Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Asad Zia | -- | 8536 | 2022-11-02 08:47:06 | | | |

| 2 | Sirius Huang | Meta information modification | 8536 | 2022-11-03 02:29:25 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zia, A.; Pu, Z.; Holly, I.; Umar, T.; Tariq, M.A.U.R.; Sufian, M. Properties of Recycled Steel Fibers-Incorporated Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/32435 (accessed on 07 February 2026).

Zia A, Pu Z, Holly I, Umar T, Tariq MAUR, Sufian M. Properties of Recycled Steel Fibers-Incorporated Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/32435. Accessed February 07, 2026.

Zia, Asad, Zhang Pu, Ivan Holly, Tariq Umar, Muhammad Atiq Ur Rehman Tariq, Muhammad Sufian. "Properties of Recycled Steel Fibers-Incorporated Concrete" Encyclopedia, https://encyclopedia.pub/entry/32435 (accessed February 07, 2026).

Zia, A., Pu, Z., Holly, I., Umar, T., Tariq, M.A.U.R., & Sufian, M. (2022, November 02). Properties of Recycled Steel Fibers-Incorporated Concrete. In Encyclopedia. https://encyclopedia.pub/entry/32435

Zia, Asad, et al. "Properties of Recycled Steel Fibers-Incorporated Concrete." Encyclopedia. Web. 02 November, 2022.

Copy Citation

Accumulating vast amounts of pollutants drives modern civilization toward sustainable development. Construction waste is one of the prominent issues impeding progress toward net zero. Pollutants must be utilized in constructing civil engineering structures for a green ecosystem. Large-scale production of industrial steel fibers (ISFs) causes significant damage to the goal of a sustainable environment. Recycled steel fibers (RSFs) from waste tires have been suggested to replace ISFs. Using RSFs can help reduce pollution due to ISFs production; on the other hand, it can improve the performance of the concrete at a low cost.

concrete

mortars

fiber reinforced concrete

mechanical strength

recycled steel fibers

raw steel fibers

waste tires

pollution reduction

1. Background

1.1. Tires and Global Pollution

Great attention to the global increase in tires is required, especially in the European Union [1][2]. More than one billion tires are used for replacement every year globally, with more than half being abandoned and waiting to be disposed of [3]. According to the European Tire and Rubber Manufacturers Association (ETRMA2021), its members manufactured 4.24 million tons of tires in 2021, representing 70% of the global tire industry’s turnover [4]. The European Union’s Landfill Directive [5], which went into force in July 2006, requires all end-of-life tires (ELTs) to be recycled or reused. Following the implementation of this regulation, ETRMA estimates that 91% of end-of-life tires (ELTs) were collected and treated for material recycling and energy recovery in 2018 [6]. About 40 million worn tires are processed annually in the United Kingdom alone. Material recovery, which uses secondary materials from ELTs in construction, automotive, and civil engineering applications, was used to treat around 2 million tons (61.75 percent of total ELTs handled). Apart from this, in 2009, China’s tire production by rubber consumption accounted for around 70% of the country’s total rubber resource consumption, resulting in 233 million waste tires weighing approximately 8.6 million tons, equivalent to approximately 3 million tons of rubber resources [7]. According to Pilakoutas et al. [8], over a billion discarded tires are produced worldwide. The accumulation of these tires is a significant difficulty because tire component materials are exceedingly complex, making natural degradation impossible [9]. This necessitates the careful management of this massive quantity of trash. Waste tires can be managed using various methods, including material recovery, energy recovery, retreating, export, and landfill disposal [8]. According to ETRMA 2018 [10], approximately 72% of waste tires in Slovakia were recycled, with zero percent used in civil engineering, public works, or backfilling. As a result, investigating the potential application of waste tires or their ingredients in the construction industry to increase waste tire recycling in Slovakia and other countries is critical. Rubber content such as carbon black, steel insert, oil, and vulcanizing agents, such as inserts, synthetic yarns, and textiles, are among the components of a tire, with percentages of 46 and 48 percent, 25–28 percent, 10–12 percent, and 3–6 percent, respectively [11]. The amount of steel fiber removed from waste tires varies according to the tire type. Steel is used in tires for up to 15% of lightweight vehicles and up to 25% of trucks [8]. Liew and Akbar [12] reported that beneficial products from recycling tires consist of rubber, textile fibers, and steel fibers. Rubber makes up the majority of the tire, accounting for nearly 47–48 percent of the total weight, followed by black carbon (22 percent), steel cords (15–17 percent), textile fabric (5 percent), additives (8 percent), and zinc oxide and sulfur (1 percent each) [13][14].

1.2. Raw Steel Fiber from Waste Tires and Concrete Composites

Concrete is extensively used in building materials because of its high compressive strength, durability, and environmental compatibility. Concrete is used in various architectural projects, including foundations, walls, bridges, roadways, dams, and reservoirs [15]. However, its service life may be severely shortened in demanding conditions. Although concrete structures usually are designed and built to last at least 50 years, the sulfuric acid attack can cause them to deteriorate in just a few years. Repair and, in some cases, complete replacement of damaged structures are necessary when corrosion rates rise, which can be very costly and entail many social issues. Many research efforts have been made to improve concrete qualities for greater applicability due to these varied uses [16][17][18]. Industrial steel fiber reinforced concrete (ISFRC) has been beneficial in various applications throughout the last three decades, including tunnel linings, hydraulic structures, slabs, bridge decks, foundations, refractory concrete fiber shotcrete, and precast parts [8]. Adding 1% industrial steel fiber (ISF) to concrete automatically doubles the material cost [19]. As a result, steel fiber collected from discarded tires has become a viable option for use as reinforcement for cement composites. This advocates an environmentally beneficial method of dealing with some of the issues linked with the generation of waste tires. It also functions as a tool for improving building sector sustainability [20].

Pawelska-Mazur and Kaszynska [21] compared the energy consumption and CO2 emissions of the concrete mixture with raw steel fibers recovered from waste tires (RSF) to a concrete recipe with industrial steel fibers (ISF). It was concluded that the concrete recipe with RSF uses 31.3 percent less energy and emits 30.8 percent less CO2. However, due to intricate and energy-intensive manufacturing procedures, industrially manufactured steel fibers are the second component (after cement) that substantially impacts the natural environment. Therefore, energy consumption and greenhouse gas emissions could be reduced by substituting waste fibers obtained from the recovery of rubber from used tires for industrially manufactured steel fibers.

Qin and Kaewunruen [2] demonstrated (refer to Table 7 in Qin and Kaewunruen [2]’s paper) that the RSF is far cheaper than ISF. The average cost of ISF is over five times that of RSF. Furthermore, replacing the ISF with RSF can reduce the cost from 15.89 USD/m3 to 40 USD/m3. According to the findings, the contribution of employing RSF substitutes for ISF in terms of economy and environment is significant. Furthermore, RSF’s social role cannot be overlooked. Waste tires pose a significant environmental problem [3]. Human health and water resources are irreversibly harmed by the combustion or burying of waste tires [22]. As an environmentally acceptable resource in civil construction, scrap tires improve building cleanliness and extend the structure’s service life. Even though RSF’s performance is neither higher nor inferior to ISF concrete, it can still be a good substitute for ISF in economics, the environment, carbon emissions, and social development. According to concrete studies, replacing part of the ISF with some RSF is a good solution for waste tire disposal. Using RSF can produce similar advantages to using ISF on concrete [23].

Furthermore, 1.5 percent of RSF adds roughly 35 percent to construction budgets, and 1.5 percent of ISF contributes more than 50 percent [24]. In addition, the contribution of fiber to carbon emissions in concrete ranged from 15% (1.5 percent RSF) to 40% (1.5 percent ISF) [24]. According to a prior study, the RSF performs similarly to the ISF in enhancing concrete splitting and flexural strengths [25][26][27][28][29].

2. The Properties of RSF-Incorporated Concrete

The mechanical properties of the concrete incorporating raw steel fibers recovered from waste tires (RSFs) of previous research were demonstrated. Fundamentally, concrete is defined as a mixture of binder, fine aggregates, coarse aggregates, and water. Sometimes, additives or admixtures are added to obtain specific qualities. Hardened concrete’s three main mechanical properties are compressive strength, split tensile strength, and flexure strength. For percent comparison, the properties of the plain cement concrete of the concerned study were taken as a reference.

In some cases, it is challenging to compare the strength properties of different research studies due to differences in the scales used by authors for adding the fibers to the concrete. This becomes very difficult when the complete set of parameters of the fibers is not provided for converting their weight to volume or for interconversion among different scales of adding the fibers. To deal with this issue, the strength properties are compared separately for concrete containing RSF’s content by volume fraction of concrete, RSF’s content added by weight fraction of the concrete, and RSF’s content added in kg/m3. For this purpose, the strength properties of each category were compared individually, and the effect of variation of fiber was reported. In addition, an optimized dose for RSF was demonstrated for each of the RSF’s contents: fiber by volume or weight of concrete or in kg/m3.

Most previous research has assumed that the density of RSF is the same as that of industrial steel fibers (ISFs), presuming that the RSF is free of impurities/tire particles or that impurities/tire particles have been separated from the RSF before mixing with concrete. However, recycled steel fibers from waste tires (RSF) were utilized in some studies without separating impurities/tire particles [25]. As a result, the average density of RSF with impurities/tire particles was determined to be less (3014 kg/m3) than the industrial steel fibers (7200 kg/m3) [25]. In addition, it found that the density of the RSF varies from that of the commonly used density of steel, 7850 kg/m3, for inter-conversion of steel weight and volume [30]. Therefore, it becomes hard to calculate the exact amount of RSF by volume fraction of concrete if the RSF fibers are added to concrete in kg/m3, and the density of the fibers is not given. Therefore, the properties of the effect of the addition of RSF in kg/m3 are discussed in a separate section.

2.1. Compressive Strength of RSF Concrete

2.1.1. Compressive Strength of Concrete Containing RSF by its Volume Fraction

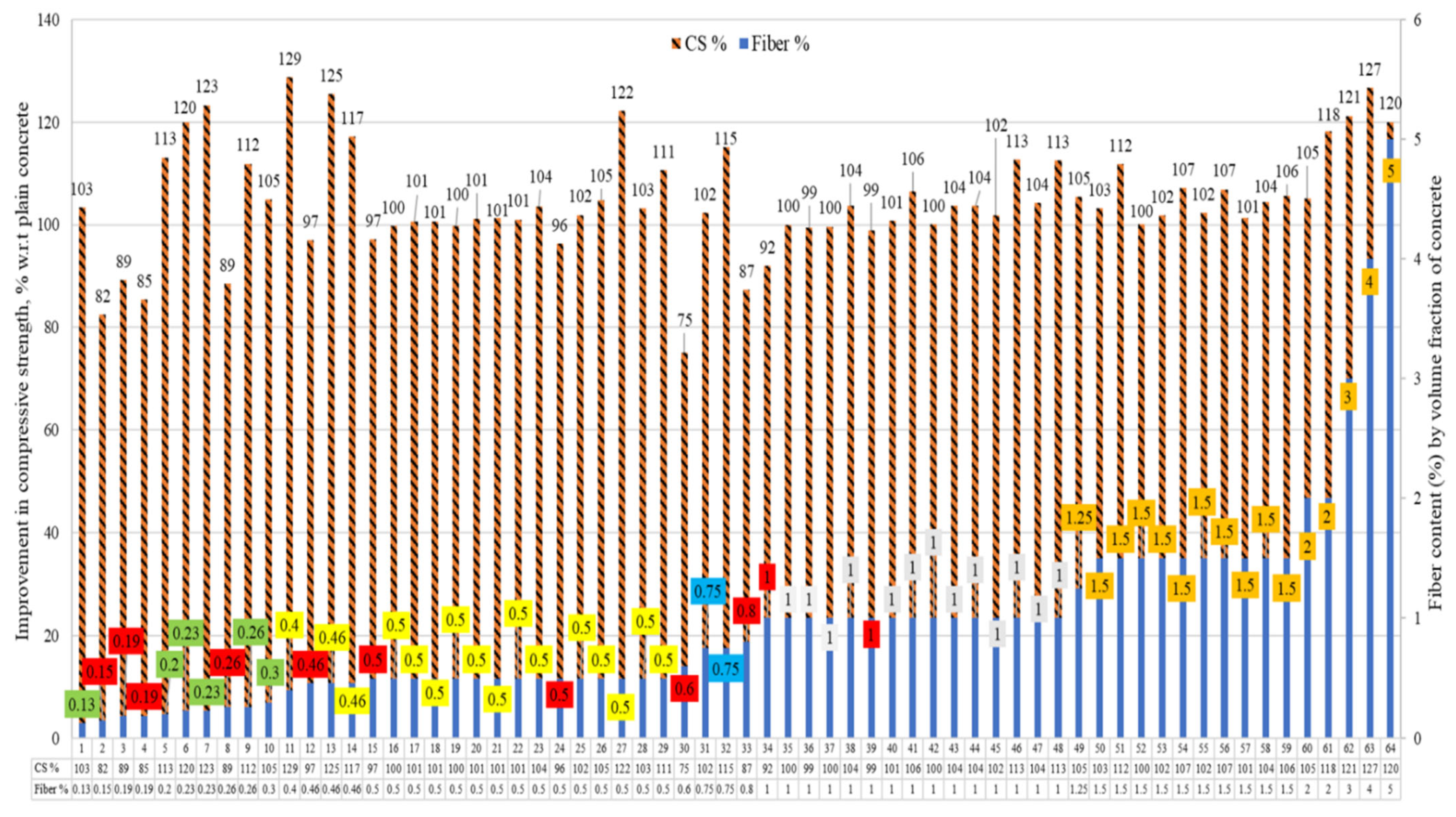

The compressive strengths (CS) of the concrete reinforced with raw steel fibers recovered from waste tires (RSF) were collected. The percent comparison of the CS is demonstrated in Figure 1. For percent comparison, the CS of the plain concrete of the concerned study was taken as a reference (equivalent to 100%). Additionally, the percent rise or decrease in the CS of RSF concrete is presented.

Figure 1. Percentage comparison of the compressive strengths of concrete containing RSF by volume fraction.

The amount of fibers for specimens is given on the right axis of the graph, while an increase or decrease in CS to plain concrete is shown on the left y-axis of the graph. The red squares show the percentages of the fibers at which the CS was less than the PC. The rest of the different colors of the boxes represent a specific range of RSF doses used. The number of specimens is shown on the x-axis of the graph. Specimens 1 to 10 contain RSF from 0.13% to 0.30%. For specimen numbers 2, 3, 4, and 8, the CS decreased 18%, 11%, 15%, and 11%, respectively, from adding 0.15%, 0.19%, 0.19%, and 0.26% of RSF by volume fraction of concrete. The CS increased for specimens 1, 5, 6, 7, 9, and 10 by 3%, 13%, 20%, 23%, 12%, and 5% respectively. For RSF range from 0.46% to 0.50%, no significant decrease was reported except for specimens 12, 15, and 24, as shown in Figure 1.

Moreover, contradictory results were reported for specimen numbers 12, 13, and 14, incorporating the same amount of 0.46% RSF. The possible reason is that for specimens 13 and 14, the authors used a planetary concrete mixer; thus, good fiber dispersion and better mixing were obtained [31][32]. On the other hand, better mixing was not achieved for specimen 12 due to the traditional mixing method [33] used.

