Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Wenpeng Zhao | -- | 1866 | 2022-09-16 08:44:16 | | | |

| 2 | Rita Xu | -3 word(s) | 1863 | 2022-09-16 08:53:57 | | | | |

| 3 | Rita Xu | -5 word(s) | 1858 | 2022-09-20 09:53:46 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Xu, J.; Zhu, L.; Nie, Y.; Li, Y.; Wei, S.; Chen, X.; Zhao, W.; Yan, S. Intrinsic Self-Healing Polymers. Encyclopedia. Available online: https://encyclopedia.pub/entry/27240 (accessed on 07 February 2026).

Xu J, Zhu L, Nie Y, Li Y, Wei S, Chen X, et al. Intrinsic Self-Healing Polymers. Encyclopedia. Available at: https://encyclopedia.pub/entry/27240. Accessed February 07, 2026.

Xu, Jun, Lei Zhu, Yongjia Nie, Yuan Li, Shicheng Wei, Xu Chen, Wenpeng Zhao, Shouke Yan. "Intrinsic Self-Healing Polymers" Encyclopedia, https://encyclopedia.pub/entry/27240 (accessed February 07, 2026).

Xu, J., Zhu, L., Nie, Y., Li, Y., Wei, S., Chen, X., Zhao, W., & Yan, S. (2022, September 16). Intrinsic Self-Healing Polymers. In Encyclopedia. https://encyclopedia.pub/entry/27240

Xu, Jun, et al. "Intrinsic Self-Healing Polymers." Encyclopedia. Web. 16 September, 2022.

Copy Citation

Self-healing polymeric materials have been widely investigated because they can heal the damages spontaneously and thereby prolong their service lifetime. Many ingenious synthetic procedures have been developed for fabricating self-healing polymers with high performance.

fast self-healing

elastomers

healing mechanism

1. Introduction

Polymeric materials have become one of the most widely used structural and functional materials due to their light weight, high stretchability, good processability, and multi-functionality [1]. However, compared with metals and ceramics, polymeric materials exhibit a poor mechanical strength, which makes them vulnerable to damage [2]. The creation of structural injuries will unambiguously lead to a significant decline in the mechanical properties and functions, or even to the failure of the related products for further service, which severely limited their practical applications [3][4]. Endowing the polymeric materials with a self-healing capability will certainly improve the stability and safety of them in practical applications and prolong their lifetime. Therefore, the design of self-healing polymeric materials with multiple functions has attracted increasing interest [5][6][7][8][9][10][11][12][13].

