| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mounia Achouch | -- | 3756 | 2022-08-23 15:14:37 | | | |

| 2 | Conner Chen | Meta information modification | 3756 | 2022-08-24 08:52:19 | | |

Video Upload Options

In the era of the fourth industrial revolution, several concepts have arisen in parallel with this new revolution, such as predictive maintenance, which today plays a key role in sustainable manufacturing and production systems by introducing a digital version of machine maintenance. The data extracted from production processes have increased exponentially due to the proliferation of sensing technologies. Even if Maintenance 4.0 faces organizational, financial, or even data source and machine repair challenges, it remains a strong point for the companies that use it. Indeed, it allows for minimizing machine downtime and associated costs, maximizing the life cycle of the machine, and improving the quality and cadence of production.

1. Introduction

2. Industry 4.0

2.1. Security Challenges in the Context of Industry 4.0

2.2. Human Aspects in the Context of Industry 4.0

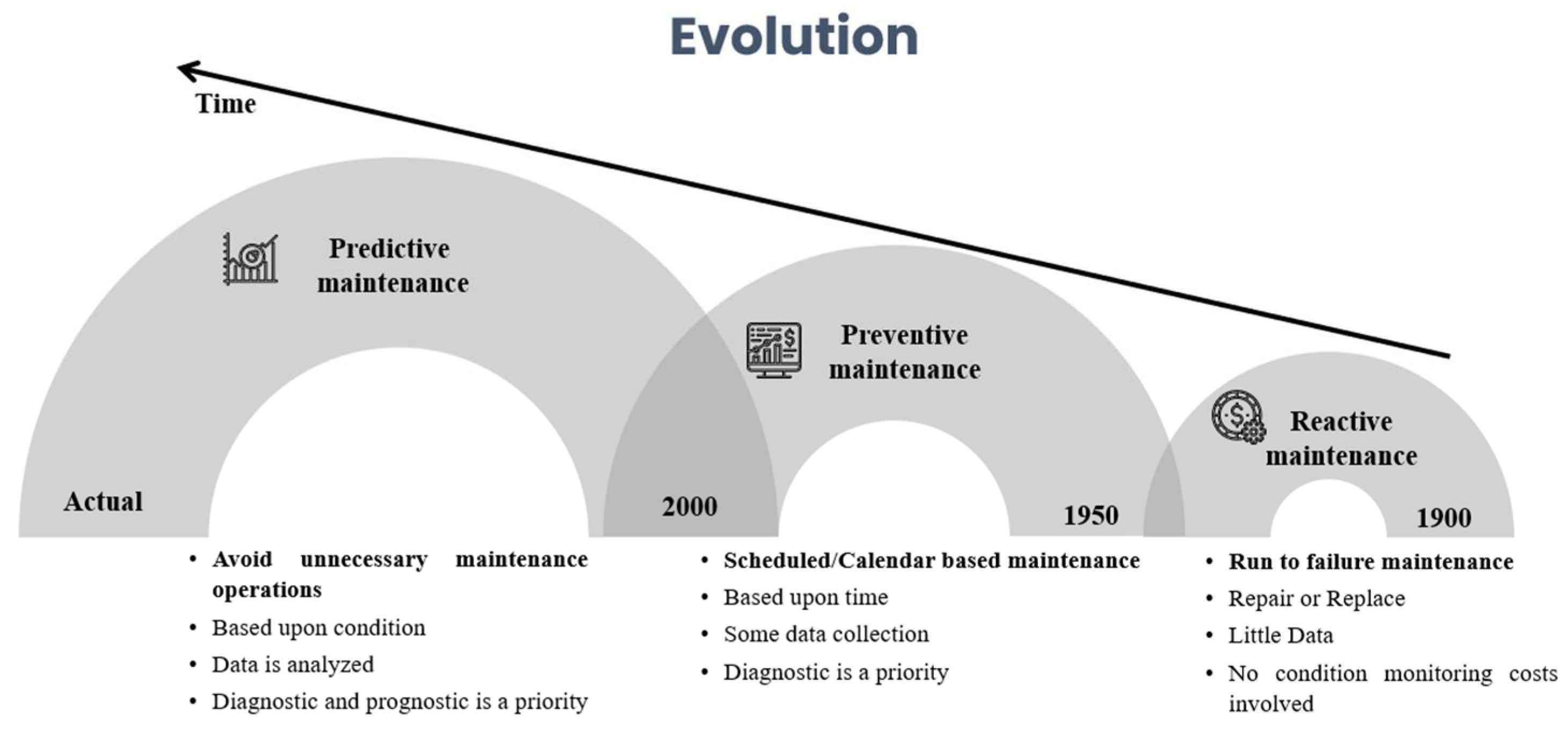

3. Evolution of Industrial Maintenance

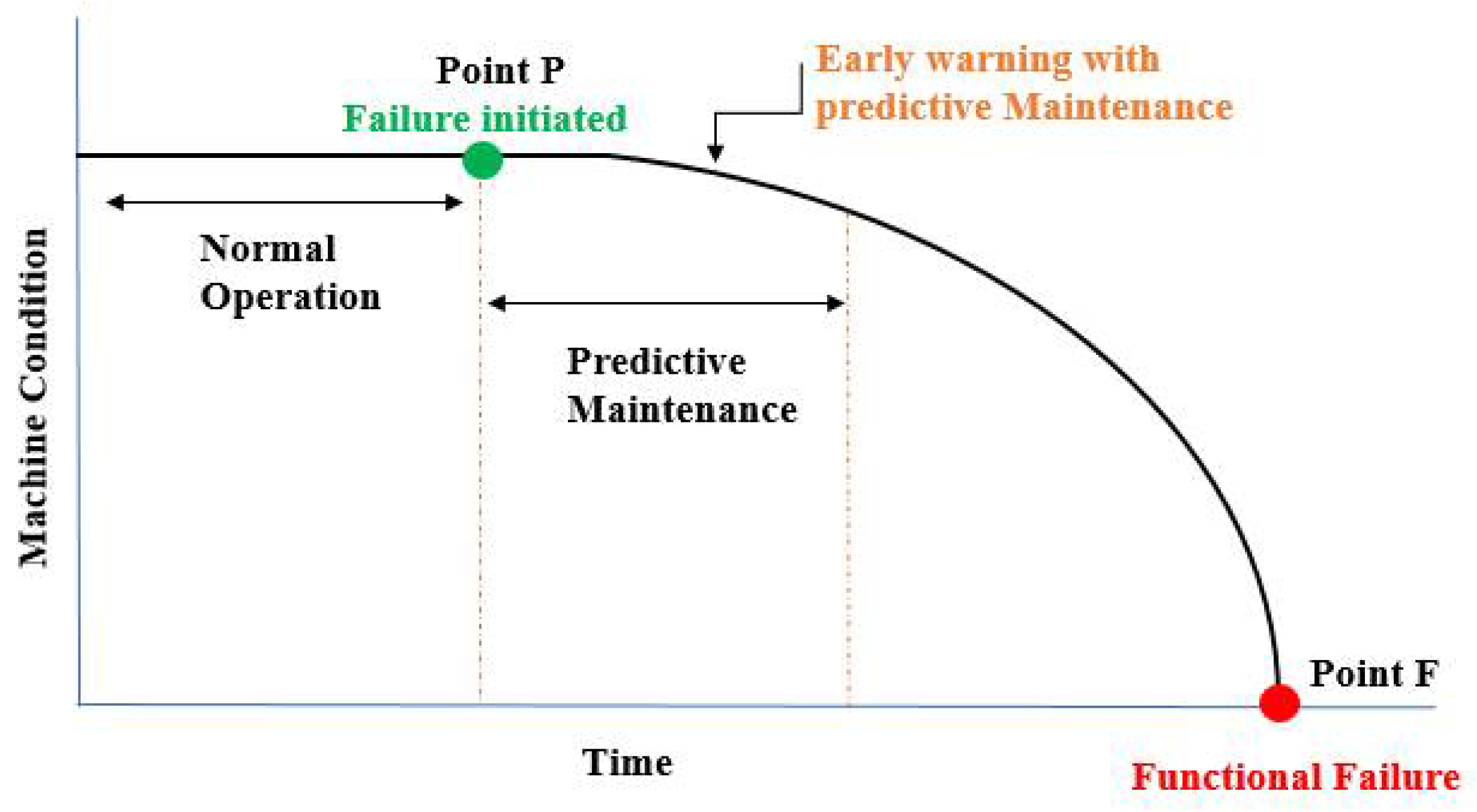

3.1. Predictive Maintenance

3.2. Predictive Maintenance Tools and Materials

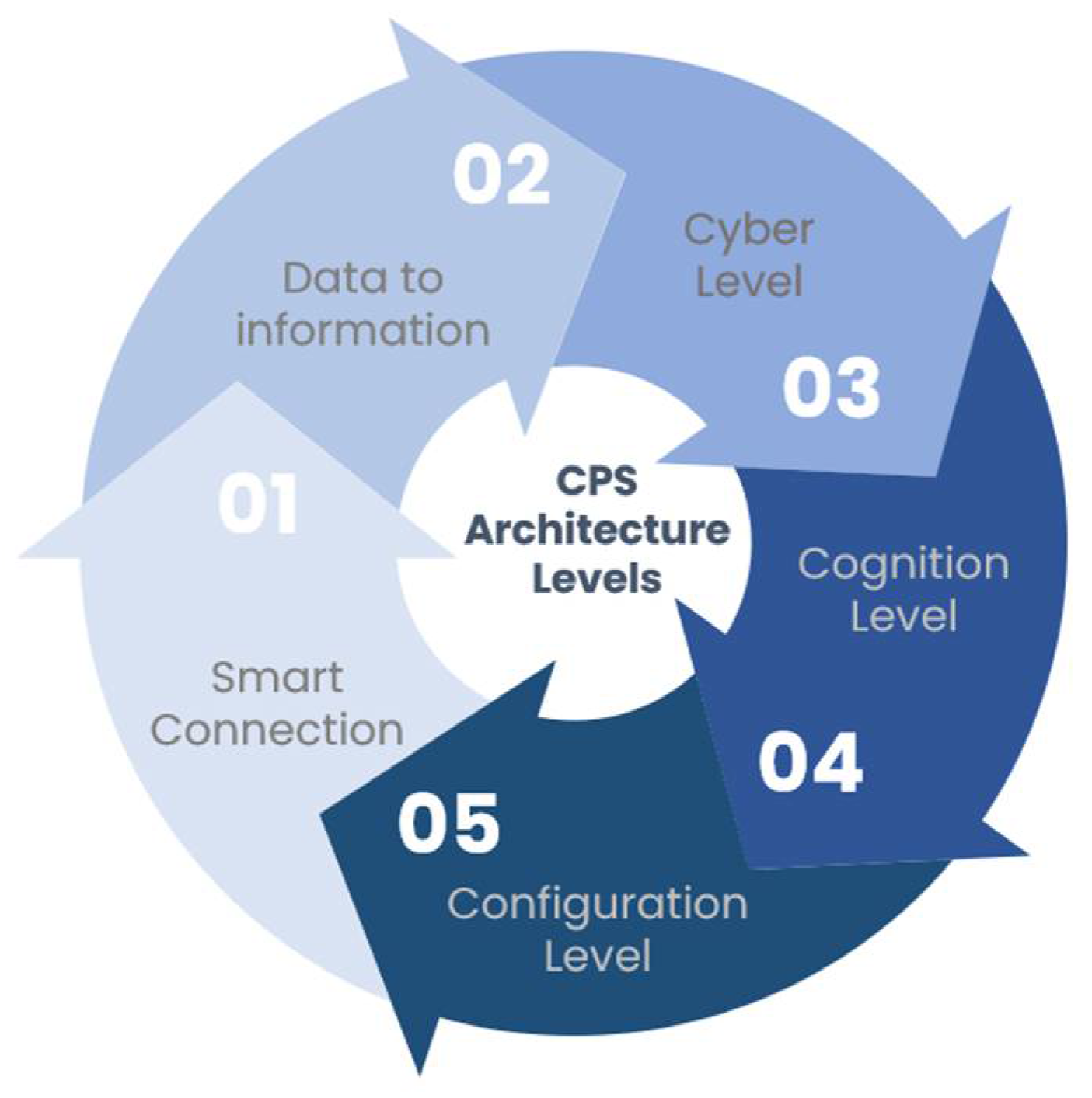

3.2.1. Cyber-Physical Systems

3.2.2. Industrial Internet of Things

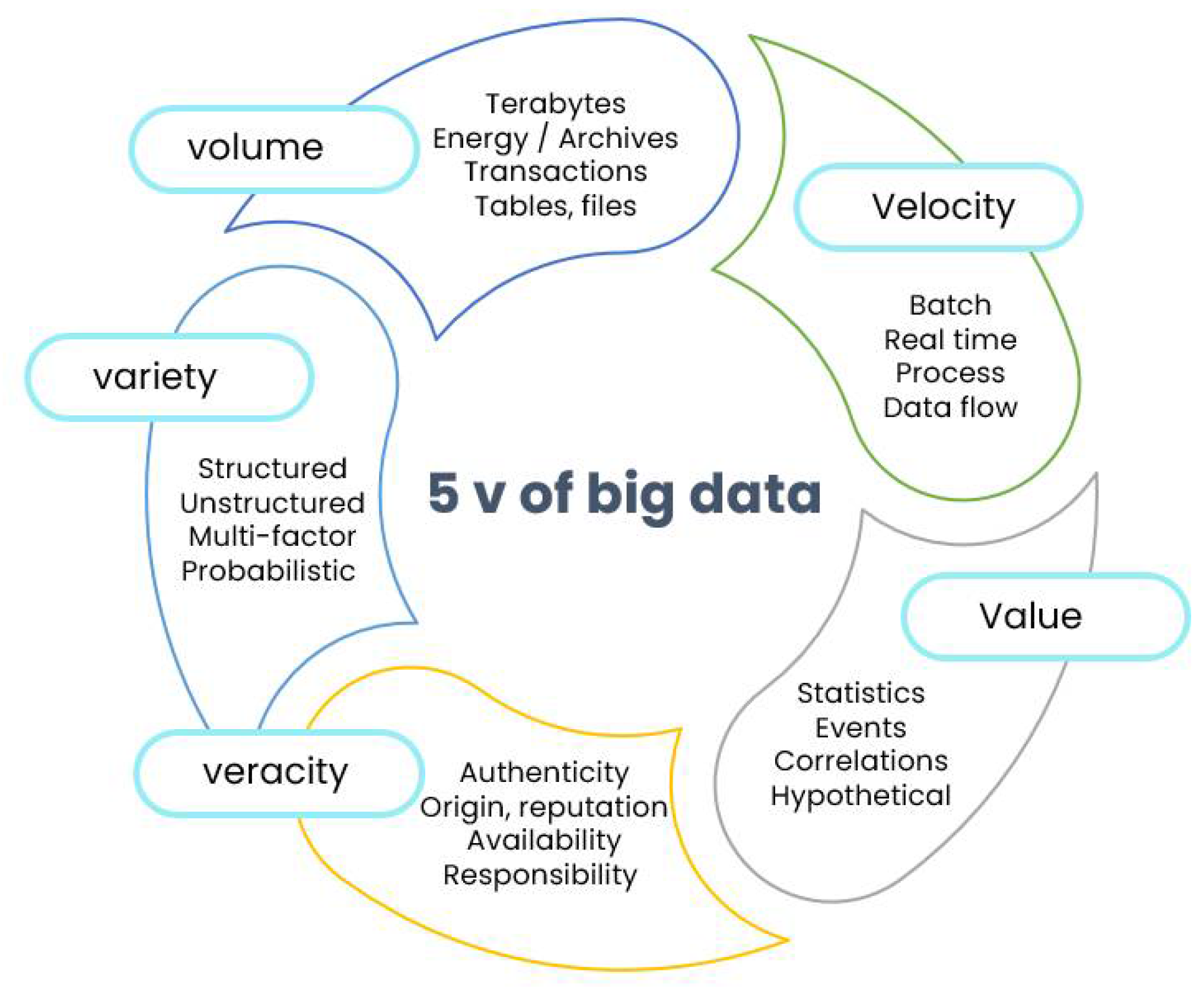

3.2.3. Big Data

3.2.4. Digital Twin

3.2.5. Augmented Reality

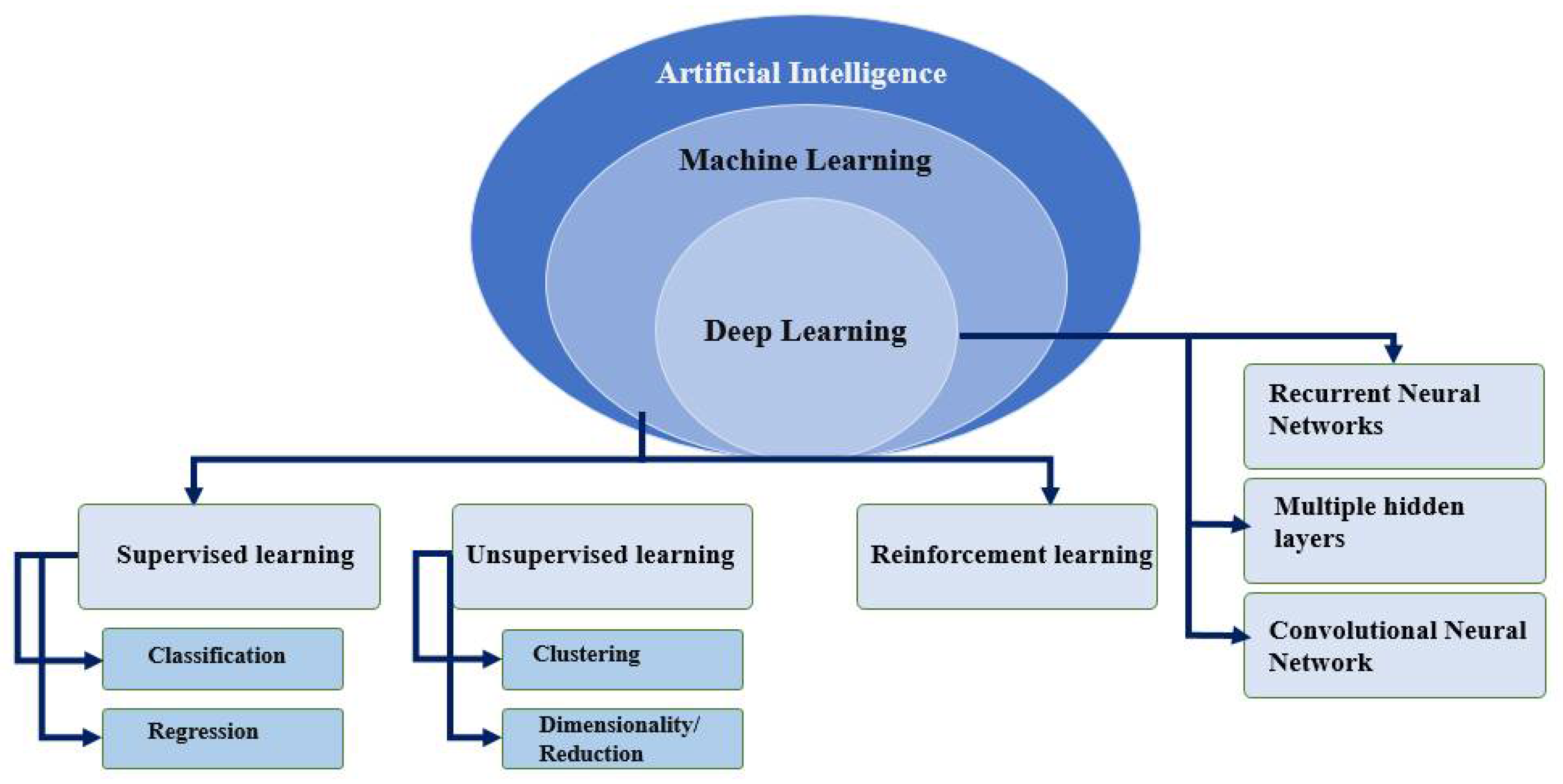

3.2.6. Artificial Intelligence

3.2.7. Machine Learning and Deep Learning

4. Challenges of Predictive Maintenance

4.1. Financial and Organizational Limits

4.2. Data Source Limits

4.3. Machine Repair Activity Limits

References

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0: The Future of Productivity and Growth in Manufacturing Industries; Boston Consulting Group: Boston, MA, USA, 2015.

- Kaczmarek, M.J.; Gola, A. Maintenance 4.0 Technologies for Sustainable Manufacturing—An Overview. IFAC-PapersOnLine 2019, 52, 91–96.

- Ran, Y.; Zhou, X.; Lin, P.; Wen, Y.; Deng, R. A Survey of Predictive Maintenance: Systems, Purposes and Approaches. arXiv 2019, arXiv:1912.07383. Available online: http://arxiv.org/abs/1912.07383 (accessed on 14 October 2021).

- Tiddens, W.; Braaksma, J.; Tinga, T. Exploring predictive maintenance applications in industry. J. Qual. Maint. Eng. 2020, 28, 68–85.

- Blancke, O. Développement D’une Approche de Pronostic Pour les Équipements Complexes Permettant L’application de la Maintenance Prévisionnelle. Ph.D. Thesis, École de Technologie Supérieure, Montreal, QC, Canada, 2020.

