| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Josu López-Fernández | + 11028 word(s) | 11028 | 2020-11-18 05:04:55 |

Video Upload Options

Lipases are biocatalysts with a significant potential to enable a shift from current pollutant manufacturing processes to environmentally sustainable approaches. The main reason of this prospect is their catalytic versatility as they carry out several industrially relevant reactions as hydrolysis of fats in water/lipid interface and synthesis reactions in solvent-free or non-aqueous media such as transesterification, interesterification and esterification. Because of the outstanding traits of Rhizopus oryzae lipase (ROL), 1,3-specificity, high enantioselectivity and stability in organic media, its application in energy, food and pharmaceutical industrial sector has been widely studied. Significant advances have been made in the biochemical characterisation of ROL particularly in how its activity and stability are affected by the presence of its prosequence. In addition, native and heterologous production of ROL, the latter in cell factories like Escherichia coli, Saccharomyces cerevisiae and Komagataella phaffii (Pichia pastoris), have been thoroughly described. Therefore, in this review, we summarise the current knowledge about R. oryzae lipase (i) biochemical characteristics, (ii) production strategies and (iii) potential industrial applications.

1. Introduction

Rhizopus oryzae is broadly employed in industry because it can carry out the synthesis of a great variety of products like organic acids (lactic and fumaric acids), volatile compounds and enzymes (cellulases, proteases, tannases, xylanasas, pyruvate decarboxylases, lipases etc.,) [1][2][3][4]. Concretely, according to Web of Knowledge data, R. oryzae lipase (ROL) is one of the most studied enzymes of this fungi. There are three major commercial formulations of this lipase (Table 1) and more than 200 scientific works have been published in the last 5 years highlighting the relevance of this enzyme. Therefore, the aim of this entry is to provide a complete overview of ROL in terms of biochemical properties, enzyme native and heterologous production and its industrial applications.

Table 1. Major commercial suppliers of Rhizopus oryzae lipase and some lipase properties [5].

|

Supplier |

Name |

Application |

Lipase Properties |

|

Amano |

Lipase DF “Amano” 15 |

Oil and fats |

Optimum pH range 6–7; stable pH range 4–7, optimum temperature range 35–40 °C, relatively specific to fatty acids |

|

Sigma |

Lipase from R. oryzae (no. 62305) |

Oil and fats |

Optimum pH 8, optimum temperature 40 °C |

|

Sigma |

Lipase, immobilised on Immobead 150 from R. oryzae (no. 89445) |

Pharmaceutical and bioenergy |

Optimum pH 7.5, optimum temperature 40 °C |

2. Biochemical Properties

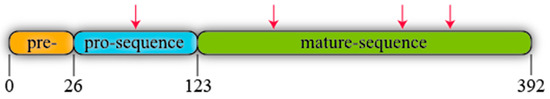

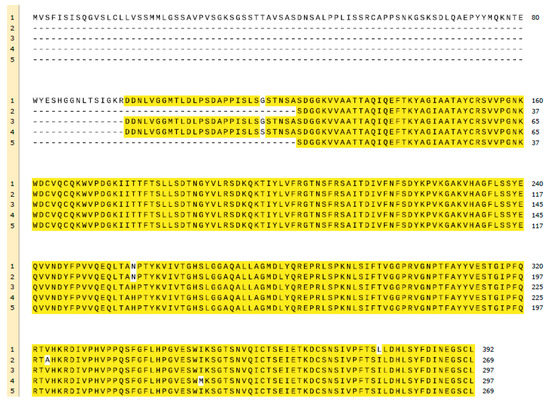

R. oryzae lipase (ROL) is a protein synthesised as a precursor form containing a presequence of 26 amino acids, followed by a prosequence of 97 attached to the N-terminal of a 269 amino acids mature sequence (Figure 1) [6]. All known lipases from Rhizopus genus follow the same identical structure even though some amino acidic substitutions can be detected when their primary sequences are compared, not only between different species but also between different isolated strains of the same species (Figure 2). For instance, Ben Salah et al. [7] addressed the presence of several substitutions in the sequences of Rhizopus lipases published by his group and Sayari et al. [8], Beer et al. [6], Derewenda et al. [9] and Khono et al. [10].

Figure 1. Schematic representation of R. oryzae lipase (ROL). Arrows stand for potential N-glycosylation points.

ROL contains four potential N-glycosylations sites (Figure 1) that follow the consensus sequence Asn-X-Ser/Thr, where X is any amino acid instead of proline. One of these putative sites is found in the prosequence where modifications in glycosylation patterns have been described to have an effect on protein secretion [11]. For instance, Yu et al. [12] added two extra N-glycosylation sites to ROL prosequence and expressed this mutant in Komagataella phaffii (Pichia pastoris). The extracellular activity and total protein were 218- and 6.25-fold higher respectively in the strain harbouring the two extra N-glycosylation sites than in the non-modified one highlighting the relevance of glycosylation.

Figure 2. Multiple alignment of the sequences published by (1) Beer et al. (ROL) [6], (2) Ben Salah et al. (ROL) [7], (3) Sayari et al. (ROL) [8], (4) Khono et al. (Rhizopus niveus lipase) [10] and (5) Derewenda et al. (Rhizopus delemar lipase) [9]. Matching amino acids are highlighted in yellow, mismatching in white. BLAST from U.S. National Library of Medicine and Snapgene have been used for the creation of this figure.

The presequence of ROL has been described to act as signal peptide promoting enzyme secretion, while the prosequence has been reported to exhibit diverse functions that are still under research. Beer et al. [13] depicted the significance of the latter in lowering lipase toxicity during its synthesis and in acting as intramolecular chaperone enabling the proper folding of the enzyme. In fact, genetically modified E. coli strains producing heterologous ROL without the prosequence resulted in cell lysis. To date, a large number of prosequences of different enzymes have also been identified to function as intramolecular chaperone and to assist the folding of their respective proteins [14]. In addition, several scientific works have related ROL prosequence with the translocation of the protein across the endoplasmic reticulum membrane, enhancement of free lipase stability and changes in enzyme substrate specificity. Nevertheless, the mechanisms that allow these traits are yet unknown despite the broad research carried out [15][16][17][18][19][20]. In any case, both the presequence and the prosequence are expected to be proteolytically removed to form the mature lipase. In spite of this, the native microorganism secretes a lipase that is attached to the N-terminal of mature sequence the 28 C-terminal amino acids of the prosequence (proROL), which then are cleaved via limited proteolysis catalysed by extracellular proteases [6][10][21]. However, some studies have indicated that the presence of these 28 amino acids of the prosequence alongside the mature sequence is enough for some of the presumed features of the prosequence to occur. For instance, higher free lipase stability and changes in enzyme specificity have been described when the 28 amino acids of the prosequence were expressed together with the mature sequence in K. phaffii [22]. In addition, these amino acids have also enabled lowering the toxicity of ROL production in E.coli [13] and they have been related to direct proteins to secretory pathway in Aspergillus oryzae [23].

The mature sequence of R. oryzae lipase (rROL) is constituted by 269 amino acids and the protein formed by them has a molecular weight (MW) of 29.542 kDa and a isoelectric point (pI) of 8—calculated by Expasy Proteomics Server [7]. These results agree with the published experimental data (Table 2) in which MW and pI values around 29 kDa and 8 have been respectively reported [8][10][24][25]. However, variations in these values can be found because of the presence of the 28 amino acids of the prosequence described above [22][10][20][26][27]. In this case, MW increases to 32 kDa and pI decreases roughly to 7, highlighting the average acid nature of these 28 amino acids. Besides, the production of a lipase including the whole prosequence and close to 40 kDa has also been described (entire-proROL) [6][15].

