Video Upload Options

Amorphous metal (AM), specifically amorphous ferromagnetic metal, is considered as a satisfactory magnetic material for exploring electromagnetic devices with high-efficiency and high-power density, such as electrical machines and transformers, benefits from its various advantages, such as reasonably low power loss and very high permeability in medium to high frequency. However, the characteristics of these materials have not been investigated comprehensively, which limits its application prospects to good-performance electrical machines that have the magnetic flux density with generally rotational and non-sinusoidal features. The appropriate characterization of AMs under different magnetizations is among the fundamentals for utilizing these materials in electrical machines.

1. Introduction

2. Measurement of Rotational Magnetic Properties of Amorphous Magnetic Materials

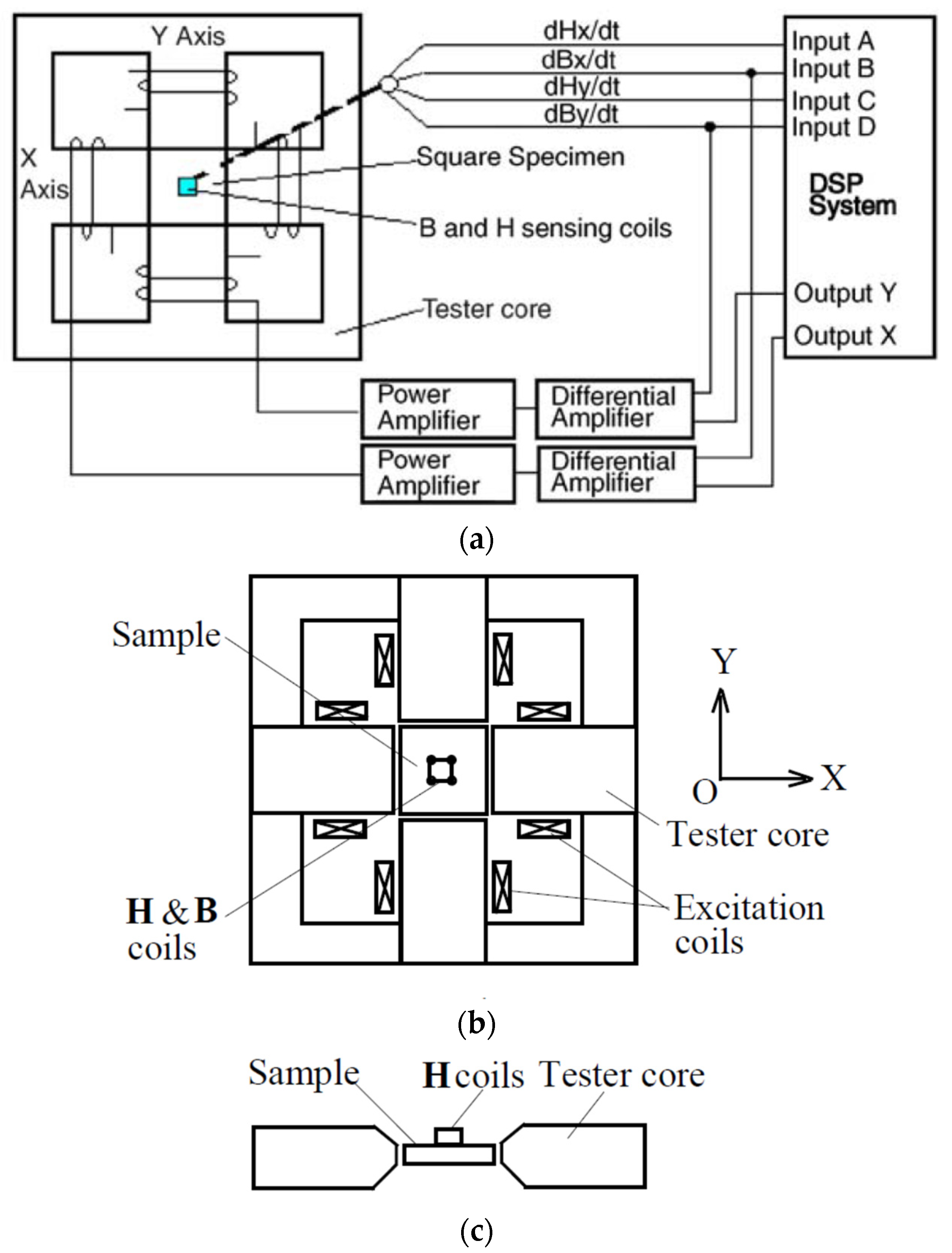

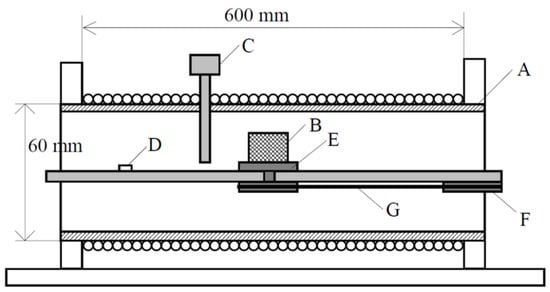

2.1. Measuring System of 2D Magnetic Properties

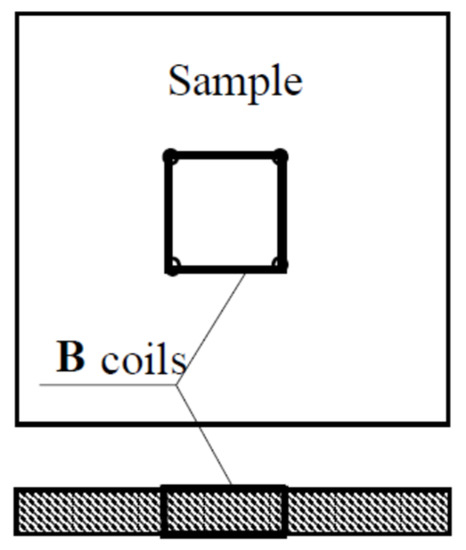

2.2. Material Sample for 2D Measurement

2.3. Measurement of 2D Magnetic Field

References

- Zhu, Z.Q.; Howe, D. Electrical Machines and Drives for Electric, Hybrid, and Fuel Cell Vehicles. Proc. IEEE 2007, 95, 746–765.

- Sun, X.; Shi, Z.; Lei, G.; Guo, Y.; Zhu, J. Analysis and Design Optimization of a Permanent Magnet Synchronous Motor for a Campus Patrol Electric Vehicle. IEEE Trans. Veh. Technol. 2019, 68, 10535–10544.

- Ritari, A.; Vepsäläinen, J.; Kivekäs, K.; Tammi, K.; Laitinen, H. Energy Consumption and Lifecycle Cost Analysis of Electric City Buses with Multispeed Gearboxes. Energies 2020, 13, 2117.

- Guo, Y.G.; Jin, J.X.; Zhu, J.G.; Lu, H.Y. Design and Analysis of a Prototype Linear Motor Driving System for HTS Maglev Transportation. IEEE Trans. Appl. Supercond. 2007, 17, 2087–2090.