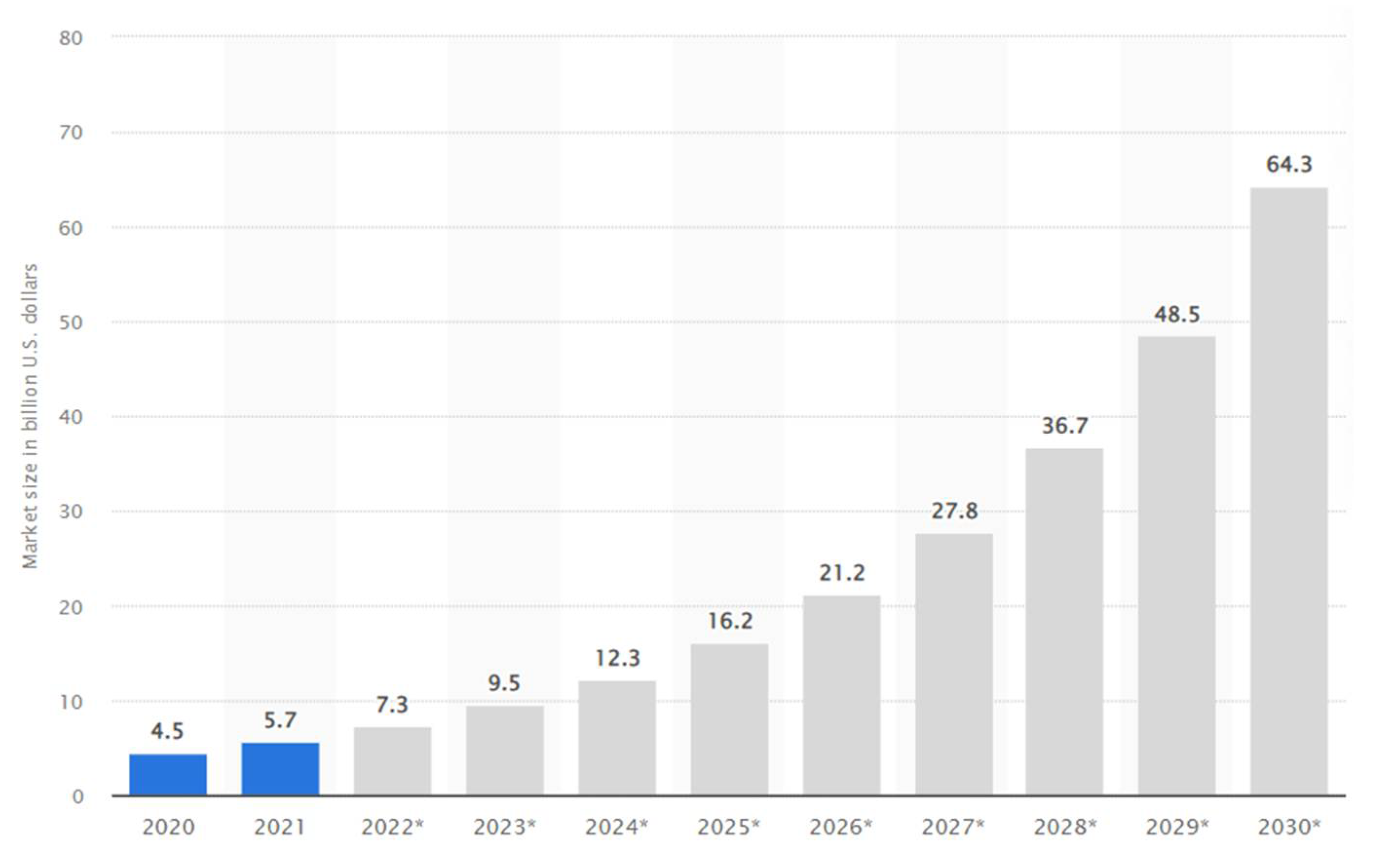

- Market Research Report, Marketsandmarkets.com. “Predictive Maintenance Market by Component (Solutions, Services), De-ployment Mode (On-Premises, Cloud), Organization Size (Large Enterprises, SME), Vertical and Region—Global Forecast to 2026”. Available online: https://www.grandviewresearch.com/industry-analysis/predictive-maintenance-market (accessed on 24 July 2022).

- Predictive Maintenance Market Size Worldwide 2020–2030|Statista. 2022. Available online: https://www.statista.com/statistics/748080/global-predictive-maintenance-market-size/ (accessed on 24 July 2022).

- Qu’est ce Que L’industrie 4.0? L’agence Digitale Créative—Les Digital Heroes. 1 October 2021. Available online: https://lesdigitalheroes.fr/quest-ce-que-lindustrie-4-0/ (accessed on 13 April 2022).

- Li, Z.; Wang, Y.; Wang, K.-S. Intelligent predictive maintenance for fault diagnosis and prognosis in machine centers: Industry 4.0 scenario. Adv. Manuf. 2017, 5, 377–387.

- Silvestri, L.; Forcina, A.; Introna, V.; Santolamazza, A.; Cesarotti, V. Maintenance transformation through Industry 4.0 technologies: A systematic literature review. Comput. Ind. 2020, 123, 103335.

- Fernandez-Carames, T.M.; Fraga-Lamas, P. A Review on Human-Centered IoT-Connected Smart Labels for the Industry 4.0. IEEE Access 2018, 6, 25939–25957.

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A Glimpse. Procedia Manuf. 2018, 20, 233–238.

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Bécue, A.; Praça, I.; Gama, J. Artificial intelligence, cyber-threats and Industry 4.0: Challenges and opportunities. Artif. Intell. Rev. 2021, 54, 3849–3886.