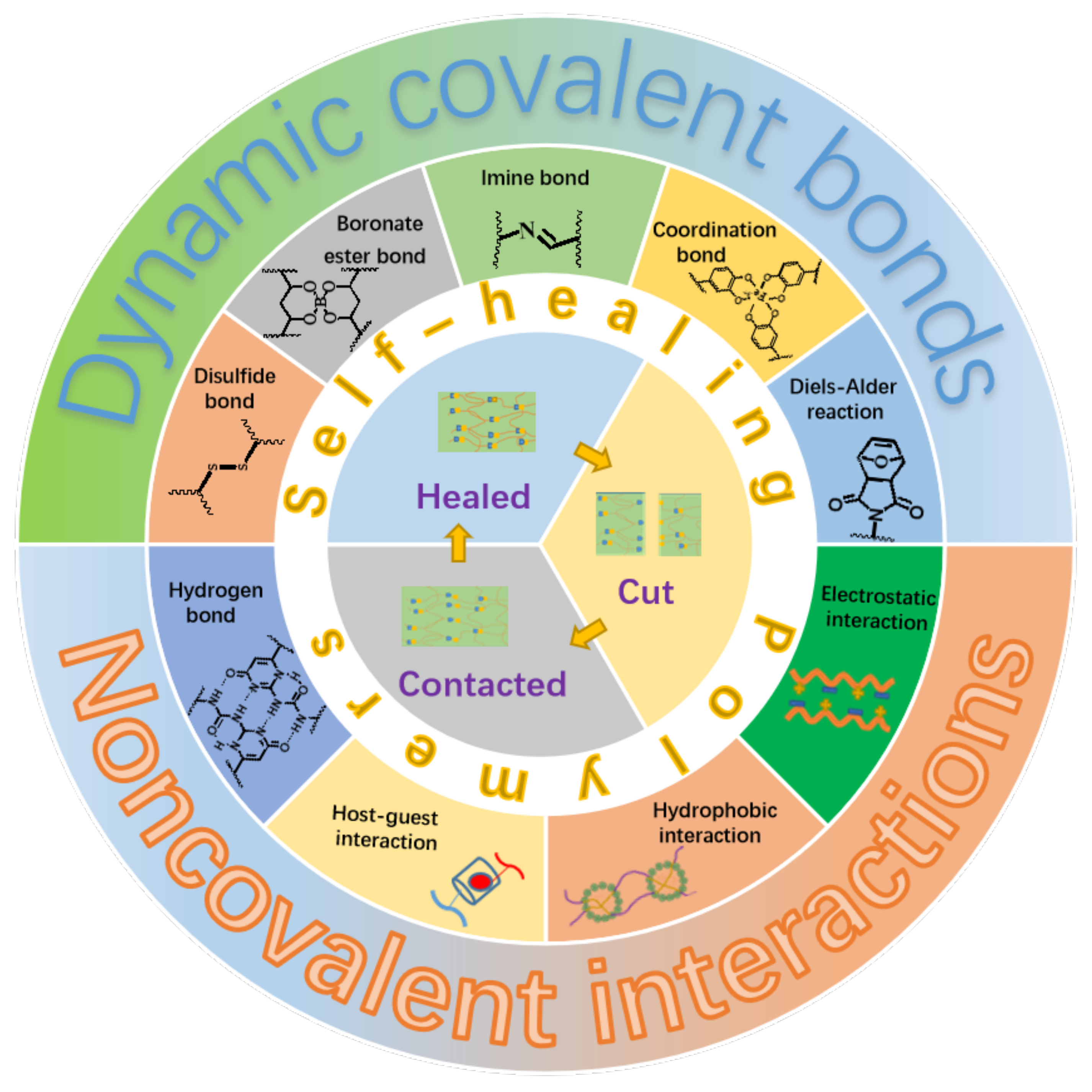

Generally, the self-healing polymers can be divided into two categories depending on their self-healing natures. The first category is named as extrinsic system, which is fabricated by embedding microcapsules with reactive fluids or agents within the polymer matrix [14]. The self-healing is realized in a way that the reactive fluids or agents flow out upon injury of the microcapsules caused by damage, which subsequently trigger the in-situ chemical reactions to heal the damaged parts. It is clear that the self-healing ability will lose after completely exhausting of the reactive fluids or agents. For the other category, as illustrated in Figure 1, the materials themselves contain some kinds of reversible dynamic covalent bonds, such as the Diels–Alder reaction and disulfide bond [15][16], or/and various kinds of physical interactions, such as metal-ligand, hydrogen bond, and electrostatic interactions [17][18][19][20][21][22], which makes the self-healing to be an intrinsic nature of the materials. This kind of material is referred to as an intrinsic system and can heal the damages repeatedly. Moreover, the self-healing polymers can be categorized into autonomic and non-autonomic ones depending upon the initiating condition or pathway of the self-healing. It is not hard to understand literally that the autonomic one can repair damages spontaneously through chemical reactions or recovery of the intermolecular interactions without the need of any kind of external stimuli. The other one, the repair of damaged polymers can only be achieved through some kinds of external stimuli such as the heat and light.

Figure 1. Illustration of self-healing elastomers based on different dynamic covalent bonds or/and non-covalent interactions.

Even though the concept of self-healing polymer was first proposed in 1950s [23], the development of it was insufficient until the 21st century. The polymeric materials with self-healing ability have then attracted much attention since 2000, and great progress has been achieved during the last 20 years. Its development can be divided into realization, blossoming, strength, mild-condition, and fast-healing stages, according to the chronological advancement, namely the perspective of their research priorities at different periods. The first stage focuses mainly on the realization of polymers with self-healing ability, while performances related to other aspects, e.g., tensile strength and functionality, are of less concern. Along with the appearance of self-healing polymer, the investigation of it has blossomed quickly [24]. In the stage referred here to as “strength”, attentions were paid on the mechanical properties of self-healing polymers in order to satisfy the demand of practical applications. At this time, a great number of self-healing polymers with high tensile strength have been reported [25][26][27][28]. While it is recognized that the self-healing of materials with high tensile strength takes place generally at high temperature, sometimes higher than 100 °C, which limited their application, the development of self-healing polymers moves to the fourth stage referred to as “mild-condition”. Among many ingenious designs such as mechano-responsive strategy [29], novel dual physical cross-linked network [30], molecular engineering of hard domains [31], and mechano-responsive hydrogen-bonding array [32], a milestone work in this stage achieved by Sun et al. [33] shows that the polymeric composite with a high tensile strength of 81 MPa can achieve 99% healing efficiency with the assistance of immersing in 45 °C water. Even ultra-robust (53 MPa) materials with high healing efficiency (80–100%) at room temperature has been reported by Zhang et al. [34].

