Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Danish Tahir | -- | 2606 | 2022-10-24 08:03:51 | | | |

| 2 | Vivi Li | Meta information modification | 2606 | 2022-10-24 10:24:56 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Tahir, D.; Karim, M.R.A.; Hu, H.; Naseem, S.; Rehan, M.; Ahmad, M.; Zhang, M. Nanocellulose and Nanocellulose-Based Composites. Encyclopedia. Available online: https://encyclopedia.pub/entry/30848 (accessed on 02 March 2026).

Tahir D, Karim MRA, Hu H, Naseem S, Rehan M, Ahmad M, et al. Nanocellulose and Nanocellulose-Based Composites. Encyclopedia. Available at: https://encyclopedia.pub/entry/30848. Accessed March 02, 2026.

Tahir, Danish, Muhammad Ramzan Abdul Karim, Hong Hu, Sufyan Naseem, Muhammad Rehan, Mairaj Ahmad, Minglonghai Zhang. "Nanocellulose and Nanocellulose-Based Composites" Encyclopedia, https://encyclopedia.pub/entry/30848 (accessed March 02, 2026).

Tahir, D., Karim, M.R.A., Hu, H., Naseem, S., Rehan, M., Ahmad, M., & Zhang, M. (2022, October 24). Nanocellulose and Nanocellulose-Based Composites. In Encyclopedia. https://encyclopedia.pub/entry/30848

Tahir, Danish, et al. "Nanocellulose and Nanocellulose-Based Composites." Encyclopedia. Web. 24 October, 2022.

Copy Citation

Nanocellulose is the most abundant material extracted from plants, animals, and bacteria. Nanocellulose is a cellulosic material with nano-scale dimensions and exists in the form of cellulose nanocrystals (CNC), bacterial nanocellulose (BNC), and nano-fibrillated cellulose (NFC). Owing to its high surface area, non-toxic nature, good mechanical properties, low thermal expansion, and high biodegradability, it is obtaining high attraction in the fields of electronics, paper making, packaging, and filtration, as well as the biomedical industry. To obtain the full potential of nanocellulose, it is chemically modified to alter the surface, resulting in improved properties.

nanocellulose

biodegradable

nanocomposites

chemical functionalization

extraction

applications

1. Introduction

Polymeric cellulosic materials with high biodegradability and eco-friendliness have received a lot of attention, owing to the damage caused by petroleum base products, such as global warming, green gas emissions, and many others [1]. Several researchers are working on cellulosic fibers, from which nanocellulose can be extracted. The use of nanocellulose as a reinforcement in composites is because of their mesoscopic properties [2]. Nanocellulose is derived from plant cell walls and has extremely valuable properties, such as high surface area and strength [3][4][5]. Furthermore, the nanocellulose surface is easy to modify because of the large number of hydroxyl groups present in its structure. Nanocellulose has numerous applications in our daily lives, including filtration membranes, food packaging, biomedical, and so on [6].

