Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Teresa M. Mata | -- | 8778 | 2022-09-27 08:52:44 | | | |

| 2 | Sirius Huang | Meta information modification | 8778 | 2022-09-28 04:02:15 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Mata, T.M.; Martins, A.A.; Calheiros, C.S.C.; Villanueva, F.; Alonso-Cuevilla, N.P.; Gabriel, M.F.; Silva, G.V. Cleaning Technologies for Indoor Air Quality Improvement. Encyclopedia. Available online: https://encyclopedia.pub/entry/27639 (accessed on 07 February 2026).

Mata TM, Martins AA, Calheiros CSC, Villanueva F, Alonso-Cuevilla NP, Gabriel MF, et al. Cleaning Technologies for Indoor Air Quality Improvement. Encyclopedia. Available at: https://encyclopedia.pub/entry/27639. Accessed February 07, 2026.

Mata, Teresa M., António A. Martins, Cristina S. C. Calheiros, Florentina Villanueva, Nuria P. Alonso-Cuevilla, Marta Fonseca Gabriel, Gabriela Ventura Silva. "Cleaning Technologies for Indoor Air Quality Improvement" Encyclopedia, https://encyclopedia.pub/entry/27639 (accessed February 07, 2026).

Mata, T.M., Martins, A.A., Calheiros, C.S.C., Villanueva, F., Alonso-Cuevilla, N.P., Gabriel, M.F., & Silva, G.V. (2022, September 27). Cleaning Technologies for Indoor Air Quality Improvement. In Encyclopedia. https://encyclopedia.pub/entry/27639

Mata, Teresa M., et al. "Cleaning Technologies for Indoor Air Quality Improvement." Encyclopedia. Web. 27 September, 2022.

Copy Citation

If outdoor air is more polluted, or in certain situations where ventilation is not possible, other strategies need to be applied, such as source control and pollutants extraction. The latter incorporates air cleaning technologies, one of the emergent areas of indoor air quality. Various air treatment technologies can be used to control contaminants, including physicochemical technologies and biological technologies.

adsorption

activated carbon

filtration

indoor air quality

ionization

microalgae

nature-based solutions

photocatalytic oxidation

UV light disinfection

1. Introduction

Increasing urbanization and modern lifestyles have contributed to humans spending an increasing amount of time inside buildings (e.g., at home, in offices, theaters, restaurants, stores, etc.), where they are exposed to indoor air pollutants [1]. Owing to the associated link between air quality and health, the WHO has recognized air pollution as one of the greatest environmental threats to human health [2]. To date, a considerable emphasis has been placed on reducing individual exposure to indoor air pollutants, making it necessary to analyze indoor sources and the possibility of reducing emissions from such sources. Thus, indoor air quality (IAQ), in all spaces where humans live and work, has become an issue of utmost importance and a significant determinant of human health and well-being. Several scientific studies have shown a direct relationship between improved air quality and positive impacts on human health [3][4][5]. The impact of indoor air pollutants on human health can be experienced in both the short and long term. Poor air quality results in unwanted health conditions and, in the worst-case scenarios, can lead to death [6].

Although the atmospheric composition, in terms of its main constituents (oxygen and nitrogen), is essentially the same indoors and outdoors, the types and amounts of indoor air pollutants differ from those found outdoors. Indoor air may contain a variety of contaminants, including particulate matter, tobacco smoke, radon, biological contaminants (e.g., mold, bacteria, fungi, dust mites, spores and pollen) and more than 400 organic and inorganic chemical compounds, with associated health effects [7][8]. Additionally, indoor air pollutants can reach concentrations of up to 10 times their levels in outdoor air, regardless of the building location [8]. Such pollutants are emitted by indoor activities (e.g., cooking and cleaning), products or materials (e.g., in furnishings and structures), to which other contaminants are added from outdoors that can penetrate indoors [9].

The concentration of pollutants in indoor air depends not only on indoor materials and activities but also on external factors [10]. Regardless of the insulation degree, even in naturally ventilated or mechanically conditioned and ventilated spaces, the internal atmosphere is an extension of the external atmosphere, i.e., the outdoor air quality directly influences the indoor air quality [11]. Non-reactive pollutants, such as carbon monoxide (CO), can penetrate the indoor environment and add to the indoor CO from unvented gas burners, defective cooking and heating devices, fireplaces, tobacco smoke and vehicle gases from attached garages [1][12]. On the other hand, reactive pollutants, such as sulfur dioxide (SO2) and ozone (O3), typically originating outdoors, quickly deplete after entering the indoor environment [11]. Carbon dioxide is considered an indicator of air quality in non-industrial indoor environments, such as homes, schools and offices and it is related to the presence of humans indoors and to human metabolism. It is also an indicator of the presence of other pollutants [13]. Although CO2 at low concentrations has few or no toxicological effects on humans, at higher concentrations, it has direct health consequences. At concentrations higher than 5%, CO2 causes the development of hypercapnia and respiratory acidosis, and at concentrations higher than 10%, it may cause convulsions, coma and death [14].

Humans are mostly exposed to air pollutants indoors via numerous sources, such as outgassing from furniture, floors, wall coverings, paints, glues, waxes, polishes, cleaning products, personal care products, tobacco smoke, heating appliances, cooking activities, etc. The indoor concentration of air pollutants can be affected by outdoor pollutant levels, as well as by other factors, such as door and window openings, air exchange rates, house age and size, and building renovations [15]. Cleaning agents and personal care products are common sources of volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs), which are partially oxidized and condensed and therefore turn into fine particles. New furniture commonly emits formaldehyde [16]. Gas appliances such as stoves, boilers, smokers and cookers are important sources of indoor NO, NO2, PM2.5 and polycyclic aromatic hydrocarbons (PAHs) [17]. Ultrafine particles with a diameter between 5.6 and 560 nm are commonly detected in indoor air [18]. However, PM10 and PM2.5 particles with a diameter of 10 and 2.5 µm or less, respectively, are more frequently detected indoors [18]. Laser printers emit ultra-fine particles, siloxanes and long-chained alkanes (C21–C45), and 3D printers are a source of nanoparticles [16]. The use of incense sticks and candles [19], toasting, frying, baking, open chimneys and older wood stoves are responsible for PM2.5-10 emissions [16]. Biological pollutants are essentially composed of mites, hair, bacteria, molds, fungi, spores, endotoxins, mycotoxins and other types of living organisms with highly variable and complex characteristics [8][18].

Ventilation to dilute the indoor air contaminants is among the most important passive methods to improve indoor air quality in most buildings [12][20]. Natural ventilation can be achieved simply by opening windows. In modern and well-insulated buildings, it is also common to find mechanical ventilation systems, such as heat recovery ventilation (HRV) and energy recovery ventilation (ERV) systems. These systems continuously remove stale indoor air and replace it with fresh air from outdoors. However, if the outdoor air is more polluted or in certain situations where ventilation is not possible, other methods and/or air purification systems are required [21].

