Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sara Filippi | -- | 2098 | 2022-08-10 10:47:56 | | | |

| 2 | Dean Liu | Meta information modification | 2098 | 2022-08-11 03:09:37 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Polacco, G.; Cappello, M.; Cuciniello, G.; Filippi, S. Molecular Weight Distributions in Bituminous Binders. Encyclopedia. Available online: https://encyclopedia.pub/entry/26020 (accessed on 07 February 2026).

Polacco G, Cappello M, Cuciniello G, Filippi S. Molecular Weight Distributions in Bituminous Binders. Encyclopedia. Available at: https://encyclopedia.pub/entry/26020. Accessed February 07, 2026.

Polacco, Giovanni, Miriam Cappello, Giacomo Cuciniello, Sara Filippi. "Molecular Weight Distributions in Bituminous Binders" Encyclopedia, https://encyclopedia.pub/entry/26020 (accessed February 07, 2026).

Polacco, G., Cappello, M., Cuciniello, G., & Filippi, S. (2022, August 10). Molecular Weight Distributions in Bituminous Binders. In Encyclopedia. https://encyclopedia.pub/entry/26020

Polacco, Giovanni, et al. "Molecular Weight Distributions in Bituminous Binders." Encyclopedia. Web. 10 August, 2022.

Copy Citation

Molecular weight distributions are widely used to evaluate the effects of aging or modifiers in bituminous binders. As with polymers, the most common techniques to obtain the distributions can be subdivided into two main groups, depending on whether or not they use a solvent.

bitumen

apparent molecular weight distribution

gel permeation chromatography

1. Introduction

The molecular weight distribution (MWD) influences the rheological and mechanical properties of viscoelastic materials, such as bitumen. For this reason, there is an increasing use of the MWD in the scientific literature related to asphalt paving, where it is correlated with the composition, performance, aging susceptibility and compatibility with additives and polymers [1]. The MWD can be determined by several experimental techniques, such as size-exclusion chromatography (SEC), field-flow fractionation and mass spectrometry [2]. Of these, the most popular in terms of bitumen is SEC, also known as gel permeation chromatography (GPC) [3][4]. In GPC, the data are collected in a diluted state, where the interactions among molecules are eliminated or at least strongly inhibited by the solvent. This therefore provides a distribution that corresponds to a disaggregate state and contributes little to the open debate on the complex structure of binders [5].

It would thus be helpful to obtain the distribution directly in bulk, as in the “inverse mechanical” approach, which uses rheological data, which are typically collected in the linear viscoelastic region. The idea is that the viscoelastic functions contain the complete spectrum of relaxation times, which can thus be deconvoluted into an MWD [6][7][8]. The procedure uses different viscoelastic functions and requires a correlation between the operating variable (i.e., reduced frequency, shear rate, time) and the molecular weight (MW).

One of the criteria adopted to derive such a correlation is to obtain a similar MWD from the GPC and inverse mechanical method. In other words, the calibration curves in the inverse mechanical approach are tuned in order to unify the results obtained with the two techniques [9][10]. This is somewhat questionable because molecules that tend to aggregate can be interpreted as a single entity in bulk and as multiple components in solution.

2. Applications

GPC has been used in several studies on bituminous binders, and the a review by Ma et al. provides a thorough overview of the available literature [1]. Here, researchers briefly analyze a few examples to show the differences and characteristics of the solution and bulk distributions.

