PM emissions depend on the housing systems and ventilation types. Most of poultry housing systems are mechanically ventilation system that applies maximum ventilation in summer for removing extra heat and uses minimum ventilation in winter for moisture removing, which can improve air quality inside the house [

]. Poultry house ventilation rate affects the PM concentration [

]. Similarly, ventilation changes as affected by seasons that winter season has the highest concentration of PM among all four seasons [

]. Oppositely, increased ventilation during the summer dilutes the PM concentration [

]. Besides seasonal effect, housing style (e.g., natural ventilation vs. mechanical ventilation), ventilation types (e.g., negative vs. positive ventilation), and fan selection could also affect PM generations. Measurements of PM in natural ventilation systems have higher variations as wind directions and speed are varying over time.

Temperature and relative humidity (RH) are inversely proportional to each other. Increased temperature decreases RH and is directly influenced by ventilation rates within poultry houses [

70]. Temperature and RH change seasonally and depend on weather conditions and experimental house design. During the winter, ventilation rates are decreased, and heaters are turned on to make a room warm, reducing RH. A decrease in RH increases PM concentration. However, ventilation rates are increased during the summer season to bring cold air or moisture from outside (cooling pad). The moisture from outside makes RH higher inside the house and decreases PM concentration by making heavy PM settle down. According to Lin et al. (2017), PM

2.5 and PM

10 concentrations depend on RH due to ambient air [

71]. Similarly, houses or rooms attached more to the outside environment possess higher RH due to individual room effects. Tang et al. (2020) tested the effect of different temperatures (21.1, 23.8, 26.4, and 29.2 °C) and RH (49.5, 74.7, 78.8, and 80.0%) on PM concentrations and found that PM

1, PM

2.5, PM

10, and TSP were significantly lower in higher RH and lower temperature treatments because RH could affect litter moisture [

64].

3.6. Other Factors

Poultry manure management plays an important role in dust emissions because manure contributes about 50% of total dust emissions in most housing systems with a raised floor [18]. Several studies show that floor-raised houses (broilers or layers) where manure gets deposited on the floor over time possess potentially higher PM concentrations than other poultry housing [17,40].

The chickens’ activity and dust emission depend on the birds’ age in poultry housing [

78]. Recent research on pullets found that an increase in pullets’ age increases birds’ activities and significantly affects or increases dust production (

p < 0.05). Similarly, Vucemilo et al. (2007) also found that increasing broiler age affects PM levels significantly [

79]. Chicken activities during feeding mainly increase PM

10 and TSP in the chicken house [

80]. However, the perching behaviors and dust bathing in open spaces showed high PM production compared to the feeding and drinking behaviors [

78]. Moreover, PM emission is also affected by housing stocking density and bird weight [

9]. PM levels are higher with the increase of birds’ weight and stocking density.

4. Impacts of PM on the Health and Welfare of Chickens and Farm Workers

High levels of PM can negatively impact the health and welfare of animals and their caretakers. According to Zhao et al. (2016), PM acts as a major carrier for airborne bacteria and endotoxin, which, once inhaled, might cause harmful effects on the respiratory systems of animals and caretakers [81]. When toxins carried by PM10 (particle size less than 10 µm) reach the bloodstream after inhalation, they can harm the respiratory system, liver, kidneys, and nervous system [12,14,82]. On the other hand, PM is more harmful to humans and birds with pre-existing cardiac diseases like asthma, making breathing difficult [83]. A low level of ventilation rate within the animal house was linked to long-term lung function impairment in animals [20]. Higher PM10 levels can increase the risk of chronic bronchitis, cardiovascular illness, pneumonia lesions, asthma-like symptoms, and lung cancer in farmers and animals [21,22].

High PM concentrations have been linked to higher avian mortality rates [84]. Particulate matters contain various airborne bacteria and endotoxin, which negatively impact health and welfare issues of birds. When birds inhale dust particles with dust-borne pathogens (especially Mycoplasma species) damage occurs to mucosal surface cilia present in the trachea [85]. Particulate matter of size PM2.5 was found to have lots of harmful microorganisms and endotoxins [86]. Long-term exposure to PM2.5 has been linked to impaired lung function, and fraction size up to PM10 has increased mortality risk [83].

Particulate matter in poultry houses can pollute the air and affect caretaker health. Poultry caretakers are at high risk due to occupational exposure to PM, leading to more respiratory hazards at work than in other work environments. Similarly, male poultry workers who smoke showed a substantially higher prevalence of chronic cough, chronic phlegm, and chronic bronchitis than nonsmokers [91]. The most common symptoms caused by PM in poultry workers are characterized by cough, phlegm, eye irritation, dyspnea, chest tightness, weariness, nasal congestion, wheezing, sneezing, nasal discharge, headache, throat irritation, and fever [12,19,20,21,22,83].

5. Mitigation Strategies Suppressing PM Levels in Poultry Houses

The high level of PM in poultry facilities is a major concern for the health and welfare of animals and their caretakers [

102,

103,

104,

105,

106,

107]. Among different PM sizes, PM

10 and PM

2.5 levels are considered measurement factors for most organizations and countries because of their harmful effects on the health and welfare of caretakers. The World Health Organization (WHO) recently amended the ambient air quality standards in 2021 and proposed the maximum of PM

10 to be 15 µg/m

3 for the annual average and 45 µg/m

3 for the 24-h mean, while for PM

2.5 to be 5 µg/m

3 for the annual average and 15 µg/m

3 for the 24-h mean [

11,

106]. According to the EPA (2022), the National Ambient Air Quality Standard (NAAQS) has set an exposure limit of PM

2.5 and PM

10 as 35 µg/m

3 and 150 µg/m

3, respectively, for 24 h (98th percentile, averaged over 3 years) [

103]. Therefore, everyone must follow OEL guidelines to improve the caretaker’s health.