Table 2. Biochemical properties and substrate specificity of different published works dealing with ROL.

|

Lipase Name 1 |

MW (kDa) |

Isoelectric Point |

pH Optimum |

T Optimum (°C) |

Substrate Specificity |

Ref. |

|

rROL |

29 |

|

8/7.252 |

30/40 2 |

C12>C10>C8>C4 4 |

[22] |

|

proROL |

32 |

|

7.25 |

40 |

C8>C12>C10>C4 4 |

[22] |

|

rROL |

30 |

|

8.5 |

|

|

[6] |

|

entire-proROL |

40 |

|

8 |

|

|

[6] |

|

pre-entire-proROL 3 |

42 |

|

8 |

|

|

[6] |

|

rROL |

29 |

|

8 |

37 |

|

[7] |

|

rROL |

29 |

|

|

|

|

[8] |

|

proROL |

32 |

|

|

|

|

[8] |

|

proROL |

34 |

|

6–6.5 |

35 |

|

[10] |

|

rROL |

30 |

|

6 |

40 |

|

[10] |

|

proROL |

35 |

|

9 |

40 |

C16>C18>C12>C8>C4 5 C16>C12>C8>C18>C4 6 |

[18] |

|

proROL |

32 |

6.9 |

|

|

|

[20] |

|

rROL |

30 |

9.3 |

8.25 |

30 |

C8>C10>C6>C4>C12>C16,C14>C2 6 |

[24] |

|

proROL |

35 |

|

5.2 |

30 |

C12>C10>C8>C6>C16>C5>C4>C3>C2 4 |

[25] |

|

proROL |

32 |

7.6 |

7.5 |

35 |

C8>C6>C4>C2 6 |

[26] |

|

rROL |

29 |

|

|

|

C12>C10>C8>C6>C4>C3>C2 4 C8>C10>C18>C4>C6 6 |

[28] |

|

proROL |

34 |

|

|

|

C2>C3>C8>C6>C12>C10>C4 4 C8>C10>C4>C6>C18 6 |

[28] |

|

proROL |

|

|

8 |

40 |

|

[29] |

|

rROL |

30.3 |

8.6 |

8–8.5 |

30 |

|

[30] |

|

proROL |

|

|

8.5 |

30 |

|

[31] |

|

proROL |

37 |

|

8.5 |

40 |

|

[32] |

|

rROL |

29 |

|

8 |

|

|

[33] |

|

ROL |

17 |

4.2 |

7 |

40 |

|

[34] |

|

ROL |

|

|

7 |

40 |

|

[35] |

|

ROL |

|

|

6 |

45 |

C8>C4>C6>C2 6 C8>C12>C14>C16>C18 5 |

[36] |

|

proROL |

32 |

|

7 |

35 |

|

[37] |

|

ROL |

|

|

6 |

30 |

C7,C8,C12,C16>C2,C3,C4,C18 5 |

[38] |

|

ROL |

|

|

7.5 |

50 |

|

[39] |

|

proROL |

32 |

|

7.5 |

30–40 |

|

[40] |

|

ROL |

14.45 |

6.5 |

9 |

30–40 |

C16>C18>C12>C8>C4>C2 4 |

[41] |

|

|

|

|

8.3 |

35–37 |

|

[42] |

|

proROL |

35 |

|

|

|

C10>C14>C12>C8>C6>C4>C16 6 |

[15] |

|

entire-proROL |

46 |

|

|

|

|

[15] |

1Names are based on the established nomenclature in this review. ROL indicates that the lipase cannot be classified under the determined parameters in this work; 2 different values caused by the employment of 200 or 400 mM tris-HCl buffer; 3 pre-entire-proROL includes the presequence as well as entire-proROL; 4 p-nitrophenol esters were employed for substrate specificity analysis; 5 methyl esters of different carbon chain length were employed for substrate specificity analysis. Saturated methyl esters are just considered; 6 homotriacylglycerols were employed for substrate specificity analysis.

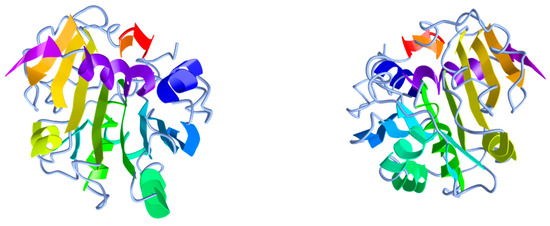

The 3D structure of the lipase from R. oryzae [9][10] (Figure 3) and several microorganisms more, such as Geotrichum candidum [43], Candida rugosa [44], Pseudomonas glumae [45] and Penicillium camemberti [46] have been crystallographically resolved and showed that all lipases have a common α/β hydrolase fold structure that can also be found in other hydrolases. Regarding ROL, it contains nine α-helixes and eight β-strands forming a molecule that it is stabilised by three disulfide bonds between residues 29–269, 40–43 and 235–244 [10]. In addition, this structure contains three key components that can be also found in most lipases besides ROL, the lid, the active site and the oxyanion hole [47]. The lid is an amphiphilic loop—also called flap—that covers the active site preventing the access of the substrate while the enzyme is in aqueous medium [48]. The active site, in turn, is mainly responsible for carrying out enzyme catalysis and consists, in all α/β hydrolases, of a highly conserved catalytic triad formed by a nucleophilic, a catalytic acidic and a histidine residues. In lipases, this triad is composed of nucleophilic serine residue and an aspartic or glutamic acid residue that it is bonded to a histidine; hence, lipases are classified as serine hydrolases. In the specific case of ROL, the lid domain is a short α-helix structure formed by six amino acids (FRSAIT) and the active site is formed by three amino acids Ser145, Asp204 and His257 [9][10][49][50]. The function of these two elements is crucial during catalysis in which the lipase binds to the water/lipid interface and the lid opening occurs by a concomitant structural change in the substrate-binding site that enables the coupling of the substrate to the active site—lid-closed and partially opened 3D structures of Rhizopus delemar (=oryzae) lipase have been described by Derewenda et al. [9]. The structural change undergone is known as ‘interfacial activation’ and it is a unique property of lipases that enables them to hydrolyse insoluble esters and to distinguish them from esterases that can hydrolyse water-soluble esters [47][51][52][53]. It must be highlighted that the 28 amino acids of the prosequence introduced above have been deemed to interfere in this process as they are located next to the lid region and contain 50% hydrophobic residues. Therefore, this sequence extends the hydrophobic patch created in the open lipase by the open lid and the catalytic crevice influencing the interaction with the lipidic substrate [8]. This role might explain some of the assumed properties of these 28 amino acids, however, the mechanism remains unknown. Additionally, together with the catalytic triad and the lid, the oxyanion hole plays an important role and it is also a highly conserved sequence that largely influences the catalytic efficiency of the enzyme. During the hydrolysis reaction, a negatively charged tetrahedral intermediate is generated and it gets stabilised by hydrogen binding with the oxyanion hole [47][54][55]. This function has been described to be presumably performed by the hydroxyl and main-chain amide groups of Thr83 in ROL [9][10][56].

Figure 3. Three-dimensional structure of R. delemar (= oryzae) lipase from two different points of view. PDB ID: 1TIC. Image obtained from iCn3D web-based 3D structure viewer.

Due to the relevance of the lipolytic activity of this enzyme, it has been widely researched in order to know how it is affected by the conditions of reaction medium. Guillen et al. [28] described that ionic strength has a remarkable impact. Actually, the relative activity of ROL in 200 mM Tris-HCl was reported to be twice the activity observed in 400 mM. Moreover, as all enzymes, ROL activity is highly influenced by the pH and temperature. Optimum activity pH values of 8 have been principally reported [6][7][24][26][28][57][29][30][31][32][33]. However, other studies have also stated more acid [25][58][35][36][37][38][39][59] and basic [18][41][42] optimums. Regarding temperature, most of the published optimum values can be found between 30 and 45 °C. In fact, 40 °C has been the most commonly reported optimum [22][10][18][28][29][32][58][35][59][41] although lower [7][10][25][26][28][30][31][37][38] and higher [36][39] values have also been described. Nevertheless, for both pH and temperature, as can be observed in Table 2, some of the differences are based on the presence of the 28 amino acids of the prosequence. In this line, Kohno et al. [10] reported these differences and afterwards, other works [22][60][28] described similar results highlighting the relevance of these amino acids in lipase catalytic performance.

The presence of metal ions in reaction medium has been extensively studied as they play different and important roles influencing the structure and activity of enzymes. These ions may bind to some of the amino acid side chains of the lipase and participate in catalysis, interfere with the bonds between amino acid side chains and cause denaturation of the active site or alter enzyme activity by stabilising or destabilising enzyme conformation [37][61][62][63]. Amongst the different published works some contradictory information can be found. Nevertheless, there are some metal ions that have been clearly described to enhance or worsen ROL and other lipases performance. Wang et al. [18] and other authors [34][37][41] found that Ca2+ increases ROL activity as it might create electrostatic interactions that mask the repulsions either between the enzyme and its emulsified substrate or between the enzyme and product-free fatty acids [30]. On the other hand, Hg2+ has been reported to act like a ROL activity inhibitor suggesting that thiol groups are required for the adequate function of the enzyme [25]. Similar results have been reported with other lipases from Pseudomonas aeruginosa AAU2 [64], Galactomyces geotrichum Y05 [65], Yarrowia lipolytica [66] and Candida rugosa [67]. In addition, no significant effects have been observed with the chelating agent EDTA, indicating that ROL activity is independent of any metal, hence, it is not a metalloprotein [25][41].