2.1. Aging

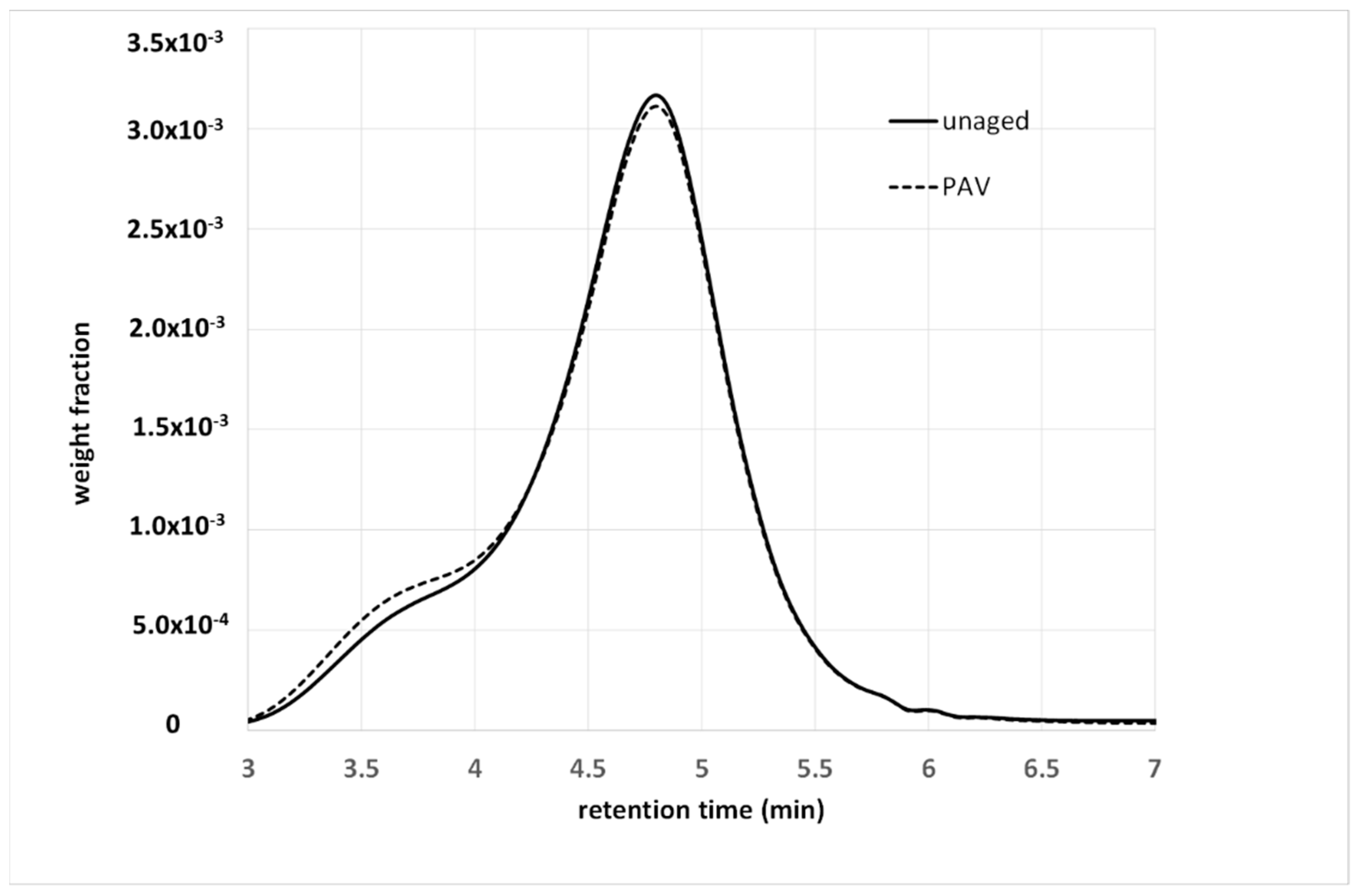

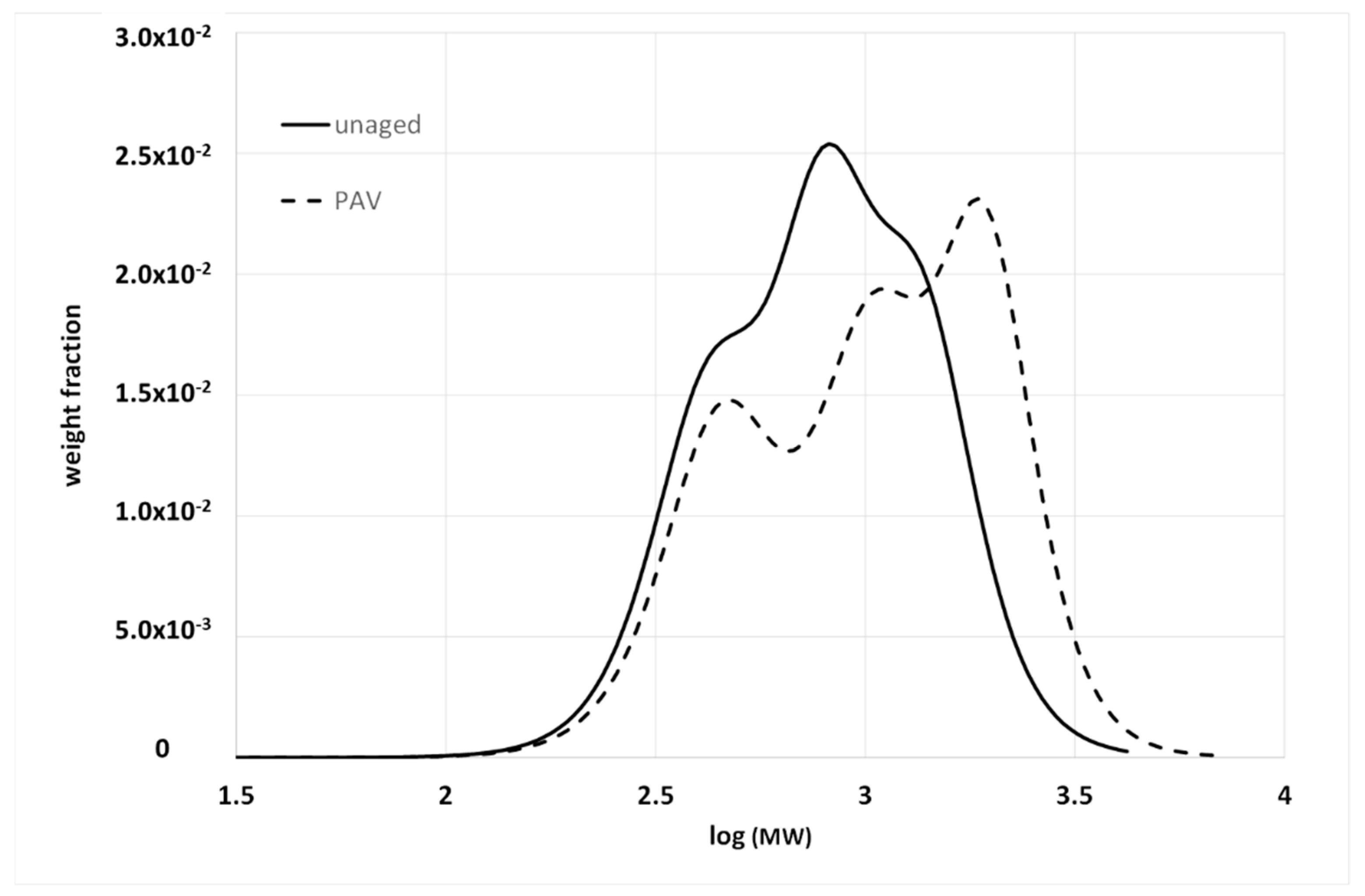

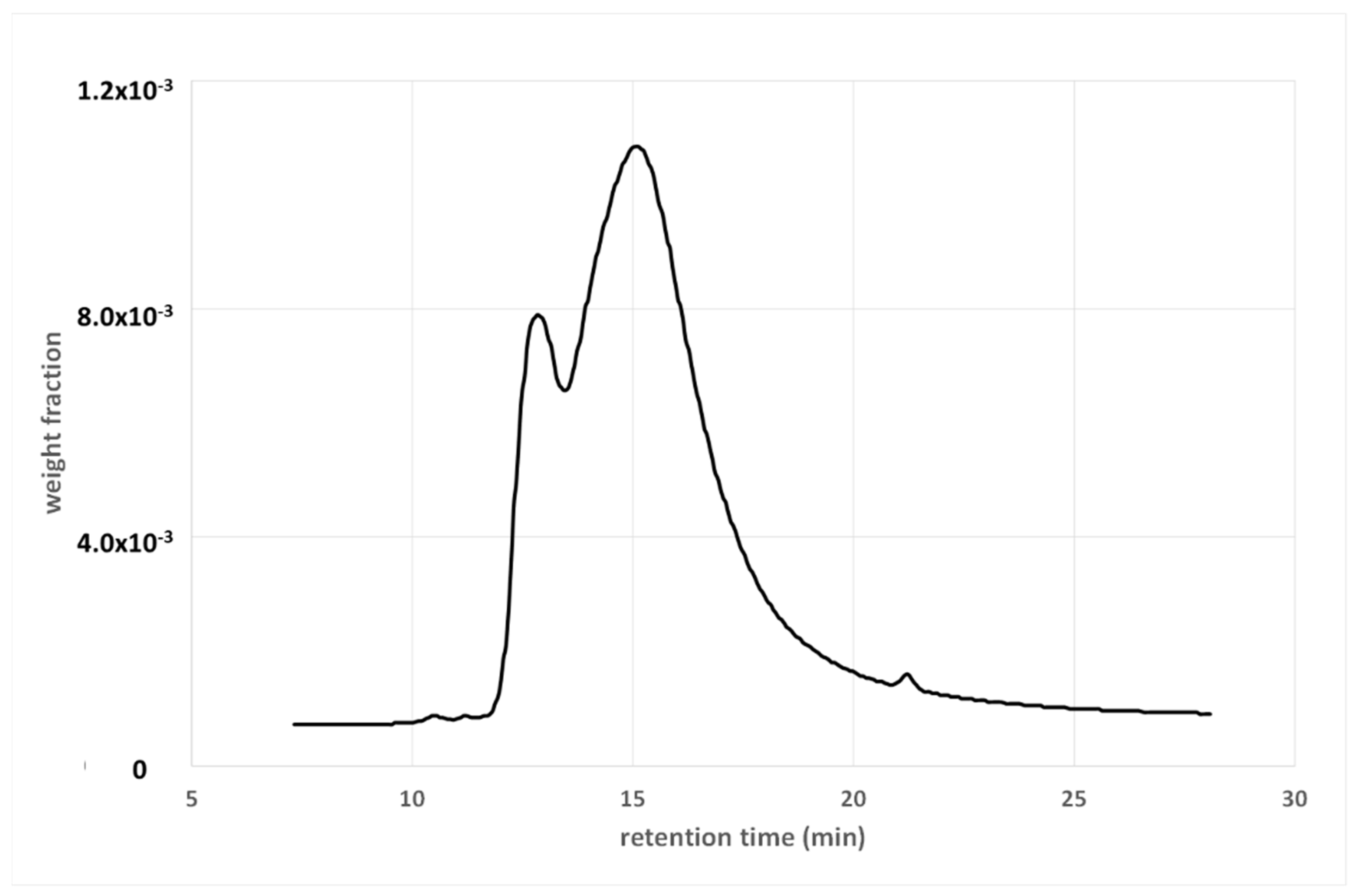

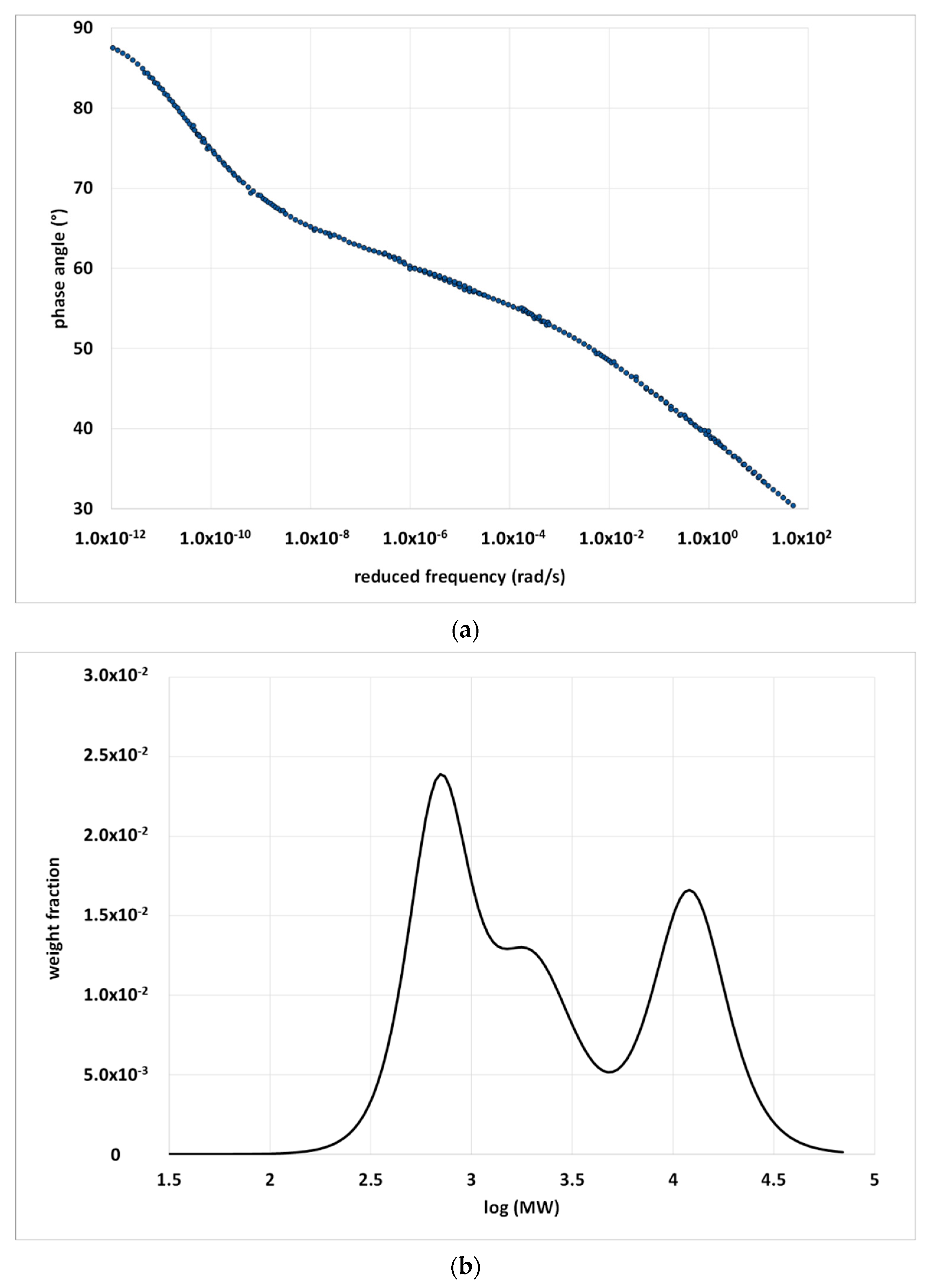

Oxidative aging is one of the main causes of long-term pavement deterioration, and there is a vast amount of literature on this topic in the field of asphalt [11][12][13]. From the AMWD perspective, the difference between bulk and solution characterization is of paramount importance. Partial oxidation of bituminous molecules determines the formation of new functional groups, and, above all, carbonyl (C=O) and sulfoxides (S=O) [12]. These functional groups alter the polarity of the molecules, and thus their contribution to the cohesive energy of the material, as well as their degree of association with the surrounding molecules. In fact, oxidative aging is often characterized by a sort