Poult. Sci. 2021, 100, 101188.

- Donham, K. Occupational Health Hazards and Recommended Exposure Limits for Workers in Poultry Buildings. In Proceedings of the National Poultry Waste Management Symposium Committee, Birmingham, AL, USA, 28–30 October 2000; pp. 92–109.

- Radon, K.; Weber, C.; Iversen, M.; Danuser, B.; Pedersen, S.; Nowak, D. Exposure Assessment and Lung Function in Pig and Poultry Farmers. Occup. Environ. Med. 2001, 58, 405–410.

- Cambra-López, M.; Aarnink, A.J.; Zhao, Y.; Calvet, S.; Torres, A.G. Airborne Particulate Matter from Livestock Production Systems: A Review of an Air Pollution Problem. Environ. Pollut. 2010, 158, 1–17.

- Michiels, A.; Piepers, S.; Ulens, T.; Van Ransbeeck, N.; Sacristán, R.D.P.; Sierens, A.; Haesebrouck, F.; Demeyer, P.; Maes, D. Impact of Particulate Matter and Ammonia on Average Daily Weight Gain, Mortality and Lung Lesions in Pigs. Prev. Vet. Med. 2015, 121, 99–107.

- Viegas, S.; Faísca, V.M.; Dias, H.; Clérigo, A.; Carolino, E.; Viegas, C. Occupational Exposure to Poultry Dust and Effects on the Respiratory System in Workers. J. Toxicol. Environ. Health Part A 2013, 76, 230–239.

- Chai, L.; Zhao, Y.; Xin, H.; Wang, T.; Atilgan, A.; Soupir, M.; Liu, K. Reduction of Particulate Matter and Ammonia by Spraying Acidic Electrolyzed Water onto Litter of Aviary Hen Houses: A Lab-Scale Study. Trans. ASABE 2017, 60, 497–506.

- Qi, R.; Manbeck, H.; Maghirang, R. Dust Net Generation Rate in a Poultry Layer House. Trans. ASAE 1992, 35, 1639–1645.

- Roumeliotis, T.S.; Dixon, B.J.; Van Heyst, B.J. Characterization of Gaseous Pollutant and Particulate Matter Emission Rates from a Commercial Broiler Operation Part I: Observed Trends in Emissions. Atmos. Environ. 2010, 44, 3770–3777.

- Donham, K.J.; Scallon, L.J.; Popendorf, W.; Treuhaft, M.W.; Roberts, R.C. Characterization of Dusts Collected from Swine Confinement Buildings. Am. Ind. Hyg. Assoc. J. 1986, 47, 404–410.

- Bonifacio, H.F.; Maghirang, R.G.; Trabue, S.L.; McConnell, L.L.; Prueger, J.H.; Bonifacio, E.R. TSP, PM10, and PM2. 5 Emissions from a Beef Cattle Feedlot Using the Flux-Gradient Technique. Atmos. Environ. 2015, 101, 49–57.

- Chai, L.; Xin, H.; Wang, Y.; Oliveira, J.; Wang, K.; Zhao, Y. Mitigating Particulate Matter Generation in a Commercial Cage-Free Hen House. Trans. ASABE 2019, 62, 877–886.

- Lin, X.-J.; Cortus, E.; Zhang, R.; Jiang, S.; Heber, A. Ammonia, Hydrogen Sulfide, Carbon Dioxide and Particulate Matter Emissions from California High-Rise Layer Houses. Atmos. Environ. 2012, 46, 81–91.

- Anderson, N.; Strader, R.; Davidson, C. Airborne Reduced Nitrogen: Ammonia Emissions from Agriculture and Other Sources. Environ. Int. 2003, 29, 277–286.

- Ten Brink, H.; Even, A. Secondary Aerosol in the Netherlands. In Proceedings of the Annual Report of Subproject AEROSOL of Eurotrac-2, Munich, Germany, 1999.

- Viegas, C.; Carolino, E.; Malta-Vacas, J.; Sabino, R.; Viegas, S.; Veríssimo, C. Fungal Contamination of Poultry Litter: A Public Health Problem. J. Toxicol. Environ. Health A 2012, 75, 1341–1350.

- Morgan, R.J.; Wood, D.J.; Van Heyst, B.J. The Development of Seasonal Emission Factors from a Canadian Commercial Laying Hen Facility. Atmos. Environ. 2014, 86, 1–8.

- Knight, R.M.; Tong, X.; Liu, Z.; Hong, S.; Zhao, L. Spatial and Seasonal Variations of PM Concentration and Size Distribution in Manure-Belt Poultry Layer Houses. Trans. ASABE 2019, 62, 415–427.