At 0.50% of RSF, all researchers found no improvement or slight increase in CS of RSF specimens 15 to 29 except a slight decrease of 3% and 4% for specimens 15 and 24, respectively. Only a few studies (specimens 30, 31, 32, and 33) tested the CS of the specimen incorporating RSF from 0.60% to 0.80% by volume fraction of concrete. Two studies reported increases of 2% and 15% for the incorporation of 0.75% RSF. At the same time, decreases of 25% and 13% were reported for specimens 30 and 33, respectively, at 0.60% RSF and 0.80% RSF, respectively. A rise in CS of the RSF specimens was reported at 1% RSF for specimens 34 to 48, except for specimens 34 and 39. Specimens 34 and 39 showed a decline of 8% and 1% in CS at 1% RSF. No decline in CS was reported by any studies for specimens 49 to 64 for concrete incorporating RSF from 1.25% to 5% RSF by volume fraction.

The data given in Figure 1 is shown in tabular format for a specific range of RSF content, along with the diameters and lengths of the fibers. This can help conclude the influential factors for the increase and decrease in CS for the exact content of the RSF. The specimens incorporating RSF content of less than 1% are demonstrated in Table 1. The possible impact of the diameters and lengths can be described by comparing the results of the compressive strengths for the exact content of fibers in the context of RSF parameters. When advanced mixing techniques were not used, the concrete declined in compressive strength for short RSF (length was less than 31 mm) by more than 0.13%. A decrease in CS was reported for specimens 2, 3, 4, and 8, incorporating 0.13% to 0.26% RSF, by Aiello et al. [34]. The CS increased when RSF exceeded 0.19% for the exact dimension of the raw steel fibers, where special techniques were applied to control the fibers’ dispersion and homogeneity of the mix. Increases of 20%, 23%, and 12% in the CS of specimens six, seven, and nine for adding RSF of 0.23%, 0.23%, and 0.26%, respectively, could be correlated with using a planetary mixer and 0.17% more plasticizer.

Table 1. Results of compressive strength’s percent comparison and fiber properties of the concrete encompassing less than 1% of RSF by its volume fraction.

| Authors | Specimen Number in Figure 4 |

Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| Fiber Less Than 0.30% | % a | mm | mm | MPa | % b | |

| Aiello et al. [34] | 1 (1% Sp) | 0.13 | 26.0 | 0.258 | 40.4 | 103 |

| 2 (1% Sp) | 0.15 | 26.0 | 0.258 | 32.2 | 82 | |

| 3 (1% Sp) | 0.19 | 26.0 | 0.258 | 34.9 | 89 | |

| 4 (1.20% Sp) * | 0.19 | 26.0 | 0.258 | 33.4 | 85 | |

| Rossli and Ibrahim [35] | 5 (0.002 Sp) | 0.20 | 62.00 | 0.8 | 52.0 | 113 |

| Aiello et al. [34] (Planetary mixer) | 6 (1.12%) | 0.23 | 26.0 | 0.258 | 38.5 | 120 |

| Centonze et al. [30] (Planetary mixer) |

7 | 0.23 | 31.4 | 0.24 | 39.0 | 123 |

| Aiello et al. [34] (Normal concrete mixure) |

8 (1.20% Sp) | 0.26 | 26.0 | 0.258 | 34.6 | 89 |

| 9 (1.37% Sp) | 0.26 | 26.0 | 0.258 | 43.7 | 112 | |

| Leone et al. [36] | 10 | 0.3 | 31.4 | 0.24 | 35.71 | 105 |

| Average | 0.21 | 30.68 | 0.31 | 102 | ||

| 0.40% to 0.50% fiber | ||||||

| Rossli and Ibrahim [35] | 11 | 0.40 | 62.00 | 0.8 | 59.2 | 129 |

| Leone et al. [33] | 12 | 0.46 | 13.94 | 0.25 | 32.6 | 97 |

| Centonze et al. [30] (Planetary mixer) |

13 | 0.46 | 31.4 | 0.24 | 39.7 | 125 |

| Aiello et al. [34] (Planetary mixer) | 14 (1.12% Sp) | 0.46 | 26.00 | 0.258 | 37.6 | 117 |

| Groli et al. [37] | 15 | 0.5 | 21 | - | 36.4 | 97 |

| Siraj and Kedir [38] (Mix-I, C-25) |

16 | 0.50 | 20.00 | 0.89 | 28.0 | 100 |

| 17 | 0.50 | 40.00 | 0.89 | 28.2 | 101 | |

| 18 | 0.50 | 60.00 | 0.89 | 28.2 | 101 | |

| Siraj and Kedir [38] (Mix-II, C-40) |

19 | 0.50 | 20.00 | 0.89 | 40.9 | 100 |

| 20 | 0.50 | 40.00 | 0.89 | 41.5 | 101 | |

| 21 | 0.50 | 60.00 | 0.89 | 41.6 | 101 | |

| Siraj and Kedir [38] (Mix-III, C-60) |

22 | 0.50 | 20.00 | 0.89 | 59.0 | 101 |

| 23 | 0.50 | 40.00 | 0.89 | 60.5 | 104 | |

| 24 | 0.50 | 60.00 | 0.89 | 56.3 | 96 | |

| Vistos et al. [39] | 25 | 0.50 | 12.00 | 0.27 | 37.4 | 102 |

| Samarakoon et al. [25] | 26 | 0.50 | 37.00 | 0.42 | 30.6 | 105 |

| Skarżyński and Suchorzewski [40] | 27 | 0.50 | 26.17 | 0.25 | 52.4 | 122 |

| Chen et al. [41] | 28 | 0.50 | 7.30 | 0.22 | 51.6 | 103 |

| Dorr et al. [42] | 29 | 0.50 | 93.60 | 1.17 | 31.3 | 111 |

| Average | 0.49 | 36.34 | 0.66 | 106 | ||

| 0.60% to 0.80% fiber | ||||||

| Rossli and Ibrahim [35] | 30 | 0.60 | 62.00 | 0.8 | 34.5 | 75 |

| Caggiano et al. [31] | 31 | 0.75 | 26.17 | 0.25 | 22.5 | 102 |

| Chen et al. [41] | 32 | 0.75 | 7.30 | 0.22 | 57.6 | 115 |

| Rossli and Ibrahim [35] | 33 | 0.80 | 62.00 | 0.8 | 40.1 | 87 |

| Average | 0.73 | 39.37 | 0.52 | 94.92 | ||

* Sp is the quantity of superplasticizer added to the mix. a content of fibers added by volume fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

Employing a planetary mixer for specimen preparation resulted in a considerable increase in the percentage of fibers supplied to the concrete mix and the dispersion of those fibers, thus significantly improving mix homogeneity. As a result, the blends were more workable for the same amount of water for specimens 6 and 7 [31][32]. On the other hand, Rossli and Ibrahim [35] reported an increase of 13% in the CS of the concrete at 0.20% RSF. The possible reason for this can be the good dispersion and use of long fibers (62 mm), which help in keeping the specimen intact and provide more resistance than the short fibers (26 mm) used by Aiello et al. [34]. Therefore, an increase in compressive strength can be expected even with less than 0.30% RSF if the homogeneity of the mix and dispersion of the fibers is controlled by using a particular procedure for mixing and preparation of the mix.

The RSF concrete specimens incorporating 0.40% to 0.50% of RSF were grouped. Significant decreases of 3%, 3%, and 4% were reported by Leone et al. [33], Centonze et al. (Centonze et al. 2012), and Siraj and Kedir [38], respectively, for 0.50%, 0.46%, and 0.50% of RSF. In contrast, other studies revealed an increase or negligible decrease in CS when adding 0.40% to 0.50% of RSF to concrete. For example, the highest increase of 29% was reported by Rossli and Ibrahim [35] for 0.40% RSF. The possible reason for obtaining a maximum increase with low RSF content seems to be the considerable length (62 mm) of the sufficiently thick (0.80 mm) RSF used by the authors.

The second-highest increase in CS was noted by Skarzynski and Suchorzewski [40] for 0.50% RSF having moderate length and diameter of 26.17 mm and 0.25 mm, respectively. On the other hand, negligible improvement was reported by Vistos et al. [39] for 0.50% RSF having a small length and diameter of 12 mm and 0.27 mm, respectively. Therefore, it can be concluded that a considerable increase can be obtained in CS within the specified limit by increasing the dimensions of the fiber for the same amount of RSF. For RSF percentages of 0.60% and 0.80%, decreases of 25% and 13% in CS were reported for 62 mm length RSFs. In comparison, for short (7.30 mm) and medium-length (26.17 mm) RSFs, increases of 2% and 15% were observed for specimens 31 and 32, respectively, at 0.75% [43][44].

The specimens incorporating the RSF content equal to or more than 1% are demonstrated in Table 2. No decrease in CS was reported at 1% RSF, except for 8%, 1%, and 1% decreases for specimens 30, 33, and 39, respectively. The possible reason for a decrease in the CS of the three specimens could be long fibers. Specimen 30, incorporating the longest fibers (62 mm), showed the highest decline in CS, while the other two showed a 1% decrease in CS for 60 mm fibers. The highest increase of 13% in CS at 1% RSF was reported for specimen 46, incorporating RSF had a length of 37 mm and diameter of 0.42 mm, and for specimen 48 [25], containing RSF with a length and diameter of 7.30 mm and 0.22 mm, respectively [41]. Hence, it can be suggested that the optimized content of the RSF can vary in RSF having different diameters for the same fiber length and vice versa.

Table 2. Results of compressive strength’s percent comparison and fiber properties of the concrete having 1% or greater than 1% RSF by its volume fraction.

| Authors | Specimen Number in Figure 4 |

Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Rossli and Ibrahim [35] | 34 | 1.00 | 62.00 | 0.8 | 42.3 | 92 |

| Groli et al. [37] | 35 | 1 | 21 | - | 37.5 | 100 |

| Köroğlu [45] | 36 | 1 | 45 | 0.245 | 36.26 | 99 |

| Siraj and Kedir [38] (Mix-I, C-25) |

37 | 1.00 | 20.00 | 0.89 | 27.9 | 100 |

| 38 | 1.00 | 40.00 | 0.89 | 29.1 | 104 | |

| 39 | 1.00 | 60.00 | 0.89 | 27.7 | 99 | |

| Siraj and Kedir [38] Mix-II, C-40 |

40 | 1.00 | 20.00 | 0.89 | 41.3 | 101 |

| 41 | 1.00 | 40.00 | 0.89 | 43.7 | 106 | |

| 42 | 1.00 | 60.00 | 0.89 | 41.1 | 100 | |

| Siraj and Kedir [38] Mix-III, C-60 |

43 | 1.00 | 20.00 | 0.89 | 27.9 | 100 |

| 44 | 1.00 | 40.00 | 0.89 | 29.1 | 104 | |

| 45 | 1.00 | 60.00 | 0.89 | 27.7 | 99 | |

| Samarakoon et al. [25] | 46 | 1.00 | 37.00 | 0.42 | 32.9 | 113 |

| Abdul Awal et al. [46] | 47 | 1.00 | 30.00 | - | 58.2 | 104 |

| Chen et al. [41] | 48 | 1.00 | 7.30 | 0.22 | 56.3 | 113 |

| Average | 1 | 37 | 1 | 102 | ||

| More than 1.25% Fiber | ||||||

| Chen et al. [41] | 49 | 1.25 | 7.30 | 0.22 | 52.7 | 105 |

| Siraj and Kedir [38] (Mix-I, C-25) |

50 | 1.50 | 20.00 | 0.89 | 29.0 | 103 |

| 51 | 1.50 | 40.00 | 0.89 | 31.4 | 112 | |

| 52 | 1.50 | 60.00 | 0.89 | 28.1 | 100 | |

| Siraj and Kedir [38] Mix-II, C-40 |

53 | 1.50 | 20.00 | 0.89 | 41.8 | 102 |

| 54 | 1.50 | 40.00 | 0.89 | 43.9 | 107 | |

| 55 | 1.50 | 60.00 | 0.89 | 42.0 | 102 | |

| Siraj and Kedir [38] Mix-III, C-60 |

56 | 1.50 | 20.00 | 0.89 | 62.4 | 107 |

| 57 | 1.50 | 40.00 | 0.89 | 59.2 | 101 | |

| 58 | 1.50 | 60.00 | 0.89 | 61.0 | 104 | |

| Abdul Awal et al. [46] | 59 | 1.50 | 30.00 | - | 59.0 | 106 |

| 60 | 2.00 | 30.00 | - | 58.7 | 105 | |

| Köroğlu [45] | 61 | 2 | 45 | 0.245 | 43.1 | 118 |

| 62 | 3 | 45 | 0.245 | 44.2 | 121 | |

| 63 | 4 | 45 | 0.245 | 46.2 | 127 | |

| 64 | 5 | 45 | 0.245 | 43.8 | 120 | |

| Average | 2.02 | 38 | 1 | 109 | ||

a content of fibers added by volume fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

For maximum CS within the same range, both the diameter and length of the fibers need to be considered. In the previous studies, an average increase of 2.53% was noted in CS for 1% RSF content having an average diameter of 38.18 mm and 0.79 mm. There was no decrease in CS for specimens incorporated with 1.25% to 2% RSF content. The highest increase of 27% was noted in specimen 63, which contained RSF, 40 mm long and 0.89 mm thick, as reported by Köroğlu [45].

The various lengths from 1.25% to 5% RSF were 7.30 mm, 20 mm, 30 mm, 40 mm, 45 mm, and 60 mm. The diameters of the RSF used were 0.22 mm and 0.245 mm for only specimens 49 and 61–64. While 0.89 mm thick RSFs were utilized in the rest of the specimens (50–60). The CS increased 9% at an average of 2.02% RSF, having an average length of 38 mm, and an average diameter of 1 mm.