It should be noted that with the rapid progress of bio-integrated electronics, such as, electronic skins, implantable electronics, and wearable sensors, the flexible electronics based on elastomers have drawn increasing interest [35][36][37][38]. However, the healing time of self-healing elastomers is usually consuming (sometimes lasting for few hours), which results in a long-term failure of the electronics [39]. Consequently, the development of self-healing elastomers with rapid healing ability is highly desired. This makes the design of fast self-healing elastomers, ideally with real-time healing ability at ambient environment, becomes a challenge in this field.

2. Healing Process of Intrinsic Self-Healing Polymers

Due to the potential technological relevance in various fields of self-healing polymers and the substantial for sustainable development, endowing the polymers with self-healing capability and exploring the fundamental mechanism underlying the healing process have attracted increasing interest [40][41][42][43]. In early 1980s, a theory of crack healing of polymers was first established by Wool et al. [44][45] in which the crack healing process of thermoplastic polymers was divided into five parts, termed surface rearrangement, surface approach, wetting, diffusion, and randomization. In a fresh crack surface, the surface rearrangement is mainly in the forms of topographic evolution or roughness of the surface, molecular weight distribution, and chain-end distributions [46]. Plus, compared to the linear molecules, the star-shape ones can form more time-stable networks. [47] Suitable pressure is applied in “surface approach” process to ensure the two freshly damaged surfaces contacting closely together in order to form an interface and wetting each other prior to the molecular level diffusion. The molecular level diffusion plays a key role in the formation of new interactions at the interfaces, which regulates the healing strength of healed polymers. To understand the diffusion at interfaces, the reptation model was used to investigate the healing at polymer–polymer interfaces, which depicted the decrease of healing rates with increasing molecular weight in a power law dependency and the proportional dependence of healing strength on the average interpenetration distance [48][49]. It should be pointed out that the self-healing process of the intrinsic system based on various dynamic bonds or/and different kinds of physical interactions is much more complex due to the multiple and diverse dynamic interactions in different individual systems [50].

Taking the self-healing polymer based on hydrogen bond as an example, the supramolecular polymers with self-healing capability was first established by Cordier et al. [51], who designed a self-healing supramolecular rubber based on small molecules assembled through hydrogen bonds. The supramolecular rubber could recover completely its mechanical properties after 3 h healing at room temperature. It is well documented that the strength of the associations based on the hydrogen bonds is lower than the one on the covalent bonds. Therefore, a large number of dissociated hydrogen bonds present at the fracture surfaces as broken, which endow the supramolecular rubber with efficient self-healing ability through reforming of the hydrogen bonds. This proposed mechanism of self-healing has been subsequently verified by testing the healing efficiency of the samples after being healed for different waiting times. The fact that the healing efficiency decreases with increment of waiting time reflecting the reduction in number of dissociated groups owing to the formation of new bonds within the broken surface during waiting, and thus the reduction of non-associated groups on the fracture surfaces available for self-healing. The aging-time-dependent healing efficiency has, actually, been observed for the majority of the reported self-healing polymers based on hydrogen bond [52][53][54]. Moreover, apart from hydrogen bond based self-healing polymer, self-healing polymers assembled through metal-ligands or ionic interactions also exhibit the similar aging sensitivity [55][56][57]. It was ascribed to the water molecules in air which take part in a series of irreversible processes by coordination with metal ions or ion clusters destroying the noncovalent cross-linkers. It is clear that the evolution of dynamic bonds on the fracture surface plays an important role in surface rearrangement stage for the self-healing polymers based on dynamic bonds.

In the self-healing process, when the two fractured surfaces were brought into contact, the wetting and the reversible bonds re-association took place at the interfaces prior to the molecule-level diffusion [46]. Interestingly, in the systems without dynamic bonds exchange, wetting can also impact the subsequent self-healing stage, and even determine the kinetics of healing process [58]. In order to obtain good wetting, almost all of the self-healing polymers based on hydrogen bonds were applied a certain pressure on the damaged interfaces during the self-healing process. [29][30][31][32]. Moreover, except for the physical interactions based self-healing polymers, dynamic covalent bonds, e.g., disulfide bond and boron-based bond, based self-healing polymers also needs external pressure during the self-healing process to achieve satisfactory self-healing performance (see Table 1) [59][60][61][62][63][64]. A recent study based on experimental and theoretical simulations suggests that the compressive force on the healing interfaces maybe attenuate the activation energy barrier of dynamic bond exchange that can further promote the healing in the manner of accelerating dynamic exchange [65].

Table 1. External pressure assistant self-healing polymers based on dynamic covalent bonds.