- Liu, Q.; Cheng, W.; Liu, L.; Hua, Y.; Guo, L.; Nie, W. Research on the Control Law of Dust in the Main Ventilation System in Excavated Tunnels for Cleaner Production. Build. Environ. 2021, 205, 108282.

- Shepherd, T.A.; Zhao, Y.; Li, H.; Stinn, J.P.; Hayes, M.D.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part II. Ammonia, Greenhouse Gas, and Particulate Matter Emissions. Poult. Sci. 2015, 94, 534–543.

- EU Council Directive 1999/74/EC of 19 July 1999 Laying down Minimum Standards for the Protection of Laying Hens. Available online: https://www.legislation.gov.uk/eudr/1999/74/contents (accessed on 30 September 2022).

- Aarnink, A.; Ellen, H. Processes and Factors Affecting Dust Emissions from Livestock Production. How to Improve Air Quality. 2007. Available online: https://www.researchgate.net/profile/Andre-Aarnink/publication/40098613_Processes_and_factors_affecting_dust_emissions_from_livestock_production/links/55adff7508aed9b7dcdb09b3/Processes-and-factors-affecting-dust-emissions-from-livestock-production.pdf (accessed on 10 September 2022).

- Munir, M.; Belloncle, C.; Irle, M.; Federighi, M. Wood-Based Litter in Poultry Production: A Review. World’s Poult. Sci. J. 2019, 75, 5–16.

- Gustafsson, G.; Von Wachenfelt, E. Reducing Airborne Dust in a Loose-Housing System for Laying Hens. J. Agric. Sci. Technol. A 2012, 2, 350.

- Van Harn, J.; Aarnink, A.; Mosquera, J.; Van Riel, J.; Ogink, N. Effect of Bedding Material on Dust and Ammonia Emission from Broiler Houses. Trans. ASABE 2012, 55, 219–226.

- Gustafsson, G.; Von Wachenfelt, E. Airborne Dust Control Measures for Floor Housing System for Laying Hens. CIGR J. 2006, VII, 1–13.

- Takai, H.; Pedersen, S.; Johnsen, J.O.; Metz, J.; Koerkamp, P.G.; Uenk, G.; Phillips, V.; Holden, M.; Sneath, R.; Short, J. Concentrations and Emissions of Airborne Dust in Livestock Buildings in Northern Europe. J. Agric. Eng. Res. 1998, 70, 59–77.

- Farghly, M.; Mahrose, K.M.; Cooper, R.; Metwally, K.A.; Abougabal, M.S.; El-Ratel, I. Use of Available Crop By-Products as Alternative Bedding Materials to Wheat Straw for Rearing Broilers. Animal 2021, 15, 100260.

- Lim, T.-T.; Heber, A.J.; Ni, J.-Q.; Gallien, J.; Xin, H. Air Quality Measurements at a Laying Hen House: Particulate Matter Concentrations and Emissions; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2003; p. 249.

- Li, H.; Xin, H.; Burns, R.T.; Jacobson, L.D.; Noll, S.; Hoff, S.; Harmon, J.; Koziel, J.A.; Hetchler, B. Air Emissions from Tom and Hen Turkey Houses in the US Midwest. Trans. ASABE 2011, 54, 305–314.

- Shang, B.; Liu, Y.; Dong, H.; Tao, X.; Yao, H. Particulate Matter Concentrations and Emissions of a Fattening Pig Facility in Northern China. Atmos. Pollut. Res. 2020, 11, 1902–1911.

- Mostafa, E.; Buescher, W. Indoor Air Quality Improvement from Particle Matters for Laying Hen Poultry Houses. Biosyst. Eng. 2011, 109, 22–36.

- Winkel, A.; Mosquera, J.; Koerkamp, P.W.G.; Ogink, N.W.; Aarnink, A.J. Emissions of Particulate Matter from Animal Houses in the Netherlands. Atmos. Environ. 2015, 111, 202–212.

- Pedersen, S.; Nonnenmann, M.; Rautiainen, R.; Demmers, T.; Banhazi, T.; Lyngbye, M. Dust in Pig Buildings. J. Agric. Saf. Health 2000, 6, 261.

- Lin, X.; Zhang, R.; Jiang, S.; El-Mashad, H.; Xin, H. Emissions of Ammonia, Carbon Dioxide and Particulate Matter from Cage-Free Layer Houses in California. Atmos. Environ. 2017, 152, 246–255.

- Tang, Q.; Huang, K.; Liu, J.; Shen, D.; Dai, P.; Li, Y.; Li, C. Seasonal Variations of Microbial Assemblage in Fine Particulate Matter from a Nursery Pig House. Sci. Total Environ. 2020, 708, 134921.

- Bist, R.B.; Chai, L.; Yang, X.; Subedi, S.; Guo, Y. Air Quality in Cage-Free Houses during Pullets Production; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2022; p. 1.