ROL activity has also been analysed in presence of amino-acid-modifying agents in order to elucidate the relevance of the different amino acids in protein catalytic performance. N-Bromosuccinimide (NBS), which acts over tryptophan residues, has been reported to strongly inhibit enzyme activity indicating that the protein might have a tryptophan residue involved in its activity [25][34]. In the case of phenylmethylsulfonyl fluoride (PMSF), a serine protease inhibitor whose activity is related to serine residues modification, no clear results have been reported. Kantak et al. [34] indicated that this agent has a relevant effect while Hiol et al. [26] stated exactly the opposite. However, these differences might be caused by the different disposition of the lipase lid during the assay, that is, if it was open or not, it could allow or not the interaction of PMSF with the serine residue of the active site [68].

ROL activity—as most lipases from Rhizopus genus—has a strong 1,3-regiospecificity that makes its activity interesting for several industrial processes such as fat and oil modification for structured lipids production [5][4][26][36]. Nevertheless, Li et al. [69] reported, while studying ROL methanolysis performance, that this lipase was not regiospecific although showed a preference to 1,3-positions. These results were lately confirmed with Rhizopus arrhizus (=oryzae) lipase [70]. However, Okumura et al. and Song et al. [38][71] stated that Rhizopus delemar (=oryzae) and R. oryzae lipases, respectively, do not hydrolyse the ester bond in position 2. Afterwards, Canet et al. and Cao et al. [72][73] proved that mature ROL exhibits a negligible activity on 2-monoolein highlighting that the lipase has a strong 1,3-regioespecificity. The observed dissimilarities amongst different works might be due to the different employed reaction conditions that could enhance spontaneous acyl-migration, or the presence of the 28 amino acids of the prosequence that has already been described to have an effect on lipase specificity [22][13]. Besides 1,3-regiospecificity, substrate specificity of ROL has been also widely studied. Many of the published works are based on the employment of p-nitrophenol esters of different carbon-chain length. For instance, ROL isolated and characterised by Adak et al. [41] was reported to be more specific to long carbon-chain p-nitrophenol esters, concretely to p-nitrophenol palmitate (C16). Guillen et al. [28] reported a similar trend for rROL produced in K. phaffii and, although a higher specificity to short carbon-chain p-nitrophenol esters was detected for proROL, the presence of esterases in the commercial product was concluded to be the reason. In fact, Tako et al. [25] also observed that the longer the carbon-chain, the higher the specificity of ROL. However, in this last case, the maximum was obtained with p-nitrophenol dodecanoate (C12) and not palmitate. ROL substrate specificity has been also analysed with homotriacylglycerols, that is, triacylglycerols in which the three fatty acids are identical. C8 and C10 homotriacylglycerols—triacylglycerols containing three C8 and C10 fatty acids respectively—are preferably hydrolysed by ROL while it barely acts over C2 and C4 homotriacylglycerols. In contrast to some of the published works, some authors have also described that no significant differences were observed with those substrates between rROL and proROL [15][24][26][28].

Lipases are widely known for their capacity to carry out synthesis reactions in non-aqueous mediums. In fact, as previously mentioned, this capacity makes them relevant for many industrial processes in which these reactions are needed, or the solubility of substrates/products requires the use of organic solvents. Therefore, the higher the lipase stability in these solvents, the more suitable the lipase for industrial applications [74]. ROL has been extensively described as a tolerant enzyme to non-aqueous solvents [18][26][31], particularly in alkanes and long-chain alcohols such as hexane and dodecanol respectively. However, polar solvents like acetone or short-chain alcohols have an important negative effect on the enzyme because they strip off the crucial bound water from the enzyme’s surface [75]. In some cases, it is remarkable the different results that can be obtained between the stability of the enzyme in a solvent, such as methanol and ethanol, and the operational stability employing that solvents as substrate. For instance, methanol has proven to be more detrimental than ethanol during biodiesel synthesis while during stability assays exactly the opposite result was obtained [22].

3. Rhizopus oryzae Lipase Production and Bioprocess Engineering

First attempts of ROL production were made with the original fungi isolated from palm fruit [26][31]. R. oryzae secretes, as previously mentioned, one form of lipase with a molecular weight close to 32 kDa—the mature sequence including 28 amino acids of its prosequence. However, a second form of ROL with a molecular weight around 29 kDa was detected after keeping the supernatant at 6 °C for few days; i.e., the lipase form corresponding to the loss of the 28 amino acids [8]. Consequently, the distinct lipases derived from R. oryzae described in the literature are originated because of the different proteolytic processing and not because of the presence of different genes [6].

To increase ROL industrial production, its expression in a cell factory is mandatory. This way, production cost, bioprocess engineering and downstream complexity are minimised [5].

In Escherichia coli, the presence of disulphide bonds in ROL structure and the lack of the necessary enzymes to process fungal maturation signals were the main causes that led to the production of enzymatically inactive protein as insoluble aggregates [6]. Thereafter, active lipase was obtained at lab scale by subjecting these aggregates to a refolding process. However, the large-scale production was not implemented due to the high cost of the procedure [13]. Despite that, Di Lorenzo et al. [76], achieved the production of an active and soluble ROL and proROL using the E. coli Origami (DE3) strain and pET-11d expression system. The final specific activities of both enzymes were quite similar but the yield of proROL production was higher than ROL, likely because of the toxic effect of the latter towards the host cells.

To avoid the inherent problems of prokaryotic cell factories producing eukaryotic proteins, particularly those related to post-translational processing, eukaryotic cell factories were tested for ROL production.

The extracellular production of ROL has been studied in S. cerevisiae and K. phaffii (P. pastoris) by expressing essentially three different genes. A gene encoding the prosequence of 97 amino acids fused to the N-terminal of the mature lipase region of 269 amino acids (proROL-gene), a gene encoding a truncated prosequence of its 28 C-terminal amino acids fused to the N-terminal of the mature lipase region (28proROL-gene) and a gene encoding the mature lipase (rROL-gene). Regardless of proROL-gene or 28proROL-gene expression, a protein with only 28 amino acids of the prosequence plus the mature lipase (proROL) was detected. Exceptionally, the complete prosequence plus the mature lipase region (entire-proROL) was also reported with proROL-gene construction. With respect to the rROL-gene construction, jus the mature lipase (rROL) was obtained.

First attempts of producing ROL in eukaryotic platforms were made with the widely used cell factory S. cerevisiae. Takahasi et al. [15] reported that S. cerevisiae secreted two active lipases when it was transformed with the proROL-gene fused to the pre-α-factor, the entire-proROL and proROL—the lipase formed after Kex2-like protease cleavage of the prosequence. In parallel, when S. cerevisiae strains were transformed with rROL-gene fused to the pre-α or prepro-α factor encoding gene, almost no activity was detected, highlighting the mentioned relevance of ROL prosequence during lipase production [16][19][21].

A summary of the results obtained with these cell factories is shown in Table 3.

Table 3. Summary of E. coli and S. cerevisiae cell factories expressing Rhizopus oryzae lipase.

|

Cell Factory |

Promotor/Vector |

Lipase |

Production |

Lipolytic Activity |

Reference |

|

E. coli Origami DE3 |

pET11 |

proROL |

Intracellular |

166 U mL−1 |

[76] |

|

pET22 |

proROL |

Intracellular |

82 U mL−1 |

||

|

S. cerevisiae |

UPR-ICL |

rROL |

Extracellular |

0.29 U flask−1 |

[15] |

|

UPR-ICL |

proROL |

Extracellular |

191 U flask−1 |

3.1. Komogataella phaffii Cell Factory

Unlike the reported results with S. cerevisiae, when proROL-gene was expressed in K. phaffii cell factory, only proROL was detected in the medium, which might indicate that the activity of the Kex2-like protease is higher in this cell factory than in S. cerevisiae [17]. Moreover, rROL-gene was satisfactorily expressed and the corresponding lipase was detected in the supernatant [24].

This appropriate performance on ROL secretion, jointly with the well-known excellent characteristics of K. phaffii, make this yeast the most suitable cell factory for heterologous ROL production [77][78][79][80]. In addition, K. phaffi does not produce endogenous extracellular lipases or esterases [81]. Thus, downstream processes might be easier and cheaper. However, two of the bottlenecks of K. phaffii cell factory are transformed clones screening and selecting the best operational strategy to maximise production. To minimise this problem, the use of microbioreactor devices has been successfully implemented [82]. Further information about K. phaffii as cell factory for ROL production was summarised by López-Fernández et al. [83]

3.2. Whole cells

Hama et al. reported that rROL and proROL are located in different regions in R. oryzae cells, proROL in the cell wall and rROL bound to the cell membrane. Besides, these cells have been successfully employed as whole cells biocatalysts (WCB) in many relevant biotransformations, for instance, for enzymatic biodiesel production [84][85]. It must be highlighted that the fatty acid composition of the membrane has been reported to influence lipase activity and stability during biodiesel reactions [86].