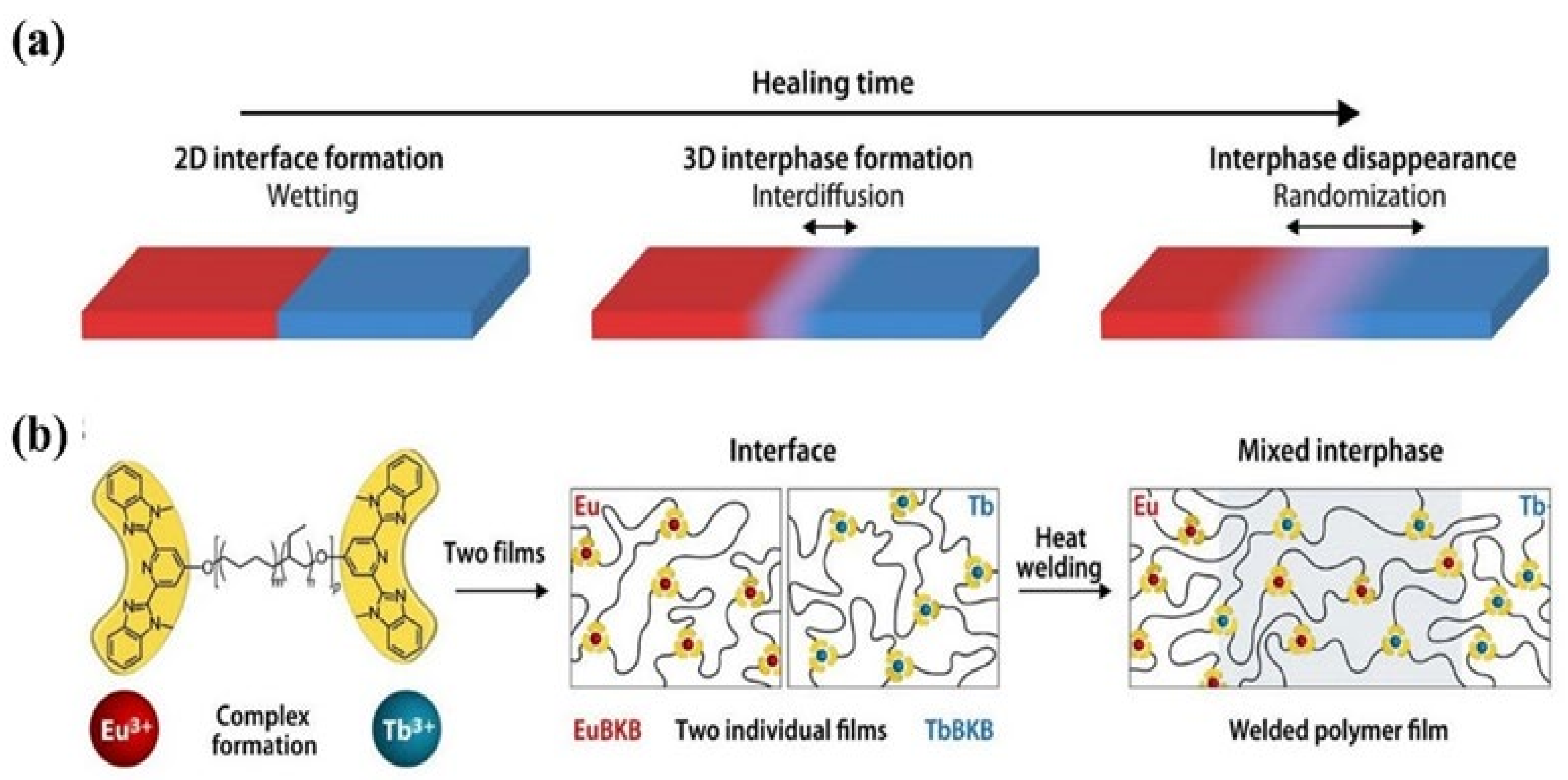

Researchers recall that the molecular-level diffusion is essential for self-healing, and the damaged sample can only recover its initial mechanical properties when the healed interfaces exhibit indistinguishable structure from the pristine sample [66]. Quantitative study on the evolution of the healed interfaces, especially the interfacial diffusion in microscopic scale during the healing process is, however, difficult. Therefore, the macroscopic experiments, e.g., disappearance of scratches, restoration ratio of tensile strength and strain are used to evaluate the healing performance of self-healing polymers. Moreover, the internal reflection infrared imaging [67] and laser speckle imaging [68] have been used to explore the microscopic healing process, even though their resolutions are not high enough. Recently, Schrettl et al. [69] reported a unique stratagem to monitor the interfacial diffusion in healing process with a high resolution of a few nanometers by energy-dispersive X-ray (EDX) spectrum imaging using scanning transmission electron microscopy. Heterogeneous interfaces as illustrated in Figure 2a were constructed to investigate the interfacial diffusion of the healing process by monitoring the diffusion of Eu3+ and Tb3+ (Figure 2b). They pointed out that a mixed interphase of more than 100 nm and less than 175 nm was required to achieve complete recovery of the mechanical properties. This study provides a direct proof for the self-healing process that molecular-level diffusion is essential to heal the cracks. Furthermore, it establishes a framework for further investigation of the healing process in intrinsic self-healing system based on the dynamic bonds.