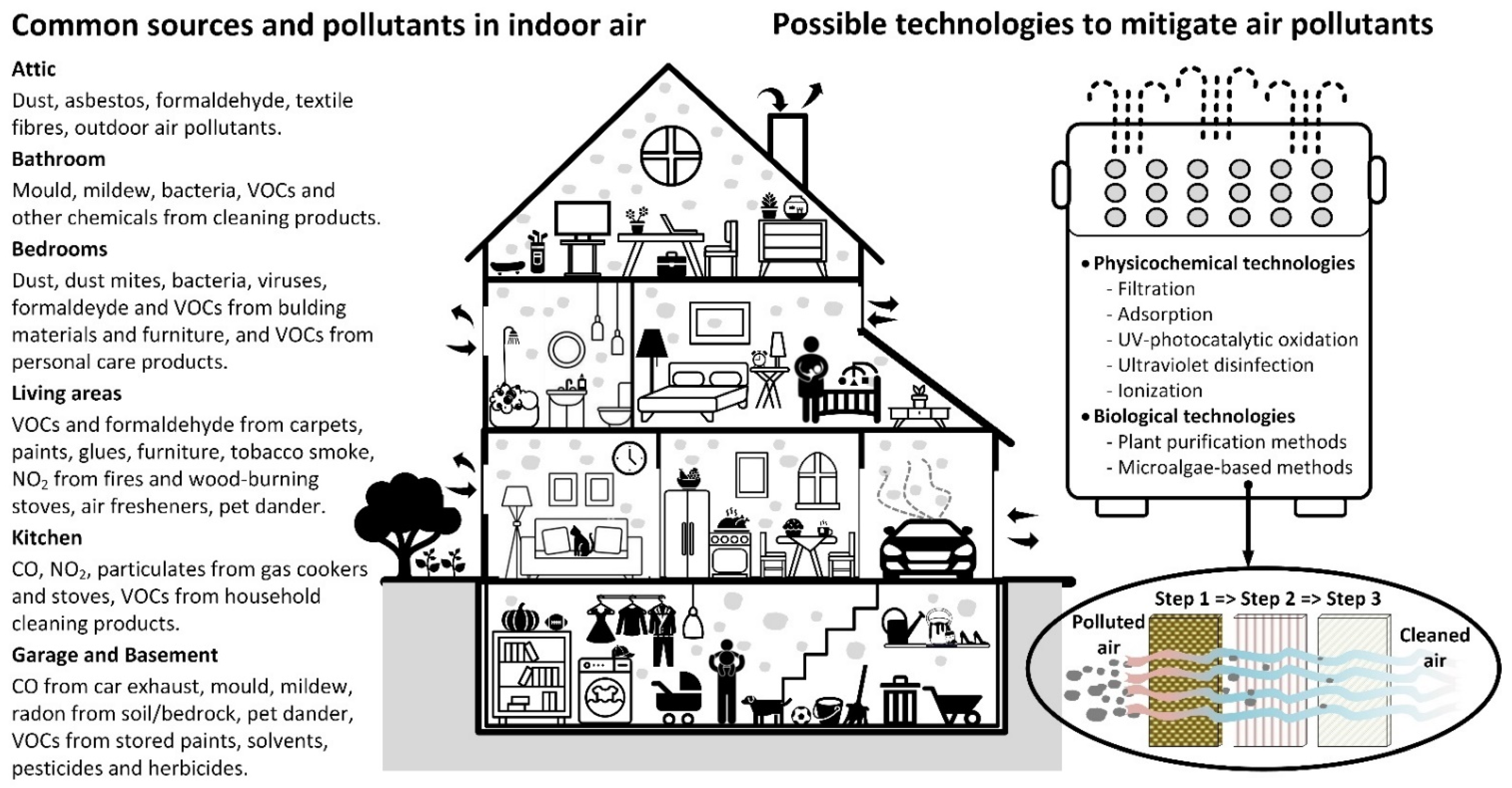

Possible methods for air purification (Figure 1), which are reviewed and discussed in this text, include physicochemical technologies (e.g., filtration, adsorption, ionization, UV-photocatalytic oxidation, ultraviolet disinfection) and biological technologies (e.g., plant purification methods and microalgae-based methods).

Figure 1. Common sources and pollutants in indoor air and some possible technologies to mitigate them.

2. Physicochemical Technologies

2.1. Filtration

Two types of filtration technologies for air cleaning are commonly used to remove particles: mechanical filtration and electronic filtration; the latter also includes electronic air cleaners (e.g., ionizers and electrostatic precipitators).

2.1.1. Mechanical Filtration

Mechanical filtration is the most used air cleaning technology for particulate matter (PM) and it can be used even for removing respiratory droplets [22][23]. Mechanical filters use media with porous structures that contain fibers or stretched membrane material in a variety of fiber sizes, densities and media expansion configurations to remove particles from air streams. Some of the particles in the air that enter a filter bind to the medium and are removed from the air as it passes through the filter. Removal mainly occurs by impaction, interception and Brownian motion/diffusion, depending on the particle size. Some filters have a static electrical charge applied to the medium to increase particulate removal [24].

The main object of filtration is the removal of PM. There is a high variety of filter types, with a classification according to its efficiency to retain PM [25]. There are standards to classify filters, such as ISO 16890 [26], EN 1822 [27] in Europe and ANSI/ASHRAE 52.2 [28] in the USA. The ISO 16890 [26] classifies the filters used in general ventilation in four groups, based on the filter efficiency for a particle size: coarse, ePM10, ePM2.5 and ePM1. To belong to each category, a filter must be capable of capturing at least 50% of the particles in that size range. The filters that capture less than 50% of PM10 (particles with diameters that are generally 10 μm and smaller) will belong to the coarse dust group. Both parameters, percentage of filtration and size, are equally relevant. For example, if the filters ePM1 50% and ePM2.5 50% are compared, the first retains 50% of particles between 0.3 µm and 1 µm and the second 50% of particles between 0.3 µm and 10 µm. There are filters with high filtration efficiencies (EPA—Efficient Particulate Air, HEPA—High Efficient Particulate Air and ULPA—Ultra Low Penetration Air), which are used in environments that require a high degree of air asepsis, being classified by EN 1822 [27]. HEPA and ULPA filters can also be used for cleaning ultrafine or nanoparticles (<0.1 μm), such as bacteria and viruses that can even pass the membrane of our lung cells [29].

A very common particulate filter, mostly used in portable air cleaners, is the HEPA filter, which means that the single-pass efficiency of the filter media is ≥99.75% if the filter is classified as H13 and ≥99.97% for filters classified as H14. These filtration characteristics are set according to the efficiency of the 0.3 µm particles, which is the most penetrating particle size (MMPS).

These filters are normally part of a central heating and ventilation system, or part of air purification equipment, usually portable. In the first case, the filters act by filtering outdoor air, although they can filter indoor air if there is recirculation, and in the second case, the Portable Air Cleaners (PAC) exclusively purify indoor air, without air renovation. Real-time sensing has been applied to these devices to optimize their performance. These sensors monitor the ambient conditions online (temperature, humidity, concentrations of key pollutants) and activate the reduction units according to the needs of the occupants and their activities, with resulting energy savings [10]. However, PACs have different modes of operation in which the clean air flow provided is different (CADR—Clean Air Delivery Rate).

During the COVID-19 pandemic, PACs were recommended as a supplementary measure for ventilation or for those spaces in which natural or mechanical ventilation was not available, or was insufficient, in order to reduce the risk of transmission [30][31]. Experimental studies provided evidence for portable HEPA purifiers’ potential to eliminate airborne SARS-CoV-2 [32]. Then, an air cleaner can be installed to remove particles potentially carrying viral particles from indoor air.

The air cleaner’s effectiveness in reducing particles is defined by their CADR, typically expressed in m3 per hour. Ventilation is defined parametrically as Air Change Rate (ACR) with its unit Air Changes per Hour (ACH, h−1). The air change rate equivalent to the air cleaner’s CADR is determined as follows:

During the pandemic it was recommended that 5–6 air changes per hour in classrooms should be achieved with ventilation and/or using PAC [33]. Therefore, the clean air flow required for a room, CADR, provided by a PAC (or several) can be calculated from Equation (1).

ACR (cleaning) = CADR/Volume of air in the room

Portable air cleaners have been widely used in different studies in order to assess the removal of aerosols in indoor air.

Cox et al. [34] performed a study in a total of 46 homes (43 of the homes completed the entire 3-month study, and an additional 3 homes completed a portion (≤1-month)) to assess the effectiveness of a Portable Air Cleaner (PAC) with a HEPA filter in reducing indoor concentrations of traffic-related and other aerosols, including black carbon (BC), PM2.5, ultraviolet absorbing particulate matter (UVPM) (a marker of tobacco smoke), and fungal spores. The PAC selected was a Whirlpool Whispure (Model AP51030K, Austin, TX) with a HEPA filter designed to capture 99.97% of 0.3 μm particles and with a CADR between 360 and 576 m3/h (minimum to maximum speed). The CADR was selected according to the room size. The results showed that Portable Air Cleaners with HEPA filters could significantly reduce traffic-related and other aerosols in different residential environments, such as tobacco smoke, PM2.5 and fungal spores.

Dubey et al. [35] have studied the effectiveness in reducing the concentration of different sized particulate matter (PM) and ions of two types of air purifiers equipped with HEPA filters in general indoor air and the presence of an external source (candles and incense). The first air purifier (API) comprised an anti-dust filter, activated carbon filter, active HEPA filter, electrostatic filter, vita ions, cold catalyst filter with programmable control panel, sleep mode, timer function, independent air ducts and a CADR of 120 m3/h, while the second air purifier (APII) was equipped with six sense technology, a humidifier and a filter replacement indicator, along with filters viz. pre-dust filter, activated carbon filter, HEPA filter, nanocaptur filter; UV lamps, in addition to an ionizer function and a CADR of 150 m3/h. The results showed that both devices reduced PM levels that varied from 12 to 53% for API and 37–68% for APII, depending on the scenario studied. In addition, both air purifiers reduced ions concentration significantly, while the concentration of some of the ions increased after the application of the air purifier. The increase in the mass concentration of ions after the application of the air purifier may be due to that air purifiers release ions continuously to purify the air. Overall, the study recommends the use of air purifiers with mechanical filters (HEPA) instead of those that release ions for air purification.

Blocken et al. [36] assessed aerosol levels in a gymnasium, and demonstrated that the existing mechanical ventilation systems alone are not efficient to decrease the levels. An air cleaning device (AC) alone with ACH = 1.39 h−1 had a similar effect as ventilation alone. Simplified mathematical models were engaged to provide further insight into ventilation, AC and deposition. It was shown that combining the above-mentioned ventilation and AC can reduce aerosol particle concentrations with 80 to 90%, depending on aerosol size. It should be stressed that it remains imperative that ventilation should be maintained at (at least) the minimum flow rates required by building codes, because many ACs do not remove gasses such as CO2.

Lee et al. [37] assessed the effectiveness of aerosol filtration by portable air cleaning devices with HEPA filters used in addition to a standard building heating ventilation and air conditioning (HVAC) system. The test rooms, including a single-bed hospital room, were filled with test aerosols to simulate aerosol movement. Aerosol counts were measured over time with various portable air cleaning devices and room ventilation systems to quantify the overall aerosol clearance rate. It was found that PAC devices were very effective for the removal of aerosols. The aerosols were cleared five times faster in a small control room with PAC devices than in the room with HVAC alone. The single-bed hospital room (37 m3) had an excellent ventilation rate (ACH = 14) provided by the HVAC system and cleared the aerosols in 20 min. However, with the addition of two air cleaning devices (CADR = 1458 m3/h, ACH = 39 h−1), the clearance time was three times faster.