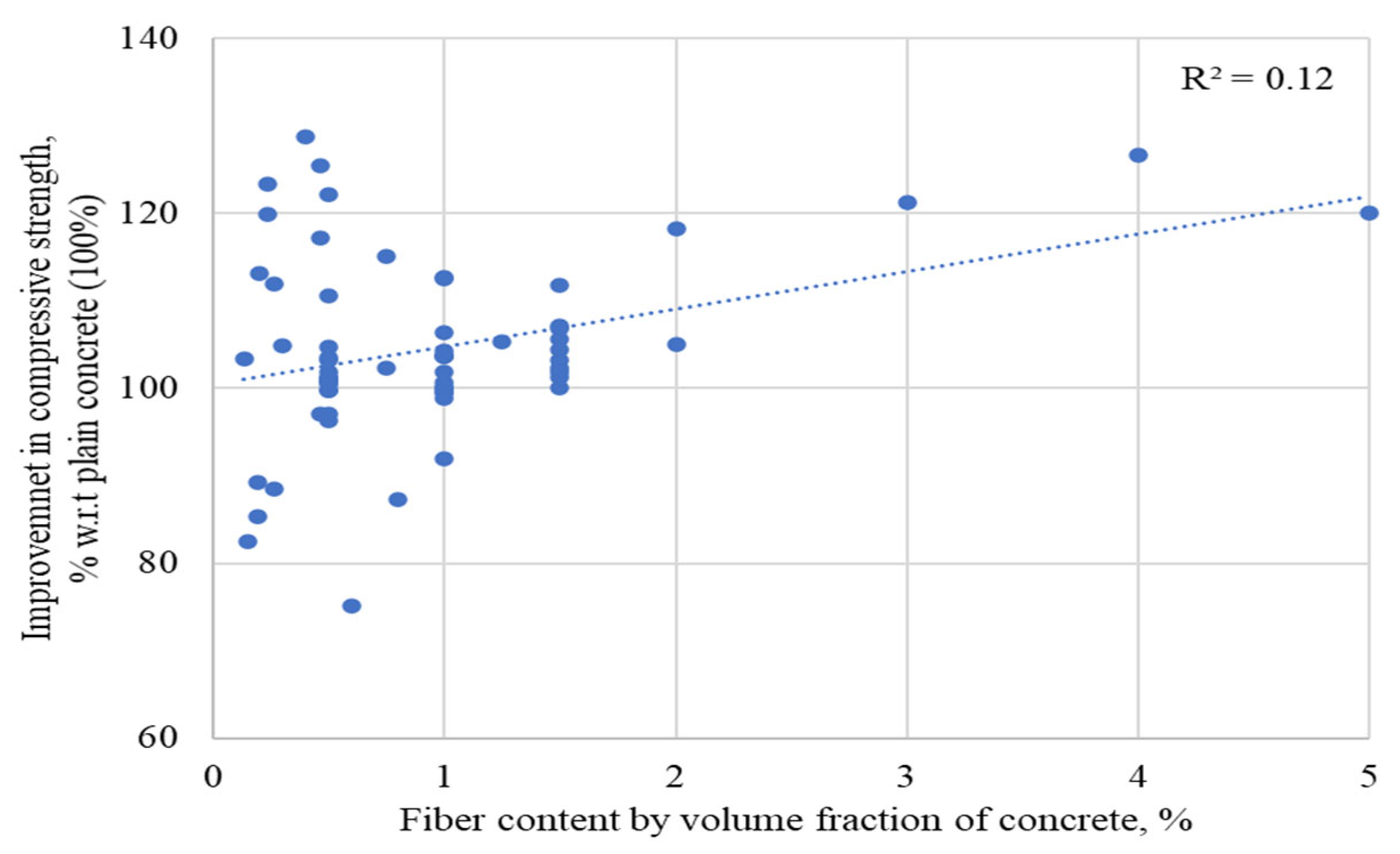

The percent improvement in compressive strengths of concrete incorporating RSF by its volume fraction is shown in Figure 2 compared to the percentage of RSFs used. It can be noted that most of the authors used various sizes of RSF in an amount less than 1.5% for evaluating the compressive behavior of RSF concrete. Few studies evaluated the effect of more than 2% of RSF having short-size fibers or RSF mix (containing various RSFs of different sizes). Nevertheless, the trend line shows the possibility of the CS being improved even at more than 1.5% of RSF. The available database’s regression coefficient (R2) is not very good (R2 = 0.12), but a reliable trend can be made possible in the near future with the comprehensive database of the compressive strength of concretes containing RSF by its volume fraction.

Figure 2. Percent comparison of RSF content with a percent increase in compressive strength of RSF concrete.

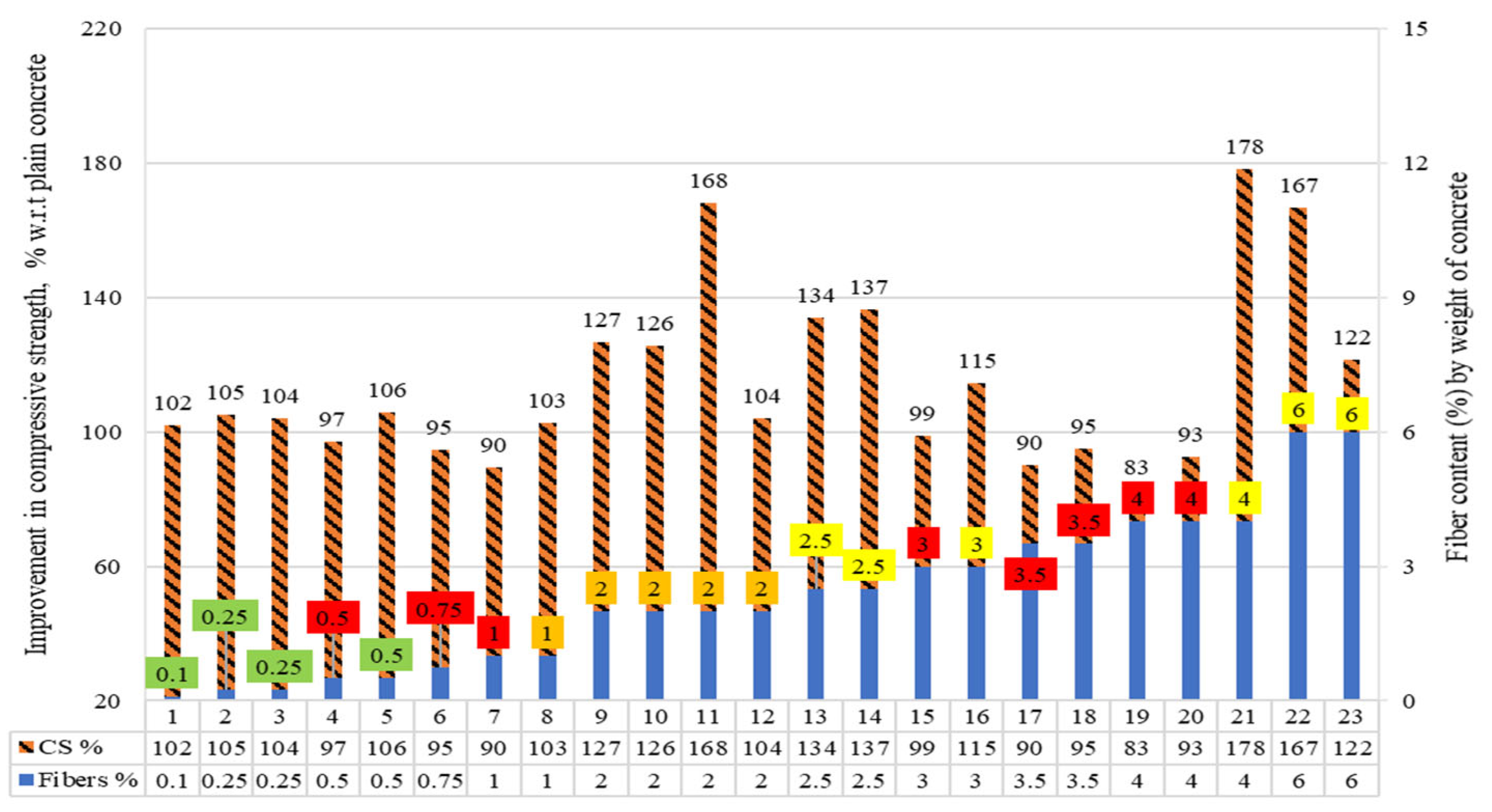

2.1.2. Compressive Strength of Concrete Having RSF Content by Weight

The compressive strengths (CS) of the concrete, including raw steel fibers recovered from waste tires (RSF) by weight fraction, are presented in Figure 3. The CSs are compared, and a percent comparison is demonstrated. The CS of plain concrete from the associated research is used as a reference for percent comparison (equivalent to 100 percent).

Figure 3. Percentage comparison of the compressive strengths of concrete containing RSF by weight fraction.

Also shown is the % increase or decrease in the CS of RSF concrete. The right axis of the graph shows the number of fibers in specimens, while the left y-axis shows the increase or decrease in CS to plain concrete. The x-axis of the graph represents the number of specimens. The percentages of fibers where the CS is less than the PC are displayed in the red squares. The remaining colored boxes each indicate a specific range of RSF dosages. RSF is present in 0.10 percent to 0.75 percent of specimens one through five. For 0.50 percent and 0.75 percent of RSF, the CS declined by 3% and 5%, respectively. The CS increased by 2%, 5%, and 4%, respectively, for specimens one, two, three, and five. For 1% to 2% RSF, a significant increase in CS was reported for specimens eight to twelve, except for specimen seven. The authors reported a 5% decrease in CS at 1% RSF. By considering the specimen including RSF from 2.5% to 3.5%, a decrease of 1%, 10%, and 5%, in CS was reported for specimens 15, 17, and 18, respectively, for 3%, 3.5%, and 3.5% of RSF, correspondingly. A 34%, 37%, and 15% increase in CS was reported for specimens 13, 14, and 16, respectively, reinforced with 2.5%, 2.5%, and 3% RSF, compatibly. For specimens 19 and 20, 17% and 7% decreased at 4% RSF. In contrast, an improvement of 78%, 67%, and 33% were reported for specimens 21, 22, and 23, respectively, for concrete incorporating RSF of 4%, 6%, and 6%, respectively.

Table 3 demonstrates the results of the percent comparison and the properties of RSF used in the respective study. RSF concrete specimens with 0.20 percent to 0.75 percent RSF added by weight of concrete are grouped. Akhter et al. [47] and Shah et al. [48] noted increases of 2%, 5%, 4%, and 6% in CS for 0.10%, 0.25%, 0.25%, and 0.50% of RSF, respectively.

Table 3. Results of compressive strength’s percent comparison and fiber properties of the concrete with RSF by its weight.

| Author | Specimen Number in Figure 6 |

Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.20% to 0.75% Fiber | % a | mm | mm | MPa | % b | |

| Shah et al. [48] | 1 | 0.1 | 31.00 | - | 56.7 | 102 |

| 2 | 0.25 | 31.00 | - | 58.3 | 105 | |

| Akhtar et al. [47] | 3 | 0.25 | 30.00 | 1.10 | 78.0 | 104 |

| Shah et al. [48] | 4 | 0.5 | 31.00 | - | 54.0 | 97 |

| Akhtar et al. [47] | 5 | 0.5 | 30.00 | 1.10 | 79.5 | 106 |

| Shah et al. [48] | 6 | 0.75 | 31.00 | - | 52.5 | 95 |

| Average | 0.39 | 30.67 | 1.10 | 63.2 | 101.5 | |

| 1% to 2% Fiber | ||||||

| Shah et al. [48] | 7 | 1 | 31.00 | - | 49.7 | 90 |

| Akhtar et al. [47] | 8 | 1 | 30.00 | 1.10 | 77.0 | 103 |

| Gul et al. [49] | 9 | 2 | 100.16 | 0.94 | 35.9 | 127 |

| 10 | 2 | 7.62 | 0.94 | 35.5 | 126 | |

| Younis [44] | 11 | 2 | 29.00 | 0.20 | 47.6 | 168 |

| Graeff et al. [50] | 12 | 2 | 13.00 | 0.20 | 61.1 | 104 |

| Average | 1.67 | 35.13 | 0.68 | 51.1 | 119.5 | |

| 2.5% to 3.5% Fiber | ||||||

| Gul et al. [49] | 13 | 2.5 | 100.16 | 0.94 | 37.9 | 134 |

| 14 | 2.5 | 7.62 | 0.94 | 38.6 | 137 | |

| 15 | 3 | 100.16 | 0.94 | 27.9 | 99 | |

| 16 | 3 | 7.62 | 0.94 | 32.4 | 115 | |

| 17 | 3.5 | 100.16 | 0.94 | 25.5 | 90 | |

| 18 | 3.5 | 7.62 | 0.94 | 26.9 | 95 | |

| Average | 3.00 | 53.89 | 0.94 | 31.5 | 111.5 | |

| 4% to 6% Fiber | ||||||

| Gul et al. [49] | 19 | 4 | 100.16 | 0.94 | 23.4 | 83 |

| 20 | 4 | 7.62 | 0.94 | 26.2 | 93 | |

| Younis [44] | 21 | 4 | 29.00 | 0.20 | 50.4 | 178 |

| 22 | 6 | 29.00 | 0.20 | 47.2 | 167 | |

| Graeff et al. [50] | 23 | 6 | 13.00 | 0.20 | 71.4 | 122 |

| Average | 4.80 | 35.76 | 0.50 | 43.7 | 128.5 | |

a content of fibers added by weight fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

A decline of 3% and 5% was reported by Shah et al. [48] for 0.50% and 0.75% RSF, respectively. Contradictory results were reported by Akhter et al. [47] and Shah et al. [48] for 0.50% RSF. The possible reason for improved CS could be better workability and uniformity achieved with reduced length (1 mm less) and diameters of the RSF utilized by Shah et al. [48]. A reduction in CS at 0.50% and 0.75% RSF can be associated with decreased workability due to excessive RSF within the same mix. The CS increased by 1.5% by incorporating 0.39% RSF in concrete by weight fraction. All authors reported an increase in CS by using 1% and 2% RSF except Shah et al. [48], who reported a 10% decline for specimen 7.

Shah et al. [30] reported the same rhythm of decrease when RSF exceeded 0.25% of the concrete weight. At the same time, an increase in CS was reported for specimens 8 to 12, even for RSF having diameters of 100.16 mm. The maximum enhancement of 68 percent was noted in CS with 2% RSF, 29 mm long, and 0.20 mm thick [44]. Interestingly, Graeff et al. [50] and Gul et al. [49] reported an increase in CS for RSF with a minimum length of 13 mm and 7.62 mm, respectively. It can be deduced that an increase in CS can be achieved for the exact content of the RSF for varying dimensions of RSF. More RSF content can be used for small-size RSF compared to large-size RSF for achieving the same CS. For 2.5% RSF, the CS improved by 34% and 37% for specimens 13 and 14, while at 3% RSF, the CS decreased compared to 2.5% RSF concrete. A similar trend of decline in CS was reported for 3.5% RSF. However, it can be noticed that the short-length fibers could sustain a CS somewhat higher than the plain concrete at 2.5% RSF, while at 3% RSF, both types of RSF showed a decline in CS.

Therefore, maximum strength can be attained for 2% to 3% RSF by keeping the diameters of the fibers below 7.62 mm for traditional concrete mixers. A decline of 17% and 7% were reported in CS for specimens 19 and 20 when diameters of RSF were 100.16 mm and 7.62 mm, respectively. Short RSF showed less decline in CS. Interesting results are reported when 4% and 6% RSF had reduced diameters and lengths added to concrete. It was investigated that the highest increase of 78% in CS was achieved using 29 mm long RSF, which had a diameter of 0.20 mm. When the same RSF (29 mm long and 0.20 thick) was increased from 4% by weight of concrete to 6%, the increase in CS reduced from 78% to 67% [44]. An increase of 22% was noted by Graeff [50] when incorporating 6% of RSF with 13 mm length and 0.20 mm thickness. On average, no decline of CS was reported for 4% to 6% of RSF with a length of 13 mm to 29 mm and a diameter of 0.20 mm.