2. Nanocellulose and Its Various Sources

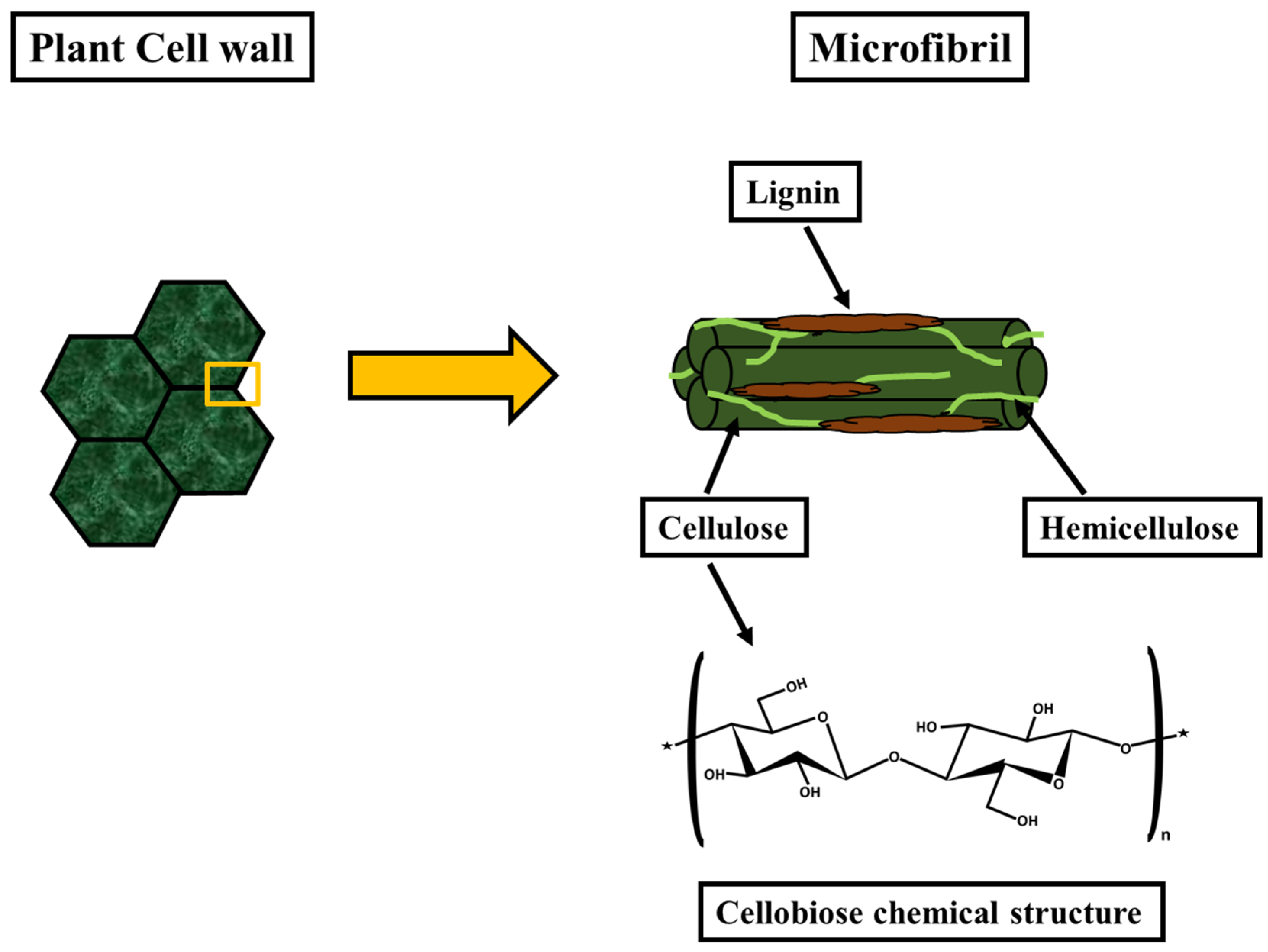

As shown in Figure 1, the cell walls of most plants contain hemicellulose, cellulose, and lignin. Lignin acts as a binder between cellulose and hemicellulose, holding them together. It has high stiffness and strength and can protect the cell wall from the outside environment. The amount of lignin in the plant cell wall ranges from 10 to 25% by weight, while the amounts of hemicellulose and cellulose are 20–35% and 35–50%, respectively [1][7][8]. The main component of the cell wall is cellulose, composed of repeating units of cellobiose, linked together with β-1,4 linkages, as shown in Figure 1. Intermolecular or intermolecular hydrogen bonding is used to connect the repeated units. Bonding occurs between the same or different chains via open hydroxyl groups [9]. Hemicelluloses are primarily xylans and glucomannans, connected by short or branched chains. Hydrogen bonding plays a vital role in providing compactness, strength, and solvent impermeability to the networks in cellulose fibers.

Figure 1. Plant cell wall structure and cellobiose chemical structure.

Strong hydrogen bonding networks and a variety of hydroxyl groups give cellulose fiber exceptional physical and mechanical qualities. The orderly packing of the chain molecules in the crystalline parts promotes high stiffness, whereas the amorphous parts give flexibility to the bulk material [10]. For general lignocellulosic biomass, the cellulose fibers present in between the crystalline and amorphous regions have a diameter of 3–100 μm and a length of 1–4 mm [11].

Nanocellulose fibers with a diameter of less than 100 nm and a length in the micrometers range deserve special attention. Nanocellulose fibers are transparent and rich in hydroxyl groups. These groups have a reactive surface that can be modified to obtain the desired properties [12]. Nanocellulose nanofibers have a low density of 1.6 g/cm3 and has exceptional strength [11]. Additionally, they have a tensile strength of nearly 10 GPa and a high strength-to-weight ratio that is eight times greater than stainless steel.

The three primary forms of nanocellulose materials are BNC, NFC, and CNC, as shown in Table 1. Three cellulosic forms have unique qualities, including biodegradability, tunable surface chemistry, barrier properties, non-toxicity, high mechanical strength, crystallinity, and high aspect ratio. Such a remarkable nature of nanocellulose makes it a new material for food packaging and fillers in composites [13][14]. High-strength nanocellulose, sometimes referred to as CNC, is typically recovered by the process of acid hydrolysis from cellulose fibrils [15]. It is shaped like a short rod or a whisker and has a diameter of 2–20 nm and a length of 100–500 nm. Additionally, it is entirely composed of cellulose, with high crystallinity ranging from 54 to 88%. The long and entangled nanocellulose that may be mechanically removed from cellulose fibrils is another type of nanocellulose and is known as NFC, often referred to as micro-fibrillated cellulose. Its size ranges from 500 to 2000 nm in length and 1–100 nm in diameter [16][17]. It is made from 100% cellulose, with crystalline and amorphous region parts. Another different type of nanocellulose is BNC. It is formed by bacteria, primarily Gluconacetobacter xylinus, over a few days to two weeks, whereas lignocellulosic biomass is the primary constituent for the extraction of CNC and NFC (top-down method). As BNC is extracted from bacteria, other amorphous compounds, such as lignin, hemicellulose, and pectin, are never present in the pure form of BNC [18][19]. The chemical makeup of BNC is identical to that of the other two types of nanocellulose.