Finally, Cheek et al. [38] carried out a systematic literature review to examine the impacts of portable air purification on indoor air quality (PM2.5) and health, focusing on adults and children in indoor environments (homes, schools and offices). These authors [38] report positive long-term impacts with reduced PM2.5 concentrations. The current evidence demonstrates that using a PAC results in short-term reductions in PM2.5 in the indoor environment, which has the potential to offer health benefits.

It is consensual that filters can efficiently remove particles but are not effective for organic and inorganic chemical pollutants. A solution seems to be a combination of particulate filter and other air purification systems, or the development of filters with other properties, such as chemisorption. Regarding gas purification, the most effective and commonly used purification method is adsorption, with activated carbon filtration being the most prevalent approach due to their high surface area and high storage capacity, although other technologies are available [25][39].

Swamy [40] assessed the use of filters prepared with different percentages of NaOH doping on calcium silicate granules in order to reduce CO2 concentration levels. The results showed an over 40% reduction in CO2 concentrations with this purification system. Fresh air intake, to maintain the desired ventilation rates, has been reduced to over 50%, further reducing the heat load. Nanofibers can also be modified with adsorbent nanomaterials effective in the adsorption of VOCs [41]. Buyukada-Kesici et al. [42] have used cellulose nanocrystals and polyamide 6 to develop a porous electrospun material, which can adsorb around 50% of toluene in 45 min of trials, maintaining the same removal efficiency of conventional adsorbents in the form of powder or particles.

Protein-based nanofibers have also gained prominence in the air filtration field. The study performed by Kadam et al. [43] showed that Gelatin/β-CD composite nanofibers presented excellent adsorption of xylene (287 mg/g), benzene (242 mg/g) and formaldehyde (0.75 mg/g). The gelatin/β-CD biomaterial-based nanofibers filtered solid/liquid aerosols and gaseous pollutants simultaneously at a lower base weight with low air resistance.

Another interesting study was presented by Liu et al. [25], who developed a transparent polyacrylonitrile air filter to protect indoor air quality through natural passive ventilation windows. They obtained highly effective air filters, ~90% transparency, with a removal rate greater than 95% for PM2.5, under extremely hazardous PM2.5 concentrations (>250 μg m−3). Its material is an excellent alternative for perspective windows, especially in large urban centers.

The studies presented are a small portion of all studies around new materials and new combinations involving filtration. With the advent of nanotechnology, there is enormous research potential in this area.

Concerning usual filtration, the traditional fibrous filters have numerous advantages, such as high removal efficiency, low initial cost and simple structure [25].

The main disadvantages are high pressure drop, high maintenance costs and filter colonization [25]. Another negative point is that filters are not effective for pollutants other than PM. The filtration efficiency of general fiber filters is directly proportional to the air pressure drop. High pressure drop means additional energy consumption and increased operating costs. Filter maintenance is often neglected during a system operating period. Filters must be replaced or cleaned regularly, otherwise they could become sources of pollution. The longer the filter operating time, the greater the possibility of potential pollution, by re-emission of VOCs or dissemination of fungi or bacteria by aerosols diffusion [44].

2.1.2. Electronic Filtration

There are two types of electronic filters for particles removal: electrostatic precipitators and ion generator or ionizers. Electronic filters include a wide variety of electrically connected air-cleaning devices that are designed to remove particles from airstreams. Removal, typically occurs by electrically charging particles, using corona wires or through the generation of ions (e.g., using pin ionizers), and by collecting the particles on oppositely charged deposition plates (precipitators), or by the particles’ enhanced removal to a conventional media filter, or to room surfaces [24]. According to Bliss [45], the efficiency of electrostatic filters for a particle range of 0.3–6 µm is over 90%, while this value oscillates between 75 and 95% for ion generators. Some studies have found adverse health effects when using electrostatic precipitators such as the modification of cardiorespiratory function associated with the production of negative air ions, which may outweigh the potential benefits from PM reductions (e.g., Liu et al. [46]). In addition, the filters can become clogged over time, and so require regular cleaning. Generally speaking, electronic filters can generate hazardous charged particles [47] or new pollutants such as ozone, ultrafine particles and other compounds derived from VOCs ionization [48].

2.2. Adsorption

Adsorption consists of capturing air pollutants on the surface of an adsorbent material. It has been successfully applied for retaining both volatile organic compounds and inorganic pollutants on adsorbents, such as activated carbon, zeolites, silica gel, activated alumina, mineral clay and some polymers. The most commonly used are activated carbon and hydrophobic zeolites, due to their high surface area and adsorption capacity [18]. Activated carbon has high porosity and is a non-polar adsorbent. It can be produced from agricultural wastes such as sugarcane bagasse, apple pomace or coconut shell for more cost-effective pollutants removal [49]. Due to its microporous structure and large surface area, activated carbon is able to remove up to 100 mg m−3 of VOCs [50], although medium and high molecular weight volatiles are better adsorbed on activated carbon than low molecular weight volatiles.

Adsorbents can be easily incorporated into building materials and/or integrated into interior surfaces to remove air pollutants with no additional energy input and minimal byproduct formation; for this reason, they are classified as passive removal materials (PRMs). Passive removal materials enable ozone control, for example, in susceptible populations with health benefits, creating healthy indoor environments [51].

Hybrid technologies of adsorption combined with other methods have been proposed for pollutants removal from indoor air. For example, Jo and Yang [52] investigated the technical feasibility of an hybrid system composed of activated carbon and photocatalytic oxidation for controlling indoor air levels of BTEX (benzene, toluene, ethylbenzene, and xylenes) at low concentrations (of 0.1–1 ppmv). These authors [52] concluded that this hybrid system can enhance control efficiency of BTEX in indoor air levels with higher removal efficiencies (close to 100%) compared to using activated carbon alone (with removal efficiencies close to or higher than 90%), with a negligible addition to indoor CO levels from the photocatalytic oxidation process. However, some drawbacks of this technology include the decrease in removal efficiency with increasing relative humidity due to the capillary condensation of water vapor inside the activated carbon that blocks the adsorption sites. Additionally, the adsorption capacity of activated carbon decreases with increasing inlet concentrations. Furthermore, these authors [52] reported that a temperature of 300 °C is necessary to obtain significant desorption yields (75–95%) and the adsorbents need to be regularly replaced in order to avoid re-emission of already adsorbed compounds.

Ao and Lee [53] examined the effect of TiO2 immobilized on activated carbon under different humidity levels for the removal of air pollutants from indoor air at parts-per-billion (ppb) levels. In this research [53], NO (200 ppb), BTEX (20 ppb) and SO2 (200 ppb) were used as target pollutants. Different resident times and relative humidity levels were tested to investigate their mutual effect on TiO2 and TiO2 immobilized on activated carbon. The results showed that the effect of TiO2/AC is more significant with decreasing residence time and increasing levels of humidity. At a longer residence time, no significant pollutant removal difference is observed between TiO2 and TiO2 immobilized on activated carbon. At high humidity levels, the inhibition effect of water vapor is more significant compared to the presence of other pollutants, although it is still practically feasible to remove multiple pollutants under high humidity levels [53]. To further evaluate the performance for indoor air purification of a TiO2 immobilized on activated carbon (TiO2/AC) filter, Ao and Lee [54] examined it installed in a commercially available air cleaner. The authors tested it inside an environmental chamber, using NO and toluene as target pollutants. The original commercial air cleaner setting (AC + HEPA) showed no NO and little toluene removal. The TiO2 filter removed 83.2% of NO but generated 12.9% of NO2. Using TiO2/AC, the NO removal efficiency increased to 97% and the generation of NO2 decreased to 1.6%. The authors concluded that the TiO2/AC filter not only increases the pollutants removal efficiency, but also reduces the release of intermediate compounds by the system.

Sidheswaran et al. [55] demonstrated the potential environmental and energy benefits of using activated carbon fiber filters for air cleaning in HVAC (heating, ventilation and air conditioning) systems. These filters are prepared from fabric precursors and have a very high specific BET surface area, typically higher than 1000 m2 g−1 and low pressure drop, making them ideal for use in HVAC systems for VOC removal. In order to measure the removal efficiency of this activated carbon filter, the authors exposed it to a VOCs mixture of model pollutants, with concentrations in the range 20–30 ppbv (parts per billion by volume), composed of toluene, benzene, o-xylene, 1-butanol, limonene, undecane and formaldehyde at 29 °C and 30% relative humidity. The experiments showed the consistent removal (retaining) efficiencies of 70–80% for most VOCs [55].

Cheng et al. [56] evaluated the antibacterial and regenerated characteristics of a zeolite impregnated with metallic silver (Ag-Z) for removing bioaerosols (bacteria and fungi) in indoor environments, showing a 95% removal efficiency after 120 min of operation. These authors considered the 1 wt% Ag-Z to be more cost-effective, with an antibacterial efficiency near 90% in less than 60 min and an excellent repeated use performance up to nine times.

Adsorption materials can not only act as a sink for airborne pollutants, but also for excess moisture through adsorption. For example, a medium density fiberboard modified with walnut shell was investigated to regulate relative humidity, toluene, limonene, dodecane and formaldehyde [57]. A negative feature of the adsorption technology is the possibility of the deposition and development of airborne bacteria on the adsorbent surface due to the high biocompatibility of these materials [18]. Additionally, adsorption technology does not treat or destroy contaminants, but they are simply transferred from one phase to another, producing a hazardous solid waste that must be further treated and/or disposed of correctly.