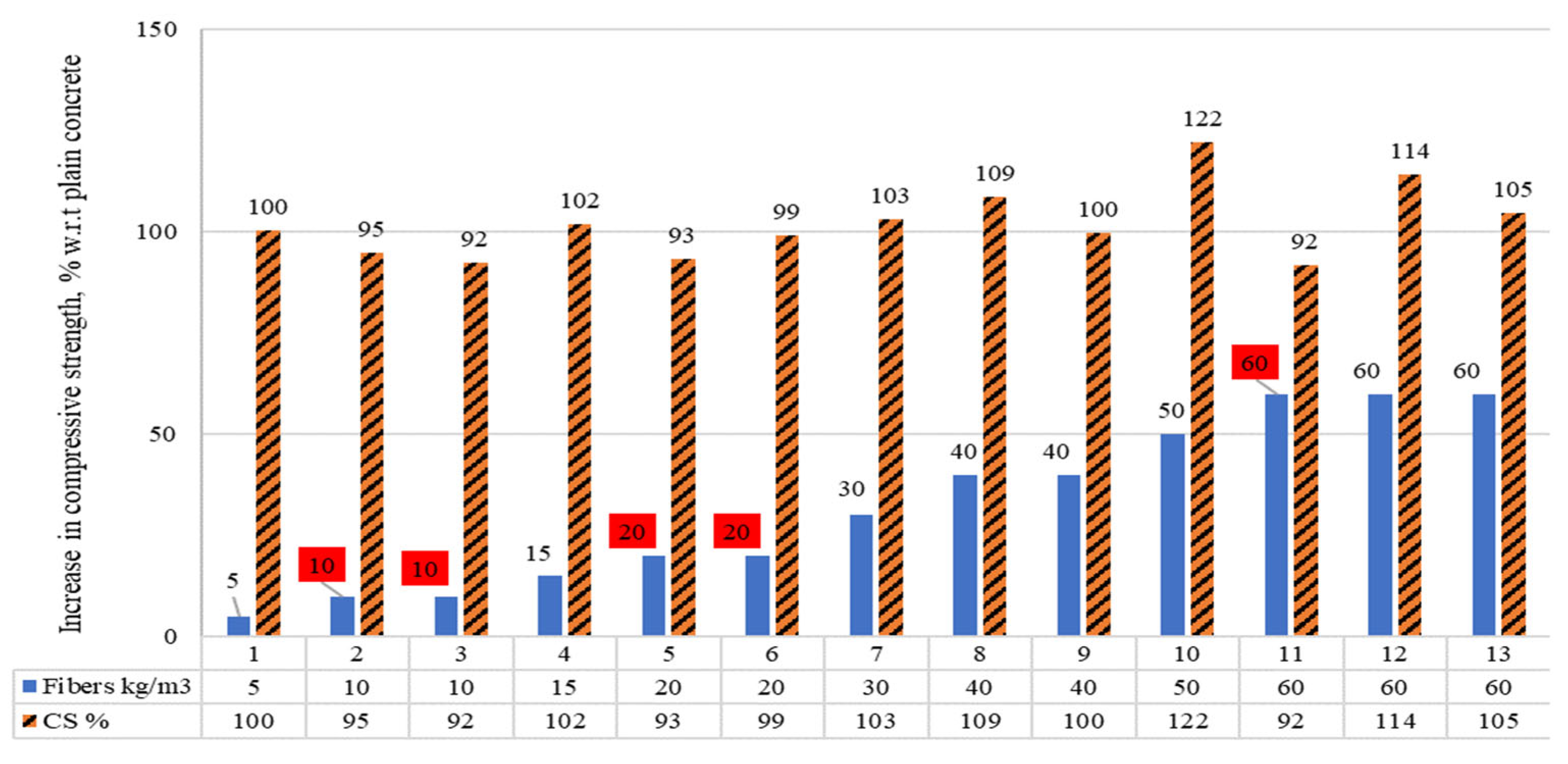

2.1.3. Compressive Strength of Concrete Using RSF Content in Kg/m3

The compressive strengths (CS) of the concrete, containing raw steel fibers recovered from waste tires (RSF) in kg/m3, are demonstrated in Figure 4. The percentages of fibers where the CS was less than the PC are displayed in the red squares. A reduction in CS is noted for specimens 2, 3, 4, 5, 6, and 9 having RSF less than or equal to 20 kg/m3. However, a 3.2 percent increase was reported for specimen seven, incorporating 30 kg/m3 RSF. Specimens reinforced with RSF of 30 kg/m3 to 60 kg/m3 showed a considerable rise in CS. Specimens 9 and 11 showed a decrease of about 1% and 8% in CS at 40 kg/m3 and 60 kg/m3, respectively. The data given in Figure 4 is presented in tabular format along with the length and diameters of the fibers used to assess the effect of the dimension of the RSF on compressive strength (CS) for the same amount of RSF.

Figure 4. Percentage comparison of the compressive strengths of concrete containing RSF in kg/m3.

The given data are shown for a particular range of RSF content in Table 4, along with the diameter and length of the fibers. For 5 to 30 kg/m3 of RSF, no significant increase (more than three percent) in CS of concrete was reported except for a decline in CS. A decline of 2% is noted in the CS of concrete for average RSF content of 15.71 kg/m3 (5 to 20 kg/m3). This is noticed for 50 mm to 52 mm-long fiber, whose average diameter ranges from 0.30 mm to 1.40 mm. Therefore, it can be suggested that the RSF content below 20 kg/m3 cannot help to improve the CS of the concrete.

Table 4. Results of compressive strength’s percent comparison and fiber properties of the concrete with RSF in kg/m3.

| Author | Specimen No. in Figure 7 | Fiber Properties | Compressive Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 30 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [51] | 1 | 5 | 52.00 | 0.30 | 69.50 | 100 |

| 2 | 10 | 52.00 | 0.30 | 65.80 | 95 | |

| 3 | 10 | 50.00 | 0.60 | 64.10 | 92 | |

| 4 | 15 | 52.00 | 0.30 | 70.60 | 102 | |

| 5 | 20 | 50.00 | 0.60 | 64.70 | 93 | |

| 6 | 20 | 50.00 | 1.40 | 68.70 | 99 | |

| 7 | 30 | 50.00 | 0.60 | 71.50 | 103 | |

| Average | 15.71 | 50.86 | 0.59 | 98 | ||

| 40 to 60 kg/m3 | ||||||

| Sengul [51] | 8 | 40 | 50.00 | 0.60 | 75.30 | 109 |

| 9 | 40 | 50.00 | 1.40 | 69.10 | 100 | |

| Pawelska-Mazur and Kaszynska [21] | 10 | 50 | 17.50 | 0.25 | 52.40 | 122 |

| Sengul [51] | 11 | 60 | 50.00 | 1.40 | 63.60 | 92 |

| Peng et al. [28] | 12 | 60 | 30.00 | 1.00 | 154.30 | 114 |

| 13 | 60 | 35.00 | 1.00 | 141.30 | 105 | |

| Average | 51.67 | 38.75 | 0.94 | - | 107 | |

a percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

On the other hand, for the RSF ranging from 20 to 40 kg/m3, significant improvement was reported by the authors in CS, except for the 8.2% decrease reported by Sengul [51] for utilizing 60 kg/m3 of RSF. The possible reason for the decrease reported by [51] is the fibers’ large diameter (1.40 mm) and considerable length (50 mm). Therefore, the average length and diameters of the fibers used in the range from 20 kg/m3 to 60 kg/m3 are 38.75 mm and 0.81 mm, respectively. Hence, it can be concluded that 60 kg/m3 of RSF can be a suitable dose for improving the CS within the limited diameter and length of the fibers. However, in-depth analysis and research are still needed to optimize the suitable diameter and length of the fibers for the different ranges of RSF dosage.

2.2. Split Tensile Strength of RSF Concrete

2.2.1. Split Tensile Strength of Concrete Using RSF Content by Its Volume Fraction

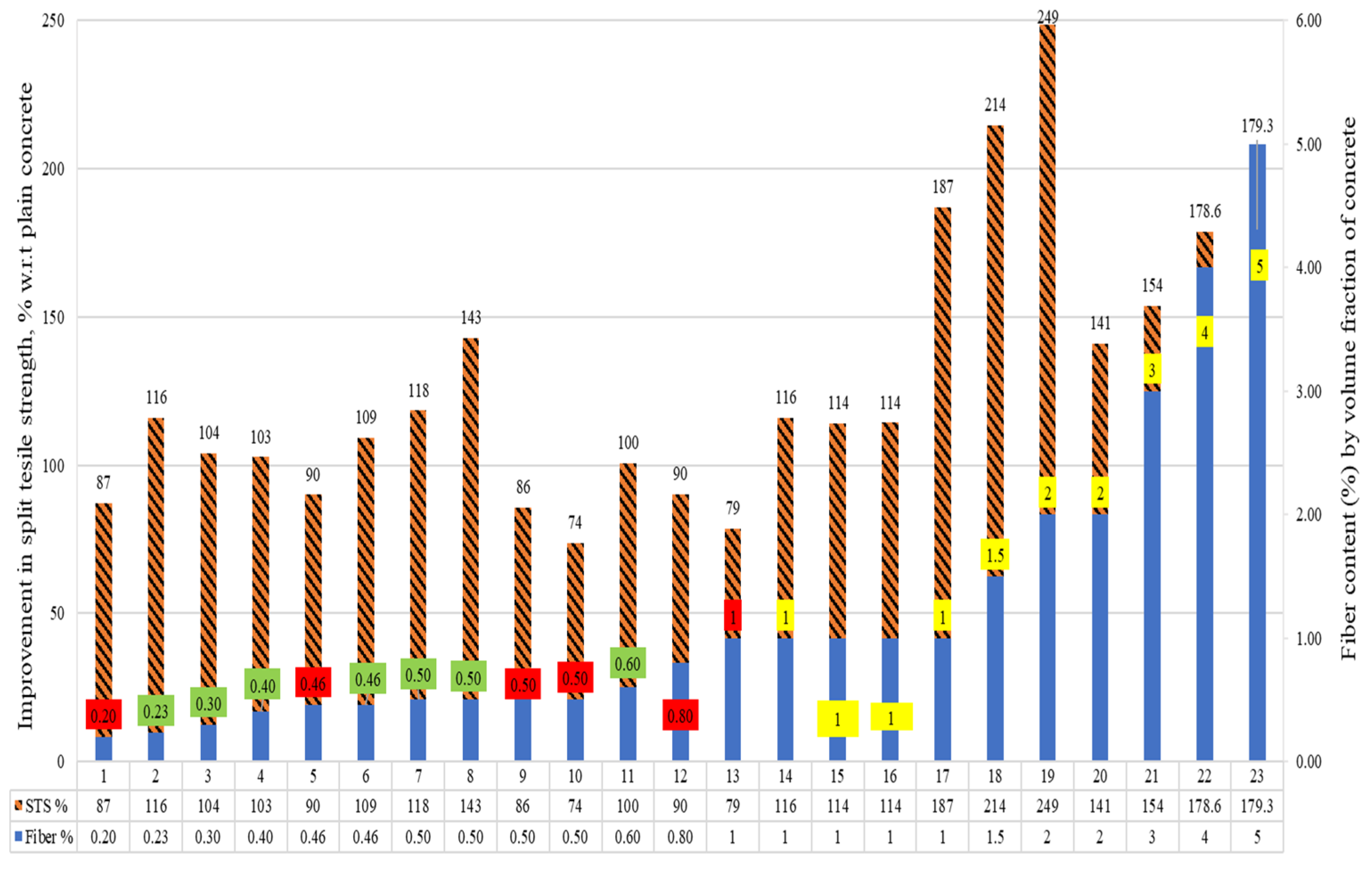

The percent comparison of the split tensile strength (STS) of the concrete, including raw steel fibers recovered from waste tires (RSF) by its volume fraction, is presented in Figure 5. An inevitable decline was reported in STS when the content of RSF was lower than 1%. However, some specimens showed a substantial increase in STS even for RSF of less than 1%. The specimens 1, 5, 9, 10, and 11 incorporating RSF of 0.20%, 0.46%, 0.50%, 0.50%, and 0.80%, respectively, showed a decrease of 13%, 10%, 14%, 26%, and 10%, respectively, in the corresponding STS. On the other hand, specimens 2, 3, 4, 6, 7, and 8, containing 0.23%, 0.30%, 0.40%, 0.46%, 0.50%, and 0.50%, respectively, showed substantial improvement of 16%, 4%, 3%, 9%, 18%, and 43%, in respective STS. No improvement in STS was reported for specimen 11 at 0.60% RSF. A decline of 10% in STS was noted only for specimen 13 at 1% of RSF. For more than 0.60% of RSF, no decline was reported. The authors noted a significant improvement in STS by adding 1%, 1.50%, 2%, 3%, 4%, and 5% of RSF, as reflected in Figure 5. In addition, the STS of the plain concrete of the concerned study is taken as a reference (equivalent to 100%) to assess the percent rise or decrease in the STS of RSF concrete.

Figure 5. Percentage comparison of split tensile strength of concrete containing RSF by volume fraction.

A certain decline was reported in STS when the content of RSF was lower than 1%. However, some specimens showed a substantial increase in STS even for RSF of less than 1%. The specimens 1, 5, 9, 10, and 11 incorporating RSF of 0.20%, 0.46%, 0.50%, 0.50%, and 0.80%, respectively, showed a decrease of 13%, 10%, 14%, 26%, and 10%, respectively, in the corresponding STS. On the other hand, specimens 2, 3, 4, 6, 7, and 8, containing 0.23%, 0.30%, 0.40%, 0.46%, 0.50%, and 0.50%, respectively, showed a substantial improvement of 16%, 4%, 3%, 9%, 18%, and 43%, in respective STS. No improvement in STS was reported for specimen 11 at 0.60% RSF. A decline of 10% in STS was noted only for specimen 13 at 1% of RSF. For more than 0.60% of RSF, no decline was reported. The authors noted a significant improvement in STS by adding 1%, 1.50%, 2%, 3%, 4%, and 5% of RSF, as reflected in Figure 5.

The data regarding the STS of RSF-incorporated concrete and the properties of RSF used in each study are in Table 5. This can help analyze the factors that can affect the split tensile strengths of concrete for the same percentage of RSF. For example, the effect of the fibers’ diameter and length can easily be observed on the STS of the concrete incorporating RSF ranging from 0.20% to 0.50%. Furthermore, it can be observed that a significant decrease, 13%, was noticed even for lengthy RSF at 0.20% [35] when traditional mixers were used.