of shifting to a fraction with a higher polarity (for example, an increase in resins and asphaltenes with a decrease in the aromatic content with saturates, which tend to remain stable). This has a significant effect on the bulk properties that macroscopically show the hardening of the materials, with a consequent reduction in their strain tolerance. In contrast, the new functional groups have a modest effect on the molecular weight of the molecules. Therefore, the BMWD is expected to be more sensitive to aging than the SMWD. This is highlighted in Figure 1 and Figure 2, which show the effects of artificial aging on the SMWD and BMWD for the same unmodified base bitumen.

Figure 1. SMWD for a 35/50 Pen-grade base bitumen, before and after being subjected to a pressure-aging vessel (PAV).

Figure 2. BMWD for a 35/50 Pen-grade base bitumen before and after PAV. All details are given in [14].

In Figure 1, the SMWDs before and after aging are almost superimposable, and especially on the right-hand side, where they correspond to low-MW fractions. In contrast, aging stretches the BMWD toward high molecular weights, with a simultaneous variation in the relative intensity of the peaks (the meaning of which has been discussed in a previous work) [14].

Both distributions confirm that oxidation does not involve the less polar low-MW molecules, but mainly affects the aromatics, resins and asphaltenes. The asphaltenes undergo an increase in polarity and mutual interactions, which decrease their mobility and thus increase the apparent molecular weight. What is barely appreciable in solution becomes a well-visible effect in bulk. Consequently, several aging indexes have been proposed based on the evolution of the BMWD [15][16].