2.3. UV-Photocatalytic Oxidation

UV-Photocatalytic Oxidation (PCO) is a very interesting air cleaning technology that has been the subject of much investigation in recent years. PCO is defined [24] as a light-mediated, redox reaction of gases and biological particles adsorbed on the surface of a solid pure or doped metal oxide semiconductor material or photocatalyst. The most common photocatalyst is TiO2 (titanium dioxide), while zinc oxide (ZnO), tungsten trioxide (WO3), zirconium dioxide (ZrO2), cadmium sulfide (CdS), and iron (III) (Fe(III)-doped TiO2), among others, are also used. To improve the efficiency of each elementary step, various strategies have been used to modify the physicochemical properties of nanomaterials. For example, element doping (metal or nonmetal) to induce impurity states in wide bandgap semiconductors has been used to extend the light absorption range, while plasmonic noble metal (Ag and Au) deposition is a popular way to enhance light absorption and inhibit photoinduced charge recombination. Several examples of these nanomaterials can be found in the review organized by Cao et al. [58]. The photocatalyst generates oxygen species (or reactive oxygen species) that remain surface-bound when exposed to light of particular wavelengths in the ultraviolet (UV) range. The oxygen species are highly reactive with adsorbed gases and biological particles. A variety of UV light sources can be used in PCO, including black lights (UV-A: long-wave; 400 to 315 nm), germicidal lamps (UV-C: short-wave; 280 to 200 nm), and lamps that generate ozone (vacuum UV [UV-V]: under 200 nm). Under reaction conditions allowing for deep oxidation (referred to as mineralization), carbon, hydrogen, and oxygen atoms in the reacting species will be converted completely via chemical reaction to water vapor and carbon dioxide. However, the oxidizing process can be incomplete, and origin reaction byproducts can be more toxic or harmful than the original constituents, as is the case for formaldehyde. Several studies [59][60][61] showed the generation of formaldehyde and acetaldehyde from the partial oxidation of ubiquitous VOCs such as alcohols. To minimize these problems, mixed technologies have emerged, which, for example, combine the use of PCO with filters. The combination of two techniques [62], or the development of filters with PCO properties, was found [63][64][65].

The research in this area is vast, and it would be impossible to list all the different nanomaterials developed to increase the PCO efficiency. Notably, in 2020, more than 9000 journal papers were published on the photocatalytic degradation of several pollutants [65]. Several review articles can be found [66] where an overview of the most recent studies for applications in indoor air cleaning is presented.

One of the most interesting applications is the incorporation of well-known and efficient photocatalytic materials into construction materials suitable for indoor applications to degrade priority air pollutants indoors and to inactivate various pathogens. Examples of such applications in confined spaces are TiO2-based paints [67][68][69], roofing tiles [70], paper sheets [71], or textiles [72]. There is also the so-called indoor passive panel technology (IPPT), which includes as typical materials modified gypsum board, acoustic ceiling tiles, ceramic tiles, wallpaper and other coatings and pre-coated products relying on either sorptive or photocatalytic oxidation (PCO) processes [73]. Shayegan et al. [74] present a review focused on the application of passive removal materials to improve indoor air quality, which have recently gained interest due to their ability to remove pollutants without additional energy consumption and lower amounts of byproducts formation. Two types of materials are the object of the review: photocatalytic oxidation-based materials and sorptive-based materials. These authors [74] concluded that further scientific evaluation is necessary to assess the application of these passive materials in the indoor environment, and to better understand their impact on the IAQ.

From the exposed, it can be concluded that PCO is a promising cleaning technology, but studies show that there are aspects that need to be addressed before UV-photocatalytic oxidation can be used safely in buildings. The design of a photocatalytic air purification system is complex, and it is dependent on a wide variety of factors, including the intensity of the light falling on the catalyst, chemical makeup and pollutants concentration, the air flow rate through the device, moisture levels in the air, properties of the specific catalyst used, pollutant residence time, and how the device itself is configured [62].

However, the technology has several advantages:

- (1)

-

Use of solar light, a sustainable resource that is of major significance from the perspective of energy conservation and environmental remediation;

- (2)

-

Quick reaction rate and low energy consumption of heterogeneous photocatalytic oxidation;

- (3)

-

Relatively low pressure drop;

- (4)

-

Ability to treat a wide variety of compounds;

- (5)

-

Theoretically long-life cycle of reactive process (self-cleaning or regenerating feature of the photocatalyst).

The main disadvantage is the incomplete oxidation, which produces reaction byproducts that can be more toxic or harmful than the original constituents (e.g., formaldehyde). The catalysts can also be contaminated (poisoned) by airborne reagents and/or products of oxidation, which results in reduced or total efficiency failure of the process. In the cases where a lamp us utilized instead of solar light, the list of disadvantages includes the lamp energy consumption, lamp replacement costs, and the likelihood of ozone generation depending on the lamp source employed (e.g., UV-V lamps ~185 nm produces ozone) [24].

2.4. UV Light Technology-Based Disinfection Systems

There are four types of ultraviolet (UV) radiation, defined according to their wavelength range in nm: vacuum UV (100–200), UVC (200–280), UVB (280–320) and UVA (320–400). Although all UV wavelengths are described to cause some photochemical effects, wavelengths within the UVC or UVGI range, specifically at 253.7 nm, are particularly harmful to cells, because it is absorbed by proteins, RNA and DNA. This process induces molecular breaks of the simple covalent bonds C, H, O and N of the nucleotide chain, resulting in irreversible molecular damage that leads to the inactivation of all types of microorganisms [75][76][77].

During the last century, several authors have studied the disinfection properties of ultraviolet (UVGI) light, at a first stage for water disinfection and, afterwards, for both air and surface disinfection purposes. In addition, throughout the years, efforts have been devoted to identify the configuration of an UVGI system that is most effective for each type of building ventilation system, as well as to disclose data on the effectiveness of UV in decreasing levels of microorganisms in indoor air and, consequently, the risk of developing health problems, such as respiratory infections and allergies [78][79][80][81]. The best-known application of UVGI disinfection in air is in buildings belonging to the healthcare sector [82][83][84][85]. However, a growing number of studies have provided robust evidence on the effectiveness of this air cleaning technology in several indoor environments, including offices, commercial areas, schools and universities [81][86][87]. For instance, although UVC systems have been used to disinfect hospital environments since 1936 [88], this approach was only formally recognized as being effective against airborne bio-pollutants by official authorities at the Center for Disease Control and Prevention (CDC) in 2003 [89]. Since then, UV light-based systems have been recommended by the CDC (2003) as an adjunct to routine chemical cleaning, as traditional cleaning and disinfection protocols can be insufficient for insuring proper disinfection in some contaminated areas [90]. Recently, ASHRAE and EPA recognized the importance of employing air cleaning solutions that include both filtration and UVC-based systems to prevent the spread of infectious diseases in indoor environments [91][92].

Air disinfection can be performed using UVC in several modalities, including irradiation in forced air or stand-alone systems, upper room, irradiation of an entire room (when the room is empty) and irradiation of the air circulating through a heating, ventilation, and air conditioning (HVAC) system, both in-duct and in the coils [91]. From the existing studies aiming at investigating the effectiveness of the use of UVGI for air treatment, it was particularly demonstrated that the use of in-duct in central ventilation systems, as well as upper-room and stand-alone systems, results in an effective reduction in the levels of microorganisms and endotoxins [81][92][93][94][95][96][97][98]. UVC systems in ducts are known to be cheaper and demand a lower energy consumption, as they are able to disinfect air and surfaces, while upper and stand-alone room devices only disinfect air [99].

Building ventilation systems are typically designed taking into consideration comfort needs. Even when ventilation systems are reconditioned to incorporate UV lamps there may be limitations related to air distribution and the removal of polluted air at the source [100]. Thus, based on the evidence, mainly for the indoor spaces with special needs of disinfection (e.g., hospitals) it is preferable to consider, in addition to filters, an UV disinfection technology, at an early stage of designing the ventilation system to serve the building. A very important criteria related to the choice/designing of the system to be installed is the type of lamp(s) to employ. Typically, low pressure (LP) mercury lamps, which radiate 95% of their energy at the wavelength 253.7 nm and are “monochromatic”; are described to have greater germicidal power than medium pressure (MP) polychromatic lamps, Xenon or UV LED [75]. The radiant energy flow of the systems should be determined, since systems, especially in ducts and stand-alone modalities, must be coated with material of high UV reflectance such as aluminum (not plastic) to reduce the number and size of lamps needed to be installed. Nevertheless, these conditions are difficult to standardize, given the geometry of the ducts and the eventual deterioration of reflectivity when internal surfaces are exposed to an airflow that carries can include variable levels of moisture and particles. This is why it is necessary to install lamps with a high UVC, preferably up to 30% of the rated power (e.g., Sanuvox technologies SL), as well as to correctly calculate and size each HVAC duct system, stand-alone, upper-room considering airflow, humidity, temperature, sizes, materials. In 1954, Harstad et al. [101] demonstrated that despite the installation of UV light in the air conditioner, there could still be airborne pollution from the growth of microorganisms in air conditioner components such as filters, cooling coils and duct surfaces [101]. In fact, one of the most widespread applications are UVC systems in cold batteries to destroy fungi, bacteria and endotoxins, avoiding their proliferation in the HVAC systems, achieving energy savings (average of 5–15%) and improving the efficiency of cooling transfer by reducing static pressure through the coil [81][99].

