Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Soo-Jin Park | -- | 1761 | 2022-11-01 09:27:33 | | | |

| 2 | Camila Xu | Meta information modification | 1761 | 2022-11-02 06:10:02 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kumar, N.; Kim, S.; Lee, S.; Park, S. Ceramic-Based Hybrid Supercapacitors. Encyclopedia. Available online: https://encyclopedia.pub/entry/32270 (accessed on 01 March 2026).

Kumar N, Kim S, Lee S, Park S. Ceramic-Based Hybrid Supercapacitors. Encyclopedia. Available at: https://encyclopedia.pub/entry/32270. Accessed March 01, 2026.

Kumar, Niraj, Su-Bin Kim, Seul-Yi Lee, Soo-Jin Park. "Ceramic-Based Hybrid Supercapacitors" Encyclopedia, https://encyclopedia.pub/entry/32270 (accessed March 01, 2026).

Kumar, N., Kim, S., Lee, S., & Park, S. (2022, November 01). Ceramic-Based Hybrid Supercapacitors. In Encyclopedia. https://encyclopedia.pub/entry/32270

Kumar, Niraj, et al. "Ceramic-Based Hybrid Supercapacitors." Encyclopedia. Web. 01 November, 2022.

Copy Citation

Supercapacitors (SCs) have attracted considerable attention among various energy storage devices due to their high specific capacity, high power density, long cycle life, economic efficiency, environmental friendliness, high safety, and fast charge/discharge rates. SCs are devices that can store large amounts of electrical energy and release it quickly, making them ideal for use in a wide range of applications. They are often used in conjunction with batteries to provide a power boost when needed and can also be used as a standalone power source. They can be used in various potential applications, such as portable equipment, smart electronic systems, electric vehicles, and grid energy storage systems.

carbon-based materials

metal oxides

conductive polymers

1. Introduction

In recent years, the world has experienced an increase in development, leading to energy shortages and global warming. These problems have underscored the need for supercapacitors as green energy storage devices. Supercapacitors can store large amounts of energy and deliver excellent power, making them ideal for various applications. Supercapacitors are an increasingly attractive option in the race to develop new and improved energy storage technologies due to their high-power density and long cycle life. As the supercapacitor market grows, so does the need for improved fabrication processes and electrode materials. Supercapacitors have several advantages over other energy storage devices. They can charge and discharge quickly, making them well-suited for various applications. In addition, supercapacitors are environmentally friendly and have a long lifetime. Supercapacitors are expected to grow in the coming years as the world looks for ways to address energy shortages and global warming.

Identifying clean and renewable new energy sources and developing efficient energy storage technologies and devices for low-carbon and sustainable economic development have become important [1][2][3][4]. Common electrochemical energy storage and conversion systems include batteries, capacitors, and supercapacitors [5]. The three energy storage systems complement each other in practical applications and meet different needs in different situations. Although the three systems have different energy storage and conversion mechanisms, they are all based on similar electrochemical thermodynamics and kinetics, i.e., the process of supplying energy occurs at the phase boundary of the electrode/electrolyte interface with independent electron and ion transport [6]. Recent advances in smart electronic devices have spurred a corresponding increase in the use of supercapacitors.