Table 5. Results of split tensile strength’s percent comparison and fiber properties of the concrete incorporating RSF by its volume fraction.

| Author | Specimen No. in Figure 8 | Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.20% to 0.80% Fiber Content | % a | mm | mm | MPa | % b | |

| Rossli and Ibrahim [35] | 1 | 0.20 | 62.00 | 0.8 | 3.39 | 87 |

| Aiello et al. [34] | 2 | 0.23 | 26.00 | 0.258 | 2.70 | 116 |

| Leone et al. [36] | 3 | 0.30 | 31.40 | 0.24 | 4.73 | 104 |

| Rossli and Ibrahim [35] | 4 | 0.40 | 62.00 | 0.8 | 3.99 | 103 |

| Leone et al. [33] | 5 | 0.46 | 13.94 | 0.25 | 4.55 | 90 |

| Aiello et al. [34] | 6 | 0.46 | 26.00 | 0.258 | 2.54 | 109 |

| Samarakoon et al. [25] | 7 | 0.50 | 37.00 | 0.42 | 2.58 | 118 |

| Skarżyński and Suchorzewski [40] | 8 | 0.50 | 26.17 | 0.25 | 3.87 | 143 |

| Dorr et al. [42] | 9 | 0.50 | 93.60 | 1.17 | 1.80 | 86 |

| Groli et al. [37] | 10 | 0.50 | 21.00 | - | 3.1 | 74 |

| Rossli and Ibrahim [35] | 11 | 0.60 | 62.00 | 0.8 | 3.90 | 100 |

| 12 | 0.80 | 62.00 | 0.8 | 3.50 | 90 | |

| Average | 0.45 | 43.59 | 0.55 | 102 | ||

| 1% to 2% Fiber Content | ||||||

| Groli et al. [37] | 13 | 1 | 21.00 | - | 3.3 | 79 |

| Köroğlu [45] | 14 | 1 | 45.00 | 0.245 | 3.14 | 116 |

| Rossli and Ibrahim [35] | 15 | 1 | 62.00 | 0.8 | 4.44 | 114 |

| Samarakoon et al. [25] | 16 | 1 | 37.00 | 0.42 | 2.49 | 114 |

| Abdul Awal et al. [46] | 17 | 1 | 30.00 | - | 7.10 | 187 |

| 18 | 1.5 | 30.00 | - | 8.15 | 214 | |

| 19 | 2 | 30.00 | - | 9.45 | 249 | |

| Köroğlu [45] | 20 | 2 | 45.00 | 0.245 | 3.82 | 141 |

| 21 | 3 | 45.00 | 0.245 | 4.16 | 154 | |

| 22 | 4 | 45.00 | 0.245 | 4.84 | 178.6 | |

| 23 | 5 | 45.00 | 0.245 | 4.86 | 179.3 | |

| Average | 2.05 | 39.55 | 0.35 | 5.07 | 157 | |

a content of fibers added by volume fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

In comparison, Aiello et al. [34] confirmed that an advanced vertical planetary concrete mixer substantially increases STS for 0.20% of RSF. In addition, a decline of 10% was reported in STS by utilizing 0.46% RSF having 14 mm length and 0.25 mm diameter [33]. In contrast, Aiello et al. [34] noted an increase of 16% in STS at the same amount of RSF (0.46%) by using lengthy (26 mm) fibers instead of 14 mm. The other possibility for an increase in the STS achieved by Aiello et al. [34] was using a planetary concrete mixer, which helped in the dispersion of fibers. Similarly, Dorr et al. [42] reported that the STS of RSF concrete declined by 14% for 0.50% of RSF when the best mixing method was not used. Overall, if reasonable care is taken during mixing and fibers are well dispersed, a relatively suitable STS increase can be achieved using 0.46% or more RSF. This is supported by the increase in STS reported by many researchers at 0.40% or more RSF by using a conventional concrete mixer [25][35][40]. At 1% RSF, a considerable increase of 16%, 14%, 14%, and 87% was noticed for specimens 14 to 17, respectively [25][35][45][46]). In contrast, Rossli and Ibrahim [35] stated that STS decreased by 10%, including 0.80% RSF. The results reported by Rossli and Ibrahim [35] contradict other research studies, which need to be cross-verified for possible justification. But Abdul Awal et al. [46] reported an increase in STS by increasing the dosage of the RSF to 2%.

An increase of more than 100% in STS was noted for specimens 18 and 19 using 1.5% and 2% of 30 mm long RSF. In comparison, a lower increase of 41% was reported in STS at 2% RSF [45]. Similarly, an increase of 54%, 78.6%, and 79.3% was noted by incorporating 3%, 4%, and 5% to 45 mm-long RSFs in specimens 20, 21, and 22, respectively [45].

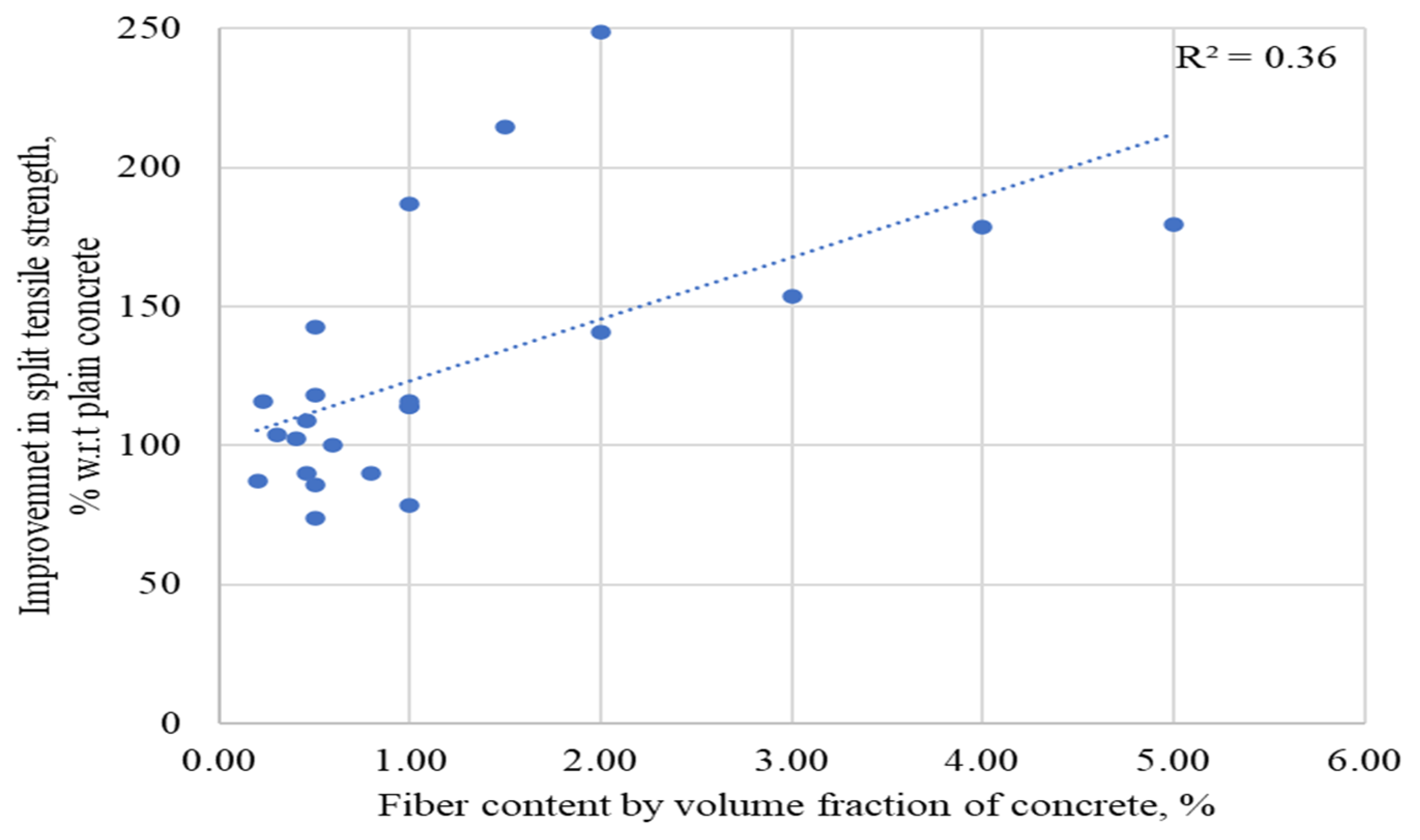

Furthermore, exploring the relation between the content of RSFs used in previous studies and percentage improvements in split tensile strengths in corresponding research is also required. Therefore, the relation between the percent improvement in STS of RSF concrete concerning plain concrete and the content of the RSFs is presented in Figure 6. It can be observed that most of the authors evaluated the split tensile behavior of RSF concrete using various sizes of RSF in amounts less than 1.5 percent. Few researchers looked at the impact of having more than 2% RSF with short fibers or an RSF mix (containing various RSFs of different sizes). The trend line illustrates that even at more than 1.5 percent RSF, the STS has the potential to improve.

Figure 6. Percent comparison of RSF content with a percent increase in split tensile strength of RSF concrete.

The available database’s coefficient of regression (R2) is not very low (R2 = 0.36); however, an increased database of concrete STSs containing RSF by volume fraction can help obtain a clear image of the effect of more than 2% RSF. In addition, the various dimensional parameters of RSF must be considered to specify the trend of the increase in STS of the RSF concrete at a specific percentage of RSF.

2.2.2. Split Tensile Strength of Concrete Using RSF Content by Weight

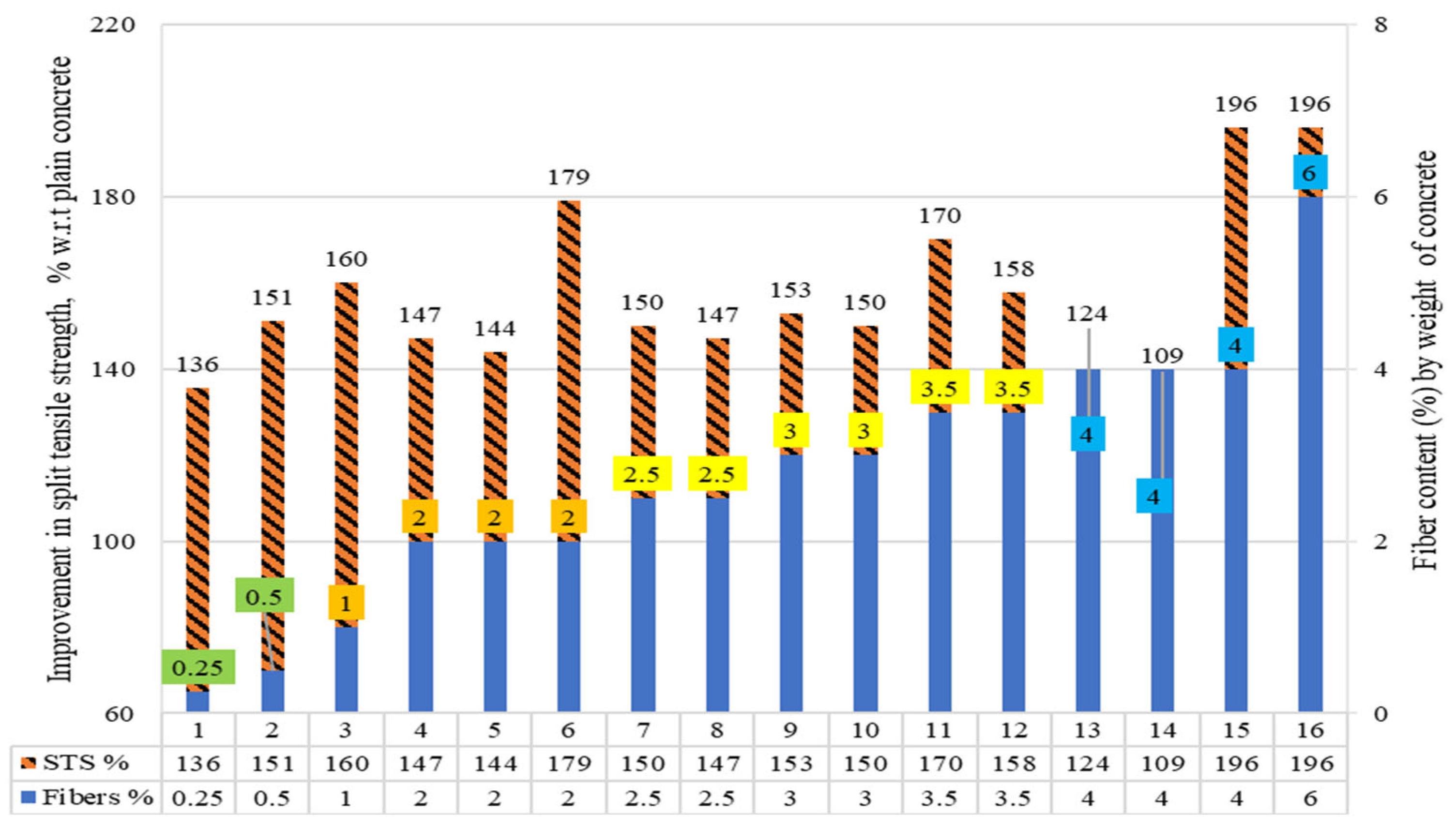

The split tensile strength (STS) of the concretes containing raw steel fibers recovered from waste tires (RSF) by their weight fraction is shown in Figure 7. The percentages of fibers where the STS was less than the PC are displayed in the red squares. The remaining colored boxes each indicate a certain range of RSF dosages.

Figure 7. Percentage comparison of split tensile strength of concrete containing RSF by weight.

The percent comparison among the results was revealed and discussed. The STS of the plain concrete of the concerned study was taken as a reference (equivalent to 100%) to assess the percent rise or decrease in the STS of RSF concrete. No decline was reported when including 0.25% to 6% of RSF in concrete by weight fraction. On the other hand, an increase of 9% to 96% was reported for RSF concrete compared to plain concrete. The STS of RSF-included concrete is summarized in Table 6, and the parameters of RSF employed in each study are also listed. This can assist in determining what factors influenced the split tensile strengths of concrete for the same RSF percentage. For example, maximum STS was reported for 1.1 mm thick RSF whose length was 30 mm when RSF varied from 0.25% to 1% by weight of concrete.

Table 6. Results of split tensile strength’s percent comparison and fiber properties of the concrete incorporating RSF by its weight fraction.

| Author | Specimen Number In Figure 10 |

Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.25% to 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Akhtar et al. [47] | 1 | 0.25 | 30 | 1.1 | 6.10 | 135.6 |

| 2 | 0.5 | 30 | 1.1 | 6.80 | 151.1 | |

| 3 | 1 | 30 | 1.1 | 7.20 | 160.0 | |

| Average | 0.58 | 30.00 | 1.10 | 148.89 | ||

| 2% to 3.5% Fiber Content | ||||||

| Gul et al. [49] | 4 | 2 | 100.16 | 0.94 | 3.45 | 147.1 |

| 5 | 2 | 7.62 | 0.94 | 3.38 | 144.1 | |

| Younis [44] | 6 | 2 | 29.00 | 0.20 | 4.20 | 179.1 |

| Gul et al. [49] | 7 | 2.5 | 100.16 | 0.94 | 3.52 | 150.0 |

| 8 | 2.5 | 7.62 | 0.94 | 3.45 | 147.1 | |

| 9 | 3 | 100.16 | 0.94 | 3.59 | 152.9 | |

| 10 | 3 | 7.62 | 0.94 | 3.52 | 150.0 | |

| 11 | 3.5 | 100.16 | 0.94 | 3.99 | 170.3 | |

| 12 | 3.5 | 7.62 | 0.94 | 3.70 | 157.9 | |

| Average | 2.67 | 51.12 | 0.86 | 155.39 | ||

| 4% to 6% Fiber Content | ||||||

| Gul et al. [49] | 13 | 4 | 100.16 | 0.94 | 2.90 | 123.5 |

| 14 | 4 | 7.62 | 0.94 | 2.55 | 108.8 | |

| Younis [44] | 15 | 4 | 29.00 | 0.20 | 4.60 | 196.2 |

| 16 | 6 | 29.00 | 0.20 | 4.60 | 196.2 | |

| Average | 4.50 | 41.45 | 0.57 | - | 156.18 | |

a content of fibers added by weight fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

Furthermore, when typical mixers were utilized, a considerable enhancement of 70.3 percent was seen in STS, even for long RSF (100 mm length) at 3.5 percent [49]. Younis [44] reported a maximum increase in STS by adding 2% of 29 mm long and 0.20 mm thick RSF. For 4% to 6% RSF, a decrease in STS was noted for specimens 13 and 14 compared to concrete, including same-size RSF in 3.5%. Still, the STS didn’t decline below the STS of plain concrete.

In contrast, a higher increase of 96% in split tensile strengths was noted for 4% and 6% RSF having small diameter and length compared to RSF of specimens 13 and 14. It showed that the diameter of the RSF can also have a detrimental effect on the concrete’s STS as the length of the RSF. Therefore, for optimizing RSF dose, the diameters of RSF need to be considered for the same length of RSF.