Each organism has a different sensitivity to UVGI light. Kowalski [75] and Malayeri [102] are some of the researchers who have collected data from several studies on the dose of UV needed to achieve the inactivation of bacteria, fungus, virus, protozoan and microalgae in vegetative forms and spores. Bedford [103] and Gates [104][105] were among the first to establish the UV doses needed for bacterial disinfection. Fulton and Coblentz [106] reported the UV doses for fungal inactivation, while data on the respective doses for viruses removal were first published by Rivers and Gates [107]. It is important to know the target pathogens to calculate the optimal UV dose based on their susceptibility constants, named K or z-value. This susceptibility, z-value, of each microorganism varies according to factors such as the pathogen biological structure, the conditions of environmental exposure and the distribution of the particles size, among others [75][96][108]. In fact, some environmental factors can influence the effectiveness of UV microbial inactivation. In this regard, there is evidence showing that airborne bacteria become more resistant to UV rays as relative humidity increases [75][96][108]. In addition, the use of an increased airflow rate passing through the UV system can result in a lower effectiveness of UV disinfection because microorganisms are exposed to UV rays for less time [75][96][97][109]. A low or a very high airflow temperature is also described to negatively affect the UV output, UV disinfection efficiency and susceptibility constants of microorganisms [75][96][97][108][109].

In addition to the selection of proper design, another aspect of utmost importance to consider is to ensure the proper sizing and operation of the systems. In fact, since the irradiance of the UV dose decreases with distance, to reach the same z-value, it can be necessary to operate the system with more time, in order to ensure effective disinfection [84]. Regarding the maintenance of the UV-based system, it is crucial to consider the nominal output potential of UVC lamps, which decreases over time. UVC lamps are classified into effective hours of UVC emission, and not at the end of the hours of electrical life. Many UVC lamps are designed to emit intensity levels at the end of their service life that are 50 to 85% or more than that measured in initial operation (after 100 h of burning time), although current models continue to emit blue visible light. Specification data from lamp manufacturers can verify depreciation over the useful life [110], the better the longer the lamp life, and the cost of spare parts and maintenance will be reduced (e.g., Sanuvox technologies SL lamps have a useful life of 17.000 h).

Importantly, in order to avoid any collateral health risks to the occupants, the potential release of toxic byproducts (such as ozone) by all kinds of UV systems should be carefully controlled. The devices must be tested by the manufacturer (and preferentially also by an independent third party laboratory) to ensure that the ozone concentration generated during operation respects the recommended maximum limits [91]. Another aspect to keep in mind is that there are limit values established for exposure to UVC light that cannot be exceeded. For systems that are closed (e.g., in ducts, cleaning of surface coils, autonomous systems), it is important to include a security system for opening doors that interrupts the operation of the lamps. In the case of upper room systems, these should be placed to an adequate distance from the ground that does not endanger people, because direct UVC light can induce damages to the eyes and skin [75][91][100].

2.5. Ionization

Bipolar ionization is generated when an alternating voltage (AC) source is applied to a special tube with two electrodes. This phenomenon can occur in nature, especially in mountain areas and waterfalls, where the production of positive and negative ions are reported to purify the air [111]. In the process of ionization, a neutral atom is given a positive/negative charge through the removal/addition of an electron, respectively. In bipolar ionization, positive (H+) and negative (O2−) ions are generated when water molecules are exposed to high-voltage electrodes. Although the mechanism associated with the biocidal effect of positive and negative ions have not been yet clearly established, the purposed mechanism involves the clustering of these ions around micro-organisms, resulting in the formation of OH radicals, which remove hydrogen, leading to the production of water vapor and to microbial inactivation [112]. Air ionization-based devices include those that generate only negative ions (i.e., unipolar ionizers) and those that generate positive and negative ions (i.e., bipolar ionizers). Bipolar ionization technologies, especially Corona Discharge and Needlepoint (NBPI), generally produce the same types of ions, which have the same theoretical mechanism of action when it comes to fighting pathogens, VOCs, and particles. However, a shared mechanism of action between the various air ionization technologies is not necessarily indicative of a shared method of ion creation [87]. Bipolar ionization technology has been around for decades, but the limited number of peer-reviewed studies in this topic makes it difficult to accurately support the effectiveness of this technology for air and surface disinfection purposes. Nevertheless, a growing body of recent evidence has presented the potential of using air ionization to decrease bacterial deposition on surfaces [113][114], inactivate airborne bacteria, viruses, and fungi [98][114][115][116] and to remove airborne particles and VOCs, being more effective when used in long-term applications [114][117].

Air ionization modules are often fitted directly into central air handling units to treat entire airflows. Modules can also be fitted into existing ductwork immediately downstream of central HVAC systems. Freestanding devices can also be placed into individual room spaces to meet immediate demands from internal sources. It is common to employ air ionization along with other technologies, such as air filtration [118], and some reports suggest that the efficiency of filtration increases when the ionizer is running [116]. Because the ions have a short service life of milliseconds, the distance from the ion generating equipment and the area to be treated must be estimated [118]. There are authors that recommend that the system should be installed vertically and deployed near both the inlet and return outlet for ensuring a better inactivation efficacy against airborne bacteria, especially in hospitals [119].

Since it has been seen that these systems can produce high levels of ozone and other organic compounds, similarly to UV-based systems, an aspect to consider is that the systems to be installed must have the certificate that accredits the non-generation of ozone [120]. In this regard, it has been described that when the energy potential produced through the ionization process is limited to 12 eV or less, ozone will not be produced because the oxygen has an ionization energy of 12.07 eV [111].

Some of the great advantages of NBPI systems are the elimination of VOCs, particles, odors and pathogens with reduced energy consumption and very low maintenance costs [114]. The main disadvantage is that while there is some evidence showing the efficacy of some of these approaches, the literature is still too scarce to draw robust conclusions- Thus, it is necessary to carry out more studies considering the implementation of air ionization-based technologies in real life situations and not only in controlled environments. Likewise, further work is needed to explore the potential capabilities that this technology has in combination with other systems to improve indoor air quality and reduce risks to human health.

3. Biological Technologies

3.1. Plant Purification Methods

Indoor greenery provides several benefits such as producing oxygen, generating humidity, pleasant aesthetical integration, passive acoustic insulation system [121], positive psychological effect on task performance, health, level of stress and comfort [122]. Besides that, the potential of plants for purifying and remediating the indoor atmospheric environment has long been identified (e.g., Wolverton [123]). Nevertheless, in the last twenty years, there has been a rising trend of more in-depth research on air purification mechanisms, technological solutions and methods [7][124][125]. Recently, in the context of the COVID-19 pandemic, the role of indoor plants in air purification and human health was looked at closely and considered as an alternative solution that could be used to reduce the viability of SARS-CoV-2 [126][127].

The purification methods mostly rely on phytoremediation, which is characterized by the use of plants to remove pollutants, or in this case from air, since it can be applied to water and soil, being based on a plant’s ability to absorb, catabolize and degrade airborne pollutants, associated with their metabolic activities [121][124][125][128]. Regarding the plant microbiome, both the endobacteria and phyllobacteria may have an influence on the removal process to different extents, having in consideration the type of pollutant.

Interest associated with phytoremediation is high since it is considered an approach with low implementation cost and maintenance, compared with other technologies [129]. Moya et al. [121] provide a detailed description of the phytoremediation techniques. Additionally, Teiri et al. [130] revised different phytoremediation methods and the critical factors for the purification of indoor air, concluding that plants are able to efficiently remove different harmful contaminants from indoor air, including VOCs. This can be achieved through passive filtration using potted plants, or through active filtration using plant filters or green walls.

In general terms, active vegetation systems (in combination with mechanical systems) and passive vegetation systems (without additional energy requirements) can be considered for the present purpose [121][125]. Active systems increase the availability of polluting gases through the incorporation of mechanical ventilation devices; being associated with higher air-cleaning rates than passive systems. The passive ones are dependent on the diffusion of polluting gases, characterized by slower operation and lower concentrations [7].

Indoor plants are generally considered small shrubs and herbs that fit into the selected greenery system [124]. Plants used for indoor air phytoremediation are, in general, ornamental and limited to a small number of model species [125]. Following the recent review by Prigioniero et al. [125], the most widely considered species for this purpose is Chlorophytum comosum (Thunb.) Jacques, although other species are mentioned in the literature, often related with the type of pollutant to be removed [124][128][131]. An extensive list of indoor plants and their pollutant removal efficiency are mentioned in the literature [122][128]. Pollutant removal is plant specific and each part of the plant has different removal potential [122].

When using plant-based systems to promote indoor air quality, it is also important to consider the pollen load and allergenicity potential, such as flowering plants with strong fragrances [124]. Nevertheless, the main source of indoor pollen and fungi spores typically come from outdoors [132]. Plants also emit compounds, some of which are biologically active [133]. For example, plant volatile organic compounds (VOCs) are important in the ecosystem for chemical information transfer [124]. Gas exchange intensity and extent vary from night to day, and also depends on several factors such as temperature, humidity, light intensity, photosynthetic system, carbon dioxide concentration, and concentration of air pollutants [129][133].