Modified S. cerevisiae strains producing ROL have also been used as WCB [87][88]. Matsumoto et al. [87] reported the intracellular production of proROL in S. cerevisiae under the 5′ upstream region of the isocitrate lyase gene of Candida tropicalis (UPR-ICL). Additionally, the expression of the lipase under the constitutive promoter glyceraldehyde-3-phosphate dehydrogenase was also studied. However, this system did not improve the results obtained with UPR-ICL.

proROL was successfully expressed under PAOX control and displayed on Mut+ phenotype K. phaffii cell surface using the Flo1P anchor system previously developed in S. cerevisiae. The obtained WCB showed higher thermal stability than free enzyme [89]. Additionally, a similar approach using Sed1p anchor protein was studied in a MutS phenotype. In the same sense, the obtained biocatalysts was stable in a wide range of temperatures and pH [90].

4. Industrial Applications of Rhizopus oryzae Lipase

Its 1,3-regiospecificity and catalytic versatility make ROL appropriate for improving the sustainability of food, pharmaceutical and energy industry [5][91][92].

4.1. Biodiesel Production

Because of petroleum depletion and environmental concerns, in the past decade, biodiesel (mono-alkyl esters of long chain fatty acids) is gathering significant interest as a renewable, biodegradable and more environmentally friendly alternative to fossil fuels. Biodiesel can be classified into three different generations based on the source from which it is derived. First-generation biodiesel is synthesised with edible-oils such as soybean or sunflower oils. Therefore, it might cause the so-called “food vs. fuel” ethical issue because of the use of food and agricultural lands for biofuel production [93]. In order to prevent this problem, alternative substrates have emerged for biodiesel synthesis, leading to second- and third-generation biodiesel production. The former uses non-edible oils that are not considered for human consumption and are produced from crops that, even if they require lands, are generally poor lands not useful for agriculture. Meanwhile, third-generation biodiesel completely avoids ethical issues by using microbial lipids and oleaginous wastes such as oils from microalgae or oleaginous yeasts and waste cooking oils (WCO) respectively [94][95][96][97]. Additionally, there is a fourth-generation biodiesel that is at its preliminary research stages and is based on man-made biological tools, that is, biodiesel producing genetically modified microorganisms [98][99].

Typically, these alternative substrates, those yielding second- and third-generation biodiesel, have a higher free fatty acid (FFA) content, which can make biodiesel production through chemical synthesis—the most common process for current industrial biodiesel production—more complex because a previous operation of FFA neutralisation is required to avoid soap formation, an usual side reaction when substrates with high FFA content and basic catalysts are employed [95][100][101]. In this context, enzymatic biodiesel synthesis with lipases arouses as an alternative owing to its several advantages such as the milder reaction conditions, less water consumption, easier downstream and particularly, the absence of side reactions and consequently the capacity of employing substrates with high FFA content [102][103]. In fact, substrates with initial high amounts of FFA have been reported to enhance enzymatic biodiesel synthesis reaction rate and biocatalysts operational stability [102][104][105]. Given all the advantages, numerous lipases have been studied in this biotransformation with significant results, such as the lipases of Candida rugosa [106][107], Candida antartica [108][109] and Burkholderia cepacia [110][111].

In the seeking for the best lipase to make enzymatic biodiesel feasible at industrial scale, lipases’ regiospecificity has become a crucial trait. Non-specific enzymes produce mono-alkyl esters and glycerol, which is an undesired by-product of the transesterification reaction that has been described to hinder reaction progress or even affect negatively on enzymes stability and biodiesel downstream [112]. Conversely, 1,3-regioespecific lipases, avoid glycerol formation by producing 2-monoacylglycerol which acts as lubricant and in certain amount, upgrades biodiesel characteristics [113][114][115]. Furthermore, monoacylglycerols can improve the cost-effectiveness of a biodiesel biorefinery as they are more valuable products than glycerol because of their utility in pharmaceutical and food industry as emulsifiers [116][117][118]. Consequently, ROL has been widely studied in biodiesel production because of its regiospecificity.

Considering biodiesel ethical issues, even if several studies have employed ROL with edible oils such as olive [119], rapeseed [120][121], soybean [122][123][124][125] and sunflower [126][127] oils—commonly as model substrates for research—most of the published works have focused on the use of alternative substrates (Table 4). Jatropha curcas oil is one of the non-edible oils with higher potential for second-generation biodiesel production, probably because of the easy cultivation process and worldwide spread of the plant [128]. Rodrigues et al. [129] reported yields close to the theoretical 100%—real 66% considering ROL 1,3-regioespecificity—and high operational stability of the biocatalysts. In Table 4 are detailed other studies with promising results using this substrate as well as other non-edible oils like Pistacia chinensis bge oil [130], Tung oil [32], Calophyllum inophyllum oil [131] and alperujo oil (olive pomace) [115].

Table 4. Summary of biodiesel production with Rhizopus oryzae lipase as main biocatalyst.

|

Substrates |

Lipase |

Immobilisation Technique |

Reactor Type |

Stepwise Addition |

Biodiesel Generation |

Yield-Conversion/Op. Stability |

Ref. |

|

|

OO + MeOH |

rROL |

IA onto ReliZymeTM OD 403M |

PBR |

Yes |

1st |

Y: PBR 49.1% OS: second batch 44.8% |

[119] |

|

|

OO + MeOH |

rROL |

IA onto ReliZymeTM OD 403M |

STR |

Yes |

1st |

Y: STR 33.56% OS: second batch 7.7% |

[119] |

|

|

RO + MeOH |

proROL |

WCB over agar plate |

SLLB |

No |

1st |

No biodiesel production |

[120] |

|

|

RO + EtOH |

proROL |

WCB over agar plate |

SLLB |

No |

1st |

No biodiesel production |

[120] |

|

|

RO + MeOH |

proROL |

WCB over agar plate |

SGLB |

No |

1st |

Y: 58% |

[120] |

|

|

RO + EtOH |

proROL |

WCB over agar plate |

SGLB |

No |

1st |

Y: 72% |

[120] |

|

|

Crude CO + MeOH |

proROL |

Free enzymes |

BR |

Yes |

1st |

Y: 68.56% |

[121] |

|

|

Crude CO + MeOH |

proROL-CRL |

Free enzymes |

BR |

Yes |

1st |

Y: 84.25% |

[121] |

|

|

Crude CO + MeOH |

proROL-CRL |

CI onto functionalised silica gel |

BR |

Yes |

1st |

Y: 88.9% |

[121] |

|

|

SYO + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 82.2% OS: after 6 cycles almost all activity loss |

[122] |

|

|

SYO + MeOH |

proROL |

CI WCB immobilised onto BSPs |

BR |

Yes |

1st |

Y: 92.2% OS: after 6 cycles no loss of activity |

[122] |

|

|

SYO + EtOH |

proROL |

IA onto microporous resin NKA (polystyrene) |

BR |

Yes |

1st |

Y: 58.5% |

[123] |

|

|

SYO + EtOH |

proROL-CRL |

IA onto microporous resin NKA (polystyrene) |

BR |

Yes |

1st |

Y: 80.8% |

[123] |

|

|

SYO + EtOH |

proROL-Novozyme 435 |

proROL: IA onto microporous resin NKA (polystyrene). Novozyme 435: IA onto Lewatit VP OC 1600 |

BR |

Yes |

1st |

Y: 98.5% OS: after 20 cycles Y decreased to 78.3% |

[123] |

|

|

SYO + EtOH |

proROL-PFL |

IA onto microporous resin NKA (polystyrene) |

BR |

Yes |

1st |

Y: 55.8% |

[123] |

|

|

SYO + MeOH |

proROL |

CI onto magnetic chitosan microspheres |

MSFBR |

Yes |

1st |

Y: 91.3% OS: after 6 reaction cycles Y decreased to around 80% |

[124] |

|

|

SYO + MeoH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: over 90% OS: after 10 reaction cycles Y decreased to 10% |

[125] |

|

|

SYO + MeoH |

proROL |

WCB immobilised into BSPs |

PBR |

Yes |

1st |

Y: over 90% OS: after 10 reaction cycles Y decreased to 80% |

[125] |

|

|

SO + EtOH |

proROL |

CI onto modified sepiolite with p-hydroxybenzaldehyde linker |

BR |

No |

1st |

C: 84.3% OS: after 9 cycles C decreased to 21.4% |

[126]] |

|

|

SO + EtOH |

proROL |

CI onto modified sepiolite with benzylamine-terephthalic aldehyde linker |

BR |

No |

1st |

|

[126] |

|

|

SO + EtOH |

proROL |

IE onto demineralised sepiolite |

BR |

No |

1st |

Y: 90.2% OS: proROL IE after 9 cycles C decreased to 18.1% |

[126] |

|

|

Pistacia chinensis bge seed oil + MeOH |

rROL |

CI onto Amberlite IRA-93 |

BR |

Yes |

2nd |

Y: 92% OS: after 8 cycles Y decreased to 60% |

[130] |

|

|

Pistacia chinensis bge seed oil + MeOH |

rROL |

IA microporous resin HPD-400 |

BR |

Yes |

2nd |

Y: 94% OS: after 8 cycles Y decreased to 50% |

[130] |

|

|

Calophyllum inophyllum linn oil + MeOH |

proROL |

WCB immobilised into BSPs |

PBR |

Yes |

2nd |

Y: 92% OS: after 6 cycles Y decreased a 4.9% |

[131] |

|

|

Oil extracted from Nannochloropsis gaditana + MeOH |

proROL |

WCB |

BR |

Yes |

3rd |

Y: 83% OS: after 3 cycles Y decreased to 71% |

[132] |

|

|

Oil extracted from Nannochloropsis gaditana + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