2.2.3. Split Tensile Strength of Concrete Containing RSF Content in kg/m3

The split tensile strength (STS) of the concrete, including raw steel fibers recovered from waste tires (RSF) in kg/m3, is shown in Figure 8. Comparisons among the STSs are shown. The red squares show the percentages of fibers where the STS was less than the PC. For the percent rise or decrease in STS of RSF concrete, the STS of plain concrete in the concerned study was used as a reference (equal to 100 percent). It was noticed that significant improvement in the STS was not reported when using 20 kg/m3 or less than 20 kg/m3 of RSF, except for specimen five, which showed a 7% rise in STS at 20 kg/m3 RSF. Most of the research studied demonstrated a noticeable increase in STS when incorporating more than 20 kg/m3 RSF. Specimens seven to thirteen showed an increment of 18%, 34%, 7%, 43%, 7.5%, 4%, 27%, and 36%, respectively, in their STS as compared to plain concrete. It showed the potential of the RSF to increase the split tensile strength of the concrete when the ratio of RSF was 20 kg/m3 or more.

Figure 8. Percentage comparison of split tensile strengths of concrete containing RSF in kg/m3.

The data in Figure 8 are presented in Table 7, as well as the properties of the RSF used in the corresponding study. The table can help better understand the effect of RSF dimension on split tensile strength (STS) for the same range of RSF percentage. There was a decrease in STS of concrete with RSF 5 to 20 kg/m3, except for specimens five and six. The STS was improved when the content of the same RSF was increased for the same mix from 10 kg/m3 to 20 kg/m3 [51]. However, increasing the diameter of RSF for the same quantity decreased the STS of concrete as reported for specimen five (small diameter RSF) compared to specimen six (large diameter RSF).

Table 7. Results of split tensile strength’s percent comparison and fiber properties of the concrete incorporating RSF in kg/m3.

| Author | Specimen No. in Figure 11 | Fiber Properties | Split Tensile Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 20 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [51] | 1 | 5 | 52.00 | 0.30 | 5.60 | 84 |

| 2 | 10 | 52.00 | 0.30 | 6.50 | 97 | |

| 3 | 10 | 50.00 | 0.60 | 6.00 | 90 | |

| 4 | 15 | 52.00 | 0.30 | 6.60 | 99 | |

| 5 | 20 | 50.00 | 0.60 | 7.20 | 107 | |

| 6 | 20 | 50.00 | 1.40 | 6.80 | 101 | |

| 7 | 30 | 50.00 | 0.60 | 7.90 | 118 | |

| Average | 15.71 | 50.86 | 0.59 | - | 99 | |

| 20 to 60 kg/m3 | ||||||

| Sengul [51] | 8 | 40 | 50.00 | 0.60 | 9.00 | 134 |

| 9 | 40 | 50.00 | 1.40 | 7.20 | 107 | |

| Pawelska-Mazur and Kaszynska [21] | 10 | 50 | 17.50 | 0.25 | 3.87 | 143 |

| Sengul [51] | 11 | 60 | 50.00 | 1.40 | 7.00 | 104 |

| Peng et al. [28] | 12 | 60 | 30.00 | 1.00 | 8.75 | 127 |

| 13 | 60 | 35.00 | 1.00 | 9.39 | 136 | |

| Average | 51.67 | 38.75 | 0.94 | - | 125 | |

a percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

Overall, the average dose of 15.71 kg/m3 RSF with an average length and diameter of 50.86 mm and 0.59 mm reduced STS. However, for all reported diameters and lengths, the RSF ranging from 20 to 60 kg/m3, the authors noted a significant increase in STS. The highest increase of 43% in STS was reported by Pawelska-Mazur and Kaszynska [21] when RSF had a 17.50 mm length and 0.25 mm diameter. It can be noted that the short fibers with a length of less than 20 mm and a diameter of less than 0.30 mm could be more beneficial in increasing the STS even at 60 kg/m3. For long fibers that were 50 mm long, the STS increased 34% at 40 kg/m3. When the content of the same-size fibers increases from 40 to 60 kg/m3, the STS enhancement lowers to 4% [51]. At the same 60 kg/m3 content of RSF, the 50 mm long and 1.40 mm thick RSF showed a lesser improvement of 4% in STS, and small-sized RSF (30–35 mm long and 1 mm thick) showed a higher enhancement of 27% and 36% for 30 mm long and 35 mm long RSFs, respectively. This showed that at the same proportion of RSF, an increase in STS can differ for different sizes of RSFs.

2.3. Flexure Strength of RSF Concrete

2.3.1. Flexure Strength of Concrete Using RSF Content by Its Volume Fraction

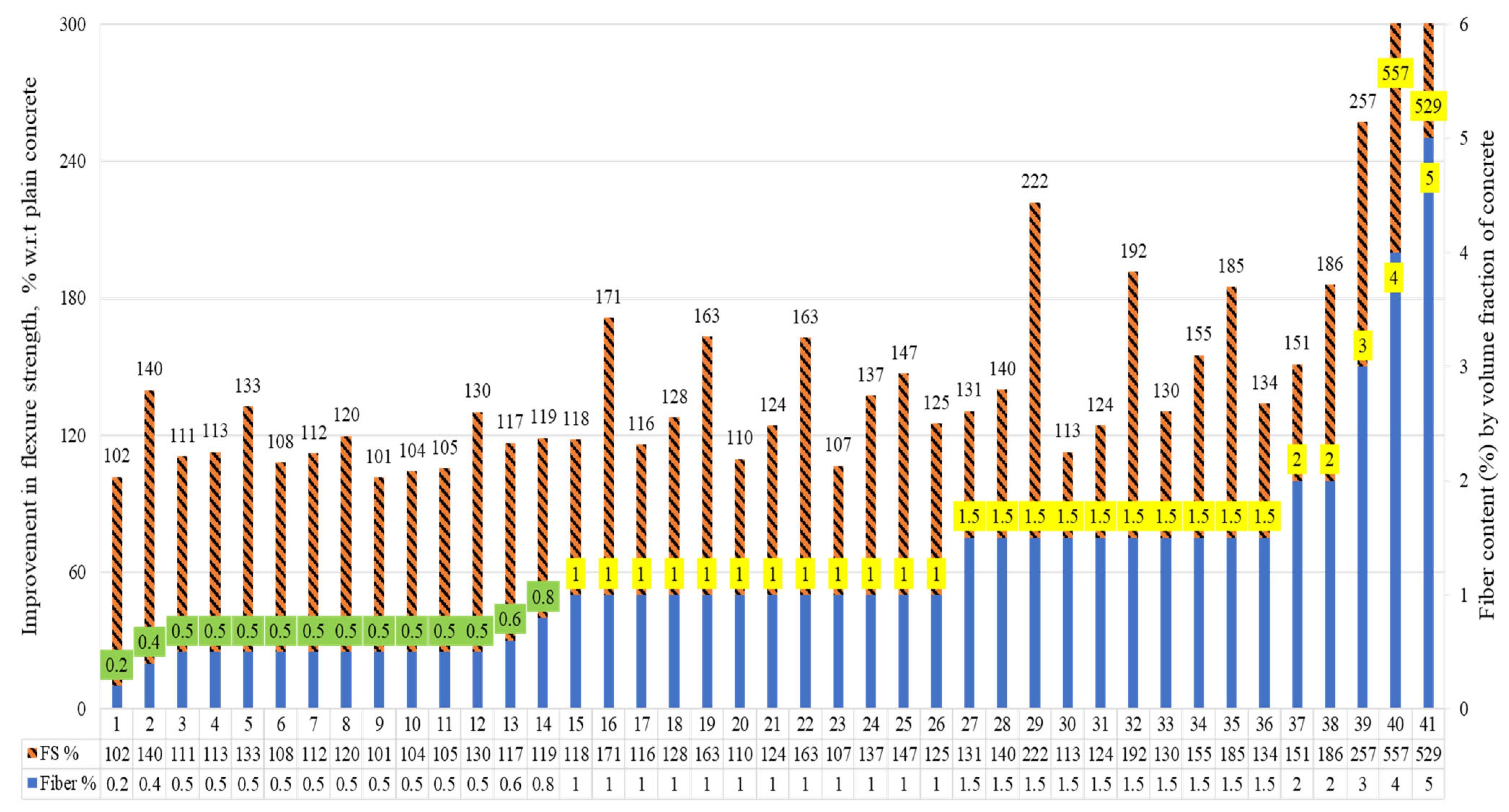

The flexural strengths (FSs) of the concrete, in which the raw steel fibers recovered from waste tires (RSF) were added by its volume fraction, are demonstrated in Figure 9.

Figure 9. Percentage comparison of the flexure strength of concrete containing RSF by volume fraction.

The percent increase and decrease are reported with reference to plain concrete. All specimens demonstrated a significant rise in FS with RSF of 0.20 percent to 5 percent. The contents of the RSFs used were 0.20%, 0.40%, 0.50%, 0.60%, 0.80%, 1%, 1.5%, 2%, 3%, 4%, and 5% by volume fraction of concrete. The enhancement in FS to plain concrete was 2% to 457% for RSF concrete.

The flexure strength of concrete specimens incorporating RSF by volume fraction and properties of RSF are provided in Table 8. The enhancement in FS increased from 2% to 40% when RSF enhanced from 0.2% to 0.4% and had a length and diameter of 62 mm and 0.80 mm, respectively [35], while the rise in FS was decreased when [35] increased the RSF content from 0.40% to 0.60% and 0.80%. A slight increase of 2% (117% to 119%) in FS was reported when RSF was increased from 0.60% to 0.80% for specimens 13 and 14, respectively. A considerable increase of 33% in FS was confirmed by [38] at 0.50% RSF for specimen five, for which the length and diameter of RSF were 60 mm and 0.89 mm, respectively. Siraj and Kedir [38] noted that within the range of 0.50% RSF, the longest (60 mm) fibers performed well in improving FS as compared to smaller (20 mm and 40 mm).

Table 8. Results of flexure strength’s percent comparison and fiber properties of the concrete incorporating RSF by its volume fraction.

| Author | Specimen Number in Figure 14 |

Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.25% to 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Shah et al. [48] | 1 | 0.10 | 31.00 | - | 5.23 | 116 |

| 2 | 0.25 | 31.00 | - | 5.7 | 127 | |

| Akhtar et al. [47] | 3 | 0.25 | 30.00 | 1.10 | 9.3 | 124 |

| Shah et al. [48] | 4 | 0.50 | 31.00 | - | 6.41 | 142 |

| Akhtar et al. [47] | 5 | 0.50 | 30.00 | 1.10 | 11.8 | 157 |

| Shah et al. [48] | 6 | 0.75 | 31.00 | - | 5.63 | 125 |

| 7 | 1 | 31.00 | - | 5.53 | 123 | |

| Akhtar et al. [47] | 8 | 1 | 30.00 | 1.10 | 12.8 | 171 |

| Average | 0.54 | 30.63 | 1.10 | 136 | ||

| 2% to 3.5% Fiber Content | ||||||

| Akhtar et al. [49] | 9 | 2 | 100.16 | 0.94 | 7.17 | 179 |

| 10 | 2 | 7.62 | 0.94 | 6.34 | 159 | |

| Younis [44] | 11 | 2 | 29.00 | 0.20 | 4.60 | 100 |

| Graeff et al. [50] | 12 | 2 | 13.00 | 0.20 | 6.47 | 135 |

| Gul et al. [49] | 13 | 2.5 | 100.16 | 0.94 | 7.72 | 193 |

| 14 | 2.5 | 7.62 | 0.94 | 6.62 | 166 | |

| 15 | 3 | 100.16 | 0.94 | 8.97 | 224 | |

| 16 | 3 | 7.62 | 0.94 | 7.45 | 186 | |

| 17 | 3.5 | 100.16 | 0.94 | 10.5 | 262 | |

| 18 | 3.5 | 7.62 | 0.94 | 8.14 | 203 | |

| Average | 2.60 | 47.31 | 0.79 | 181 | ||

| 4% to 6% Fiber Content | ||||||

| Gul et al. [49] | 19 | 4 | 100.16 | 0.94 | 9.1 | 228 |

| 20 | 4 | 7.62 | 0.94 | 8.9 | 222 | |

| Younis [44] | 21 | 4 | 29.00 | 0.20 | 5 | 109 |

| 22 | 6 | 29.00 | 0.20 | 4.8 | 104 | |

| Graeff et al. [50] | 23 | 6 | 13 | 0.2 | 7.11 | 148 |

| Average | 4.80 | 35.76 | 0.50 | 162 | ||

a content of fibers added by weight fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

An increment of 30% was also reported for specimen 12 at 0.50% RSF with 26.17 mm length and 0.25 mm diameter. This confirms that RSF can help improve the FS when added in a small dose of 0.4% by volume of concrete. However, while the long fibers can perform well, the maximum optimized length for better performance of the concrete in flexure still needs to be explored in depth.

For specimens 15 to 41, the flexure strength increased by adding the content of RSF from 1% to 1.5% for the same-size RSF [38]. Similarly, the increasing trend in flexure strength by increasing the RSF from 1% to 2% was also confirmed by Abdul Awal et al. [46]. For specimens 26, 36, and 37, an increase of 25%, 34%, and 51% was observed for 1%, 1.5%, and 2%, respectively, of RSF.

Significant increases of 157%, 457%, and 429% in FS were reported for specimens 38 to 41 for incorporation of 3%, 4%, and 5% of RSF, respectively [45]. All factors confirmed that a significant enhancement could be achieved for different dosages of RSF ranging from 0.4% to 2% by volume of concrete. The lengths of the RSF used in various studies were 20 mm, 26.17 mm, 30 mm, 40 mm, 60 mm, and 62 mm. The diameters of the RSF used were 0.25 mm, 0.80 mm, and 0.89 mm. The long-fiber (more than 62 mm) and thick-fiber (with a diameter of more than 0.89 mm) RSFs need to be investigated to check their optimized content within 0.40% to 2%.

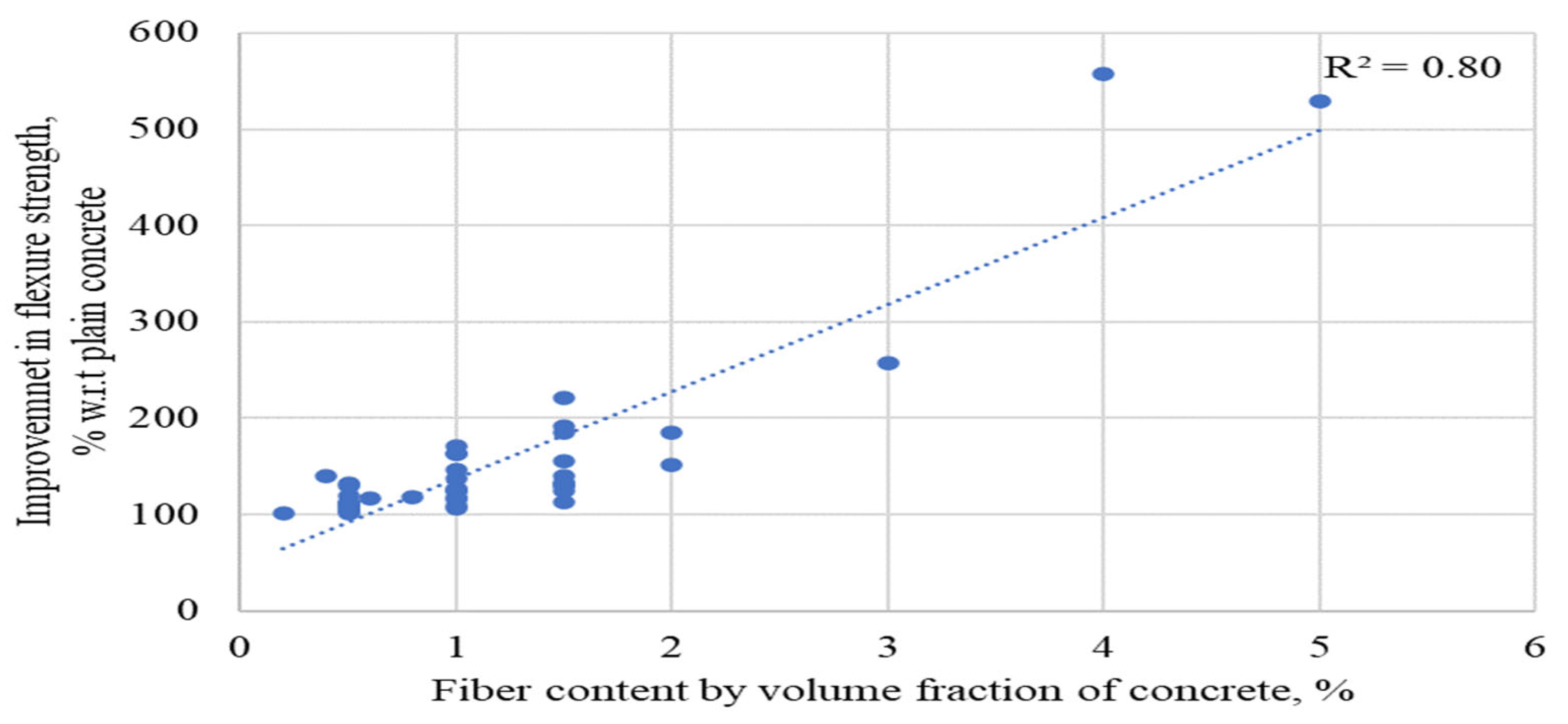

Investigating the relationship between the content of RSFs employed in prior experiments and % gains in flexure strengths in a subsequent study is necessary. Figure 10 shows the relationship between the percent changes in STS of RSF concrete compared to plain concrete and the RSF content by volume fraction of concrete.