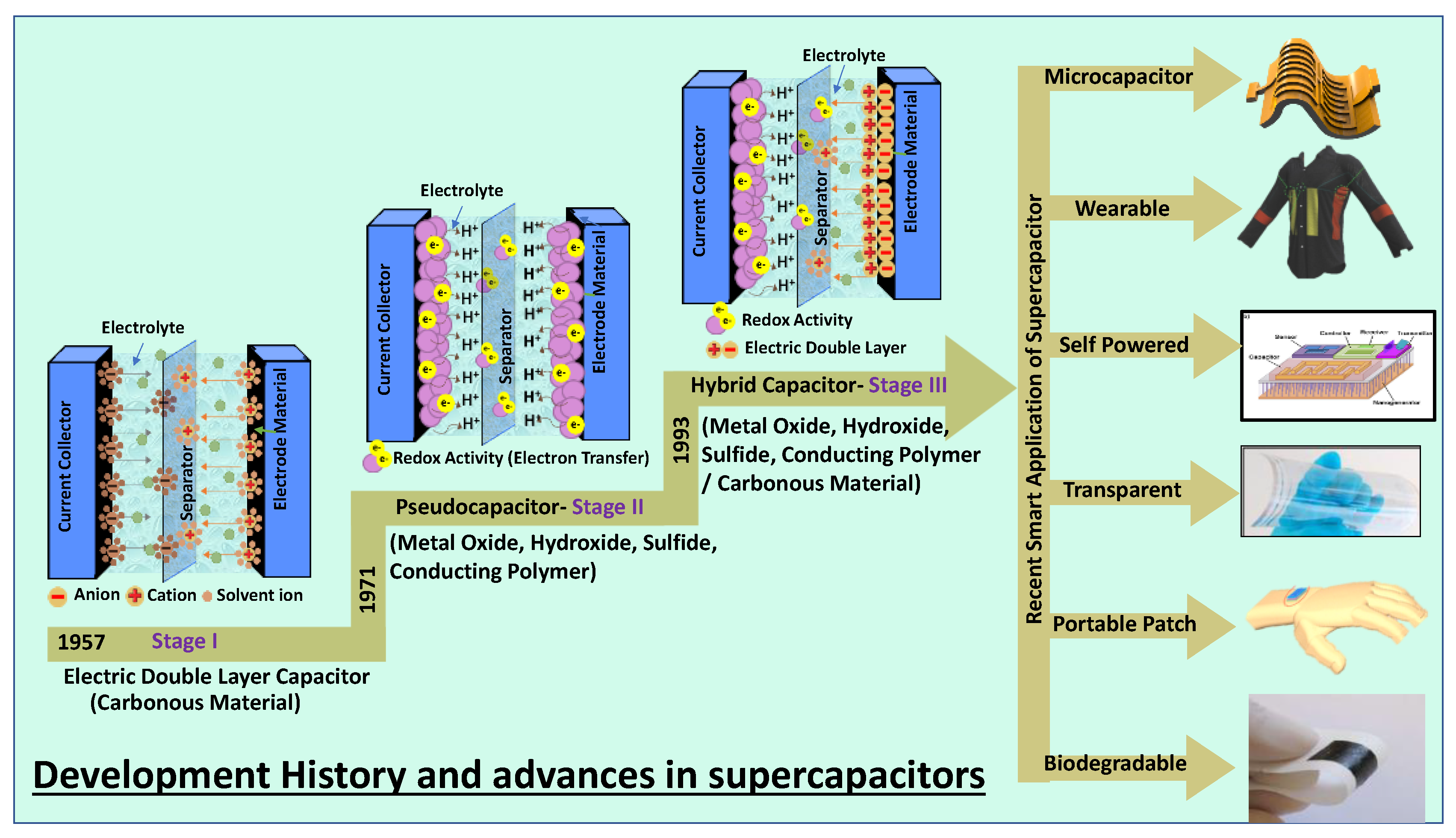

A supercapacitor is a promising energy storage device between a traditional physical capacitor and a battery. Based on the differences in energy storage models and structures, supercapacitors are generally divided into three categories: electrochemical double-layer capacitors (EDLCs), redox electrochemical capacitors (pseudocapacitors), and hybrid capacitors (Figure 1) [7]. Figure 1 summarizes the basic energy storage principles of supercapacitors with the classification as the basic framework and examines the research progress of electrode materials commonly used in recent years.

Figure 1. Classification of supercapacitors based on various electrode materials and their advanced applications.