Table 1. Types of nanocellulose materials.

| Nanocellulose Types | Sources | Extraction Method and Size |

|---|---|---|

| CNC | Cotton, tunicin, mulberry bark, hemp, wood, wheat straw. | Acid hydrolysis 5–70 nm in diameter 100–250 nm in length |

| BNC | Sugars and alcohols. | Extracted from bacterial synthesis 20–100 nm in diameter |

| NFC | Wood, hemp, flax, potato tuber, sugar beet. | A mechanical method of breaking the cellulose 5–60 nm in diameter |

3. Nanocellulose Extraction Processes

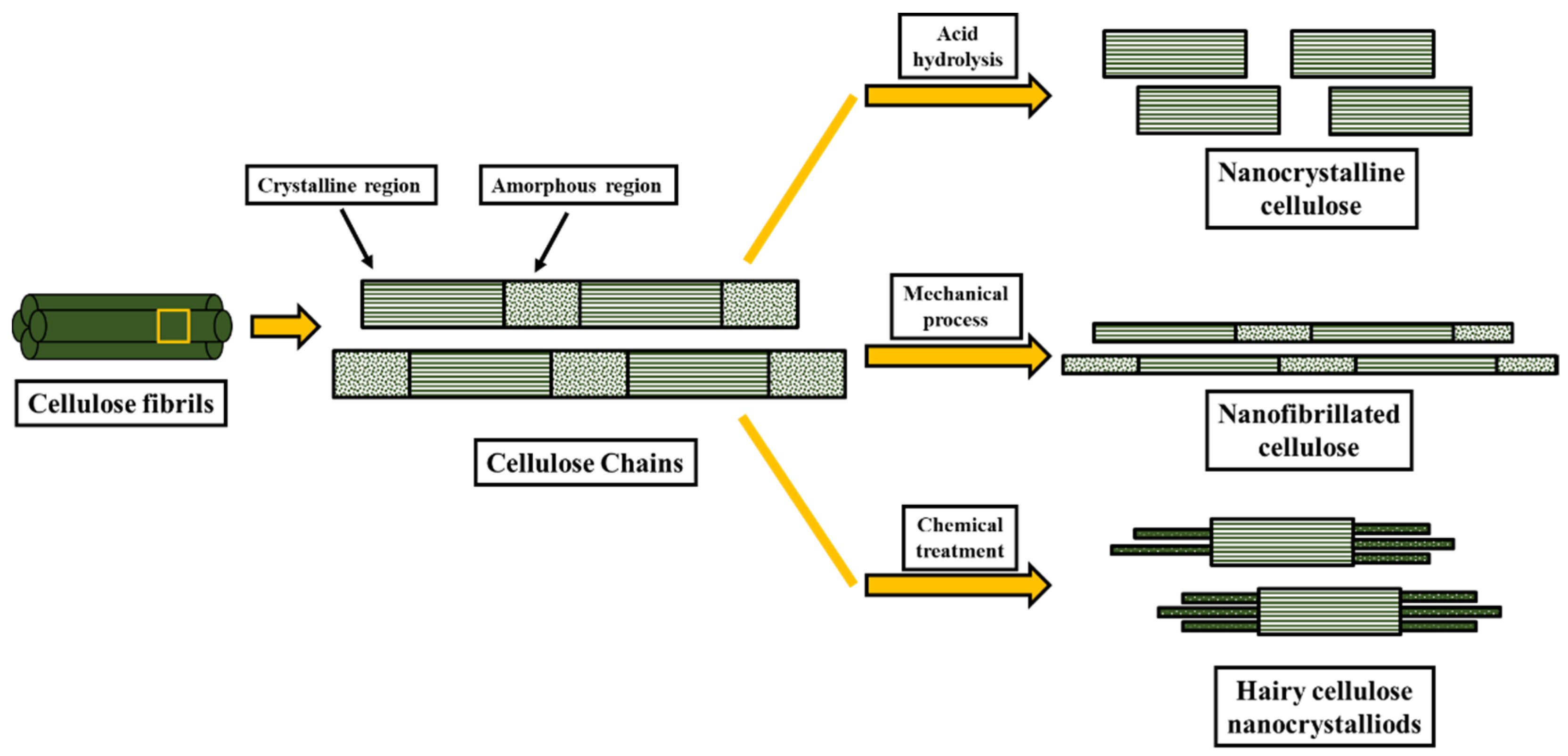

The use of agricultural leftovers for the extraction of nanocellulose is a very appealing field from the researcher’s point of view. Agriculture leftovers are lignocellulosic biomass that are rich in cellulosic content. The extraction of nanocellulose from lignocellulosic biomass involves various steps that can be seen in Figure 2. First, the pretreatment eliminates the non-cellulosic compounds, including lignin, hemicellulose, pectin, etc., followed by nanocellulose extraction through various extraction techniques [20].

Figure 2. Schematic showing nanocellulose extraction from lignocellulosic biomass.

3.1. Biomass Treatment for Nanocellulose Extraction

The pretreatment of lignocellulosic biomass to remove the amorphous compounds is the first step in the extraction of nanocellulose. Alkali treatment and acid-chlorite treatment are the two common methods for pretreating biomass. The amorphous compounds are removed from the biomass in the process of alkali treatment, primarily by treating the biomass with an alkali solution. Alkali can be sodium hydroxide or potassium hydroxide. Several scholars have provided in-depth descriptions of the alkaline pretreatment process [21]. Sharma et al. [22] worked on an alkali treatment technique to extract cellulose nanofibers from rice straw waste. For the removal of hemicelluloses and lignin, the rice straw was heated to 90–160 °C for 1–2 h after being soaked in various NaOH concentrations (8–16%).