The use of potted plants to promote air purification has been studied for a long time [123]. Although considered a passive approach, it has been investigated for the removal of harmful pollutants such NO2, with promising results, for example with a combination of species Spathip-hyllum wallisii “Verdi”, Dracaena fragrans “Golden Coast” and Zamioculcas zamiifoli [134]. Jung and Awad [135] demonstrated that indoor plants can improve the IAQ in University classrooms, showing that the increase in CO2 concentration in classrooms with plant placement was lower (624 ppm) compared with the case without plant placement (about 1205 ppm). Later, Dela Cruz et al. [136] reviewed the use of potted plants to remove VOCs from indoor air, including the removal mechanisms and the relationship between plant, soil, and associated microorganisms. The literature mentions other pollutants, such formaldehyde and particulate matter, that are also affected by potted plants [124]. The extent of cleaning efficiency by plants can be increased by increasing the number of plants [137]. However, it is not possible to accurately estimate the number and size of plants needed to effectively purify indoor air. This is because different plant species have differences in photosynthesis, such as different optimal light intensity levels; some species grow slowly and others faster. Additionally, the type of plant and pollutant affects the phytoremediation efficiency. Moreover, the type of soil used for the plants to grow is another important factor, demonstrated in a study [130] using as a mixture of coco coir and activated carbon (for adsorption) as growing media. This significantly increased the VOCs removal efficiency (p-value > 0.05). Additionally, there is a lack of information concerning most contaminants in indoor air, thus it is very important to determine the concentration of indoor air pollutants.

Another challenge when using plants is the quantity needed to effectively improve the indoor air quality, which is not always practical in housing and/or offices with reduced areas. Thus, instead of using potted plants, several studies [138][139] suggested the use of “green walls” or “biowalls” with different plant species, which can simultaneously remove a mixture of different contaminants with less space requirement.

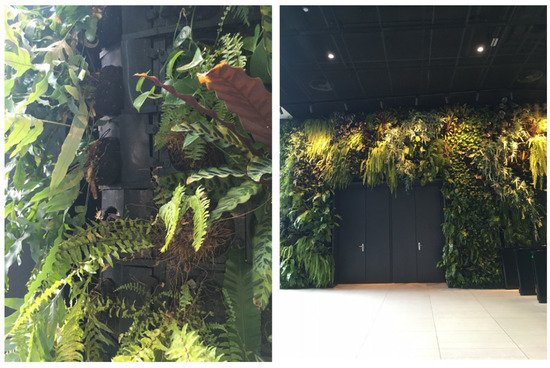

Biowalls are considered plant-based systems that mainly act to enhance the atmosphere and indoor environment and can be classified as living walls, vertical gardens or green facades, depending on their characteristics (type of plants and structural system) [140]. Figure 2 shows an example of a modular living wall system with planter boxes, implemented in an office building (Porto Office Park, Porto-Portugal). Figure 3 shows an example of a continuous system living wall with felt pockets, implemented in a Portuguese shopping center (Norteshopping, Matosinhos-Portugal).

Figure 2. Modular system living wall with planter boxes in an office building (Porto Office Park, Porto-Portugal). Credits: Cristina Calheiros.

Figure 3. Continuous living wall system with felt pockets in a shopping center (Norteshopping, Matosinhos-Portugal). Credits: Cristina Calheiros.

Irga et al. [128] highlighted the importance of the technological advancements related to active botanical biofilters or functional green walls, which are becoming increasingly efficient and a rapidly growing field of research interest.

Several plant-based systems have emerged to support the improved indoor environment, such as the biofiltration system, where air is drawn through organic material (such as moss, soil and plants), resulting in the removal of organic gases and contaminants involving a mechanical system [121], and the nature-based air filtering system, which was installed at a students’ residence, replacing an existing window with a mini-greenhouse, containing upwards of 30 plants connected to an air circuit to treat the indoor air [141]. The combination of systems can often boost and optimize the air purification effect, such as the combination of living wall systems with biofiltration. They are thus emerging technologies providing beneficial effects on the improvement of indoor comfort [121].

The main recommendations associated with vegetation systems for indoor air quality promotion comprise a detailed selection of plant species, growth medium, irrigation systems, adequate light setting and abiotic conditions (e.g., temperature and humidity). The main research gaps center on the need for phytoremediation operational systems, which are important when considering a wider range of pollutants and plant organisms for indoor purposes [125]. Since the process performance depends on the interactions between pollutant, plant and microorganisms [121], it would be relevant to develop tools to support indoor air phytoremediation in order to further expand its use and allow a wider array of applications. For example, Thomas et al. [142] developed a mathematical model that takes into account the amount of plant material, building air volume, VOC concentrations and air exchange. More tools are needed to allow continuous and long-term monitoring of these systems performance.

3.2. Microalgae-Based Air Purification Systems

Microalgae are prokaryotic or eukaryotic microorganisms with a unicellular or simple multicellular structure. They are among the most efficient photosynthetic organisms on earth, with high biomass productivity and relatively low nutrient requirements, accumulating metabolites with several applications. They can live in harsh conditions, in seawater or freshwater, and multiply exponentially under favorable environments [143].

Microalgae for carbon capture via photosynthesis has gained increasing attention from the scientific community due to their ability to capture CO2 and other pollutants, which they use to grow while producing O2. In particular, microalgae are among the most efficient photosynthetic organisms, with high biomass productivity and relatively low nutrient requirements. They accumulate metabolites (e.g., pigments, fatty acids, etc.) with important biotechnological applications [144][145]. The biomass can be converted into chemicals and/or biofuels (e.g., biohydrogen, biodiesel, bioethanol, biobutanol, biomethanol and other biohydrocarbons), thus generating environmental and economic value [143][146].

The CO2 bio-fixation by microalgae is a complex physicochemical process. Microalgae can tolerate up to a certain level of CO2, after which it becomes detrimental to cell growth. This is due to the lowering of the medium pH, and to the environmental stress caused by higher CO2 levels, reducing the cells’ ability to fix more carbon. In an aqueous environment, inorganic carbon is available in different chemical forms, such as CO2, H2CO3, CO32− and HCO3−. Depending on the species and on the physicochemical and hydrodynamic conditions, microalgae can biofix around 1.875 g of CO2 per gram of biomass, [147]. Nonetheless, microalgae harvesting is still an energy intensive process due to the low cell density in the culture medium, typically in the range of 0.3–0.5 g/L, with exceptional cases reaching 5 g/L [148].

With the world’s rapid urbanization and demand for renewable energy sources, a recent focus on the potential of microalgae is to contribute to the development of green cities and build a more sustainable future [149]. In particular, microalgae systems can be implemented as nature-based solutions to improve indoor air quality, along with other benefits [7], in alignment with the United Nations Sustainable development Goals (UN SDG) [150]. Moreover, their implementation will promote good health and well-being (Goal 3) and sustainable cities and communities (Goal 11), contributing to the European Commission’s plans of Building a Green Infrastructure for Europe [151], allowing for thermal regulation and new architectural features [152]. Recommendations for sustainable urban planning include the implementation and, subsequently, the increase in urban greenery [140] as part of an urban renewal and rehabilitation strategy towards smarter and more sustainable development, and responding to global demands such as mitigation and adaptation to climate change [153].

With regard to the construction and architecture sectors, it is very common to find buildings with integrated photovoltaic energy. Despite the potential of microalgae biomass in the generation of renewable energy, its integration in buildings is still quite modest and at an early stage. In particular, microalgae have a great ability to biofix CO2, produce O2, treat wastewater, and produce biomass that can be used for bioenergy and bioproducts. The few examples of microalgae implementation in buildings and architectural design have demonstrated their significant contribution to energy efficiency, but they have never been tested for indoor air purification [7][154]. Recent studies have highlighted the potential of microalgae for indoor air purification.

In buildings, microalgae can be cultivated in closed photobioreactors (PBRs) of different shapes (e.g., flat panels, multi-tubular, etc.) and dimensions that can act as dynamic shading devices (Figure 4). Depending on the density of microalgae biomass inside the PBRs, and the amount of sunlight absorbed by cells, various shading levels can be provided. On the other hand, the biomass density depends on the microalgae species, their growth cycle, the available carbon dioxide and sunlight, temperature of the culture medium, and frequency of biomass harvesting, among other factors. However, these conditions can be adjusted to the needs of the building’s users.

Figure 4. Example of integration of microalgae PBRs and plants in buildings.

References

- Mannan, M.; Al-Ghamdi, S. Indoor Air Quality in Buildings: A Comprehensive Review on the Factors Influencing Air Pollution in Residential and Commercial Structure. Int. J. Environ. Res. Public Health 2021, 18, 3276.

- WHO. Ambient Air Pollution: A Global Assessment of Exposure and Burden of Disease; Department of Public Health, Environmental and Social Health Organization, World Health Organization: Geneve, Switzerland, 2016; pp. 1–121.

- Sundell, J. On the history of indoor air quality and health. Indoor Air 2004, 14, 51–58.

- Coggins, M.A.; Semple, S.; Hurley, F.; Shafrir, A.; Galea, K.S.; Cowie, H.; Sanchez-Jimenez, A.; Garden, C.; Whelan, P.; Ayres, J.G. Indoor Air Pollution and Health (IAPAH) (2008-EH-MS-8-S3); STRIVE Report Series No.104. EPA STRIVE Programme 2007–2013; EPA—Environmental Protection Agency: Wexford, Ireland, 2013; ISBN 9781840954852.