3rd |

Y: 70% OS: second cycle Y decreased to 43% |

[132] |

|

|

Oil extracted from Nannochloropsis gaditana + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

3rd |

Y: 83% OS: after 3 cycles Y decreased to 71% |

[133] |

|

|

Oil extracted from Nannochloropsis gaditana + MeOH |

proROL |

WCB |

TPB |

No |

3rd |

Y: 58% |

[134] |

|

|

Oil extracted from Nannochloropsis gaditana + EtOH |

proROL |

WCB |

TPB |

No |

3rd |

Y: 92% |

[134] |

|

|

Oil extracted from Botryococcus braunii + MeOH |

proROL |

WCB |

TPB |

No |

3rd |

Y: 58% |

[134] |

|

|

Oil extracted from Botryococcus braunii + EtOH |

proROL |

WCB |

TPB |

No |

3rd |

Y: 68% |

[134] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

Free enzyme |

BR |

Yes |

3rd |

C: 75% |

[135] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

IA onto MNP |

BR |

Yes |

3rd |

C: 46% OS: after 5 cycles decreased to 10% |

[135] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

CI onto AP modified MNP |

BR |

Yes |

3rd |

C: 53% OS: after 5 cycles C decreased to 25% |

[135] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

CI onto AP-GA modified MNP |

BR |

Yes |

3rd |

C: 69.8% OS: after 5 cycles C decreased to 45% |

[135] |

|

|

Sludge palm oil + MeOH |

proROL |

IE into alginate-polyvinyl alcohol beads |

BR |

No |

3rd |

Y: 91.30% OS: no activity loss after 15 cycles |

[136] |

|

|

Oil extracted from SCG + MeOH |

R. delemar (= oryzae) lipase |

Free enzyme |

BR |

No |

3rd |

Y: 18% |

[137] |

|

|

WCO + MeOH |

proROL |

Free enzyme |

BR |

|

3rd |

Y: 93% |

[138] |

|

|

WCO + iso-propanol |

proROL |

Free enzyme |

BR |

|

3rd |

Y: 86.8% |

[138] |

|

|

WCO + iso-butanol |

proROL |

Free enzyme |

BR |

|

3rd |

Y: 80.2% |

[138] |

|

|

WCO + iso-amyl alcohol |

proROL |

Free enzyme |

BR |

|

3rd |

Y: 64% |

[138] |

|

|

WCO + MeOH |

proROL |

WCB IE into calcium alginate beads |

BR |

|

3rd |

Y: 84% |

[138] |

|

|

WCO + iso-propanol |

proROL |

WCB IE into calcium alginate beads |

BR |

|

3rd |

Y: 71% |

[138] |

|

|

WCO + iso-butanol |

proROL |

WCB IE into calcium alginate beads |

BR |

|

3rd |

Y: 62% |

[138] |

|

|

WCO+ iso-amyl alcohol |

proROL |

WCB IE into calcium alginate beads |

BR |

|

3rd |

Y: 43% |

[138] |

|

|

JO + MeOH |

proROL |

WCB IE into sodium alginate beads |

BR |

No |

2nd |

Y: 80.5% OS: after 6 cycles Y decreased to 61.5% |

[139] |

|

|

KO + MeOH |

proROL |

WCB IE into sodium alginate beads |

BR |

No |

2nd |

Y: 78.3% OS: after 6 cycles Y decreased to 63.4% |

[139] |

|

|

SYO + MeOH |

proROL |

WCB |

BR |

Yes |

1st |

Y: 80% OS: after 3 cycles Y decreased to 18% |

[140] |

|

|

SYO + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 82% OS: after 10 cycles Y decreased to 10% |

[140] |

|

|

SYO + MeOH |

proROL |

CI WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 74% OS: after 35 cycles Y decreased to 65% |

[140] |

|

|

SYO + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 82% OS: after 6 cycles Y decreased to 48% |

[141] |

|

|

SYO + MeOH |

proROL |

CI WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 80% OS: after 6 cycles Y decreased to 70% |