2.2. Additives or Modifiers

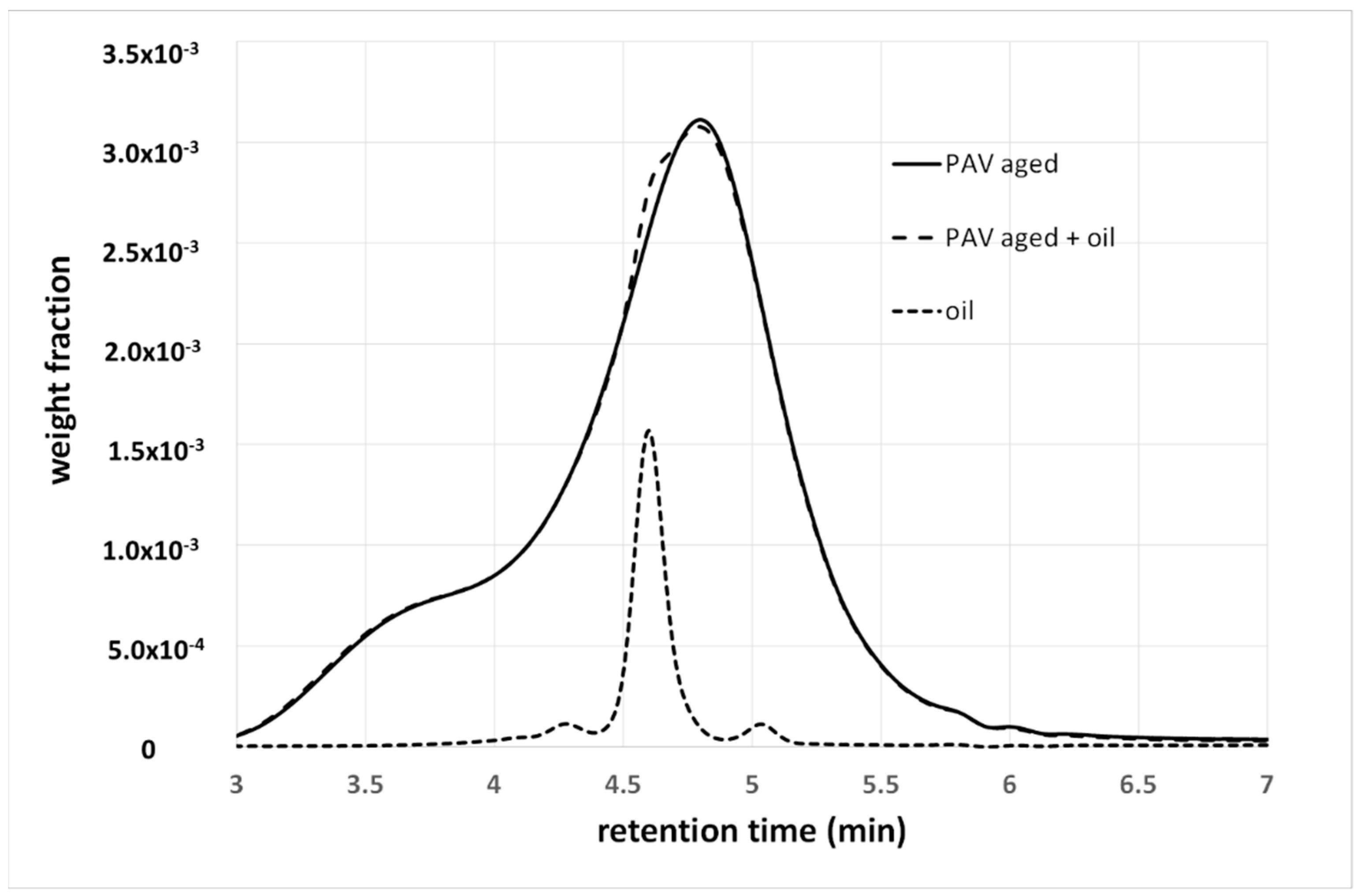

Many types of additives may be used to improve or restore the physical properties of bituminous binders, and, again, the SMWD and BMWD provide different information. Let researchers consider the case of rejuvenators, for example, which are vegetable oil added to an aged binder. Figure 3 shows the GPC spectra of a PAV-aged 50/70 penetration-grade binder, before and after the addition of a rejuvenating vegetable oil, as well as that of the oil.

The oil causes the appearance of a small shoulder (between approximately four and five minutes), as the interactions with the binder are hidden by the solvent. In this case, the GPC confirms, at least qualitatively, the presence of the additive, as the latter gives a signal at a specific elution time. In some cases (for example, isolated or well-visible peaks), a quantitative determination of the additive can also be obtained from the spectrum.