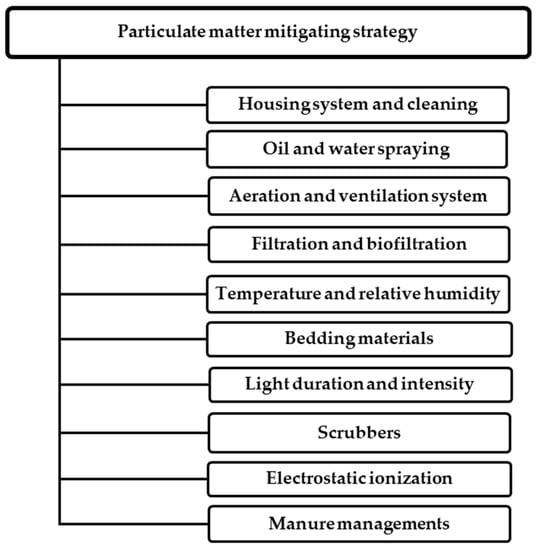

6. Particulate Matter Emission Mitigating Strategies

The PM concentration in poultry housing is primarily affected by housing and feeding, animal species, stocking density, lighting duration, environment conditions (season), and existing mitigation practices [

22,

24,

72,

108]. It is important to possess a deep knowledge of PM morphology to evaluate their effects and propose the best mitigating technologies in animal housing. Particulate matter mitigating strategies can be classified into three different groups: dilution and effective room air distribution, source-control techniques to reduce PM from the source, and PM removal or cleaning techniques by using acid scrubbers, electrostatic precipitators, or ionizers [

109]. Other techniques for improving air quality are oil spraying, manure handling, and electrolyzed water spray [

24]. Controlling the living space environment, including temperature, humidity, air quality, and litter quality, is critical for poultry well-being [

110]. Variations in indoor air quality have been linked to various factors, including barn architecture, manure management, animal densities, feed regimens, building ventilation, and farm management practices. Therefore, various biochemical, chemical, managerial, physical, and physiological practices must be implemented to decrease PM significantly lower than recommended guidelines (

Figure 3).

Figure 3. Overview of the PM emission mitigating strategy used in poultry housing.

7. Summary

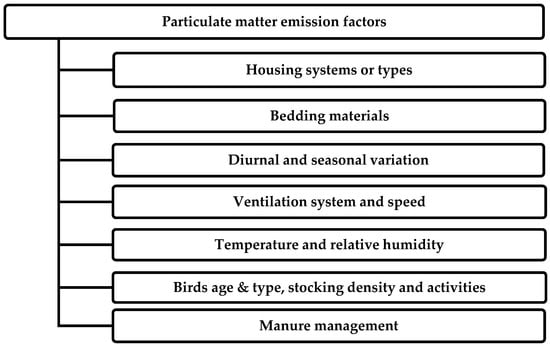

Particulate matters (PM) found in poultry houses are biological, organic, and inorganic in composition, which originated from bedding materials, feathers, feeds, skin, excreta, bacteria, and feathers. Fine PM such as PM2.5 is crucial in affecting the health and well-being of birds and caretakers as that can enter animals’ respiratory system easier. According to the WHO, the occupational exposure limits of PM2.5 annual mean and 24-h mean should not exceed 5 µg/m3 and 15 µg/m3, respectively. The levels of PM in poultry houses could be 100 times of WHO limit or higher (e.g., PM2.5 levels in cage-free henhouse are higher than 1500 µg/m3 in most time of the year), and thus affect animals’ health and welfare, including eye irritation, throat irritation, cough, phlegm, chest tightness, sneezing, headache, fever, nasal congestion, and wheezing, especially in cold periods when the house will have limited ventilation. Furthermore, long-term exposure to PM increases obstructive pulmonary disorder, chronic bronchitis, chronic obstructive pulmonary disease, pneumonia lesions, cardiovascular disease, asthma-like symptoms, lung cancer, or even mortality in humans. Similarly, a higher level of PM with endotoxin in birds causes impaired lung function, chronic bronchitis, pneumonia lesions, cardiovascular illness, and cardiotoxicity in chicken embryos and hatchling chickens and might increase the risk of mortality rates. That is why it is very important to identify primary emissions factors and investigate PM mitigating strategies.

PM emissions depend on various factors and changes according to climatic conditions, housing type, applied manure management strategies, ventilation system, temperature and relative humidity, bird numbers, and bedding materials used. The factors that release significantly high PM levels must be managed and decreased to preserve and improve the environment, and human and animal health and welfare. Several studies have shown significant PM reduction by applying biochemical, chemical, managerial, physical, and physiological practices, which can be managing housing system and cleaning, light intensity, oil and water spraying, filtration and biofiltration, acid scrubber, bedding materials, and electrostatic ionization. Single or integrated mitigation has shown significant PM reduction in the past. Future research must be implemented by including integrated mitigating strategies to obtain much better results to improve air quality in poultry houses and enhance the health of both caretakers and birds. In addition, mitigation strategies could be cost prohibitive and have side effects. For instance, an acid scrubber has up to 95% efficiency in mitigating both dust and NH3, but the cost for installing the system is a primary barrier; the water spray has a lower cost in controlling PM generations in poultry houses, but the increased NH3 should be considered in quantifying the mitigation efficiency and costs. Additional strategies such as litter additives and new bedding will be needed for NH3 control if water spray results in higher NH3 generations. Therefore, poultry farms should select mitigation strategies based on a number of considerations, such as farm location, climate conditions, environmental policies, and available resources (assistance programs).