[141] |

|

|

ALO + MeOH |

rROL |

IA onto rice husk |

BR |

Yes |

2nd |

|

[142] |

|

|

ALO + MeOH |

rROL |

IA onto ReliZymeTM OD403 |

BR |

Yes |

2nd |

Y: 64.5% OS: after 7 cycles Y decreased to 41.3% |

[142] |

|

|

Crude microbial oil from Candida sp. LEB-M3 + MeOH |

rROL |

IA onto ReliZymeTM OD403 |

BR |

Yes |

3rd |

Y: 38% OS: after 7 cycles Y decreased to 26.6% |

[143] |

|

|

Neutralised microbial oil from Candida sp. LEB-M3 + MeOH |

rROL |

IA onto ReliZymeTM OD403 |

BR |

Yes |

3rd |

Y: 38% |

[143] |

|

|

OO + MeOH |

rROL |

IA onto ReliZymeTM OD403 |

BR |

Yes |

1st |

Y: 54.3% OS: after 7 cycles Y decreased to 40% |

[143] |

|

|

OA + MeOH |

rROL |

IA onto ReliZymeTM OD403 |

BR |

Yes |

1st |

Y: 68% |

[143] |

|

|

RO + EtOH |

proROL |

IA onto microporous resin NKA |

BR |

No |

1st |

Y: above 98% OS: After 10 cycles Y decreased to 60% |

[144] |

|

|

JO + MeOH |

proROL-CRL |

WCB (proROL) and free enzyme (CRL) IE into sodium alginate beads |

PBR |

No |

2nd |

Y: 84.2% |

[145] |

|

|

KO + MeOH |

proROL-CRL |

WCB (proROL) and free enzyme (CRL) IE into sodium alginate beads |

PBR |

No |

2nd |

Y: 81% |

[145] |

|

|

WCO + MeOH |

proROL |

WCB IE into sodium alginate beads |

BR |

No |

3rd |

Y: 94.01% |

[146] |

|

|

WCO + Methyl acetate |

proROL |

WCB IE into sodium alginate beads |

BR |

No |

3rd |

Y: 91.11% |

[146] |

|

|

WCO + Ethyl acetate |

proROL |

WCB IE into sodium alginate beads |

BR |

No |

3rd |

Y: 90.06 |

[146] |

|

|

WCO + MeOH |

proROL |

IE into sodium alginate beads |

BR |

No |

3rd |

Y: 83% |

[146] |

|

|

WCO + Methyl acetate |

proROL |

IE into sodium alginate beads |

BR |

No |

3rd |

Y: 80% |

[146] |

|

|

WCO + Ethyl acetate |

proROL |

IE into sodium alginate beads |

BR |

No |

3rd |

Y: 78% |

[146] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

IA into MNP |

BR |

Yes |

3rd |

Y: 45% OS: after 5 cycles Y decreased to 10% |

[147] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

IA into MGO |

BR |

Yes |

3rd |

Y: 51% OS: after 5 cycles Y decreased to 16% |

[147] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

IA into MGO-AP |

BR |

Yes |

3rd |

Y: 54% OS: after 5 cycles Y decreased to 25% |

[147] |

|

|

Oil extracted from Chlorella vulgaris + MeOH |

proROL |

CI into MGO-AP-GA |

BR |

Yes |

3rd |

Y: 68% OS: after 5 cycles Y decreased to 58.77% |

[147] |

|

|

Cottonseed oil + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

1st |

Y: 27.9% |

[148] |

|

|

Rubber seed oil + MeOHe |

proROL |

Free enzyme |

BR |

Yes |

2nd |

Y: 31% |

[149] |

|

|

Rubber seed oil + Ethyl acetate |

proROL |

Free enzyme |

BR |

No |

2nd |

Y: 33.3% |

[149] |

|

|

SYO + MeOH |

proROL-CRL |

CI onto silica gel pretreated with AP and GA |

BR |

Yes |

1st |

Y: 99.99% OS: after 20 cycles Y decreased to 85% |

[150] |

|

|

RO deodoriser distillate + MeOH |

proROL |

Free enzyme |

BR |

Yes |

1st |

Y: 93.07% |

[151] |

|

|

RO deodoriser distillate + MeOH |

proROL-CRL |

Free enzyme |

BR |

Yes |

1st |

Y: 98.16% |

[151] |

|

|

ALO + MeOH |

rROL |

CI onto ET, AP and GA pretreated ReliZymeTM HFA403 |

BR |

Yes |

2nd |

Y: 57.16% OS: after 5 cycles Y decreased a 12.31% |

[115] |

|

|

ALO + EtOH |

rROL |

CI onto ET, AP and GA pretreated ReliZymeTM HFA403 |

BR |

Yes |

2nd |

Y: 60.25% OS: after 7 cycles Y decreased a 11.89% |

[115] |

|

|

Triolein + MeOH |

rROL |

Free enzyme |

BR |

No |

1st |

Y: 71.2% |

[72] |

|

|

Triolein + EtOH |

rROL |

Free enzyme |

BR |

No |

1st |

Y: 64.2% |

[72] |

|

|

Triolein + MeOH |

rROL |

IA onto RelyZymeTM OD403S |

BR |

No |

1st |

Y: 82.6% |

[72] |

|

|

Triolein + EtOH |

rROL |

IA onto RelyZymeTM OD403S |

BR |

No |

1st |

Y:100.7% |

[72] |

|

|

JO + MeOH |

rROL |

IA onto Lewatit VP OC 1600 |

BR |

Yes |

2nd |

Y: 61% OS: after 10 cycles Y decreased a 40% |

[152] |

|

|

JO + MeOH |

rROL |

IA onto LifetechTM ECR1030M |

BR |

Yes |

2nd |

Y: 63% OS: after 10 cycles Y decreased a 40% |

[152] |

|

|

JO + MeOH |

rROL |

IA onto LifetechTM AP1090M |

BR |

Yes |

2nd |

Y: 55% OS: after 10 cycles Y decreased a 25% |

[152] |

|

|

JO + MeOH |

rROL |

CI onto LifetechTM ECR8285M |

BR |

Yes |

2nd |

Y: 63% OS: after 10 cycles Y decreased a 60% |

[152] |

|

|

JO + MeOH |

rROL |

CI onto Amberlita IRA 96 |

BR |

Yes |

2nd |

Y: 68% OS: after 10 cycles Y decreased a 20% |

[152] |

|

|

OO + MeOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 77% |

[153] |

|

|

OO + EtOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 62% |

[153] |

|

|

OO + Propanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 46% |

[153] |

|

|

OO + Butanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 18% |

[153] |

|

|

SYO + MeOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 50% |

[153] |

|

|

SYO + EtOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 46% |

[153] |

|

|

SYO + Propanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 35% |

[153] |

|

|

SYO + Butanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 10% |

[153] |

|

|

CO + MeOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 70% |

[153] |

|

|

CO + EtOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 56% |

[153] |

|

|

CO + Propanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 43% |

[153] |

|

|

CO + Butanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 16% |

[153] |

|

|

SO + MeOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 32% |

[153] |

|

|

SO + EtOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 28% |

[153] |

|

|

SO + Propanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 17% |

[153] |

|

|

SO + Butanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

1st |

Y: 7% |

[153] |

|

|

Algal oil + MeOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

3rd |

Y: 63% |

[153] |

|

|

Algal oil + EtOH |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

3rd |

Y: 55% |

[153] |

|

|

Algal oil + Propanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

3rd |

Y: 40% |

[153] |

|

|

Algal oil + Butanol |

prorROL |

IA onto Amberlite XAD 761 |

BR |

No |

3rd |

Y: 13% |

[153] |

|

|

ALO + MeOH |

rROL |

CI onto AP and GA treated ReliZymeTM HFA403 |

BR |

Yes |

2nd |

Y: 28.62% OS: after 9 cycles, Y decreased a 43% |

[104] |

|

|

JO + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

Yes |

2nd |

Y: 88.6% OS: after 6 cycles Y decreased a 21% |

[154] |

|

|

OA + MeOH |

proROL |

WCB immobilised into BSPs |

BR |

No |

1st |

Y: 80% OS: after 8 cycles, almost no activity loss. |

[155] |

|

|

Rice bran oil + MeOH |

proROL |

IA onto rod-like mesoporous silica |

BR |

No |

1st |

Y: 81.7% OS: after 3 cycles Y decreased to 67.7% |

[156] |

|

|

JO + MeOH |

proROL |

IE into polyvinyl alcohol—alginate matrix |

BR |

No |

2nd |

Yield: 87.1% |

[157] |

|

|

ALO + MeOH |

rROL |

IA Octadecyl-Sepabeads |

BR |

Yes |

2nd |

Y: 58.31% OS: after 2 cycles Y decreased to 54.67% |

[158] |

|

|

Tung oil + MeOH |

proROL |

CI onto Amberlite IRA 93 |

BR |

Yes |

2nd |

Y: 91.9% OS: after 6 cycles Y decreased to 85.1% |

[32] |

|

|

Babassu oil + EtOH |

proROL |

WCB immobilised into BSPs |

BR |

No |

1st |

Y: 74.15% |

[159] |

|

Regarding third-generation biodiesel, microalgae and waste oils have been the most studied substrates. The former has several advantages that make the overall process of biodiesel production more environmentally friendly as microalgae oil production involves atmospheric CO2 fixation and can use domestic wastewater like growth substrate facilitating its posterior treatment. However, the main drawbacks for microalgae oil employment are the scale-up of photobioreactors and lipids extraction [160][161]. Nevertheless, ROL has been satisfactorily employed with this substrate, for instance, with oils extracted from Nannochloropsis gaditana [132][133][134], Botryococcus braunii [134] and Chlorella vulgaris [135]. Actually, with the last one, fatty acid methyl esters (FAME) conversions over 70% were obtained indicating ROL suitability for biodiesel production with microalgae oil. Additionally, oils extracted from oleaginous yeasts, such as Candida sp. LEB-M3, have been also employed. The use of yeasts becomes important in biodiesel refineries as they might grow in the glycerol coming from this biofuel production [143]. Regarding waste oils, they have a significant potential in biodiesel industry because of their relevance in circular economy strategies, which aim to avoid residue generation by seeking new applications to waste [162][163]. Moreover, considering the tight economic competition between biodiesel and fossil fuels, cheap raw materials are required. In fact, the cost of the feedstocks is more than the 70% of the total cost of biodiesel. Thus, oleaginous wastes might help lowering these percentage and making enzymatic biodiesel production feasible [164]. Sludge from palm oil [136] and spent coffee grounds [137]can be found amongst some of the oleaginous residues studied in biodiesel production with ROL. However, waste cooking oil is the foremost substrate of this category because it is inexpensive and, through its employment in biodiesel synthesis, public institutions avoid the great cost of its management [165][166]. Relevant results have been published with WCO, for instance, Bharathiraja et al. [138] reported maximum triglyceride conversion of 94%. Nevertheless, not many studies dealing with ROL and WCO have been published and, considering the great relevance of this substrate for biodiesel industry, it could be a possible research target for future projects.

Biocatalysts operational stability, reusability and price are related and essential traits that must be considered in enzymatic biodiesel production because of the high cost of enzymes and the tight economic competition with conventional diesel. Some approaches have focused on cutting prices of the enzymes through heterologous production, as it has been explained in the previous section. Besides, other strategies have centred on lipase immobilisation. This technique allows enzyme reutilisation and generally enhances enzyme stability [167][168][169]. In the following paragraphs, the different immobilisation strategies assessed with ROL in biodiesel production will be introduced.

Earlier attempts of employing this enzyme in biodiesel synthesis were principally based on whole-cell biocatalysts (WCBs). Thus, the enzyme acts confined in its natural cellular environment, which protects the lipase from inactivation and degradation. Moreover, as no downstream processes of the biocatalyst are needed, its final cost is considerably lowered [170]. Syed et al. [139] immobilised lipase-producing R. oryzae cells into alginate beads and employed them in biodiesel production with jatropha and karanja oil. A response surface optimisation was applied and under the best conditions, biodiesel yields of 73.5% and 72.5% with each respective oil were obtained. In addition, operational stability of the biocatalyst was evaluated and after six cycles, just an activity loss of 20% was reported. Even if free cells, without immobilisation into alginate beads, could have been used in biodiesel production, Sun et al. [140] stated the suitability of cell immobilisation to avoid enzyme leakage and denaturation. This author immobilised R. oryzae fungus cells onto biomass support particles (BSPs) and obtained higher operational stability than using free cells. Moreover, to further minimise the enzyme leakage and deactivation, the crosslinking agent glutaraldehyde was used for immobilised cells treatment. The crosslinked biocatalyst obtained better FAMEs yields and operational stability. In the same sense, glutaraldehyde treatment of WCBs—also called WCBs stabilisation—was reported by Ban et al. [141] as well. Lately, He et al. [122] employed this strategy too and obtained a ROL biocatalyst with increased operational stability. After six reactions cycles, more than 90% of initial activity was maintained. However, WCBs show higher complexity in being reused and worse conversion rates than free lipases immobilised onto acrylic resins [170]. For instance, Bharathiraja et al. [138] published that WCBs exhibit worse reaction rate than immobilised purified proROL because of diffusional problems. Therefore, considering these inconveniences and how heterologous production of ROL has been improved, the use of free ROL and its subsequent immobilisation have gained importance amongst the published works.