Acid-chlorite treatment is another technique used for the removal of amorphous compounds. The simultaneous treatment of sodium chlorite, along with glacial acetic acid as an acidifying agent, removes the majority of the lignin from the lignocellulosic biomass. This procedure is also referred to as a bleaching or delignification technique. It is carried out when a mixture of lignocellulosic biomass and distilled water is added to the sodium chlorite and acetic acid solution at 70–80 °C for 4–12 h [23]. After completion of the treatment, the mixture is stirred continuously for an entire night before being washed with distilled water to bring the pH level to a neutral state. This leads to a collection of white residue, which is then dried at 50 °C in an oven to obtain lignin-free holocellulose [24].

3.2. Nanocellulose Isolation

Acid hydrolysis, mechanical treatment processes, and enzymatic hydrolysis are some of the techniques used for nanocellulose isolation. Table 2 shows three cellulose isolation processes. The most commonly used technique for extracting nanocellulose is acid hydrolysis [25]. It involves the use of strong acids, such as sulfuric acid, that can easily hydrolyze the amorphous area of cellulose fibrils by esterifying the hydroxyl groups with sulfate ions [26][27]. Maiti et al. [28] suggested the use of 47% of sulfuric acid to recover nanocellulose from waste tissue papers, China cotton, and south African cotton. The results show that the types of the precursors and the hydrolysis conditions largely determine the shape and size of the nanocellulose. It was noted that esterification creates a colloidal dispersion of crystalline nanocellulose inside the reaction mixture. Acid hydrolysis can be performed by other mild acids, such as formic acid, phosphoric acid, etc. Bond cleavage is the mechanism behind the acid hydrolysis of cellulose. The glycosidic bonds present between anhydroglucose units are subjected to hydrolytic cleavage, resulting in the rearrangement of tangling chains and strain release. Acid hydrolysis thereby dissolves the amorphous portion, leaving the crystalline sections intact. Formed crystalline regions are then projected to mechanical treatment, which transforms them into fine cellulose particles. The use of a 30–50% concentration of sulphuric acid in acid hydrolysis gives very fine cellulose particles. Reinforcing fine cellulose particles in biocomposites facilitates high plastic deformation in the composite. Acid hydrolysis reactions and the properties of nanocellulose can be controlled by varying the concentration, time, and temperature provided [29]. The size of cellulose particles and their distribution depend highly on the temperature, time, and concentration of the acid. A high temperature and short reaction time are usually recommended for dilute acid hydrolysis. Using dilute acid eliminates the need for acid recovery. Iranmahboob et al. [30] performed dilute acid hydrolysis and found that, to achieve a high yield from dilute acid, high temperature, less time, and high pressure are required. Similarly, Hamelinck et al. [31] performed hydrolysis using concentrated acid and concluded that hydrolysis through concentrated acids requires moderate temperatures and longer reaction times. The use of concentrated acid enhances the difficulty of recovering acid from the mixture. Later stages of acid hydrolysis also involve the washing of cellulose, which is usually achieved by centrifuging the mixture of cellulose and cold water [32]. The main disadvantage of this procedure is the need to treat acid-containing wastewater before releasing it into the environment.

Table 2. Nanocellulose isolation methods.

| Biological Methods | Mechanical Methods | Chemical Methods |

|---|---|---|

| Fungi treatment | Steam explosion | Ionic treatment |

| Bacteria treatment | Ball milling | Alkaline treatment |

| Enzymatic hydrolysis | Disintegration | Acid hydrolysis |

| Grinding | Oxidation | |

| Electrospinning | Solvent extraction | |

| Ultrasonication | ||

| Homogenization |

Enzymatic hydrolysis comes under the list of biological processes that use enzymes to break down the cellulose fibers into washed cellulose [33]. The literature reveals that cellulase, cellobiohydrolase, endoglucanase, etc., are frequently used enzymes for this process. Although the mechanism is intricate, the enzyme’s activity is dependent on catalyzing the breakage of the connecting H-bond in between the cellulosic fibers [34]. Enzymes activity involves the removal of hemicellulose, protection of cellulose from hydrolysis, and production of monosaccharides from hemicellulose for subsequent fermentation to produce bioethanol [35]. The cellulases and hemicellulases present in the process are closely connected to effectively hydrolyze a variety of lignocellulosic biomasses. When compared to acid hydrolysis, it is normally conducted under milder conditions and takes significantly longer to operate. To reduce the processing time, enzymatic hydrolysis can be used in combination with other techniques. Moniruzzaman et al. [36] used a novel method to separate nanocellulose from wood by pre-treating the cellulose with an ionic solution, followed by laccase-enhanced enzymatic hydrolysis. A comparison of the produced nanocellulose to the existing methods of cellulose preparation shows that the produced cellulose has a high surface area and higher crystallinity with enhanced thermal properties.