Figure 10. Percent comparison of RSF content with a percent increase in flexure strength of RSF concrete.

Most researchers examined the flexure behavior of RSF concrete using various sizes of RSF in amounts less than 1.5 percent, as can be seen. On the other hand, few studies have examined the effects of having more than 2% RSF with short fibers or an RSF mix (containing various RSFs of different sizes). Nevertheless, the trend line shows that the FS has the potential to improve at even more than 2 percent RSF. The graph’s coefficient of regression (R2) is good (R2 = 0.80); however, a more extensive database of split tensile testing results of concrete containing RSF by its volume fraction may assist in obtaining a clear picture of the effect for more than 2% RSF. Furthermore, the various RSF dimension aspects must be considered to specify the trend of the rise in STS of RSF concrete at a certain percentage of RSF.

2.3.2. Flexure Strength of Concrete Using RSF Content by Weight Fraction

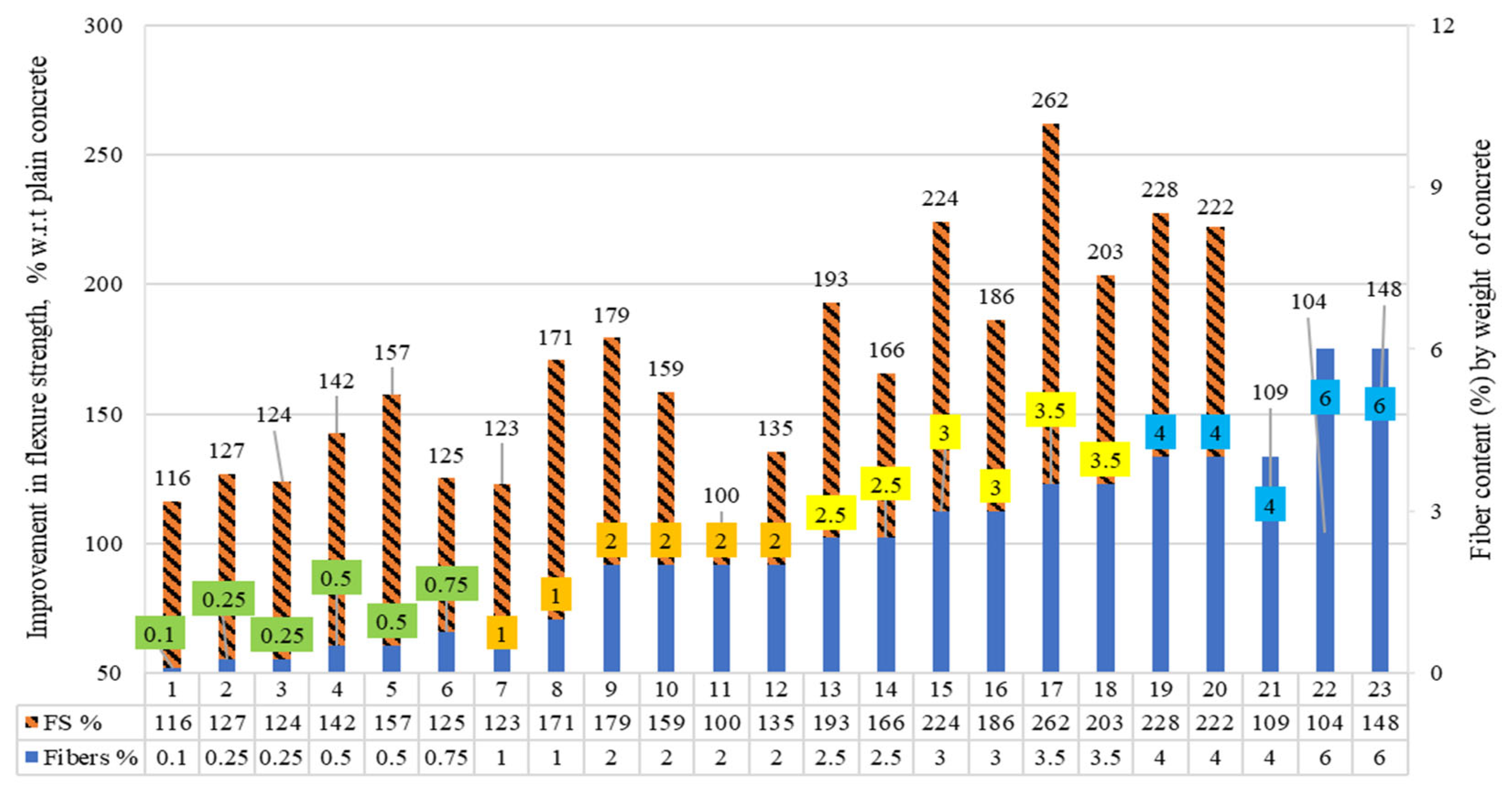

Figure 11 shows the concrete’s flexural strengths (FSs), in which raw steel fibers recovered from waste tires (RSF) were added by the weight fraction of concrete. The percentage growth and reduction are presented in comparison to plain concrete.

Figure 11. Percentage comparison of flexure strength of concrete containing RSF by weight.

By adding RSF 0.10 percent to 6%, all specimens showed a significant increase in FS except specimen 11. Only specimen 11 showed no improvement in FS for the inclusion of 2% of RSF by concrete weight.

Table 9 shows the flexure strength of concrete specimens possessing RSF by weight fraction and RSF characteristics. The FS of RSF concrete did not decline between the authors’ RSF ranges. When RSF climbed from 0.10 percent to 1 percent and had a length of 30 mm and 31 mm and diameter of 0.80 mm, enhancement in FS increased from 16% to 71%.

Table 9. Results of flexure strength’s percent comparison and fiber properties of the concrete incorporating RSF by weight fraction.

| Author | Specimen Number in Figure 14 |

Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 0.25% to 1% Fiber Content | % a | mm | mm | MPa | % b | |

| Shah et al. [48] | 1 | 0.10 | 31.00 | - | 5.23 | 116 |

| 2 | 0.25 | 31.00 | - | 5.7 | 127 | |

| Akhtar et al. [47] | 3 | 0.25 | 30.00 | 1.10 | 9.3 | 124 |

| Shah et al. [48] | 4 | 0.50 | 31.00 | - | 6.41 | 142 |

| Akhtar et al. [47] | 5 | 0.50 | 30.00 | 1.10 | 11.8 | 157 |

| Shah et al. [48] | 6 | 0.75 | 31.00 | - | 5.63 | 125 |

| 7 | 1 | 31.00 | - | 5.53 | 123 | |

| Akhtar et al. [47] | 8 | 1 | 30.00 | 1.10 | 12.8 | 171 |

| Average | 0.54 | 30.63 | 1.10 | 136 | ||

| 2% to 3.5% Fiber Content | ||||||

| Akhtar et al. [49] | 9 | 2 | 100.16 | 0.94 | 7.17 | 179 |

| 10 | 2 | 7.62 | 0.94 | 6.34 | 159 | |

| Younis [44] | 11 | 2 | 29.00 | 0.20 | 4.60 | 100 |

| Graeff et al. [50] | 12 | 2 | 13.00 | 0.20 | 6.47 | 135 |

| Gul et al. [49] | 13 | 2.5 | 100.16 | 0.94 | 7.72 | 193 |

| 14 | 2.5 | 7.62 | 0.94 | 6.62 | 166 | |

| 15 | 3 | 100.16 | 0.94 | 8.97 | 224 | |

| 16 | 3 | 7.62 | 0.94 | 7.45 | 186 | |

| 17 | 3.5 | 100.16 | 0.94 | 10.5 | 262 | |

| 18 | 3.5 | 7.62 | 0.94 | 8.14 | 203 | |

| Average | 2.60 | 47.31 | 0.79 | 181 | ||

| 4% to 6% Fiber Content | ||||||

| Gul et al. [49] | 19 | 4 | 100.16 | 0.94 | 9.1 | 228 |

| 20 | 4 | 7.62 | 0.94 | 8.9 | 222 | |

| Younis [44] | 21 | 4 | 29.00 | 0.20 | 5 | 109 |

| 22 | 6 | 29.00 | 0.20 | 4.8 | 104 | |

| Graeff et al. [50] | 23 | 6 | 13 | 0.2 | 7.11 | 148 |

| Average | 4.80 | 35.76 | 0.50 | 162 | ||

a content of fibers added by weight fraction of concrete, b percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

When 30 mm long RSF content increased from 0.10 percent to 0.25 percent and 0.80 percent, improvement in FS compared to plain concrete increased from 16% to 27% [48]. While at the same 0.35% content of 31 mm long RSF, an increase of 24% was reported for specimen three [47]. Similarly, the improvement in FS was 42% and 57% for specimens four [48] and five [47] at 0.50% RSF. However, dissimilarity among the results was noted by researchers for 0.75% and 1% RSF, at 0.75% and 1% of 30 mm RSF. Compared to plain concrete, an enhancement in FS reduced from 42% (at 0.50% RSF) to 25% and 23% for specimens six and seven, respectively [48]. Hence, using 30 mm RSF, the FS started declining gradually to increase RSF from 0.50%. However, at the same 1% content of 31 mm RSF, an increase of 71% in FS was reported for specimen eight [47]. The possible reason can be a difference in the homogeneity of the mixture with each author, while the other possible explanation could be the large 1.10 mm thickness of the RSF used in specimens six and seven [48]. However, both studies cannot be compared because the diameters of the fibers were not given for specimens six and seven [48].

For the RSF content of 2% to 3.5%, the maximum increase in FS was 162% compared to plain concrete at 3.5% RSF, which had a 100.16 mm length and 0.94 mm thickness for specimen 17 [49]. At the percentage of RSF, an improvement of 101% was reported for 7.62 mm long and 0.94 mm thick RSF for specimen 18 [49]. This confirmed that decreasing the diameter of RSF for the same percentage of RSF could cause an inevitable decrease for the same concrete mixture. A similar reduction in FS for reducing the length of the fibers was supported by results reported for specimens 12 to 16 [49]. On the other hand, an incline of 35% was reported in FS, when 2% of small-size 13 mm long RSF had a diameter of 0.20 mm were incorporated in specimen 12 [50].

The contrasting results (no increase in FS) were reported for specimen 11 at 2% RSF (29 mm long and 0.20 mm thick) [44]. The possible reason could be low-strength concrete (FS = 4.60 MPa); thus, less cement paste was available to keep the mix homogeneous and uniform. For using 4% to 6% RSF, a significant increase in FS was reported for all specimens, as shown in the table. For the same-size RSF (100.16 mm long and 0.94 mm thick), the increase in FS reduced from 162% (specimen 17) to 128% (specimen 19) [49] by increasing the RSF content from 3.5% to 4%, respectively, while for the smaller-size RSF (7.62 mm and 0.94 mm diameter), the FS gradually improved from 103% to 122% for specimen 20 [49]. An increase of 9% was also reported for specimen 21 for low-strength concrete (5 MPa), incorporating 4% RSF, which was 29 mm in length and 0.20 mm in diameter [44]. However, the improvement in FS declined to 4% when the content of same-size RSF was increased to 6% for specimen 22 [44]. A similar trend of 35% and 48% increases in FS were noticed at 2% to 6% small-size RSF (13 mm length and 0.20 mm diameter), respectively, correspondingly for specimens 12 and 23 [50]. This showed that a significant enhancement in flexure strength could be achieved even at 6% RSF if rationally small-sized fibers are used, while the same strength can be achieved using less lengthy RSF in concrete. There is a dire need to evaluate the possible optimized content of RSF for the flexure strength of concrete by considering the specific size of the fibers. Still, more research studies are required to evaluate the effect of different contents of the same size of the RSF on flexure strength, particularly the addition of 5% or more of small-size RSF in concrete by weight proportion of concrete.