Traditionally, lipases have been immobilised through adsorption, particularly onto hydrophobic supports—generally acrylic resins with hydrophobic superficial groups such as octadecyl or divinylbenzene—because of the presence of a large hydrophobic patch around the catalytic triad of the lipases that enables an easy immobilisation and might lead to their hyperactivation [171][172]. However, during biodiesel enzymatic synthesis, highly non-polar reaction mediums are employed that might cause enzyme desorption and in consequence, poor biocatalyst operational stability [51]. Nevertheless, some authors have used ROL with this immobilisation technique and obtained outstanding stability results. For instance, Bonet-Ragel et al. [142] reported that after six consecutive reaction cycles, the biocatalysts retained more than the 60% of the initial activity, in accordance with the results published by Duarte et al. [143] and Su et al. [144]. Moreover, in order to overcome the potential enzyme leakage when adsorption techniques are used, some published works have treated the obtained biocatalysts with crosslinking agents like glutaraldehyde, as it was previously explained for WCBs [130][173]. Notwithstanding these mentioned works and other listed in Table 4, ROL entrapment and covalent immobilisation are the most common immobilisation techniques. The former has been used not only with free ROL but with WCBs because it is an easy, fast and cheap immobilisation technique [174]. The most common entrapment strategies are based on polyvinyl alcohol and alginate employment [145][146][157][175]. Muanruksa et al. [136] obtained outstanding results with free proROL immobilised into alginate-polyvinyl alcohol beads. Esterification degrees over 90% were reported and the biocatalyst exhibited a high operational stability, 15 reaction cycles were done with almost no loss of activity.

Regarding covalent immobilisation, since the binding forces between the lipase and the supports are strong, obtained biocatalysts tend to show high stability, high resistance to extreme pH and temperature conditions and almost no enzyme leakage. However, these strong links between the enzyme and the support, as well as the harsh conditions employed during immobilisation process, might have a negative impact on the enzyme activity [176][177]. In any case, there are several studies that employ this immobilisation technique in biodiesel synthesis. Nematian et al. [147] immobilised proROL onto a superparamagnetic nanostructure and described that amongst the three different biocatalysts studied—two based on lipase-support electrostatic interactions and the third one on covalent-linkage—the covalently immobilised proROL showed higher conversion and operational stability. Bonet-Ragel et al. [115] covalently immobilised rROL onto glutaraldehyde pre-treated epoxide acrylic resins and studied its reaction performance and operational stability in biodiesel synthesis with methanol and ethanol as acyl-acceptors. Under the best conditions, yields close to the theoretical 100% were obtained after 360 min for methanol and 260 min for ethanol. In addition, regarding operational stability, no significant activity loss was observed after five consecutive reaction cycles with both alcohols. Besides, Luna et al. [126]described similar operational stability results with ethanol and sunflower oil as substrates, indicating that covalent immobilisation is an adequate technique for biodiesel synthesis with ROL.

In terms of operational strategy in biodiesel synthesis, although ROL has been described as a suitable industrial and solvent-tolerant enzyme, some improvements have been reported to obtain better reaction yields, higher stability or enhance the scale-up of the bioprocess. One of the most commonly employed approach is based on the stepwise addition of the alcohol as the interaction between the lipase and the alcohol is the main enzyme-deactivating factor [178][179]. Several authors have published works in which ROL and stepwise addition strategy have been employed [115][148]. Additionally, other authors have focused on seeking the most adequate acyl-acceptor—the one that has fewer negative effect on the enzyme—by testing different alcohols [138][175] and even the short-esters of the corresponding alcohols performing interesterification reactions [146][149]. Besides, regarding solvents employment, their absence in solvent-free systems has aroused as an interesting operational alternative because of the minimisation of biodiesel downstream processes and the avoidance of hazardous solvents, making the overall biotransformations more cost-effective and environmentally friendly [104][142][149][152].

Lately, the joint employment of both 1,3-regiospecific and non-specific lipases have been researched in order to accelerate biodiesel reaction rates and obtain higher yields [121]. Lee et al. [150] reported yields close to 100% in 2-h reaction and outstanding operational stabilities when using proROL and Candida rugosa lipase (CRL). Actually, the conversion yield was still 85% after 20 reaction cycles. In line with these results, Zeng et al. [151] described higher biodiesel production rates when employing together proROL and CRL.

Regarding the scale-up of biodiesel production using ROL, Canet et al. [119] compared packed bed reactor (PBR) with stirred tank reactor (STR) in biodiesel synthesis with rROL immobilised through hydrophobic adsorption. Results showed a higher reaction rate with STR than PBR but, just the opposite outcome when operational stability was the analysed trait. Other authors have also employed PBRs [125][131][145] or even more genuine reactors such as the magnetically stabilised fluidised bed reactor [124] or three-phase bioreactors [120]. However, there are not many works related to the scale-up of biodiesel production with ROL considering the vast amount of research papers published dealing with this biocatalyst. Therefore, more research in this field could be relevant for future projects.

4.2. Structured Lipids Production

Fats and oils are consumed in daily diets as an important source of energy, essential fatty acids and fat-soluble nutrients. Their functional, nutritional and organoleptic properties depend on their composition in saturated and polyunsaturated fatty acids, fatty acid chain length and on the distribution of the different fatty acids in the triacylglycerols (TAGs) (position sn-1, sn-3 or sn-2). Therefore, by modifying the fatty acids composition or its profile, lipids with improved properties might be obtained, the so-called structured lipids (SL). Currently, there are various SLs of commercial interest whose properties have been widely described (Table 5), (i) low caloric and dietetic triacylglycerols that include TAGs with medium-chains (MMM) and TAGs with short- and medium-chain fatty acids in sn-1 and sn-3 and a long-chain fatty acids in sn-2 position, SLS and MLM respectively; (ii) human milk fat substitutes (HMFS), (iii) cocoa butter equivalents (CBE), (iv) trans- free plastic fats, (v) triacylglycerols rich in specific long-chain and polyunsaturated fatty acids (PUFAs) and recently, even (vi) diacylglycerols (DAG) and monoacylglycerols (MAG) have been considered as SLs [180][181].

Table 5. Definition and properties of the main commercially relevant structured lipids.

|

SL Type |

Definition |

Properties |

Ref. |

|

Low caloric and dietetic TAGs |

Present lower caloric value than conventional oils and fats. SLS-, MLM- and MMM- type TAGs. |

M and S fatty acids present lower caloric value than their counterparts L. M fatty acids have lower tendency to get accumulated. Released M fatty acids can be directly absorbed and provide readily energy in the liver. |

|

|

Human milk fat substitutes (HMFS) |

Mimic the fatty acid profile of human milk. Contain oleic (30–35%), palmitic (20–30%), linoleic (7–14%) and stearic acids (5.7–8%). Palmitic acid mainly in sn-2 position. |

Promote palmitic acid absorption as 2-monoacylpalmitate Promote calcium absorption |

|

|

Cocoa butter equivalents (CBE) |

Mimic the scarce natural cocoa butter Mainly formed by saturated fatty acids (stearic and palmitic acids) in sn-1,3 and monounsaturated fatty acids (oleic acid) in sn-2 position. |

Desirable polymorph is β form Similar organoleptic properties to cocoa butter |

|

|

Trans-free plastic fats |

Mimic trans fatty acids containing hydrogenated vegetable oils. |

Avoid potential cardiovascular diseases caused by trans fatty acids. |

|

|

TAGs rich in specific long-chain and polyunsaturated fatty acids (PUFAs) |

Modified TAGs containing a combination of n-3 and n-6 PUFAs to enhance nutritional values. Mainly eicosapentaenoic (EPA) and docosahexaenoic acid (DHA) are employed. |

EPA decreases blood viscosity, platelets aggregation and promotes vasodilation. DHA promotes sensorial and neuronal maturation in babies. |

|

|

MAGs and DAGs |

Modified lipids containing one or two fatty acids linked to a glycerol |

Non-ionic surfactants capable of using as emulsifiers in the food industry. 1,3-DAGs reduce serum TAGs level and supress body fat accumulation |

SLs production can be carried out through chemical or enzymatical processes, the latter having several advantages when compared to chemical catalysis [192]. Hence, in the same way as stated for biodiesel synthesis in the previous section, enzymatically catalysed reactions allow milder reaction conditions what in this case, as well as lowering energy consumption, might lead to a reduction in the loss of original attributes of temperature-sensitive substrates and products. Moreover, through enzymatic catalysis, the use of deleterious solvents can be avoided enabling a safer and more environmentally friendly food production. However, the most remarkable advantage of lipase employment in this biotransformation is their specificity and selectivity [193][194]. Concretely, 1,3-regiospecific lipases like ROL arouse a keen interest because of their capacity to only modify the sn-1 and sn-3 positions of TAGs—even though acyl-migration phenomena might occur depending on reaction conditions.