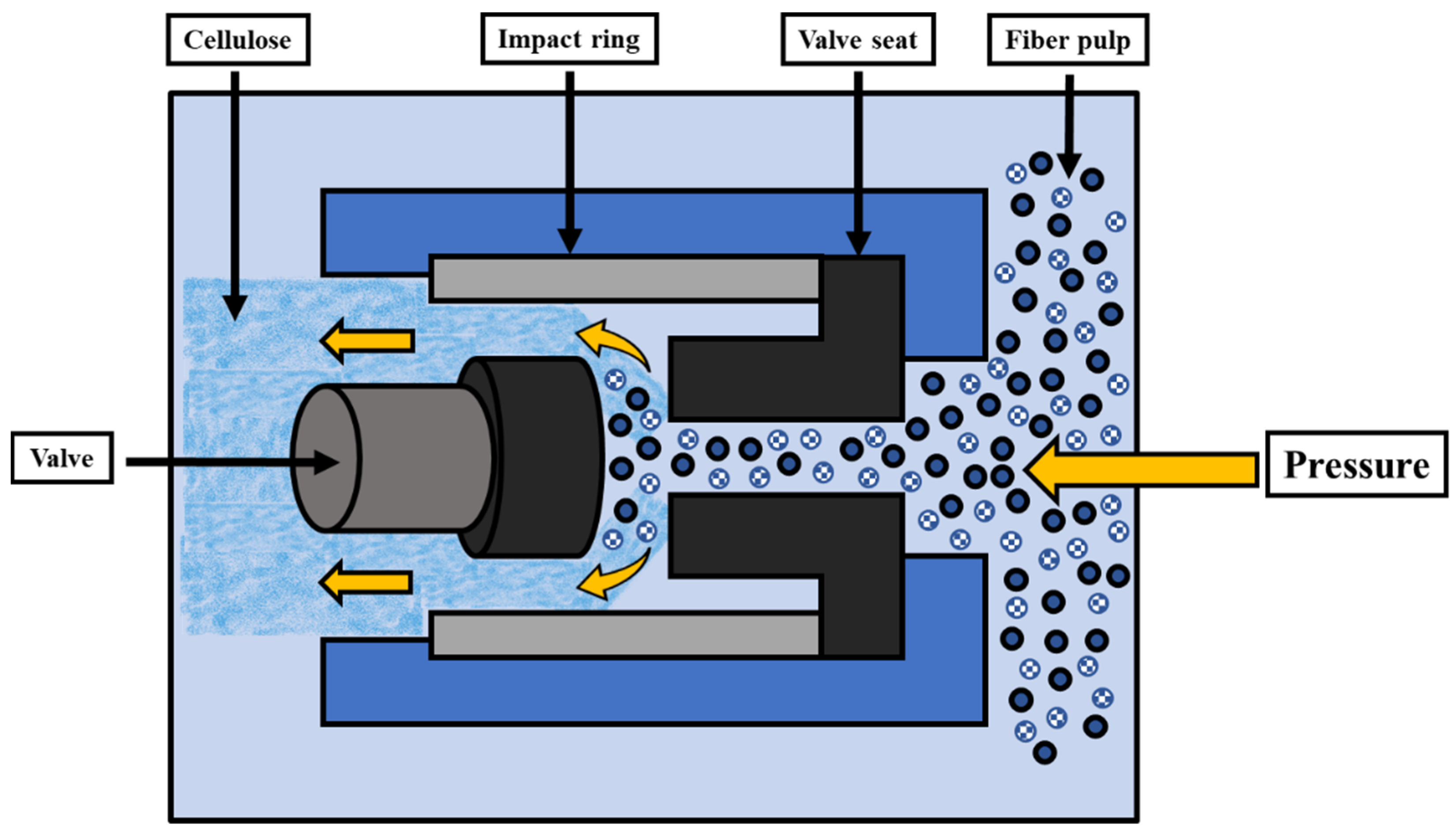

Different mechanical techniques, including ball milling, ultrasonication, and high-pressure homogenization (HPH), can be used to mechanically prepare nanocellulosic fibers [14]. However, these methods require a lot of energy, which is why some pre-treatment is always suggested to save energy. HPH involves the treatment of a cellulose mixture at high pressure and velocity [33]. High pressure and velocity divide the cellulose microfibrils into nanometre-sized fragments, based on the fluid shear and impact forces created. Figure 3 shows the schematic of the homogenizer used for cellulose isolation. Li et al. [37] used HPH to separate nanocellulose from sugarcane bagasse. To dissolve the bagasse cellulose, the material was initially pre-treated with an ionic liquid (1-butyl-3-methylimidazolium chloride ([Bmim]Cl)), followed by passing the homogenized solution at high pressure, without becoming clogged. The produced nanocellulose had a diameter of 10–20 nm, with a crystallinity lesser than the original cellulose. By using HPH, Wang et al. [38] separated nanocellulose from cotton cellulose. The final product obtained (20 nm in diameter) was less thermally stable and had a low crystallinity than the pre-treated cotton cellulose. A decrease in crystallinity is because of the high pressure, which disrupts cellulose intermolecular and intramolecular hydrogen bonding.

Figure 3. Schematic for HPH.

Cellulose fiber can also be defibrillated using the ultrasound’s hydrodynamic forces, through the process of ultrasonication [39]. In this technique, ultrasonic energy is generated by mechanically oscillating the power and implosion of gas bubbles. The generated energy is then absorbed by the liquid molecules [40][41]. Tang et al. [42] used the process of ultrasonication to extract the nanocellulose from the wood pulp. The results showed that cellulose obtained without ultrasonication has a yield of 48.16%, whereas ultrasonication of the sample gives the cellulose sample a yield of 85.38%. The obtained nanocellulose had widths of 10–100 nm and a yield of 85.38%.