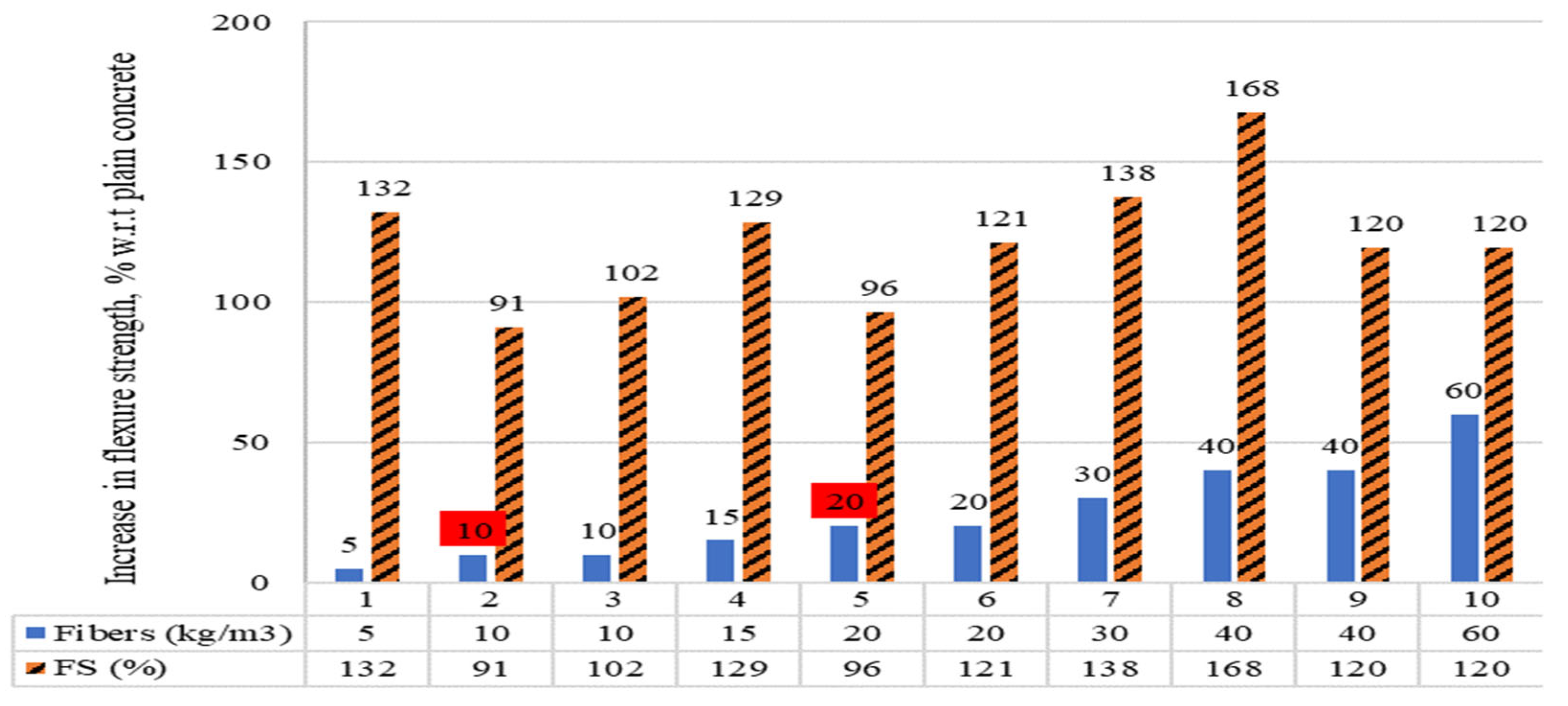

2.3.3. Flexure Strength of Concrete Using RSF Content in kg/m3

The percentage comparisons among the flexure strengths (FS) of concrete, in which raw steel fibers recovered from discarded tires (RSF) were added in kg/m3, are demonstrated in Figure 12. The percentage rise or decrease in FS of RSF concrete with respect to plain concrete is revealed. A 9% and 4% decrease in FS was noted for less than 20 kg/m3 RSF content for specimens two and five, respectively. For more than 20 kg/m3 of RSF, a decline in FS was not reported for any specimen. An increase of 32%, 29%, 2%, 21%, 38%, 68%, 20%, and 20% was reported for specimens 1, 4, 6, 7, 8, 9, and 10, respectively.

Figure 12. Percentage comparison of flexure strength of concrete containing RSF in kg/m3.

The results presented in Figure 12 are illustrated in Table 10, along with the features of the RSF. An increase of 32% and 29% were reported at 5 kg/m3 and 15 kg/m3 of 52 mm long and 0.30 mm thick RSFs for specimens one and four, respectively. The 9% decrease in FS noted for same-size RSF at 10 kg/m3 was not well-justified by the authors. Similarly, a decline of 4% in FS noted at 20 kg/m3 RSF (50 mm long and 0.60 mm thick) for specimen five was not logically justified [51].

Table 10. Results of flexure strength’s percent comparison and fiber properties of the concrete incorporating RSF in kg/m3.

| Author | Specimen Number in Figure 15 |

Fiber Properties | Flexure Strength | |||

|---|---|---|---|---|---|---|

| Content | Length | Diameter | ||||

| 5 to 20 kg/m3 | kg/m3 | mm | mm | MPa | % a | |

| Sengul [51] | 1 | 5 | 52.00 | 0.30 | 7.40 | 132 |

| 2 | 10 | 52.00 | 0.30 | 5.10 | 91 | |

| 3 | 10 | 50.00 | 0.60 | 5.70 | 102 | |

| 4 | 15 | 52.00 | 0.30 | 7.20 | 129 | |

| 5 | 20 | 50.00 | 0.60 | 5.40 | 96 | |

| 6 | 20 | 50.00 | 1.40 | 6.80 | 121 | |

| Average | - | 13.33 | 51.00 | 0.58 | - | 112 |

| 30 to 60 kg/m3 | ||||||

| Sengul [51] | 7 | 30 | 50.00 | 0.60 | 7.70 | 138 |

| 8 | 40 | 50.00 | 0.60 | 9.40 | 168 | |

| 9 | 40 | 50.00 | 1.40 | 6.70 | 120 | |

| 10 | 60 | 50.00 | 1.40 | 6.70 | 120 | |

| Average | - | 42.5 | 50.00 | 1.00 | - | 136 |

a percent increase or decrease in strength of RSF concrete w.r.t plain concrete (100%).

For the same-size RSF (50 mm long and 0.60 mm thick), an increase of 2% and 21% was noticed in FS at 10 kg/m3 and 20 kg/m3, respectively, for specimens three and six. It can be noted that at the lower percentage (5 kg/m3) for small-diameter (0.30 mm) RSF 32.1% increase in FS was noted, while the 4.5 times increase in RSF diameter (1.40 mm) showed little increase (21%) in FS at 20 kg/m3. This confirms that the diameter and length of raw steel fibers recovered from waste tires must be considered to optimize their flexure strength.

References

- Revuelta, D.; Carballosa, P.; García Calvo, J.L.; Pedrosa, F. Residual strength and drying behavior of concrete reinforced with recycled steel fiber from tires. Materials 2021, 14, 6111.

- Qin, X.; Kaewunruen, S. Environment-friendly recycled steel fibre reinforced concrete. Constr. Build. Mater. 2022, 327, 126967.

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679.

- ETRMA. European Tyre and Rubber Industry Statistics 2021; ETRMA: Brussels, Belgium, 2021.

- European Council. Council Directive 1999/31/EC of April 1999 on the Landfill of Waste. Off. J. Eur. Communities 1999, L182, 1–9.

- ETRMA. ELT-Management-Figures-2017-vf; ETRMA: Brussels, Belgium, 2019.

- Binglin, Y. Research status and prospect of waste steel fiber reinforced concrete. In Proceedings of the E3S Web of Conferences, Hangzhou, China, 13–15 August 2021; Volume 248.

- Pilakoutas, K.; Neocleous, K.; Tlemat, H. Reuse of tyre steel fibres as concrete reinforcement. Eng. Sustain. 2004, 157, 131–138.

- Gupta, T.; Sharma, R.K.; Chaudhary, S. Impact resistance of concrete containing waste rubber fiber and silica fume. Int. J. Impact Eng. 2015, 83, 76–87.

- ETRMA. ETRMA-2018. End of Life Tyres Management-Europe-Status; ETRMA: Brussels, Belgium, 2018.

- Bulei, C.; Todor, M.P.; Heput, T.; Kiss, I. Directions for material recovery of used tires and their use in the production of new products intended for the industry of civil construction and pavements. Proc. IOP Conf. Ser. Mater. Sci. Eng. 2018, 294, 012064.

- Liew, K.M.; Akbar, A. The recent progress of recycled steel fiber reinforced concrete. Constr. Build. Mater. 2020, 232, 117232.

- Scott, E. End-of-life Tyre REPORT, European Tyre & Rubber Manufacturers Association, 2015. Resour. Conserv. Recycl. 2015, 3.

- Evans, R. The Composition of a Tyre: Typical Components Creating Markets for Recycled Resources. Heliyon 2006, 5, e02139.

- Shannag, M.J. Characteristics of lightweight concrete containing mineral admixtures. Constr. Build. Mater. 2011, 25, 658–662.

- Atoyebi, O.D.; Odeyemi, S.O.; Orama, J.A. Experimental data on the splitting tensile strength of bamboo reinforced lateritic concrete using different culm sizes. Data Br. 2018, 20, 1960–1964.

- Zia, A.; Ali, M. Behavior of fiber reinforced concrete for controlling the rate of cracking in canal-lining. Constr. Build. Mater. 2017, 155, 726–739.

- Zia, A.; Khan, A.A. Effectiveness of bagasse ash for performance improvement of asphalt concrete pavements. SN Appl. Sci. 2021, 3, 502.

- Bedewi, N. Steel Fiber Reinforced Concrete Made with Fibers Extracted from Used Tyres. Master’s Thesis, Addis Ababa University, Addis Ababa, Ethiopia, 2009.

- Thomas, B.S.; Gupta, R.C.; Kalla, P.; Cseteneyi, L. Strength, abrasion and permeation characteristics of cement concrete containing discarded rubber fine aggregates. Constr. Build. Mater. 2014, 59, 204–212.

- Pawelska-Mazur, M.; Kaszynska, M. Mechanical performance and environmental assessment of sustainable concrete reinforced with recycled end-of-life tyre fibres. Materials 2021, 14, 256.

- Ayanoğlu, A.; Yumrutaş, R. Production of gasoline and diesel like fuels from waste tire oil by using catalytic pyrolysis. Energy 2016, 103, 456–468.

- Golpasand, G.B.; Farzam, M.; Shishvan, S.S. Behavior of recycled steel fiber reinforced concrete under uniaxial cyclic compression and biaxial tests. Constr. Build. Mater. 2020, 263, 120664.

- Mastali, M.; Dalvand, A.; Sattarifard, A.R.; Illikainen, M. Development of eco-efficient and cost-effective reinforced self-consolidation concretes with hybrid industrial/recycled steel fibers. Constr. Build. Mater. 2018, 166, 214–226.

- Samarakoon, S.M.S.M.K.; Ruben, P.; Wie Pedersen, J.; Evangelista, L. Mechanical performance of concrete made of steel fibers from tire waste. Case Stud. Constr. Mater. 2019, 11, e00259.

- Rutherford, S. Process for Recycling Vehicle Tires. U.S. Patent 5115983A, 26 May 1992.

- Bartolac, M.; Damjanovic, D.; Krolo, J.; Baricevic, A. Punching Shear Strength of Concrete Slabs Reinforced with Recycled Steel Fibres from Waste Tires. In Proceedings of the II International Conference on Concrete Sustainability ICCS16, Barselona, Spain, 13–15 June 2016.

- Peng, G.F.; Niu, X.J.; Long, Q.Q. Experimental study of strengthening and toughening for recycled steel fiber reinforced ultra-high performance concrete. Proc. Key Eng. Mater. 2015, 629–630, 104–111.

- Bjegovic, D.; Baricevic, A.; Lakusic, S.; Damjanovic, D.; Duvnjak, I. Positive interaction of industrial and recycled steel fibres in fibre reinforced concrete. J. Civ. Eng. Manag. 2013, 19, S50–S60.

- Centonze, G.; Leone, M.; Aiello, M.A. Steel fibers from waste tires as reinforcement in concrete: A mechanical characterization. Constr. Build. Mater. 2012, 36, 46–57.

- Caggiano, A.; Folino, P.; Lima, C.; Martinelli, E.; Pepe, M. On the mechanical response of Hybrid Fiber Reinforced Concrete with Recycled and Industrial Steel Fibers. Constr. Build. Mater. 2017, 147, 286–295.

- Shi, X.; Brescia-Norambuena, L.; Grasley, Z.; Hogancamp, J. Fracture Properties and Restrained Shrinkage Cracking Resistance of Cement Mortar Reinforced by Recycled Steel Fiber from Scrap Tires. Transp. Res. Rec. 2020, 2674, 581–590.

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Fiber-reinforced concrete with low content of recycled steel fiber: Shear behaviour. Constr. Build. Mater. 2018, 161, 141–155.

- Aiello, M.A.; Leuzzi, F.; Centonze, G.; Maffezzoli, A. Use of steel fibres recovered from waste tyres as reinforcement in concrete: Pull-out behaviour, compressive and flexural strength. Waste Manag. 2009, 29, 1960–1970.

- Rossli, S.A.; Ibrahim, I.S. Mechanical Properties of Recycled Steel Tire Fibres in Concrete; Technical Report; Universiti Teknologi Malaysia: Johor Bahru, Malaysia, 2012.

- Leone, M.; Centonze, G.; Colonna, D.; Micelli, F.; Aiello, M.A. Experimental Study on Bond Behavior in Fiber-Reinforced Concrete with Low Content of Recycled Steel Fiber. J. Mater. Civ. Eng. 2016, 28, 04016068.

- Groli, G.; Pérez Caldentey, A.; Soto, A.G. Cracking performance of SCC reinforced with recycled fibres—An experimental study. Struct. Concr. 2014, 15, 136–153.

- Siraj, N.; Kedir, N.S. Synthesis and characterization of pyrolised recycled steel fibers for use in reinforced concrete. Int. J. Eng. Sci. Manag. Res. 2017, 4, 21–32.

- Vistos, L.; Galladini, D.; Xargay, H.; Caggiano, A.; Folino, P.; Martinelli, E. Hybrid industrial/recycled SFRC: Experimental analysis and design. In Proceedings of Italian Concrete Days 2016. ICD 2016; Lecture Notes in Civil Engineering; Springer: Cham, Switzrland, 2018; Volume 10.

- Skarżyński, Ł.; Suchorzewski, J. Mechanical and fracture properties of concrete reinforced with recycled and industrial steel fibers using Digital Image Correlation technique and X-ray micro computed tomography. Constr. Build. Mater. 2018, 183, 283–299.

- Chen, M.; Si, H.; Fan, X.; Xuan, Y.; Zhang, M. Dynamic compressive behaviour of recycled tyre steel fibre reinforced concrete. Constr. Build. Mater. 2022, 316, 125896.

- Dorr, B.J.; Kanali, C.L.; Onchiri, R.O. Shear Performance of Recycled Tyres Steel Fibres Reinforced Lightweight Concrete Beam using Palm Kernel Shear as Partial Replacement of Coarse Aggregate. Int. J. Eng. Res. Technol. 2019, 12, 1818–1823.

- Mastali, M.; Dalvand, A. Fresh and Hardened Properties of Self-Compacting Concrete Reinforced with Hybrid Recycled Steel–Polypropylene Fiber. J. Mater. Civ. Eng. 2017, 29, 04017012.

- Younis, K.H. Mechanical Performance of Concrete Reinforced with Steel Fibres Extracted from Post-Consumer Tyres. In Proceedings of the 2nd Internationa Engineering Conference on Developments in Civil and Computer Applications, Erbil, Kudistan Region, Iraq, 20–21 February 2016.

- Köroğlu, M.A. Behavior of composite self-compacting concrete (SCC) reinforced with steel wires from waste tires. Rev. La Constr. 2019, 17, 484–498.

- Abdul Awal, A.S.M.; Kadir, M.A.A.; Yee, L.L.; Memon, N. Strength and Deformation Behaviour of Concrete Incorporating Steel Fibre from Recycled Tyre. In CIEC 2014, Proceedings of the International Civil and Infrastructure Engineering Conference; Springer: Singapore, 2015.

- Akhtar, T.; Ali, B.; Ben Kahla, N.; Kurda, R.; Rizwan, M.; Mohsin Javed, M.; Raza, A. Experimental investigation of eco-friendly high strength fiber-reinforced concrete developed with combined incorporation of tyre-steel fiber and fly ash. Constr. Build. Mater. 2022, 314, 125626.

- Shah, S.H.A.; Ali, B.; Ahmed, G.H.; Tirmazi, S.M.T.; El Ouni, M.H.; Hussain, I. Effect of recycled steel fibers on the mechanical strength and impact toughness of precast paving blocks. Case Stud. Constr. Mater. 2022, 16, e01025.

- Gul, A.; Alam, B.; Iqbal, M.J.; Ahmed, W.; Shahzada, K.; Javed, M.H.; Khan, E.A. Impact of Length and Percent Dosage of Recycled Steel Fibers on the Mechanical Properties of Concrete. Civ. Eng. J. 2021, 7, 1650–1666.