- Mentsiev, A.U.; Guzueva, E.R.; Magomaev, T.R. Security challenges of the Industry 4.0. J. Phys. Conf. Ser. 2020, 1515, 032074.

- Pereira, T.; Barreto, L.; Amaral, A. Network and information security challenges within Industry 4.0 paradigm. Procedia Manuf. 2017, 13, 1253–1260.

- Kashmar, N.; Adda, M.; Atieh, M. From access control models to access control metamodels: A survey. In Proceedings of the Future of Information and Communication Conference, San Francisco, CA, USA, 14–15 March 2019; Springer: Cham, Switzerland, 2019; pp. 892–911.

- Pedreira, V.; Barros, D.; Pinto, P. A review of attacks, vulnerabilities, and defenses in industry 4.0 with new chal-lenges on data sovereignty ahead. Sensors 2021, 21, 5189.

- Reiman, A.; Kaivooja, J.; Parviainen, E.; Takala, E.P.; Lauraeus, T. Human factors and ergonomics in manufac-turing in the industry 4.0 context–A scoping review. Technol. Soc. 2021, 65, 101572.

- Neumann, W.P.; Winkelhaus, S.; Grosse, E.H.; Glock, C.H. Industry 4.0 and the human factor–A systems frame-work and analysis methodology for successful development. Int. J. Prod. Econ. 2021, 233, 107992.

- Veile, J.W.; Kiel, D.; Müller, J.M.; Voigt, K.-I. Lessons learned from Industry 4.0 implementation in the German manufacturing industry. J. Manuf. Technol. Manag. 2019, 31, 977–997.

- Pilloni, V. How Data Will Transform Industrial Processes: Crowdsensing, Crowdsourcing and Big Data as Pillars of Industry 4.0. Future Internet 2018, 10, 24.

- Lee, J.; Ni, J.; Singh, J.; Jiang, B.; Azamfar, M.; Feng, J. Intelligent Maintenance Systems and Predictive Manufacturing. J. Manuf. Sci. Eng. 2020, 142, 110805.

- de Faria, H.; Costa, J.G.S.; Olivas, J.L.M. A review of monitoring methods for predictive maintenance of electric power transformers based on dissolved gas analysis. Renew. Sustain. Energy Rev. 2015, 46, 201–209.

- Levitt, J. Complete Guide to Preventive and Predictive Maintenance; Industrial Press Inc.: New York, NY, USA, 2003.

- Pech, M.; Vrchota, J.; Bednář, J. Predictive Maintenance and Intelligent Sensors in Smart Factory: Review. Sensors 2021, 21, 1470.

- Cakir, M.; Guvenc, M.A.; Mistikoglu, S. The experimental application of popular machine learning algorithms on predictive maintenance and the design of IIoT based condition monitoring system. Comput. Ind. Eng. 2020, 151, 106948.

- Poór, P.; Basl, J.; Zenisek, D. Predictive Maintenance 4.0 as next evolution step in industrial maintenance development. In Proceedings of the 2019 International Research Conference on Smart Computing and Systems Engineering (SCSE), Colombo, Sri Lanka, 28 March 2019; pp. 245–253.

- Jimenez-Cortadi, A.; Irigoien, I.; Boto, F.; Sierra, B.; Rodriguez, G. Predictive Maintenance on the Machining Process and Machine Tool. Appl. Sci. 2019, 10, 224.

- Maktoubian, J.; Taskhiri, M.S.; Turner, P. Intelligent Predictive Maintenance (IPdM) in Forestry: A Review of Challenges and Opportunities. Forests 2021, 12, 1495.

- Okano, M.T. IOT and Industry 4.0: The Industrial New Revolution. In Proceedings of the ICMIS-17—International Conference on Management and Information Systems, Bangkok, Thailand, 25–26 September 2017; pp. 75–82.

- Lee, J.; Ardakani, H.D.; Yang, S.; Bagheri, B. Industrial Big Data Analytics and Cyber-physical Systems for Future Maintenance & Service Innovation. Procedia CIRP 2015, 38, 3–7.

- Lambán, M.P.; Morella, P.; Royo, J.; Sánchez, J.C. Using Industry 4.0 to face the challenges of Predictive Mainte-nance: A Key Performance Indicators development in a Cyber Physical System. Comput. Ind. Eng. 2022, 171, 108400.

- Wang, J.; Xu, C.; Zhang, J.; Zhong, R. Big data analytics for intelligent manufacturing systems: A review. J. Manuf. Syst. 2021, 62, 738–752.