- Reusser, C.A.; Young, H. Full Electric Ship Propulsion based on a Flying Capacitor Converter and an Induction Motor Drive. In Proceedings of the International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles, Aachen, Germany, 3–5 March 2015; pp. 170–176.

- Tom, L.; Khowja, M.; Vakil, G.; Gerada, C. Commercial Aircraft Electrification—Current State and Future Scope. Energies 2021, 14, 8381.

- Masson, P.; Luongo, C. High Power Density Superconducting Motor for All-Electric Aircraft Propulsion. IEEE Trans. Appl. Supercond. 2005, 15, 2226–2229.

- Jin, J.X.; Zheng, L.; Guo, Y.; Zhu, J.G.; Grantham, C.; Sorrell, C.C.; Xu, W. High-Temperature Superconducting Linear Synchronous Motors Integrated with HTS Magnetic Levitation Components. IEEE Trans. Appl. Supercond. 2012, 22, 5202617.

- Enokizono, M.; Wakabayashi, D.; Soda, N.; Tsuchida, Y.; Ueno, S.; Oka, M. High Power Density and High Efficiency of High-Speed Motor. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020; pp. 170–176.

- Guo, Y.; Zhu, J.G.; Dorrell, D.G. Design and Analysis of a Claw Pole Permanent Magnet Motor with Molded SMC Core. IEEE Trans. Magn. 2009, 45, 4582–4585.

- Liu, C.; Lei, G.; Wang, T.; Guo, Y.; Wang, Y.; Zhu, J. Comparative Study of Small Electrical Machines with Soft Magnetic Composite Cores. IEEE Trans. Ind. Electron. 2016, 64, 1049–1060.

- Du, W.; Zhao, S.; Zhang, H.; Zhang, M.; Gao, J. A Novel Claw Motor with Soft Magnetic Composites. IEEE Trans. Magn. 2021, 57, 8200904.

- Johnson, L.A.; Cornell, E.P.; Bailey, D.J.; Hegyi, S.M. Application of Low Loss Amorphous Metals in Motors and Transformers. IEEE Trans. Power Appar. Syst. 1982, 7, 2109–2114.

- Fukao, T.; Chiba, A.; Matsui, M. Test results on a super-high-speed amorphous-iron reluctance motor. IEEE Trans. Ind. Appl. 1989, 25, 119–125.

- Jensen, C.C.; Profumo, F.; Lipo, T.A. A Low-Loss Permanent-Magnet Brushless DC Motor Utilizing Tape Wound Amorphous Iron. IEEE Trans. Magn. 1992, 28, 646–651.