- Vucemilo, M.; Matković, K.; Vinković, B.; Jakšić, S.; Granić, K.; Mas, N. The Effect of Animal Age on Air Pollutant Concentration in a Broiler House. Czech J. Anim. Sci 2007, 52, 170–174.

- Shen, D.; Li, C. Distribution of Particulate Matter and Ammonia in a Mechanically Ventilated Layer House. In Proceedings of the International Symposium Animal Environment and Welfare, Chongqing, China, 23–25 October 2017.

- Zhao, Y.; Zhao, D.; Ma, H.; Liu, K.; Atilgan, A.; Xin, H. Environmental Assessment of Three Egg Production Systems—Part III: Airborne Bacteria Concentrations and Emissions. Poult. Sci. 2016, 95, 1473–1481.

- Koren, H.; Bisesi, M. Handbook of Environmental Health, Fourth Edition, Volume II: Pollutant Interactions in Air, Water and Soil; CRC Press: Boca Raton, FL, USA, 2003; Volume 2.

- Schwarze, P.; Øvrevik, J.; Låg, M.; Refsnes, M.; Nafstad, P.; Hetland, R.; Dybing, E. Particulate Matter Properties and Health Effects: Consistency of Epidemiological and Toxicological Studies. Hum. Exp. Toxicol. 2006, 25, 559–579.

- Guarino, M.; Caroli, A.; Navarotto, P. Dust Concentration and Mortality Distribution in an Enclosed Laying House. Trans. ASAE 1999, 42, 1127.

- Green, A.R.; Wesley, I.; Trampel, D.W.; Xin, H. Air Quality and Bird Health Status in Three Types of Commercial Egg Layer Houses. J. Appl. Poult. Res. 2009, 18, 605–621.

- Dai, P.; Shen, D.; Tang, Q.; Huang, K.; Li, C. PM2. 5 from a Broiler Breeding Production System: The Characteristics and Microbial Community Analysis. Environ. Pollut. 2020, 256, 113368.

- Zuskin, E.; Mustajbegovic, J.; Schachter, E.N.; Kern, J.; Rienzi, N.; Goswami, S.; Marom, Z.; Maayani, S. Respiratory Function in Poultry Workers and Pharmacologic Characterization of Poultry Dust Extract. Environ. Res. 1995, 70, 11–19.

- Banhazi, T.; Seedorf, J.; Laffrique, M.; Rutley, D. Identification of the Risk Factors for High Airborne Particle Concentrations in Broiler Buildings Using Statistical Modelling. Biosyst. Eng. 2008, 101, 100–110.

- US EPA. National Ambient Air Quality Standards (NAAQS) for PM. Available online: https://www.epa.gov/pm-pollution/national-ambient-air-quality-standards-naaqs-pm (accessed on 30 September 2022).

- DES Smoke and Dust Health Action Levels—Environment, Land and Water. Available online: https://apps.des.qld.gov.au/air-quality/health/ (accessed on 30 September 2022).

- OSHA Permissible Exposure Limits—OSHA Annotated Table Z-1—Occupational Safety and Health Administration. Available online: https://www.osha.gov/annotated-pels/table-z-1 (accessed on 30 September 2022).

- WHO (World Health Organization). Air Quality Guidelines: Global Update 2005: Particulate Matter, Ozone, Nitrogen Dioxide, and Sulfur Dioxide; World Health Organization: Geneva, Switzerland, 2006; ISBN 92-890-2192-6.

- IOM. Occupational Exposure Limits for Dusts; IOM: Edinburgh, UK, 1984; Volume 23, Available online: http://winnipegsafetycompanies.com/wp-content/uploads/2016/09/dust-overview-john-cherrie.pdf#:~:text=1984%20HSE%20publish%20Guidance%20Note%20EH40%2C%20Occupational%20Exposure,or%205%20mg%2Fm3%20of%20respirable%20dust.%20COSHH%20Regulations (accessed on 3 April 2022).

- Chai, L.; Xin, H.; Zhao, Y.; Wang, T.; Soupir, M.; Liu, K. Mitigating Ammonia Emissions from Liquid-Sprayed Litter of Cage-Free Hen House with a Solid Litter Additive; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2017; p. 1.

- Wood, D. The Evaluation of Ammonia and Particulate Matter Control Strategies for Poultry Production Facilities. Ph.D. Thesis, University of Guelph, Guelph, ON, Canada, 2015.

- Almuhanna, E.A. Dust Control in Livestock Buildings with Electrostatically-Charged Water Spray; Kansas State University: Manhattan, KS, USA, 2007; ISBN 1-109-97127-3.

- Dawkins, M.S.; Donnelly, C.A.; Jones, T.A. Chicken Welfare Is Influenced More by Housing Conditions than by Stocking Density. Nature 2004, 427, 342–344.