- Kaarlela, T.; Arnarson, H.; Pitkäaho, T.; Shu, B.; Solvang, B.; Pieskä, S. Common Educational Teleoperation Plat-form for Robotics Utilizing Digital Twins. Machines 2022, 10, 577.

- Azeez, N.A.; Adjekpiyede, O.O. Digital Twin Technology: A Review of Its Applications and Prominent Challenges. Covenant J. Inform. Commun. Technol. 2022, 10. Available online: https://journals.covenantuniversity.edu.ng/index.php/cjict/article/view/2995 (accessed on 10 June 2022).

- Hosamo, H.H.; Svennevig, P.R.; Svidt, K.; Han, D.; Nielsen, H.K. A Digital Twin predictive maintenance framework of air handling units based on automatic fault detection and diagnostics. Energy Build. 2022, 261, 111988.

- You, Y.; Chen, C.; Hu, F.; Liu, Y.; Ji, Z. Advances of Digital Twins for Predictive Maintenance. Procedia Comput. Sci. 2022, 200, 1471–1480.

- Wang, Y.; Martinsen, K.; Yu, T.; Wang, K. Advanced Manufacturing and Automation XI; Springer: Singapore, 2022.

- Chiang, F.-K.; Shang, X.; Qiao, L. Augmented reality in vocational training: A systematic review of research and applications. Comput. Hum. Behav. 2021, 129, 107125.

- Ho, P.T.; Albajez, J.A.; Santolaria, J.; Yagüe-Fabra, J.A. Study of Augmented Reality Based Manufacturing for Further Integration of Quality Control 4.0: A Systematic Literature Review. Appl. Sci. 2022, 12, 1961.

- Arena, F.; Collotta, M.; Pau, G.; Termine, F. An Overview of Augmented Reality. Computers 2022, 11, 28.

- Liu, C.; Zhu, H.; Tang, D.; Nie, Q.; Zhou, T.; Wang, L.; Song, Y. Probing an intelligent predictive maintenance approach with deep learning and augmented reality for machine tools in IoT-enabled manufacturing. Robot. Comput.-Integr. Manuf. 2022, 77, 102357.

- Daniyan, I.; Mpofu, K.; Oyesola, M.; Ramatsetse, B.; Adeodu, A. Artificial intelligence for predictive maintenance in the railcar learning factories. Procedia Manuf. 2020, 45, 13–18.

- Carvalho, T.P.; Soares, F.A.A.M.N.; Vita, R.; Francisco, R.D.P.; Basto, J.P.; Alcalá, S.G.S. A systematic literature review of machine learning methods applied to predictive maintenance. Comput. Ind. Eng. 2019, 137, 106024.

- Barja-Martinez, S.; Aragüés-Peñalba, M.; Munné-Collado, Í.; Lloret-Gallego, P.; Bullich-Massagué, E.; Villafafila-Robles, R. Artificial intelligence techniques for enabling Big Data services in distribution networks: A review. Renew. Sustain. Energy Rev. 2021, 150, 111459.

- Nacchia, M.; Fruggiero, F.; Lambiase, A.; Bruton, K. A Systematic Mapping of the Advancing Use of Machine Learning Techniques for Predictive Maintenance in the Manufacturing Sector. Appl. Sci. 2021, 11, 2546.

- zu Wickern, V.F.M. Challenges and Reliability of Predictive Maintenance. Master’s Thesis, Faculty of Communication and Environment, Rhine-Waal University of Applied Sciences, Kleve, Germany, 2019.

- Wellsandt, S.; Klein, K.; Hribernik, K.; Lewandowski, M.; Bousdekis, A.; Mentzas, G.; Thoben, K.D. Hybrid-augmented intelligence in predictive maintenance with digital intelligent assistants. Annu. Rev. Control 2022, 53, 382–390.

- Diamond, S. Predictive Maintenance For Dummies®, IBM Limited Edition; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013; p. 51.

- Jin, X.; Weiss, B.A.; Siegel, D.; Lee, J. Present Status and Future Growth of Advanced Maintenance Technology and Strategy in US Manufacturing. Int. J. Progn. Health Manag. 2016, 7, 12.

- Keleko, A.T.; Kamsu-Foguem, B.; Ngouna, R.H.; Tongne, A. Artificial intelligence and real-time predictive maintenance in industry 4.0: A bibliometric analysis. AI Ethics 2022, 1–25.

- Mousavi, S. Simultaneous Control of the Production, Maintenance, and Inspection Strategies for a Failure-Prone Manufacturing System with Quality-Based Financial Penalties/Incentives. Ph.D. Thesis, École de Technologie Supérieure, Montreal, QC, Canada, 2021.