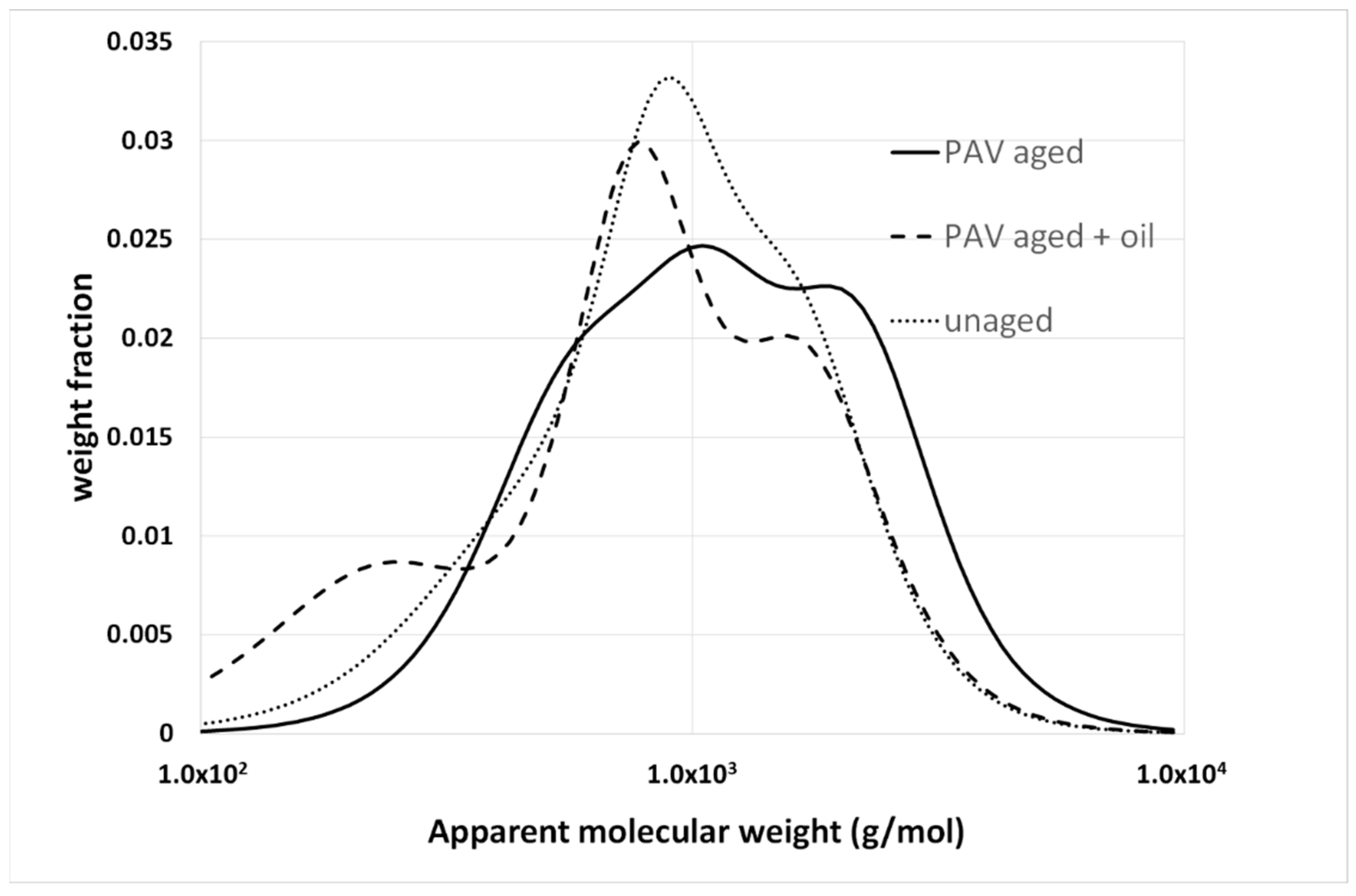

The BMWDs of the same two binders are given in Figure 4, together with that of the original unaged binder.

Figure 4. BMWDs of original PAV-aged and rejuvenated 50/70 binder.

As expected, the oil affects the whole bulk distribution because it replaces the lost light fractions in order to restore the original degree of aggregation in the binder. Therefore, the main advantage of a bulk distribution is that it provides useful information. In Figure 4, a comparison between the original and rejuvenated binder shows that this goal is partially achieved, with the two distributions being similar, and overlapping in the high-MW region.

2.3. Polymer-Modified Bitumen (PMB)

The use of polymers to modify bitumen is well known. The polymer-modified bitumen (PMB) obtained is a blend of two constituents with very different average molecular weights, and, thus, in theory, they are easy to identify in the MWD. This is why GPC can assess the presence of polymers when there is a rapid elution peak that corresponds to the polymer, which is clearly distinguishable from the signal associated with the bitumen molecules [19][20].

The weight fraction of the polymer corresponds to the relative area of the peak in the spectrum, but this calculation can be quite difficult due to the small amount of loaded polymer. Moreover, due to both the presence of short chains in the polymer and interactions with the stationary phase, the polymer and bitumen signals cannot be completely separated. This can happen, for example, in the case of HS-SEC, which confirms that the appropriate operating conditions are necessary, depending on the aims of the analysis. A moderate flow rate and a highly diluted solution favor the separation of the peaks and are preferable when polymer content is required. The role of GPC in PMB is thus similar to the above-described example of low-molecular-weight additives. In Figure 5, the signal corresponding to the SBS copolymer is observable between 10 and 12 minutes of retention time.

Figure 5. Weight fraction as a function of retention time of a PMB containing 6% SBS. Details on the materials and procedures are given in [21].

Another potential cause of uncertainty in SBS-based PMBs derives from the common practice of adding sulfur to improve their storage stability and morphology [22]. Sulfur induces a chemical crosslinking of the polymer and the formation of covalent bonds between polymer and bitumen molecules [23]. This alters the length of the polymer chains and causes the inclusion of bitumen molecules in the signal attributed to the polymer. Moreover, the crosslinking may lead to insoluble polymer clusters that remain in the prefilter instead of being fed to the GPC column.

In contrast, the BMWD of a PMB provides useful information on the binder structure; however, the interpretation of the distribution may not be simple. If the polymer confers its elastomeric properties to the whole material, then it has a large effect on the relaxation time of the bitumen molecules. In the phase-angle master curves of PMBs, the elastic behavior induced by the polymer is manifested as a plateau in the intermediate viscoelastic zone. Before the plateau, at lower frequencies (higher temperatures), the material has a liquid-like behavior. At higher frequencies (lower temperatures), the rigid bituminous matrix tends to prevail in determining the overall mechanical properties, and the behavior shifts to solid-like. The extension of the time–temperature intervals in which these behaviors occur depends on the type of polymer, concentration and use of crosslinker. Because the plateau zone corresponds to low values of the first derivative of the phase angle in the frequency axis, it becomes the separation zone of a bimodal distribution in the molecular weight axis. The longer the plateau zone, the better the separation between the two modes of distribution.

Figure 6a,b shows a master curve and the corresponding BMWD. The polymer is revealed by the high-molecular-weight peak, as in the GPC spectra; however, the relative area under this peak is much higher than the polymer content. This is because the polymeric network is swollen and includes bitumen molecules, the mobility of which is reduced, as in a gel [23]. The area of the peaks gives a quantification of the effect of the polymer on the overall distribution of the relaxation times and depends on the degree of the interactions between the polymer and bitumen.

Figure 6. (a) Phase-angle master curve of a PMB containing 5% SBS. (b) BMWD obtained from the master curve reported in (a). Details are given in [16].