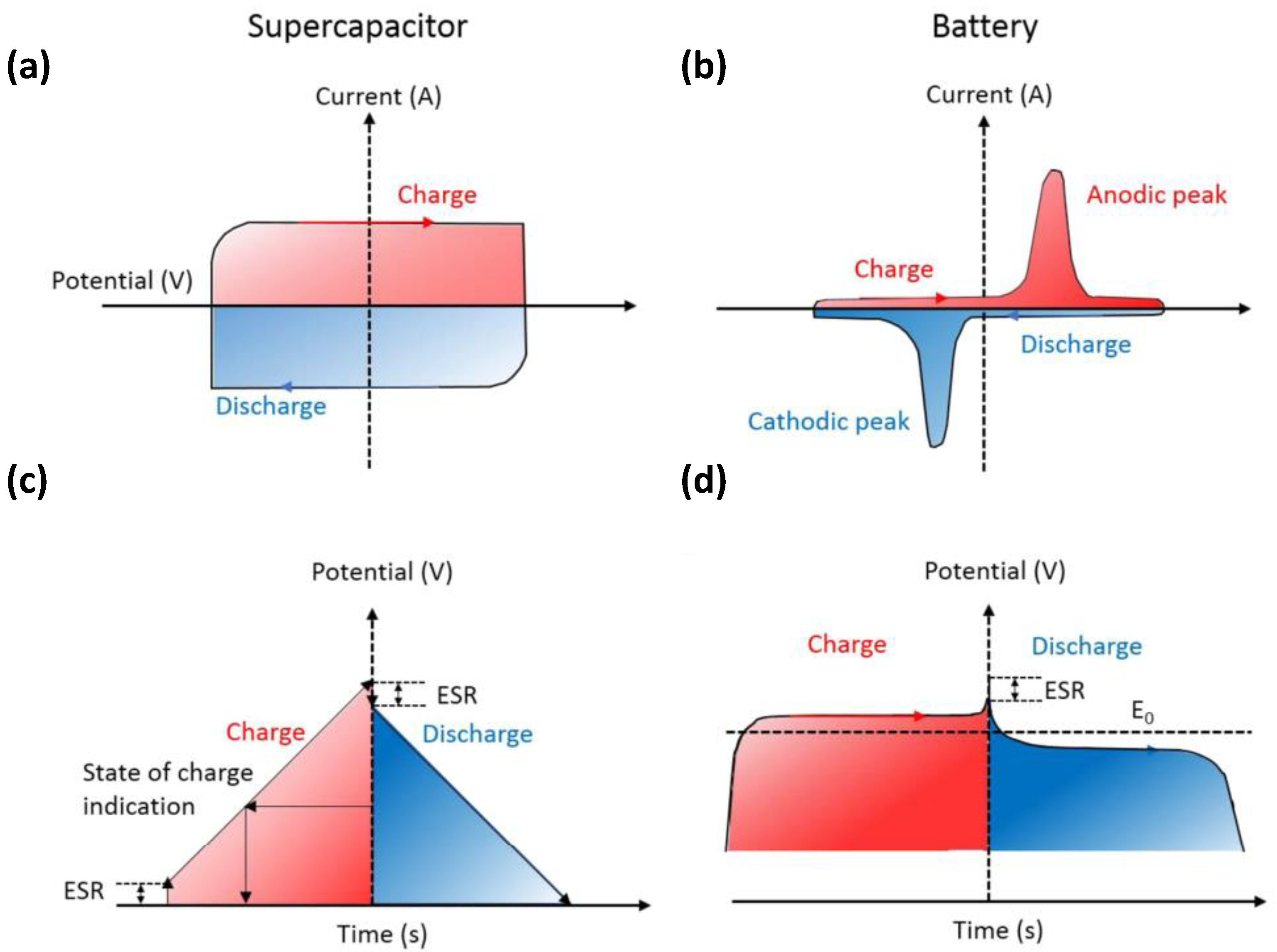

Supercapacitors are being researched extensively in smart electronics applications such as flexible, biodegradable, transparent, wearable, flexible, on-chip, and portable energy storage. In comparison with conventional capacitors, supercapacitors use materials with a high specific surface area as electrodes [8][9]. A higher specific surface area and thinner dielectrics result in greater specific capacitance and energy density. In comparison with the rated capacitance of traditional capacitors in the range between micro and milli- Farads, the capacitance of a supercapacitor unit can reach thousands of Farads. In contrast with batteries, the charge storage mechanism of supercapacitors is based on the surface reaction of the electrode material, and there is no diffusion of ions inside the material. Therefore, supercapacitors have a better power density under the same volume. Another electrochemical characteristic that is different between supercapacitors and batteries is that the charge on the electrodes of a typical supercapacitor always increases (or decreases) linearly, resulting in voltage rise (or fall) during the charge and discharge process.

As shown in Figure 2, during the charge and discharge process, the cyclic voltammetry (CV) curve of the supercapacitor (Figure 2a) remains rectangular, whereas the current is almost constant. In addition, its galvanostatic charge-discharge (GCD) curve (Figure 2c) is usually inclined with a constant slope. A battery exhibits Faradaic reactions during the charge and discharge process, and its CV curve shows a clear redox peak; it maintains a constant voltage except when it is near 100% charged/discharged (TOC/EOD) (the GCD curve shows a relatively flat charge-discharge platform).