Table 6 shows a summary of the latest published works about SLs synthesis employing ROL. Nunes et al. [195] produced MLM-type SLs by acidolysis of olive oil with capric and caprylic acids. The employed biocatalysts were rROL produced in K. phaffii and commercial native ROL (proROL), both of them covalently immobilised onto Eupergit© C and modified Sepiolite. Noticeably, rROL showed a better performance than the native lipase, the percentages of incorporated capric and caprylic acids were higher as well as the operational stability. In spite of the use of pure or commercial substrates, oleaginous wastes or even non-commercially profitable oils might also be employed for MLM-type SLs synthesis with ROL. For instance, Mota et al. [196] described how low-calorie SLs of MLM-type can be produced using oil extracted from spent coffee grounds and oil from olive pomace with proROL immobilised onto magnetic nanoparticles. In the same line, Costa et al. [197] synthesised MLM-type SLs with the oil extracted from grapeseeds of Vitis vinifera L., which are a by-product of the wine industry. Moreover, instead of residual oils, Nagao et al. [198] employed the oil from the oleaginous microorganism Mortierella alpina to produce MLMs rich in arachidonic acid, a precursor of several hormones.

Table 6. Summary of structured lipids production with Rhizopus oryzae lipase as main biotcatalyst.

|

Product |

Substrates |

Reaction Type |

Lipase |

Immobilisation Technique |

ID/OS |

Ref. |

|

MLM |

OO + CRA |

Acidolysis |

proROL/rROL |

CI onto Eupergit®C/sepiolite (AlPO4-sepiolite) |

ID: 21.6%. OS: half-life 159 h |

[195] |

|

MLM |

OO + CA |

Acidolysis |

proROL/rROL |

CI onto Eupergit®C/sepiolite (AlPO4-sepiolite) |

ID: 34.82%. OS: half-life 136 h |

[195] |

|

MLM |

SCG + CA |

Acidolysis |

proROL |

CI onto GA treated MNP |

ID: 50% |

[196] |

|

MLM |

SCG + ethyl caprate |

Interesterification |

proROL |

CI onto GA treated MNP |

ID: 26% |

[196] |

|

MLM |

OP + CA |

Acidolysis |

proROL |

CI onto GA treated MNP |

ID: 51% OS: 6.8 batches |

[196] |

|

MLM |

OP + ethyl caprate |

Interesterification |

proROL |

CI onto GA treated MNP |

ID: 46%. OS: 9.1 batches |

[196] |

|

MLM |

Grapeseed oil + CRA |

Acidolysis |

rROL |

CI onto Amberlite IRA 96 |

ID: 54%. OS: half-life 166 h |

[197] |

|

MLM |

Grapeseed oil + CA |

Acidolysis |

rROL |

CI onto Amberlite IRA 96 |

ID: 69% OS: half-life 118 h |

[197] |

|

MLM |

TGA58F + CA |

Acidolysis |

proROL |

IA onto Dowex WBA |

ID: 64.6% |

[198] |

|

MLM |

TGA40 + CA |

Acidolysis |

proROL |

IA onto Dowex WBA |

ID: 62.8% |

[198] |

|

MLM |

TGA55E + CA |

Acidolysis |

proROL |

IA onto Dowex WBA |

ID: 64.8% OS: 90 days in PBR1 dropped 10% |

[198] |

|

MLM |

OO + CRA |

Acidolysis |

rROL |

CI onto Eupergit® C/IA onto Lewatit VP OC 1600 |

OS: half time 2.4 batches (54.3 h) with Eupergit®C |

[199] |

|

MLM |

OO + CA |

Acidolysis |

rROL |

CI onto Eupergit® C/IA onto Lewatit VP OC 1600 |

OS: half time 10.2 batches (234 h) with Lewatit VP OC 1600 |

[199] |

|

MLM |

OO + CRA |

Acidolysis |

rROL |

CI onto Eupergit® C |

ID: 15.5% |

[200] |

|

MLM |

OO + CA |

Acidolysis |

rROL |

CI onto Eupergit® C |

ID: 33.3% |

[200] |

|

MLM |

OO + CRA |

Acidolysis |

rROL |

CI onto Amberlite IRA 96 |

ID: 76.9 |

[201] |

|

MLM |

OO + CA |

Acidolysis |

rROL |

CI onto Amberlite IRA 96 |

ID: 85.6% |

[201] |

|

HMFS |

PA enriched TAGs + OA enriched mixtures |

Acidolysis |

proROL |

IA onto Accurel® MP-1000 |

ID: OA in sn-1,3 67.2% - PA in sn-2 67.8%. OS: no activity loss in 10 uses (190 h) |

[202] |

|

HMFS |

Lard + FFA from EPAX 1050TG |

Acidolysis |

rROL |

CI onto Accurel® MP-1000 |

ID: 24 mol%. OS: after 4 batches, 55% of original activity |

[203] |

|

HMFS |

Tripalmitin + FFA from camelina oil |

Acidolysis |

rROL |

AI onto RelizymeTM OD403/S/CI onto Lewatit VP OC 1600 |

ID: 52% |

[204] |

|

TAGs rich in PUFAs |

cod liver + tuna oil + ethanol. |

Alcoholysis |

proROL |

IA onto Accurel® MP-1000 |

Alcoholysis ID: 72% OS: after 6 cycles, complete deactivation. |

[205] |

|

2-MAG from alcoholysis + CRA |

Esterification |

proROL |

IA onto Accurel® MP-1000 |

ID: 95%. OS: after 5 cycles, no activity loss. |

[205] |

|

|

TAGs rich in PUFAs |

Tuna oil + CRA |

Acidolysis |

proROL |

IA onto Accurel® MP-1000 |

OS: over one week |

[206] |

|

TAGs rich in PUFAs |

cod liver oil + ethanol 96% |

Alcoholysis |

proROL |

IA onto Accurel® MP-1000 |

Alcoholysis Y: 78%. OS: after 3 cycles, a 57% decrease |

[207] |

|

cod liver oil + 1-butanol |

Alcoholysis |

proROL |

IA onto Accurel® MP-1000 |

Alcoholysis Y: 78%. OS: after 3 cycles, no activity decrease |

[207] |

|

|

Esterification: 2-MAG from alcoholysis + CRA |

Esterification |

proROL |

IA onto Accurel® MP-1000 |

Esterification Y: 71%. |

[207] |

|

|

TAGs rich in PUFAs |

Fish oil + CRA |

Acidolysis |

proROL |

Non-immobilised |

ID: 2.5% |

[208] |

|

HMFS |

Milkfat + SYO |

Interesterification |

proROL |

EI into polysiloxane-PVA |

ID: 8.14%. OS: after 10 batches, no activity loss |

[209] |

|

CBE |

SO + SA-PA mixtures |

Acidolysis |

proROL |

IA onto Accurel® MP-1000 |

|

[210] |

Regarding HMFS, Esteban et al. [202] used several commercial lipases, amongst them proROL immobilised onto Accurel® MP-1000, to produce a TAG rich in palmitic acid in sn-2 and oleic acid in sn-1,3; the so called OPO, which is the main component of human milk TAGs. proROL showed the best performance in oleic acid incorporation and exhibited a high operational stability, after ten reuse cycles almost no activity loss was found. Simões et al. [203] also tested different lipases for HMFS production and reported that rROL immobilised onto Accurel® MP-1000 showed a similar performance to Novozymes 435 and Lipozyme RM IM in acidolysis reaction between lard and FFA mixture from fish oil rich in docosahexaenoic acid. Besides, Faustino et al. [204] immobilised rROL produced in K. phaffii onto two different supports, Lewatit VP OC 1600 and Relizyme OD403/S, and applied the formed biocatalysts in the production of HMFS rich in polyunsaturated fatty acids (PUFAs). The acidolysis reaction was carried out in solvent-free system between tripalmitin and FFAs (mainly linoleic and linolenic acids) from camelina oil, which proved to be a good source of PUFAs. According to the authors, the results obtained with rROL immobilised onto Lewatit VP OC 1600 were comparable to the commonly used commercial lipase Lipozyme RM IM.