Figure 2. The healing process in polymers. (a) The final stages of the healing process in polymers involve wetting, interdiffusion with re-entanglement, and randomization. (b) To investigate the healing process on a length scale of a few nanometers, metallosupramolecular polymers (MSPs) assembled from telechelic PEB with terminal Mebip ligands (Mn = 3800 g mol−1; m ≈ 0.32, n ≈ 0.68, p ≈ 55) and either Eu(ClO4)3 or Tb(ClO4)3 were studied. The two metallosupramolecular polymers display similar properties, but the different ion types can be monitored in a spatially resolved manner. Reproduced with permission [69]. Copyright 2021, American Association for the Advancement of Science.

References

- Chen, X.C.; Huang, W.P.; Ren, K.F.; Ji, J. Self-healing label materials based on photo-cross-linkable polymeric films with dynamic surface structures. ACS Nano 2018, 12, 8686–8696.

- Lai, J.C.; Mei, J.F.; Jia, X.Y.; Li, C.H.; You, X.Z.; Bao, Z.N. A stiff and healable polymer based on dynamic-covalent boroxine bonds. Adv. Mater. 2016, 28, 8277–8282.

- Yang, Y.; Ding, X.C.; Urban, W.M. Chemical and physical aspects of self-healing materials. Prog. Polym. Sci. 2015, 49–50, 34–59.

- Li, M.X.; Rong, M.Z.; Zhang, M.Q. Reversible mechanochemistry enabled autonomous sustaining of robustness of polymers—An example of next generation self-healing strategy. Chin. J. Polym. Sci. 2021, 39, 545–553.

- Wu, D.Y.; Meure, S.; Solomon, D. Self-healing polymeric materials: A review of recent developments. Prog. Polym. Sci. 2008, 33, 479–522.

- Wei, Z.; Yang, J.H.; Zhou, J.X.; Xu, F.; Zrı’nyi, M.; Dussault, P.H.; Osadag, Y.; Chen, Y.M. Self-healing gels based on constitutional dynamic chemistry and their potential applications. Chem. Soc. Rev. 2014, 43, 8114–8131.

- Roy, N.; Bruchmannb, B.; Lehn, J.M. Dynamers: Dynamic polymers as self-healing materials. Chem. Soc. Rev. 2015, 44, 3786–3807.

- Murphy, E.B.; Wudl, F. The world of smart healable materials. Prog. Polym. Sci. 2010, 35, 223–251.

- Hou, R.; Li, G.Q.; Zhang, Y.; Li, M.J.; Zhou, G.M.; Chai, X.M. Self-healing polymers materials based on dynamic supramolecular motifs. Prog. Chem. 2019, 31, 690–698.

- Espinosaa, L.M.D.; Fiorea, G.L.; Wedera, C.; Fosterb, E.J.; Simon, Y.C. Healable supramolecular polymer solids. Prog. Polym. Sci. 2015, 49–50, 60–78.

- Burattini, S.; Greenland, B.W.; Chappell, D.; Colquhoun, H.M.; Hayes, W. Healable polymeric materials: A tutorial review. Chem. Soc. Rev. 2010, 39, 1973–1985.

- Yang, Y.; Urban, M.W. Self-healing polymeric materials. Chem. Soc. Rev. 2013, 42, 7446–7467.

- Zhang, L.Z.; You, Z.W. Dynamic oxime-urethane bonds, a versatile unit of high performance self-healing polymers for diverse applications. Chin. J. Polym. Sci. 2021, 39, 1281–1291.

- White, S.R.; Sottos, N.R.; Geubelle, P.H.; Moore, J.S.; Kessler, M.R.; Sriram, S.R.; Brown, E.N.; Viswanathan, S. Autonomic healing of polymer composites. Nature 2001, 409, 794–797.

- Chen, X.X.; Dam, M.A.; Ono, K.J.; Mal, A.; Shen, H.B.; Nutt, S.R.; Sheran, K.; Wudl, F. A thermally re-mendable cross-linked polymeric material. Science 2002, 295, 1698–1702.

- Canadell, J.; Goossens, H.; Klumperman, B. Self-Healing Materials Based on Disulfide Links. Macromolecules 2011, 44, 2536–2541.

- Yang, X.; Liu, J.Z.; Fan, D.Y.; Cao, J.; Huang, X.; Zheng, Z.; Zhang, X.X. Scalable manufacturing of real-time self-healing strain sensors based on brominated natural rubber. Chem. Eng. J. 2020, 389, 124448.