Figure 2. (a,b) cyclic voltammetry (CV) curves and (c,d) galvanostatic charge-discharge (GCD) curves of supercapacitors and batteries. Reproduced with permission [10] Copyright © 2022, Chemical Reviews.

Supercapacitors have many other advantages, such as being environmentally friendly, having a long service life, being able to operate in wide temperature ranges, and being good at retaining charge even when large currents are applied; they are widely used in consumer electronics, smart meters, and transport [7][8][9][10]. Supercapacitors have shown that they can perform very well in some applications, but there are still several shortcomings that are relevant in some applications. These include high energy density requirements and very long working times. Notably, the areas in which supercapacitors can store charge are limited to the surfaces (or near the active surface area) of the electrodes; they have lower energy density than batteries.

2. Ceramic-Based Hybrid Supercapacitors

Most metal oxides used in pseudocapacitors are often hindered by the severe aggregation of nanoparticles, low electron–proton transport, and weak conductivity between nanoparticles, leading to a lower specific capacitance in practical applications. In order to effectively address these problems, the development of hybrid electrodes by combining metal oxides with carbon materials with a high specific surface area, such as activated carbon, graphene, CNTs, and carbon aerogels, has attracted widespread attention. Various metal oxide/carbon material composite electrodes for supercapacitors are summarized in Table 1 [11][12][13][14][15][16][17][18][19][20][21][22][23][24][25][26][27][28][29][30][31].

Table 1. Summary of various metal oxide/carbon composite electrodes for supercapacitors.

| Material | Potential Window/V | Electrolyte | Specific Capacitance/F g−1 (Scan Rate or Current Density) |

Retention/% (Cycles) |

Ref. |

|---|---|---|---|---|---|

| ZrO2 carbon nanofibers | 0–1 | 6 M KOH | 140 (1 A g−1) | 82.6 (10,000) | [32] |

| RuNi2O4/rGO composites | 0–1 | 0.5 M Na2SO4 | 792 (1 A g−1) | 93 (10,000) | [33] |

| NiO/activated carbon composites | 0–0.4 | 2 M KOH | 568.7 (0.5 A g−1) | 90.6 (5000) | [34] |

| Ni0.25Co0.25oxide/carbon nanofibers | −1–0 | 6 M KOH | 431.2 (1 A g−1) | 94 (2000) | [35] |

| MnO/Fe2O3/carbon nanofibers | 0–1 | 6 M KOH | 437 (1 A g−1) | 94 (10,000) | [36] |

| ZnO/MnO/carbon nanofibers | 0–1.6 | 6 M KOH | 1080 (1 A g−1) | 96 (800) | [37] |

| Au-Mn3O4/GO nanocomposites | −0.2–1 | 0.5 M H2SO4 | 475 (1 A g−1) | 94 (10,000) | [11] |

| Bi2O3/MWCNT composites | −1.2–0.2 | 6 M KOH | 437 (1 A g−1) | 88.7 (3000) | [12] |

| NiO/MnO2/MWCNT composites | 0–0.55 | 2 M KOH | 1320(1 A g−1) | 93.5 (3000) | [13] |

| Carbon nanosheets/MnO2/NiCo2O4 composites | 0–1 | 1 M KOH | 1254 (1 A g−1) | 81.9 (5000) | [14] |

| ZrO2/C nanocomposites | 0–1 | 1 M H2SO4 | 214 (1.5 A g−1) | 97 (2000) | [15] |

| NiO/porous amorphous carbon nanostructure | 0–1.6 | 6 M KOH | 508 (1 A g−1) | 78 (3000) | [16] |

| Defective mesoporous carbon/MnO2 nanocomposites | −0.8–0.8 | 1 M Na2SO4 | 292 (0.5 A g−1) | 79 (2000) | [17] |

| Activated carbon/MWCNT/ZnFe2O4 composites | −0.1–0.6 | 3 M KOH | 609 (1 A g−1) | 91 (10,000) | [18] |

| NiO/C@CNF composites | −0.1–0.5 | 3 M KOH | 742.2 (1 A g−1) | 88 (5000) | [19] |