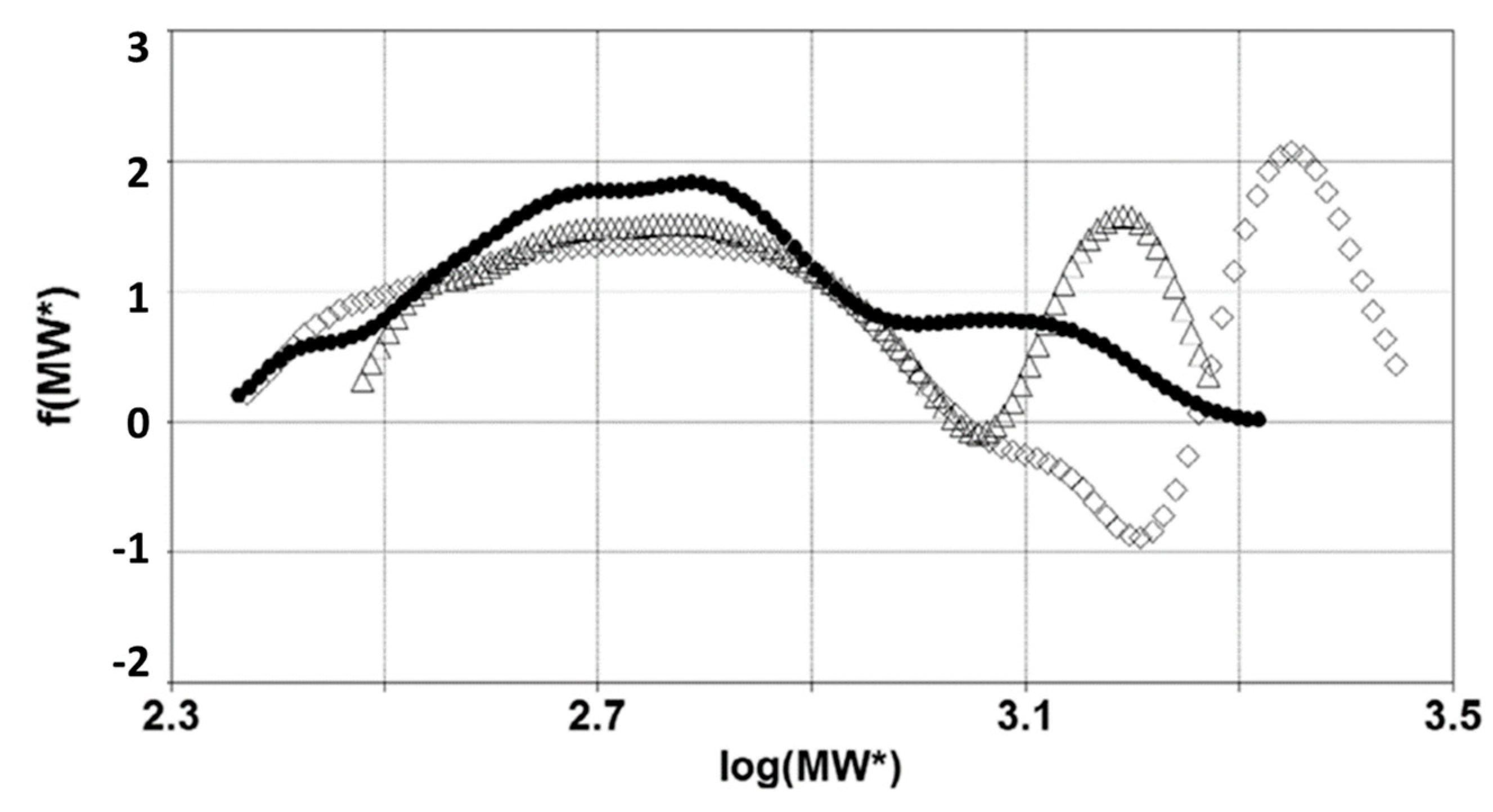

The effect of the bitumen–polymer interactions on the relaxation times is clearly shown when comparing the BMWD distribution of a base bitumen and those of the corresponding PMBs obtained with and without the use of sulfur (Figure 7).

Figure 7. Apparent BMWD for a base bitumen before (●) and after modification with SBS (Δ), or SBS and Sulfur (◊). Image from [24].

Without sulfur, the distribution of the PMB has the same range of molecular weights that correspond to the base bitumen, but the shape is very different. The presence of the polymer determines the abovementioned sharp separation between high- and low-molecular-weight zones, as the number of bituminous molecules involved in the network is proportional to the relative area of the second peak. When sulfur is added, the BMWD changes again: the second peak becomes larger and shifts significantly toward higher molecular weights, and the distributions show negative values between the low- and high-MW peaks. A larger area corresponds to a wider portion of the bitumen molecules involved in the polymeric network, which is the compatibilizing effect of sulfur. As a general observation, the more the peak is separated from the remaining part of the distribution, the higher the level of interactions and compatibility between the bitumen and polymer. The shift to the right is probably associated with the phase inversion, which is when the network assumes a sort of continuity and dominates the mechanical behavior. The whole material assumes an elastomeric character with higher relaxation times that reflect the behavior of the polymer. The negative peaks derive from the local minimum in the δ master curve. Although not acceptable from a mathematical perspective, the existence of negative weight fractions underlines a well-defined boundary between the prevalence of bitumen or polymer in determining the macroscopic behavior. Therefore, the negative values should be considered as important information on the material structure, instead of as a simple mathematical artefact.