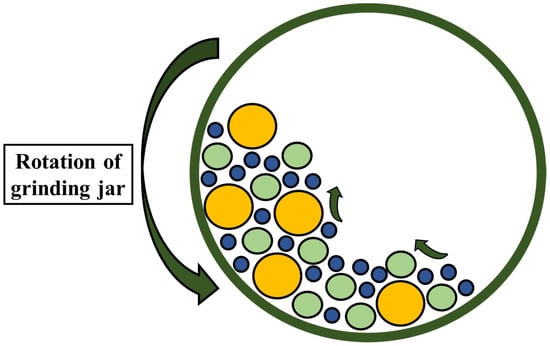

Cellulose fibers are defibrillated using another mechanical technique, which involves the use of ball milling. Since the 1990s, researchers have used ball milling for grinding and improving particle size. The milling jar contains milling balls of various sizes, as one of the primary components of the ball milling machine. Planetary ball mills and vibration ball mills are some of the common types of ball mills used in industry and laboratories today [43]. The planetary ball mill is the one that defibrillates cellulose and biomass the most frequently. In the planetary ball, the mill balls collide with each other and with the wall of the milling jar, thus creating friction, which helps in size reduction [44][45]. The created friction grinds the large-size materials into smaller particles with large surface areas. The friction is linked with the shear forces that are produced between the balls and the surface of the rotating jar as a result of the centrifugal force [46][47]. The application of shear force onto the cellulose breaks them into nano-size particles. The number and size of the balls, time, weight ratio between the balls and material, and speed are a few of the variable elements on which the characteristics of ball-milled products depend [48]. The planetary ball mill is also shown in Figure 4. Ago et al. [43] investigated the properties of ball-milled, cotton-derived cellulose at 400 rpm for two hours by varying the water content in the mixture. It was discovered that the presence of a small amount of water (10 wt.%) in a dry state changes the cellulose type I to amorphous. However, when water is up to 30 wt.% cellulose type I, it transformed into the stable form of cellulose type II. This suggests that the crystalline structure of the cellulose is greatly influenced by the amount of water in the milling jar [49].

Figure 4. Schematic for planetary ball mill.

3.3. BNC Extraction

Besides plants, bacteria can be used to produce cellulose. Bacterial cellulose can be used as a primary source for the production of CNC and cellulose nanowhiskers because of their high purity and crystallinity. It is generally acknowledged that the source of the bacterial cellulose and the isolation techniques utilized affect the shape of BNC. Some commonly used bacteria are Pseudomonas, Rhizobium, Sarcina, genera Acetobacter, Azotobacter, and Alcaligenes. Acetobacter xylinum, a species of bacteria that produces acetic acid, is the most effective generator of BNC. Cellulose biosynthesis is the method of extraction of BNC. Extracted BNC has a width of less than 100 nm and is 100–1000 nm long [50][51]. BNC isolation from bacterial cellulose can be achieved by using acid hydrolysis, enzymatic hydrolysis, and ionic liquids. By acid hydrolysis, CNC and BNC can likewise convert into bacterial nanocrystals. However, acid hydrolysis also has some disadvantages, as it decreases the degree of polymerization (DP) and reduces the number of sulphate-containing nanocrystals. Reduction in DP and nanocrystals brings down the mechanical properties of cellulose nanocomposites. Therefore, the enzymatic system is suggested to retain the actual properties of bacterial cellulose. Ullah et al. [52] developed a cell-free enzyme system for producing bio-cellulose. The system was developed using a single-cell line and contained all the enzymes needed to run a successful biosynthesis process. The prepared bio-cellulose were scattered and had extracellularly produced glucose chains. The results revealed that a better yield can be obtained by following the produced cell-free system.

References

- Karim, M.R.A.; Tahir, D.; Haq, E.U.; Hussain, A.; Malik, M.S. Natural fibres as promising environmental-friendly reinforcements for polymer composites. Polym. Polym. Compos. 2020, 29, 277–300.

- Tan, K.W.; Heo, S.K.; Foo, M.L.; Chew, I.M.L.; Yoo, C.K. An insight into nanocellulose as soft condensed matter: Challenge and future prospective toward environmental sustainability. Sci. Total Environ. 2019, 650, 1309–1326.

- Dufresne, A. Nanocellulose: A new ageless bionanomaterial. Mater. Today 2013, 16, 220–227.

- Lee, K.-Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27.

- Gabriel, T.; Belete, A.; Syrowatka, F.; Neubert, R.H.H.; Gebre-Mariam, T. Extraction and characterization of celluloses from various plant byproducts. Int. J. Biol. Macromol. 2020, 158, 1248–1258.

- Fatima, A.; Yasir, S.; Ul-Islam, M.; Kamal, T.; Ahmad, M.W.; Abbas, Y.; Manan, S.; Ullah, M.W.; Yang, G. Ex situ development and characterization of green antibacterial bacterial cellulose-based composites for potential biomedical applications. Adv. Compos. Hybrid Mater. 2022, 5, 307–321.