| N-doped carbon quantum dots/Co3O4 nanocomposites | −0.4–0.6 | 6 M KOH | 1867 (1 A g−1) | 96 (500) | [20] |

| Mn3O4/Fe3O4@Carbon composites | −0.4–1.2 | 1 M NaCl | 178 (1 A g−1) | 95 (1000) | [21] |

| rGO/CNTs/MnO2 composites/// | 0–1.8 | 1 M Na2SO4 | 332.5 (0.5 A g−1) | 89.2 (10,000) | [22] |

| (HPC)/polyaniline (PANI) nanowire | 0–1.8 | 1 M H2SO4 | 1080 (1 A g−1) | 91.6 (5000) | [23] |

| Cyclodextrin polymer-functionalized polyaniline (CDP)/porous carbon composites(PC) | −0.2–0.8 | 6 M KOH | 437 (0.1 A g−1) | 81 (5000) | [24] |

| MnO2/Graphene Oxide/Polyaniline composites | 0–1 | 1 M Na2SO4 | 512 (0.25 A g−1) | 97 (5100) | [25] |

Because nanostructures cannot be synthesized on a large scale that allows for precise size control, their real-time application is limited [38]. In recent years, tremendous advances have been made in preparing ceramic nanostructures fabricated precisely by regulating the size, including nanorod and nanofiber structure. Carbon can be combined with ceramic nanomaterials to provide very high-energy density without sacrificing other performances (e.g., power density). Recently, Tiwari et al. [39] synthesized highly conductive MnS2/CNT and MnO2/CNT core–shell heterostructures by combining two different techniques: chemical and magnetic sputtering. With the contrast in work function between MoS2 and MnO2, they explore the maximum potential window that can be gained by implementing the asymmetric design. Self-standing prepared electrodes, which are 3-electrode configurations, provide very high capacitances of 0.41 and 0.6 Fcm−2, respectively, for MoS2/CNT and MnO2/CNT. The MoS2/CNT electrode has electrostatic polarization between −0.6 and 0.2 V, whereas the MnO2/CNT electrode has non-Faradaic charge storage between 0 and 1 V. By combining chemical and physical deposition techniques, this scalable synthesis technique allows for a massive array of edge-exposed catalytic sites available for electrode–electrolyte interaction. Hu et al. [40] synthesized NiCoO2 nanosheets using CNTs to bond them together using the hydrothermal method and fabricated integrated NiCoO2@CNTs@NF electrodes. These self-supporting electrodes have some advantages, such as having a structured 3D and very strong network, good conducting properties, and many sites where ions can be trapped and react quickly using a fast Faradaic redox reaction. NiCoO2@CNTs@NF-integrated electrodes have excellent capacitance and stability due to the outstanding synergistic effect between NiCoO2 nanosheets as Faradaic pseudocapacitance materials and CNTs as EDLC materials. The fabricated device has excellent performance because it possesses a high capacitance (151 F g−1 at 5 mA cm−2) and outstanding capability to operate at a high rate. Guo et al. [41] developed a binary network of carbon aerogel/Ni cubic carbon electrodes with thickness- and shape-independent properties. It was achieved using a very efficient and economical route consisting of the facile polymerization of technical lignin and formaldehyde in hypersaline conditions. The porosity and degree of graphitization and carbon residues in LCAN are controlled by the ratio of ZnCl2 to lignin. By precisely adjusting the ratios and combining the advantages of the LCA/Ni binary network, they thusly synthesize a cubic electrode with optimal electrochemical performance. Zhou et al. [42] used radish as a cheap catalyst and developed a facile method for synthesizing 3D carbon aerogels incorporating MnOx nanoparticles. The combination of MnOx nanoparticles and carbon nanotubes into a supercapacitor electrode material can prove beneficial, as carbon nanotubes allow for the easy transport of ions, thus enhancing the capacity of the supercapacitor. The electrochemical performance of the carbon aerogel/MnOx composite can be enhanced by the synergistic effect between carbon nanotubes and MnOx nanoparticles. Prepared carbon aerogel-based electrodes (CAE) exhibit the highest gravimetric capacitance (GP) of 557 F g−1 at a current density of 1 A g−1 in a 3-electrode system. Carbon and pseudocapacitive materials generally have high specific capacitance and high energy density and are expected to be incorporated with carbon aerogels to produce composite materials with better electrochemical performance. The combination of carbon aerogel energy density, specific capacitance and electrical conductivity could produce composite materials with higher electrochemical performance. Kumar et al. [43] used a simple and fast microwave approach to synthesize the composite rGO@CoO within a short duration of only 90 s for developing an advanced supercapacitor electrode. The hybrid composite combines the advantages of its capacitance properties with enhanced electrochemical performance, including higher specific capacitance and excellent long-term cycling stability. Transition metal oxides with various morphologies demonstrated promising electrochemical performance along with the graphene materials through synergistic contribution from each component as well as easy electrolyte ion insertion without distortion of the nanostructure.