- Cao, J.; Lu, C.H.; Zhuang, J.; Liu, M.X.; Zhang, X.X.; Yu, Y.M.; Tao, Q.C. Multiple hydrogen bonding enables the self-healing of sensors for human-machine interactions. Angew. Chem. Int. Ed. Engl. 2017, 56, 8795–8800.

- Liu, X.H.; Su, G.H.; Guo, Q.Q.; Lu, C.H.; Zhou, T.; Zhou, C.L.; Zhang, X.X. Hierarchically structured self-healing sensors with tunable positive/negative piezoresistivity. Adv. Funct. Mater. 2018, 28, 1706658.

- Yin, Q.Y.; Dai, C.H.; Chen, H.; Gou, K.; Guan, H.Z.; Wang, P.H.; Jiang, J.T.; Weng, G.S. Tough double metal-ion cross-linked elastomers with temperature-adaptable self-healing and luminescence properties. Chin. J. Polym. Sci. 2021, 39, 554–565.

- Döhler, D.; Kang, J.; Cooper, C.B.; Tok, J.B.H.; Rupp, H.; Binder, W.H.; Bao, Z.N. Tuning the self-healing response of poly (dimethylsiloxane)-based elastomers. ACS Appl. Polym. Mater. 2020, 2, 4127–4139.

- Chen, S.B.; Mahmood, N.; Beiner, M.; Binder, W.H. Self-healing materials from V-and H-Shaped supramolecular architectures. Angew. Chem. Int. Ed. 2015, 127, 10326–10330.

- Bueche, F.; Cashin, W.M.; Debye, P. The measurement of self-diffusion in solid polymers. J. Chem. Phys. 1952, 20, 1956–1958.

- Zhai, L.; Narkarb, A.; Ahn, K. Self-healing polymers with nanomaterials and nanostructures. Nano Today 2020, 30, 100826.

- Song, Y.; Liu, Y.; Qi, T.; Li, G.L. Towards dynamic but supertough healable polymers through biomimetic hierarchical hydrogen-bonding interactions. Angew. Chem. Int. Edit. 2018, 57, 13838–13842.

- Feng, X.Q.; Zhang, G.Z.; Xu, B.; Jiang, H.Y.; Baia, Q.; Li, H.J. Self-healing elastomer assembly towards three-dimensional shape memory devices. Rsc Adv. 2015, 5, 70000–70004.

- Feng, X.Q.; Zhang, G.Z.; Bai, Q.M.; Jiang, H.Y.; Bo, X.; Li, H.J. High strength Self-healing magnetic elastomers with shape memory effect. Macromol. Mater. Eng. 2016, 301, 125–132.

- Fan, C.J.; Huang, Z.C.; Li, B.; Xiao, W.X.; Zheng, E.; Yang, K.K.; Wang, Y.Z. A robust self-healing polyurethane elastomer: From H-bonds and stacking interactions to well-defined microphase morphology. Sci. China. Mater. 2019, 62, 1188–1198.

- Li, Y.H.; Li, W.J.; Sun, A.L.; Jing, M.F.; Liu, X.J.; Wei, L.H.; Wu, K.; Fu, Q. A self-reinforcing and self-healing elastomer with high strength, unprecedented toughness and room-temperature reparability. Mater. Horiz. 2021, 8, 267–275.

- Chen, C.X.; Chen, S.; Guo, Z.H.; Hu, W.R.; Chen, Z.P.; Wang, J.W.; Hu, J.S.; Guo, J.; Yang, L.Q. Highly efficient self-healing materials with excellent shape memory and unprecedented mechanical properties. J. Mater. Chem. A 2020, 8, 16203–16211.

- Wang, D.; Wang, Z.F.; Ren, S.Y.; Xu, J.H.; Wang, C.; Hu, P.; Fu, J.J. Molecular engineering of a colorless, extremely tough, superiorly self-recoverable, and healable poly(urethane-urea) elastomer for impact-resistant applications. Mater. Horiz. 2021, 8, 2238–2250.

- Eom, Y.; Kim, S.M.; Lee, M.; Jeon, H.; Park, J.; Lee, E.S.; Hwang, S.Y.; Park, J.; Oh, D.X. Mechano-responsive hydrogen-bonding array of thermoplastic polyurethane elastomer captures both strength and self-healing. Nat. Commun. 2021, 12, 621.

- An, N.; Wang, X.H.; Li, Y.X.; Zhang, L.; Lu, Z.Y.; Sun, J.Q. Healable and mechanically super-Strong polymeric composites derived from hydrogen-bonded polymeric complexes. Adv. Mater. 2019, 31, 1904882.