- Dehlinger, N.; Dubois, M.R. Clawpole Transverse Flux Machines with Amorphous Stator Cores. In Proceedings of the 2008 18th International Conference on Electrical Machines, Vilamoura, Portugal, 6–9 September 2008; pp. 1–6.

- Wang, Z.; Enomoto, Y.; Masaki, R.; Souma, K.; Itabashi, H.; Tanigawa, S. Development of a High Speed Motor Using Amorphous Metal Cores. In Proceedings of the 8th International Conference on Power Electronics-ECCE Asia, Jeju, Korea, 30 May–3 June 2011; pp. 1940–1945.

- Kolano, R.; Krykowski, K.; Kolano-Burian, A.; Polak, M.; Szynowski, J.; Zackiewicz, P. Amorphous Soft Magnetic Materials for the Stator of a Novel High-Speed PMBLDC Motor. IEEE Trans. Magn. 2012, 49, 1367–1371.

- Fan, T.; Li, Q.; Wen, X. Development of a High Power Density Motor Made of Amorphous Alloy Cores. IEEE Trans. Ind. Electron. 2014, 61, 4510–4518.

- Ertugrul, N.; Hasegawa, R.; Soong, W.L.; Gayler, J.; Kloeden, S.; Kahourzade, S. A Novel Tapered Rotating Electrical Machine Topology Utilizing Cut Amorphous Magnetic Material. IEEE Trans. Magn. 2015, 51, 8106006.

- Tang, R.; Tong, W.; Han, X. Overview on Amorphous Alloy Electrical Machines and Their Key Technologies. Chin. J. Electr. Eng. 2016, 2, 1–12.

- Simizu, S.; Ohodnicki, P.R.; McHenry, M.E. Metal Amorphous Nanocomposite Soft Magnetic Material-Enabled High Power Density, Rare Earth Free Rotational Machines. IEEE Trans. Magn. 2018, 54, 8202505.

- Li, Z.; Pei, Y.; Chai, F.; Hu, H.; Wu, Y.; Yu, Y. Accurate Modeling and Performance Analysis of Synchronous Reluctance Motor Considering Amorphous Alloy Properties. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6.

- Ismagilov, F.R.; Papini, L.; Vavilov, V.E.; Gusakov, D.V. Design and Performance of a High-Speed Permanent Magnet Generator with Amorphous Alloy Magnetic Core for Aerospace Applications. IEEE Trans. Ind. Electron. 2020, 67, 1750–1758.

- Fan, Z.; Yi, H.; Xu, J.; Xie, K.; Qi, Y.; Ren, S.; Wang, H. Performance Study and Optimization Design of High-Speed Amorphous Alloy Induction Motor. Energies 2021, 14, 2468.

- Hagihara, H.; Tanaka, M.; Takahashi, Y.; Fujiwara, K.; Ishihara, Y. Standard Measurement Method for Magnetic Properties of Fe-Based Amorphous Magnetic Materials. IEEE Trans. Magn. 2014, 50, 6100604.

- Baily, F.G. The Hysteresis of Iron and Steel in a Rotating Magnetic Field. Philos. Trans. R. Soc. 1896, 187, 715–746.

- Sievert, J. Recent Advances in the One- and Two-dimensional Magnetic Measurement Technique for Electrical Sheet Steel. IEEE Trans. Magn. 1990, 26, 2553–2558.

- Guo, Y.; Zhu, J.G.; Zhong, J.; Lu, H.; Jin, J.X. Measurement and Modeling of Rotational Core Losses of Soft Magnetic Materials Used in Electrical Machines: A Review. IEEE Trans. Magn. 2008, 44, 279–291.

- Sievert, J. Two-dimensional Magnetic Measurement-History and the Achievements of the Workshop. Przeg. Elektrot. 2011, 87, 2–10.

- Brix, W.; Hempel, K.; Schroeder, W. Method for the measurement of rotational power loss and related properties in electrical steel sheets. IEEE Trans. Magn. 1982, 18, 1469–1471.

- Zhu, J.G.; Ramsden, V.S. Two Dimensional Measurement of Magnetic Field and Core Loss Using a Square Specimen Tester. IEEE Trans. Magn. 1993, 29, 2995–2997.

- Sarker, P.C.; Guo, Y.; Lu, H.Y.; Zhu, J.G. Measurement and Modeling of Rotational Core Loss of Fe-Based Amorphous Magnetic Material Under 2-D Magnetic Excitation. IEEE Trans. Magn. 2021, 57, 8402008.

- Brix, W.; Hempel, K.; Schulte, F. Improved method for the investigation of the rotational magnetization process in electrical steel sheets. IEEE Trans. Magn. 1984, 20, 1708–1710.