References

- Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. In Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2010; pp. 320–329.

- Miller, J.R.; Simon, P. Electrochemical capacitors for energy management. Science 2008, 321, 651–652.

- Chu, S.; Majumdar, A. Opportunities and challenges for a sustainable energy future. Nature 2012, 488, 294–303.

- Pomerantseva, E.; Bonaccorso, F.; Feng, X.; Cui, Y.; Gogotsi, Y. Energy storage: The future enabled by nanomaterials. Science 2019, 366, eaan8285.

- Winter, M.; Brodd, R.J. What Are Batteries, Fuel Cells, and Supercapacitors? ACS Publications: Washington, DC, USA, 2004.

- Liu, J.L.; Wang, J.; Xu, C.H.; Jiang, H.; Li, C.Z.; Zhang, L.L.; Lin, J.Y.; Shen, Z.X. Advanced Energy Storage Devices: Basic Principles, Analytical Methods, and Rational Materials Design. Adv. Sci. 2018, 5, 1700322.

- Lee, J.H.; Yang, G.; Kim, C.H.; Mahajan, R.L.; Lee, S.Y.; Park, S.J. Flexible solid-state hybrid supercapacitors for the internet of everything (IoE). Energy Environ. Sci. 2022, 15, 2233–2258.

- Chen, C.J.; Zhang, Y.; Li, Y.J.; Dai, J.Q.; Song, J.W.; Yao, Y.G.; Gong, Y.H.; Kierzewski, I.; Xie, J.; Hu, L.B. All-wood, low tortuosity, aqueous, biodegradable supercapacitors with ultra-high capacitance. Energy Environ. Sci. 2017, 10, 538–545.

- Heo, Y.J.; Lee, J.H.; Kim, S.H.; Mun, S.J.; Lee, S.Y.; Park, S.J. Paper-Derived Millimeter-Thick Yarn Supercapacitors Enabling High Volumetric Energy Density. ACS Appl. Mater Interfaces 2022, 114, 42671–42682.

- Shao, Y.; El-Kady, M.F.; Sun, J.; Li, Y.; Zhang, Q.; Zhu, M.; Wang, H.; Dunn, B.; Kaner, R.B. Design and Mechanisms of Asymmetric Supercapacitors. Chem. Rev. 2018, 118, 9233–9280.

- Aydin, H.; Kurtan, U.; Demir, M.; Karakus, S. Synthesis and Application of a Self-Standing Zirconia-Based Carbon Nanofiber in a Supercapacitor. Energy Fuels 2022, 36, 2212–2219.

- Bera, S.; Miah, M.; Mondal, T.K.; Debnath, A.; Saha, S.K. Synthesis of new mixed metal oxide RuNi2O4 phase decorated on reduced graphene oxide for supercapacitor applications. Electrochim. Acta 2022, 424, 140666.

- Vinodh, R.; Babu, R.S.; Atchudan, R.; Kim, H.J.; Yi, M.; Samyn, L.M.; de Barros, A.L.F. Fabrication of High-Performance Asymmetric Supercapacitor Consists of Nickel Oxide and Activated Carbon (NiO//AC). Catalysts 2022, 12, 375.

- Mohammadpour-Haratbar, A.; Kiaeerad, P.; Mazinani, S.; Bazargan, A.M.; Sharif, F. Bimetallic nickel-cobalt oxide nanoparticle/electrospun carbon nanofiber composites: Preparation and application for supercapacitor electrode. Ceram. Int. 2022, 48, 10015–10023.

- Samuel, E.; Aldalbahi, A.; El-Newehy, M.; El-Hamshary, H.; Yoon, S.S. Flexible and freestanding manganese/iron oxide carbon nanofibers for supercapacitor electrodes. Ceram. Int. 2022, 48, 18374–18383.