- Wang, Y.Y.; Huang, X.; Zhang, X.X. Ultrarobust, tough and highly stretchable self-healing materials based on cartilage-inspired noncovalent assembly nanostructure. Nat. Commun. 2021, 12, 1291.

- Weng, W.; Yang, J.J.; Zhang, Y.; Li, Y.; Yang, S.Y.; Zhu, L.P.; Zhu, M.F. A route toward smart system integration: From fiber design to device construction. Adv. Mater. 2020, 32, 1902301.

- Shi, Q.W.; Sun, J.Q.; Hou, C.Y.; Li, Y.G.; Zhang, Q.H.; Wang, H.Z. Advanced functional fiber and smart textile. Adv. Fiber Mater. 2019, 1, 3–31.

- Xu, K. Manipulating interphases in batteries. Natl. Sci. Rev. 2017, 4, 19–20.

- Liao, S.; Lian, X.; Wang, Y. Self-healing ionic liquid-based electronics and beyond. Chin. J. Polym. Sci. 2021, 39, 1235–1245.

- Liu, W.X.; Zhang, C.; Zhang, H.; Zhao, N.; Yu, Z.X.; Xu, J. Oxime-based and catalyst-free dynamic covalent polyurethanes. J. Am. Chem. Soc. 2017, 139, 8678–8684.

- Zhang, L.; Liu, Z.; Wu, X.; Guan, Q.; Chen, S.; Sun, L.; Guo, Y.; Wang, S.; Song, J.; Jeffries, E.M.; et al. A highly efficient self-healing elastomer with unprecedented mechanical properties. Adv. Mater. 2019, 31, 1901402.

- Chen, L.; Sun, T.L.; Cui, K.P.; King, D.R.; Kurokawa, T.; Saruwatari, Y.; Gong, J.P. Facile synthesis of novel elastomers with tunable dynamics for toughness, self-healing and adhesion. J. Mater. Chem. A. 2019, 7, 17334–17344.

- Chen, Y.; Tang, Z.H.; Zhang, X.H.; Liu, Y.J.; Wu, S.W.; Guo, B.C. Covalently cross-linked elastomers with self-healing and malleable abilities enabled by boronic ester bonds. ACS. Appl. Mater. Interfaces. 2018, 10, 24224–24231.

- Yue, D.W.; Wang, H.Q.; Tao, H.Q.; Zheng, P.; Li, C.H.; Zuo, J.L. A fast and room-temperature self-healing thermal conductive polymer composite. Chin. J. Polym. Sci. 2021, 39, 1328–1336.

- Wool, R.P.; O’Connor, K.M. A theory crack healing in polymers. J. Appl. Phys. 1981, 52, 5953–5963.

- Kim, Y.H.; Wool, R.P. A theory of healing at a polymer-polymer inter face. Macromolecules 1983, 16, 1115–1120.

- Wool, R.P. Self-healing materials: A review. Soft. Matter. 2008, 4, 400–418.

- Mordvinkin, A.; Döhler, D.; Binder, W.H.; Colby, R.H.; Saalwächter, K. Rheology, Sticky Chain, and Sticker Dynamics of Supramolecular Elastomers Based on Cluster-Forming Telechelic Linear and Star Polymers. Macromolecules 2021, 54, 5065–5076.

- De Gennes, P.G. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572–579.

- Russell, T.P.; Deline, V.R.; Dozier, W.D.; Felcher, G.P.; Agrawal, G.; Wool, R.P.; Mays, J.W. Direct observation of reputation at polymer interfaces. Nature 1993, 365, 235–237.

- Aguirresarobe, R.H.; Nevejans, S.; Reck, B.; Irusta, L.; Sardon, H.; Asua, J.M.; Ballard, N. Healable and self-healing polyurethanes using dynamic chemistry. Prog. Polym. Sci. 2021, 114, 101362.

- Cordier, P.; Tournilhac, F.; Soulie-Ziakovic, C.; Leibler, L. Self-healing and thermoreversible rubber from supramolecular assembly. Nature 2008, 451, 977–980.

- Chen, Y.L.; Kushner, A.M.; Williams, G.A.; Guan, Z.B. Multiphase design of autonomic self-healing thermoplastic elastomers. Nat. Chem. 2012, 4, 467–472.

- Zhang, R.C.; Yan, T.Z.; Lechner, B.D.; Schröter, K.; Liang, Y.; Li, B.H.; Furtado, F.; Sun, P.C.; Saalwächter, K. Heterogeneity, segmental and hydrogen bond dynamics, and aging of supramolecular self-healing rubber. Macromolecules 2013, 46, 1841–1850.