- Abdul Karim, M.R.; Tahir, D.; Hussain, A.; Ul Haq, E.; Khan, K.I. Sodium carbonate treatment of fibres to improve mechanical and water absorption characteristics of short bamboo natural fibres reinforced polyester composite. Plast. Rubber Compos. 2020, 49, 425–433.

- Abdul Karim, M.R.; Tahir, D.; Khan, K.I.; Hussain, A.; Haq, E.U.; Malik, M.S. Improved mechanical and water absorption properties of epoxy-bamboo long natural fibres composites by eco-friendly Na2CO3 treatment. Plast. Rubber Compos. 2022, 22, 1–14.

- Dufresne, A. Potential of nanocellulose as a reinforcing phase for polymers. J. Sci. Technol. For. Prod. Process. 2012, 2, 6–16.

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994.

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose—Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764.

- Abdul Khalil, H.P.S.; Bhat, A.H.; Ireana Yusra, A.F. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979.

- Ferrer, A.; Pal, L.; Hubbe, M. Nanocellulose in packaging: Advances in barrier layer technologies. Ind. Crops Prod. 2017, 95, 574–582.

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466.

- Dufresne, A. Chapter 1. Nanocellulose: Potential Reinforcement in Composites. In Natural Polymers: Volume 2: Nanocomposites; Maya, J., John, S.T., Eds.; RSC Publishing: Cambridge, UK, 2012; pp. 1–32.

- Abitbol, T.; Rivkin, A.; Cao, Y.; Nevo, Y.; Abraham, E.; Ben-Shalom, T.; Lapidot, S.; Shoseyov, O. Nanocellulose, a tiny fiber with huge applications. Curr. Opin. Biotechnol. 2016, 39, 76–88.

- Nechyporchuk, O.; Belgacem, M.N.; Bras, J. Production of cellulose nanofibrils: A review of recent advances. Ind. Crops Prod. 2016, 93, 2–25.

- Jozala, A.F.; de Lencastre-Novaes, L.C.; Lopes, A.M.; de Carvalho Santos-Ebinuma, V.; Mazzola, P.G.; Pessoa, A., Jr.; Grotto, D.; Gerenutti, M.; Chaud, M.V. Bacterial nanocellulose production and application: A 10-year overview. Appl. Microbiol. Biotechnol. 2016, 100, 2063–2072.

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Shi, Z.; Gauthier, M.; Yang, G. Bacterial cellulose: Molecular regulation of biosynthesis, supramolecular assembly, and tailored structural and functional properties. Prog. Mater. Sci. 2022, 129, 100972.

- Haafiz, M.K.M.; Hassan, A.; Zakaria, Z.; Inuwa, I.M. Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr. Polym. 2014, 103, 119–125.

- Sharma, A.; Thakur, M.; Bhattacharya, M.; Mandal, T.; Goswami, S. Commercial application of cellulose nano-composites—A review. Biotechnol. Rep. 2019, 21, e00316.

- Sharma, A.; Mandal, T.; Goswami, S. Cellulose nanofibers from rice straw: Process development for improved delignification and better crystallinity index. Trends Carbohydr. Res. 2017, 9, 16–27.

- Dos Santos, R.M.; Flauzino Neto, W.P.; Silvério, H.A.; Martins, D.F.; Dantas, N.O.; Pasquini, D. Cellulose nanocrystals from pineapple leaf, a new approach for the reuse of this agro-waste. Ind. Crops Prod. 2013, 50, 707–714.

- Phanthong, P.; Ma, Y.; Guan, G.; Abudula, A. Extraction of Nanocellulose from Raw Apple Stem. J. Jpn. Inst. Energy. 2015, 94, 787–793.

- Kargarzadeh, H.; Ioelovich, M.; Ahmad, I.; Thomas, S.; Dufresne, A. Methods for Extraction of Nanocellulose from Various Sources. In Handbook of Nanocellulose and Cellulose Nanocomposites; Kargarzadeh, H., Ahmad, I., Thomas, A.D.S., Eds.; John Wiley & Sons, Ltd.: Weinheim, Germany, 2017; pp. 1–49.

- Bondeson, D.; Mathew, A.; Oksman, K. Optimization of the isolation of nanocrystals from microcrystalline cellulose by acid hydrolysis. Cellulose 2006, 13, 171–180.

- Dong, X.M.; Revol, J.F.; Gray, D.G. Effect of microcrystallite preparation conditions on the formation of colloid crystals of cellulose. Cellulose 1998, 5, 19–32.

- Maiti, S.; Jayaramudu, J.; Das, K.; Reddy, S.M.; Sadiku, R.; Ray, S.S.; Liu, D. Preparation and characterization of nano-cellulose with new shape from different precursor. Carbohydr. Polym. 2013, 98, 562–567.

- Das, K.; Ray, D.; Bandyopadhyay, N.R.; Ghosh, T.; Mohanty, A.K.; Misra, M. A study of the mechanical, thermal and morphological properties of microcrystalline cellulose particles prepared from cotton slivers using different acid concentrations. Cellulose 2009, 16, 783–793.

- Iranmahboob, J.; Nadim, F.; Monemi, S. Optimizing acid-hydrolysis: A critical step for production of ethanol from mixed wood chips. Biomass Bioenergy 2002, 22, 401–404.