- Jones, A.P. Indoor air quality and health. Atmos. Environ. 1999, 33, 4535–4564.

- Van Tran, V.; Park, D.; Lee, Y.-C. Indoor Air Pollution, Related Human Diseases, and Recent Trends in the Control and Improvement of Indoor Air Quality. Int. J. Environ. Res. Public Health 2020, 17, 2927.

- Mata, T.M.; Oliveira, G.M.; Monteiro, H.; Silva, G.V.; Caetano, N.S.; Martins, A.A. Indoor Air Quality Improvement Using Nature-Based Solutions: Design Proposals to Greener Cities. Int. J. Environ. Res. Public Health 2021, 18, 8472.

- Mata, T.M.; Felgueiras, F.; Martins, A.A.; Monteiro, H.; Ferraz, M.P.; Oliveira, G.M.; Gabriel, M.F.; Silva, G.V. Indoor Air Quality in Elderly Centers: Pollutants Emission and Health Effects. Environments 2022, 9, 86.

- Kelly, F.J.; Fussell, J.C. Improving indoor air quality, health and performance within environments where people live, travel, learn and work. Atmos. Environ. 2018, 200, 90–109.

- González-Martín, J.; Kraakman, N.J.R.; Pérez, C.; Lebrero, R.; Muñoz, R. A state–of–the–art review on indoor air pollution and strategies for indoor air pollution control. Chemosphere 2021, 262, 128376.

- Yocom, J.E. A Critical Review. J. Air Pollut. Control. Assoc. 1982, 32, 500–520.

- Borsboom, W.; De Gids, W.; Logue, J.; Berkeley, L.; Sherman, M.; Berkeley, L.; Wargocki, P. Technical Note AIVC 68 Residential Ventilation and Health; International Energy Agency, Energy in Buildings and Communities Programme: Lozenberg, Belgium, 2016.

- Zhang, X.; Wargocki, P.; Lian, Z.; Thyregod, C. Effects of exposure to carbon dioxide and bioeffluents on perceived air quality, self-assessed acute health symptoms, and cognitive performance. Indoor Air 2016, 27, 47–64.

- Permentier, K.; Vercammen, S.; Soetaert, S.; Schellemans, C. Carbon dioxide poisoning: A literature review of an often forgotten cause of intoxication in the emergency department. Int. J. Emerg. Med. 2017, 10, 14.

- Chin, J.-Y.; Godwin, C.; Parker, E.; Robins, T.; Lewis, T.; Harbin, P.; Batterman, S. Levels and sources of volatile organic compounds in homes of children with asthma. Indoor Air 2013, 24, 403–415.

- Sokhi, R.S.; Moussiopoulos, N.; Baklanov, A.; Bartzis, J.; Coll, I.; Finardi, S.; Friedrich, R.; Geels, C.; Grönholm, T.; Halenka, T.; et al. Advances in air quality research–current and emerging challenges. Atmos. Chem. Phys. 2022, 22, 4615–4703.

- Hassanvand, M.S.; Naddafi, K.; Faridi, S.; Nabizadeh, R.; Sowlat, M.H.; Momeniha, F.; Gholampour, A.; Arhami, M.; Kashani, H.; Zare, A.; et al. Characterization of PAHs and metals in indoor/outdoor PM10/PM2.5/PM1 in a retirement home and a school dormitory. Sci. Total Environ. 2015, 527–528, 100–110.

- Luengas, A.; Barona, A.; Hort, C.; Gallastegui, G.; Platel, V.; Elias, A. A review of indoor air treatment technologies. Rev. Environ. Sci. Bio. Technol. 2015, 14, 499–522.

- Silva, G.V.; Martins, A.O.; Martins, S.D.S. Indoor Air Quality: Assessment of Dangerous Substances in Incense Products. Int. J. Environ. Res. Public Health 2021, 18, 8086.

- EUR 14449 EN; European Collaborative Action: Indoor Air Quality & Its Impact on Man. Environment and Quality of Life. Report No. 11—Guidelines for Ventilation Requirements in Buildings; Commission of the European Communities: Luxembourg, 1992; pp. 1–40.

- EN 16798-1; Energy Performance of Buildings—Ventilation of Buildings—Part 1: Indoor Environmental Input Parameters for Design and Assessment of Energy Performance of Buildings Addressing Indoor Air Quality, Thermal Environment, Lighting and Acoustics. European Committee for Standardization: Brussels, Belgium, 2019.

- Miller, S.L.; Lohascio, C.; Nazaroff, W.; Macher, J. Effectiveness of In-Room Air Filtration and Dilution Ventilation for Tuberculosis Infection Control. J. Air Waste Manag. Assoc. 1996, 46, 869–882.

- Nazarenko, Y. Air Filtration and Severe Acute Respiratory Syndrome Coronavirus 2. Epidemiol. Health 2020, 42, e2020049.

- ASHRAE. ASHRAE Position Document on Filtration and Air Cleaning; ASHRAE: Atlanta, GA, USA, 2021.

- Liu, G.; Xiao, M.; Zhang, X.; Gal, C.; Chen, X.; Liu, L.; Pan, S.; Wu, J.; Tang, L.; Clements-Croome, D. A review of air filtration technologies for sustainable and healthy building ventilation. Sustain. Cities Soc. 2017, 32, 375–396.

- ISO 16890-1:2016; Air Filters for General Ventilation—Part 1: Technical Specifications, Requirements and Classification System Based upon Particulate Matter Efficiency (ePM). International Organization for Standardization, Technical Committee: Geneva, Switzerland, 2016; pp. 1–27.

- EN 1822-1:2019; High Efficiency Air Filters (EPA, HEPA and ULPA)—Part 1: Classification, Performance Testing, Marking. European Committee for Standardization: Brussels, Belgium, 2019.

- ANSI/ASHRAE Standard 52.2; Method of Testing General Ventilation Air-Cleaning Devices for Removal Efficiency by Particle Size. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Inc. (ASHRAE): Atlanta, GA, USA, 2017; pp. 1–55.

- Bluyssen, P.M.; Ortiz, M.; Zhang, D. The effect of a mobile HEPA filter system on ‘infectious’ aerosols, sound and air velocity in the SenseLab. Build. Environ. 2020, 188, 107475.

- Villanueva, F.; Ródenas, M.; Ruus, A.; Saffell, J.; Gabriel, M.F. Sampling and analysis techniques for inorganic air pollutants in indoor air. Appl. Spectrosc. Rev. 2021, 57, 531–579.

- Zhao, B.; Liu, Y.; Chen, C. Air purifiers: A supplementary measure to remove airborne SARS-CoV-2. Build. Environ. 2020, 177, 106918.

- Liu, D.T.; Phillips, K.M.; Speth, M.M.; Besser, G.; Mueller, C.A.; Sedaghat, A.R. Portable HEPA Purifiers to Eliminate Airborne SARS-CoV-2: A Systematic Review. Otolaryngol. Neck Surg. 2021, 166, 615–622.

- Minguillón, M.C.; Querol, X.; Alastuey, A.; Riediker, M.; Felisi, J.M.; Garrido, T.; Bekö, G.; Nehr, S.; Wiesen, P.; Carslaw, N. Guide for Ventilation towards Healthy Classrooms. COST Action CA17136 Report. 2020. Available online: http://hdl.handle.net/10261/225519 (accessed on 2 July 2022).

- Cox, J.; Isiugo, K.; Ryan, P.; Grinshpun, S.A.; Yermakov, M.; Desmond, C.; Jandarov, R.; Vesper, S.; Ross, J.; Dannemiller, D.K.; et al. Effectiveness of a portable air cleaner in removing aerosol particles in homes close to highways. Indoor Air 2018, 28, 818–827.

- Dubey, S.; Rohra, H.; Taneja, A. Assessing effectiveness of air purifiers (HEPA) for controlling indoor particulate pollution. Heliyon 2021, 7, e07976.

- Blocken, B.; van Druenen, T.; Ricci, A.; Kang, L.; van Hooff, T.; Qin, P.; Xia, L.; Ruiz, C.A.; Arts, J.; Diepens, J.; et al. Ventilation and air cleaning to limit aerosol particle concentrations in a gym during the COVID-19 pandemic. Build. Environ. 2021, 193, 107659.

- Lee, J.H.; Rounds, M.; McGain, F.; Schofield, R.; Skidmore, G.; Wadlow, I.; Kevin, K.; Stevens, A.; Marshall, C.; Irving, L.; et al. Effectiveness of portable air filtration on reducing indoor aerosol transmission: Preclinical observational trials. J. Hosp. Infect. 2021, 119, 163–169.

- Cheek, E.; Guercio, V.; Shrubsole, C.; Dimitroulopoulou, S. Portable air purification: Review of impacts on indoor air quality and health. Sci. Total Environ. 2020, 766, 142585.

- Bahri, M.; Haghighat, F. Plasma-Based Indoor Air Cleaning Technologies: The State of the Art-Review. CLEAN Soil Air Water 2013, 42, 1667–1680.

- Swamy, G. Development of an indoor air purification system to improve ventilation and air quality. Heliyon 2021, 7, e08153.

- De Almeida, D.S.; Martins, L.D.; Aguiar, M.L. Air pollution control for indoor environments using nanofiber filters: A brief review and post-pandemic perspectives. Chem. Eng. J. Adv. 2022, 11, 100330.