- Wang, D.; Xu, J.H.; Chen, J.Y.; Hu, P.; Wang, Y.; Jiang, W.; Fu, J.J. Transparent, mechanically strong, extremely tough, self-recoverable, healable supramolecular elastomers facilely fabricated via dynamic hard domains design for multifunctional Applications. Adv. Funct. Mater. 2019, 30, 1907109.

- Lai, J.C.; Li, L.; Wang, D.P.; Zhang, M.H.; Mo, S.R.; Wang, X.; Zeng, K.Y.; Li, C.H.; Jiang, Q.; You, X.Z.; et al. A rigid and healable polymer cross-linked by weak but abundant Zn(II)-carboxylate interactions. Nat. Commun. 2018, 9, 2725.

- Cao, Y.; Morrissey, T.G.; Acome, E.; Allec, S.I.; Wong, B.M.; Keplinger, C.; Wang, C. A transparent, self-healing, highly stretchable ionic conductor. Adv. Mater. 2017, 29, 1605099.

- Rao, Y.L.; Chortos, A.; Pfattner, R.; Lissel, F.; Chiu, Y.C.; Feig, V.; Xu, J.; Kurosawa, T.; Gu, X.D.; Wang, C.; et al. Stretchable self-healing polymeric dielectrics cross-linked through metal-ligand coordination. J. Am. Chem. Soc. 2016, 138, 6020–6027.

- Grande, A.M.; Garcia, S.J.; Van der Zwaag, S. On the interfacial healing of a supramolecular elastomer. Polymer 2015, 56, 435–442.

- Santana, M.H.; Huete, M.; Lameda, P.; Araujo, J.; Verdejo, R.; López-Manchado, M.A. Design of a new generation of sustainable SBR compounds with good trade-off between mechanical properties and self-healing ability. Eur. Polym. J. 2018, 106, 273–283.

- AbdolahZadeh, M.; Esteves, A.C.C.; van der Zwaag, S.; Garcia, S.J. Healable dual organic–inorganic crosslinked Sol–Gel based polymers: Crosslinking density and tetrasulfide content effect. J. Polym. Sci. Part A Polym. Chem. 2014, 52, 1953–1961.

- Hernández, M.; Grande, A.M.; van der Zwaag, S.; Garcia, S.J. Monitoring network and interfacial healing processes by broadband dielectric spectroscopy: A case study on natural rubber. ACS Appl. Mater. Interfaces 2016, 8, 10647–10656.

- Xiang, H.P.; Rong, M.Z.; Zhang, M.Q. Self-healing, reshaping, and recycling of vulcanized chloroprene rubber: A case study of multitask cyclic utilization of cross-linked polymer. ACS Sustain. Chem. Eng. 2016, 4, 2715–2724.

- Hernández, M.; Grande, A.M.; Dierkes, W.; Bijleveld, J.; Van Der Zwaag, S.; García, S.J. Turning vulcanized natural rubber into a self-healing polymer: Effect of the disulfide/polysulfide ratio. ACS Sustain. Chem. Eng. 2016, 4, 5776–5784.

- Yu, H.T.; Feng, Y.Y.; Gao, L.; Chen, C.; Zhang, Z.X.; Feng, W. Self-healing high strength and thermal conductivity of 3D graphene/PDMS composites by the optimization of multiple molecular interactions. Macromolecules 2020, 53, 7161–7170.

- De Alwis Watuthanthrige, N.; Ahammed, B.; Dolan, M.T.; Fang, Q.H.; Wu, J.; Sparks, J.L.; Zanjani, M.B.; Konkolewicz, D.; Ye, Z.J. Accelerating dynamic exchange and self-healing using mechanical forces in crosslinked polymers. Mater. Horiz. 2020, 7, 1581–1587.

- Wang, S.Y.; Urban, M.W. Self-healing polymers. Nat. Rev. Mater. 2020, 5, 562–583.

- Zedler, L.; Hager, M.D.; Schubert, U.S.; Harrington, M.J.; Schmitt, M.; Popp, J.; Dietzek, B. Monitoring the chemistry of self-healing by vibrational spectroscopy—Current state and perspectives. Mater. Today 2014, 17, 57–69.

- Van der Kooij, H.M.; Susa, A.; Garcia, S.J.; Van der Zwaag, S.; Sprakel, J. Imaging the molecular motions of autonomous repair in a self-healing polymer. Adv. Mater. 2017, 29, 1701017.

- Neumann, L.N.; Oveisi, E.; Petzold, A.; Style, R.W.; Thurn-Albrecht, T.; Weder, C.; Schrettl, S. Dynamics and healing behavior of metallosupramolecular polymers. Sci. Adv. 2021, 7, 4154.

More

Information

Subjects:

Polymer Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

5.5K

Revisions:

3 times

(View History)

Update Date:

20 Sep 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No