- Hamelinck, C.N.; Van Hooijdonk, G.; Faaij, A.P.C. Ethanol from lignocellulosic biomass: Techno-economic performance in short-, middle- and long-term. Biomass Bioenergy 2005, 28, 384–410.

- Wang, N.; Ding, E.; Cheng, R. Thermal degradation behaviors of spherical cellulose nanocrystals with sulfate groups. Polymer 2007, 48, 3486–3493.

- Abdul Khalil, H.P.S.; Davoudpour, Y.; Islam, M.N.; Mustapha, A.; Sudesh, K.; Dungani, R.; Jawaid, M. Production and modification of nanofibrillated cellulose using various mechanical processes: A review. Carbohydr. Polym. 2014, 99, 649–665.

- Phanthong, P.; Reubroycharoen, P.; Hao, X.; Xu, G.; Abudula, A.; Guan, G. Nanocellulose: Extraction and application. Carbon Resour. Convers. 2018, 1, 32–43.

- Wahlström, R.M.; Suurnäkki, A. Enzymatic hydrolysis of lignocellulosic polysaccharides in the presence of ionic liquids. Green Chem. 2015, 17, 694–714.

- Moniruzzaman, M.; Ono, T. Separation and characterization of cellulose fibers from cypress wood treated with ionic liquid prior to laccase treatment. Bioresour. Technol. 2013, 127, 132–137.

- Li, J.; Wei, X.; Wang, Q.; Chen, J.; Chang, G.; Kong, L.; Su, J.; Liu, Y. Homogeneous isolation of nanocellulose from sugarcane bagasse by high pressure homogenization. Carbohydr. Polym. 2012, 90, 1609–1613.

- Wang, Y.; Bian, K.; Hu, C.; Zhang, Z.; Chen, N.; Zhang, H.; Qu, L. Flexible and wearable graphene/polypyrrole fibers towards multifunctional actuator applications. Electrochem. Commun. 2013, 35, 49–52.

- Väntsi, O.; Kärki, T. Utilization of recycled mineral wool as filler in wood-polypropylene composites. Constr. Build. Mater. 2014, 55, 220–226.

- Zhou, Y.M.; Fu, S.Y.; Zheng, L.M.; Zhan, H.Y. Effect of nanocellulose isolation techniques on the formation of reinforced poly(vinyl alcohol) nanocomposite films. Express Polym. Lett. 2012, 6, 794–804.

- Filson, P.B.; Dawson-Andoh, B.E. Sono-chemical preparation of cellulose nanocrystals from lignocellulose derived materials. Bioresour. Technol. 2009, 100, 2259–2264.

- Tang, L.; Huang, B.; Lu, Q.; Wang, S.; Ou, W.; Lin, W.; Chen, X. Ultrasonication-assisted manufacture of cellulose nanocrystals esterified with acetic acid. Bioresour. Technol. 2013, 127, 100–105.

- Ago, M.; Endo, T.; Hirotsu, T. Crystalline transformation of native cellulose from cellulose I to cellulose II polymorph by a ball-milling method with a specific amount of water. Cellulose 2004, 11, 163–167.

- Barakat, A.; Mayer-Laigle, C.; Solhy, A.; Arancon, R.A.D.; De Vries, H.; Luque, R. Mechanical pretreatments of lignocellulosic biomass: Towards facile and environmentally sound technologies for biofuels production. RSC Adv. 2014, 4, 48109–48127.

- Kim, H.J.; Lee, S.; Kim, J.; Mitchell, R.J.; Lee, J.H. Environmentally friendly pretreatment of plant biomass by planetary and attrition milling. Bioresour. Technol. 2013, 144, 50–56.

- Baheti, V.; Abbasi, R.; Militky, J. Ball milling of jute fibre wastes to prepare nanocellulose. World J. Eng. 2012, 9, 45–50.

- Feng, Y.T.; Han, K.; Owen, D.R.J. Discrete element simulation of the dynamics of high energy planetary ball milling processes. Mater. Sci. Eng. A 2004, 375, 815–819.

- Avolio, R.; Bonadies, I.; Capitani, D.; Errico, M.E.; Gentile, G.; Avella, M. A multitechnique approach to assess the effect of ball milling on cellulose. Carbohydr. Polym. 2012, 87, 265–273.

- Ago, M.; Endo, T.; Okajima, K. Effect of solvent on morphological and structural change of cellulose under ball-milling. Polym. J. 2007, 39, 435–441.

- Brown, E.E.; Laborie, M.P.G. Bioengineering bacterial cellulose/poly(ethylene oxide) nanocomposites. Biomacromolecules 2007, 8, 3074–3081.

- Choi, S.M.; Shin, E.J. The nanofication and functionalization of bacterial cellulose and its applications. Nanomaterials 2020, 10, 406.

- Ullah, M.W.; Ul-Islam, M.; Khan, S.; Kim, Y.; Park, J.K. Innovative production of bio-cellulose using a cell-free system derived from a single cell line. Carbohydr. Polym. 2015, 132, 286–294.

More

Information

Subjects:

Nanoscience & Nanotechnology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.0K

Revisions:

2 times

(View History)

Update Date:

25 Oct 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No