- Buyukada-Kesici, E.; Gezmis-Yavuz, E.; Aydin, D.; Cansoy, C.E.; Alp, K.; Koseoglu-Imer, D.Y. Design and fabrication of nano-engineered electrospun filter media with cellulose nanocrystal for toluene adsorption from indoor air. Mater. Sci. Eng. B 2020, 264, 114953.

- Kadam, V.; Truong, Y.B.; Schutz, J.; Kyratzis, I.L.; Padhye, R.; Wang, L. Gelatin/β–Cyclodextrin Bio–Nanofibers as respiratory filter media for filtration of aerosols and volatile organic compounds at low air resistance. J. Hazard. Mater. 2020, 403, 123841.

- Niu, M.; Shen, F.; Zhou, F.; Zhu, T.; Zheng, Y.; Yang, Y.; Sun, Y.; Li, X.; Wu, Y.; Fu, P.; et al. Indoor air filtration could lead to increased airborne endotoxin levels. Environ. Int. 2020, 142, 105878.

- Bliss, S. Best Practices Guide to Residential Construction: Materials, Finishes, and Details; Wiley: London, UK, 2005.

- Liu, S.; Huang, Q.; Wu, Y.; Song, Y.; Dong, W.; Chu, M.; Yang, D.; Zhang, X.; Zhang, J.; Chen, C.; et al. Metabolic linkages between indoor negative air ions, particulate matter and cardiorespiratory function: A randomized, double-blind crossover study among children. Environ. Int. 2020, 138, 105663.

- Guieysse, B.; Hort, C.; Platel, V.; Munoz, R.; Ondarts, M.; Revah, S. Biological treatment of indoor air for VOC removal: Potential and challenges. Biotechnol. Adv. 2008, 26, 398–410.

- Waring, M.S.; Siegel, J.A. The effect of an ion generator on indoor air quality in a residential room. Indoor Air 2010, 21, 267–276.

- Anirudhan, T.; Sreekumari, S. Adsorptive removal of heavy metal ions from industrial effluents using activated carbon derived from waste coconut buttons. J. Environ. Sci. 2011, 23, 1989–1998.

- Xie, T. Indoor air pollution and control technology. IOP Conf. Ser. Earth Environ. Sci. 2018, 170, 032084.

- Gall, E.T.; Corsi, R.L.; Siegel, J.A. Barriers and opportunities for passive removal of indoor ozone. Atmos. Environ. 2011, 45, 3338–3341.

- Jo, W.-K.; Yang, C.-H. Granular-activated carbon adsorption followed by annular-type photocatalytic system for control of indoor aromatic compounds. Sep. Purif. Technol. 2009, 66, 438–442.

- Ao, C.; Lee, S. Combination effect of activated carbon with TiO2 for the photodegradation of binary pollutants at typical indoor air level. J. Photochem. Photobiol. A Chem. 2004, 161, 131–140.

- Ao, C.; Lee, S.-C. Indoor air purification by photocatalyst TiO2 immobilized on an activated carbon filter installed in an air cleaner. Chem. Eng. Sci. 2005, 60, 103–109.

- Sidheswaran, M.A.; Destaillats, H.; Sullivan, D.P.; Cohn, S.; Fisk, W.J. Energy efficient indoor VOC air cleaning with activated carbon fiber (ACF) filters. Build. Environ. 2012, 47, 357–367.

- Cheng, H.-H.; Hsieh, C.-C.; Tsai, C.-H. Antibacterial and Regenerated Characteristics of Ag-zeolite for Removing Bioaerosols in Indoor Environment. Aerosol Air Qual. Res. 2012, 12, 409–419.

- da Silva, C.; Stefanowski, B.; Maskell, D.; Ormondroyd, G.; Ansell, M.; Dengel, A.; Ball, R. Improvement of indoor air quality by MDF panels containing walnut shells. Build. Environ. 2017, 123, 427–436.

- Cao, J.-J.; Huang, Y.; Zhang, Q. Ambient Air Purification by Nanotechnologies: From Theory to Application. Catalysts 2021, 11, 1276.

- Hodgson, A.T.; Destaillats, H.; Sullivan, D.P.; Fisk, W.J. Performance of ultraviolet photocatalytic oxidation for indoor air cleaning applications. Indoor Air 2007, 17, 305–316.

- Geiss, O.; Cacho, C.; Barrero-Moreno, J.; Kotzias, D. Photocatalytic degradation of organic paint constituents-formation of carbonyls. Build. Environ. 2012, 48, 107–112.

- Farhanian, D.; Haghighat, F. Photocatalytic oxidation air cleaner: Identification and quantification of by-products. Build. Environ. 2014, 72, 34–43.

- Kaushik, A.K.; Dhau, J.S. Photoelectrochemical oxidation assisted air purifiers; perspective as potential tools to control indoor SARS-CoV-2 Exposure. Appl. Surf. Sci. Adv. 2022, 9, 100236.

- Aydin-Aytekin, D.; Gezmis-Yavuz, E.; Buyukada-Kesici, E.; Cansoy, C.E.; Alp, K.; Koseoglu-Imer, D.Y. Fabrication and characterization of multifunctional nanoclay and TiO2 embedded polyamide electrospun nanofibers and their applications at indoor air filtration. Mater. Sci. Eng. B 2022, 279, 115675.

- Weon, S.; Choi, E.; Kim, H.; Kim, J.Y.; Park, H.-J.; Kim, S.-M.; Kim, W.; Choi, W. Active Facet Exposed TiO2 Nanotubes Photocatalyst Filter for Volatile Organic Compounds Removal: From Material Development to Commercial Indoor Air Cleaner Application. Environ. Sci. Technol. 2018, 52, 9330–9340.

- Wang, H.; Li, X.; Zhao, X.; Li, C.; Song, X.; Zhang, P.; Huo, P. A review on heterogeneous photocatalysis for environmental remediation: From semiconductors to modification strategies. Chin. J. Catal. 2022, 43, 178–214.

- Ren, H.; Koshy, P.; Chen, W.-F.; Qi, S.; Sorrell, C.C. Photocatalytic materials and technologies for air purification. J. Hazard. Mater. 2017, 325, 340–366.

- Monteiro, R.A.; Silva, A.M.; Ângelo, J.R.; Silva, G.V.; Mendes, A.M.; Boaventura, R.A.; Vilar, V.J. Photocatalytic oxidation of gaseous perchloroethylene over TiO 2 based paint. J. Photochem. Photobiol. A Chem. 2015, 311, 41–52.

- Maggos, T.; Binas, V.; Siaperas, V.; Terzopoulos, A.; Panagopoulos, P.; Kiriakidis, G. A Promising Technological Approach to Improve Indoor Air Quality. Appl. Sci. 2019, 9, 4837.

- Salvadores, F.; Alfano, O.; Ballari, M. Kinetic study of air treatment by photocatalytic paints under indoor radiation source: Influence of ambient conditions and photocatalyst content. Appl. Catal. B Environ. 2020, 268, 118694.

- Demeestere, K.; Dewulf, J.; De Witte, B.; Beeldens, A.; Van Langenhove, H. Heterogeneous photocatalytic removal of toluene from air on building materials enriched with TiO2. Build. Environ. 2008, 43, 406–414.

- Ichiura, H.; Kitaoka, T.; Tanaka, H. Removal of indoor pollutants under UV irradiation by a composite TiO2–zeolite sheet prepared using a papermaking technique. Chemosphere 2002, 50, 79–83.

- Dong, Y.; Bai, Z.; Liu, R.; Zhu, T. Decomposition of indoor ammonia with TiO2-loaded cotton woven fabrics prepared by different textile finishing methods. Atmos. Environ. 2006, 41, 3182–3192.

- Zuraimi, M.; Magee, R.; Won, D.; Nong, G.; Arsenault, C.; Yang, W.; So, S.; Nilsson, G.; Abebe, L.; Alliston, C. Performance of sorption- and photocatalytic oxidation-based indoor passive panel technologies. Build. Environ. 2018, 135, 85–93.

- Shayegan, Z.; Bahri, M.; Haghighat, F. A review on an emerging solution to improve indoor air quality: Application of passive removal materials. Build. Environ. 2022, 219, 109228.

- Kowalski, W. Ultraviolet Germicidal Irradiation Handbook: UVGI for Air and Surface Disinfection; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 9788578110796.

- Rauth, A.M. The Physical State of Viral Nucleic Acid and the Sensitivity of Viruses to Ultraviolet Light. Biophys. J. 1965, 5, 257–273.

- Bolton, J.R.; Cotton, C.A. The Ultraviolet Disinfection Handbook; American Water Works Association: Denver, CO, USA, 2008; ISBN1 1583215840. ISBN2 9781583215845.

- Whyte, W. Bacteriological aspects of air-conditioning plants. Epidemiol. Infect. 1968, 66, 567–584.

- Cooley, J.D.; Wong, W.C.; Jumper, C.A.; Straus, D.C. Correlation between the prevalence of certain fungi and sick building syndrome. Occup. Environ. Med. 1998, 55, 579–584.

- Lee, L.D.; Delclos, G.; Berkheiser, M.L.; Barakat, M.T.; Jensen, P.A. Evaluation of multiple fixed in-room air cleaners with ultraviolet germicidal irradiation, in high-occupancy areas of selected commercial indoor environments. J. Occup. Environ. Hyg. 2021, 19, 67–77.