- Joshi, B.; Samuel, E.; Kim, Y.; Kim, T.; El-Newehy, M.; Aldalbahi, A.; Yoon, S.S. Electrospun zinc-manganese bimetallic oxide carbon nanofibers as freestanding supercapacitor electrodes. Int. J. Energy Res. 2022.

- Rudra, S.; Deka, N.; Nayak, A.K.; Pradhan, M.; Dutta, G.K. Facile hydrothermal synthesis of Au-Mn3O4 decorated graphene oxide nanocomposites for solid-state supercapacitor. J. Energy Storage 2022, 50, 104615.

- Zhang, D.X.; Xiang, Q. Electrophoretic co-deposition of Bi2O3-multiwalled carbon nanotubes coating as supercapacitor electrode. J. Am. Ceram. Soc. 2022, 105, 5638–5648.

- Pecenek, H.; Dokan, F.K.; Onses, M.S.; Yilmaz, E.; Sahmetlioglu, E. Outstanding supercapacitor performance with intertwined flower-like NiO/MnO2/CNT electrodes. Mater. Res. Bull. 2022, 149, 111745.

- Hong, X.D.; Deng, C.Y.; Wang, X.; Dong, W.; Liang, B. Carbon nanosheets/MnO2/NiCo2O4 ternary composite for supercapacitor electrodes. J. Energy Storage 2022, 53, 105086.

- Shrivastav, V.; Sundriyal, S.; Tiwari, U.K.; Kim, K.H.; Deep, A. Metal-organic framework derived zirconium oxide/carbon composite as an improved supercapacitor electrode. Energy 2021, 235, 121351.

- Geioushy, R.A.; Attia, S.Y.; Mohamed, S.G.; Li, H.T.; Fouad, O.A. High-performance electrode materials for supercapacitor applications using Ni-catalyzed carbon nanostructures derived from biomass waste materials. J. Energy Storage 2022, 48, 104034.

- Mohammadi, N.; Pourreza, K.; Adeh, N.B.; Omidvar, M. Defective mesoporous carbon/MnO2 nanocomposite as an advanced electrode material for supercapacitor application. J. Alloy. Compd. 2021, 883, 160874.

- Mandal, M.; Subudhi, S.; Alam, I.; Subramanyam, B.V.R.S.; Patra, S.; Raiguru, J.; Das, S.; Mahanandia, P. Facile synthesis of new hybrid electrode material based on activated carbon/multiwalled carbon for supercapacitor applications. Inorg. Chem. Commun. 2021, 123, 108332.

- Shin, S.; Shin, M.W. Nickel metal-organic framework (Ni-MOF) derived NiO/ composite for the application of high performance self-standing supercapacitor electrode. Appl. Surf. Sci. 2021, 540, 148295.

- Naushad, M.; Ahamad, T.; Ubaidullah, M.; Ahmed, J.; Ghafar, A.A.; Al-Sheetan, K.M.; Arunachalam, P. Nitrogen-doped carbon quantum dots (N-CQDs)/Co3O4 nanocomposite for high performance supercapacitor. J. King Saud Univ. Sci. 2021, 33, 101252.

- Hu, B.; Wang, Y.B.; Shang, X.H.; Xu, K.B.; Yang, J.M.; Huang, M.H.; Liu, J.Y. Structure-tunable hybrids for high-performance supercapacitor. J. Colloid Interface Sci. 2021, 581, 66–75.

- Tang, C.; Zhao, K.; Tang, Y.F.; Li, F.P.; Meng, Q.N. Forest-like carbon foam templated rGO/CNTs/MnO2 electrode for high-performance supercapacitor. Electrochim. Acta 2021, 375, 137960.

- Yu, P.P.; Zhang, Z.M.; Zheng, L.X.; Teng, F.; Hu, L.F.; Fang, X.S. A Novel Sustainable Flour Derived Hierarchical Nitrogen-Doped Porous Carbon/Polyaniline Electrode for Advanced Asymmetric Supercapacitors. Adv. Energy Mater. 2016, 6, 1601111.

- Shan, S.; Lin, L.; Huo, X.; Lin, L.; Zhang, W. Preparation of cyclodextrin polymer-functionalized polyaniline/porous carbon composites for use in high-performance supercapacitors. Mater. Lett. 2022, 324, 132771.

- Han, G.Q.; Liu, Y.; Zhang, L.L.; Kan, E.J.; Zhang, S.P.; Tang, J.; Tang, W.H. MnO2 Nanorods Intercalating Graphene Oxide/Polyaniline Ternary Composites for Robust High-Performance Supercapacitors. Sci. Rep. 2014, 4, 4824.

- Yang, J.J.; Li, H.L.; He, S.J.; Du, H.J.; Liu, K.M.; Zhang, C.M.; Jiang, S.H. Facile Electrodeposition of NiCo2O4 Nanosheets on Porous Carbonized Wood for Wood-Derived Asymmetric Supercapacitors. Polymers 2022, 14, 2521.

- Wang, F.; Liu, X.L.; Duan, G.G.; Yang, H.Q.; Cheong, J.Y.; Lee, J.; Ahn, J.; Zhang, Q.; He, S.J.; Han, J.Q.; et al. Wood-Derived, Conductivity and Hierarchical Pore Integrated Thick Electrode Enabling High Areal/Volumetric Energy Density for Hybrid Capacitors. Small 2021, 17, 2102532.

- Li, H.; Cao, L.; Zhang, H.; Tian, Z.; Zhang, Q.; Yang, F.; Yang, H.; He, S.; Jiang, S. Intertwined carbon networks derived from Polyimide/Cellulose composite as porous electrode for symmetrical supercapacitor. J. Colloid Interface Sci. 2022, 609, 179–187.

- Li, H.; Liu, Y.-L.; Jin, H.; Cao, L.; Yang, H.; Jiang, S.; He, S.; Li, S.; Liu, K.; Duan, G. Bimetallic salts template-assisted strategy towards the preparation of hierarchical porous polyimide-derived carbon electrode for supercapacitor. Diam. Relat. Mater. 2022, 128, 109283.

- Zheng, S.; Zhang, J.; Deng, H.; Du, Y.; Shi, X. Chitin derived nitrogen-doped porous carbons with ultrahigh specific surface area and tailored hierarchical porosity for high performance supercapacitors. J. Bioresour. Bioprod. 2021, 6, 142–151.

- Duan, G.; Zhao, L.; Zhang, C.; Chen, L.; Zhang, Q.; Liu, K.; Wang, F. Pyrolysis of zinc salt-treated flax fiber: Hierarchically porous carbon electrode for supercapacitor. Diam. Relat. Mater. 2022, 129, 109339.

- Ramaseshan, R.; Sundarrajan, S.; Jose, R.; Ramakrishna, S. Nanostructured ceramics by electrospinning. J. Appl. Phys. 2007, 102, 111101.

- Tiwari, P.; Janas, D.; Chandra, R. Self-standing MoS2/CNT and MnO2/CNT one dimensional core shell heterostructures for asymmetric supercapacitor applications. Carbon 2021, 177, 291–303.

- Hu, C.L.; Miao, L.S.; Yang, Q.; Yu, X.Z.; Song, L.; Zheng, Y.Y.; Wang, C.C.; Li, L.; Zhu, L.W.; Cao, X.B.; et al. Self-assembly of CNTs on Ni foam for enhanced performance of NiCoO2@ supercapacitor electrode. Chem. Eng. J. 2021, 410, 128317.

- Guo, S.Q.; Li, H.C.; Zhang, X.; Nawaz, H.; Chen, S.; Zhang, X.M.; Xu, F. Lignin carbon aerogel/nickel binary network for cubic supercapacitor electrodes with ultra-high areal capacitance. Carbon 2021, 174, 500–508.

- Zhou, H.M.; Zhan, Y.B.; Guo, F.Q.; Du, S.L.; Tian, B.L.; Dong, Y.C.; Qian, L. Synthesis of biomass-derived carbon aerogel/MnOx composite as electrode material for high-performance supercapacitors. Electrochim. Acta 2021, 390, 138817.

- Kumar, R.; Sahoo, S.; Tan, W.K.; Kawamura, G.; Matsuda, A.; Kar, K.K. Microwave-assisted thin reduced graphene oxide-cobalt oxide nanoparticles as hybrids for electrode materials in supercapacitor. J. Energy Storage 2021, 40, 102724.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.2K

Revisions:

2 times

(View History)

Update Date:

02 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No