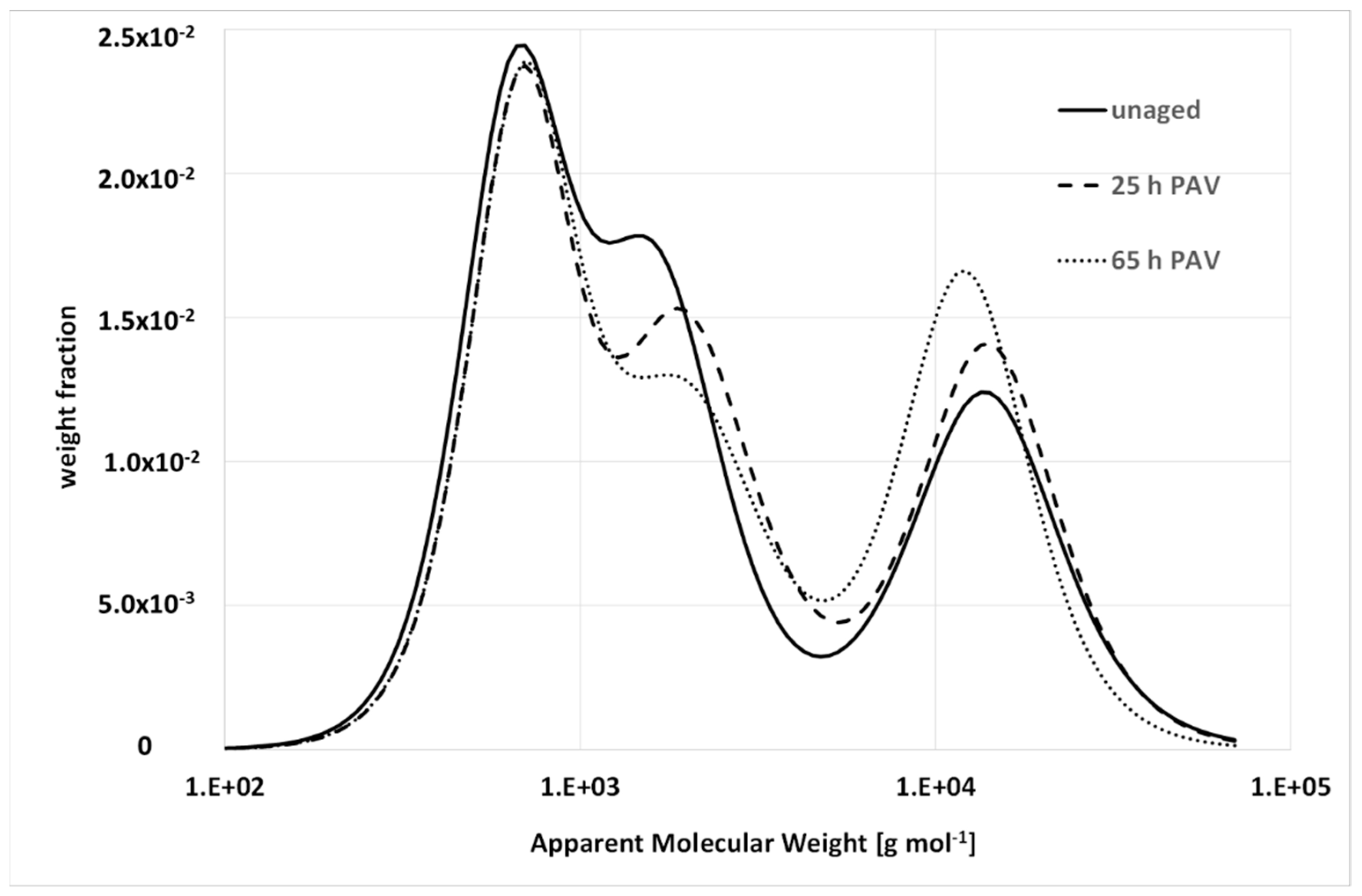

Figure 8 shows the evolution of the BMWD in the PMB subjected to different levels of artificial aging. Again, there is a significant difference between the bulk and solution. The effect of aging on the distributions is different than that observed for the unmodified binder. There is almost no horizontal stretching, and the three peaks behave differently. The first one, which corresponds to a small MW, seems invariant; the second one, the intermediate MW, decreases; the third one, polymer-bond molecules, increases. Although the thermal degradation of the polymer causes chain breaking and weakens the network, the latter is still present, and the oxidative aging increases the number of molecules with reduced mobility.

Figure 8. BMWD of a PMB with 5% SBS before and after prolonged artificial aging (25 and 65 hours of PAV, respectively). All details are given in [16].

References

- Ma, J.; Sun, G.; Sun, D.; Yu, F.; Hu, M.; Lu, T. Application of gel permeation chromatography technology in asphalt materials: A review. Constr. Build. Mater. 2021, 278, 122386.

- Young, R.J.; Lovell, P.A. Introduction to Polymers, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2011; ISBN 978-0849339295.

- Domin, M.; Herod, A.; Kandiyoti, R.; Larsen, J.W.; Lazaro, M.-J.; Li, A.S.; Rahimi, P. A Comparative Study of Bitumen Molecular-Weight Distributions. Energy Fuels 1999, 13, 552–557.

- Nciri, N.; Cho, N. A Thorough Study on the Molecular Weight Distribution in Natural Asphalts by Gel Permeation Chromatography (GPC): The Case of Trinidad Lake Asphalt and Asphalt Ridge Bitumen. Mater. Today Proc. 2018, 5, 23656–23663.

- Lesueur, D. The colloidal structure of bitumen: Consequences on the rheology and on the mechanisms of bitumen modification. Adv. Colloid Interface Sci. 2009, 145, 42–82.

- Thimm, W.; Friedrich, C.; Marth, M.; Honerkamp, J. An Analytical Relation between Relaxation Time Spectrum and Molecular Weight Distribution. J. Rheol. 1999, 43, 1663–1672.

- Tuminello, W.H. Molecular weight and molecular weight distribution from dynamic measurements of polymer melts. Polym. Eng. Sci. 1986, 26, 1339–1347.

- Tuminello, W.H.; Cudré-Mauroux, N. Determining Molecular Weight Distributions from Viscosity versus Shear Rate Flow Curves. Polym. Eng. Sci. 1991, 31, 1496–1507.

- Zanzotto, L.; Stastna, J.; Ho, S. Molecular weight distribution of regular asphalts from dynamic material functions. Mater. Struct. 1999, 32, 224–229.

- Themeli, A.; Chailleux, E.; Farcas, F.; Chazallon, C.; Migault, B. Molecular weight distribution of asphaltic paving binders from phase-angle measurements. Road Mater. Pavement Des. 2015, 16, 228–244.

- Petersen, J.C.; Glaser, R. Asphalt Oxidation Mechanisms and the Role of Oxidation Products on Age Hardening Revisited. Road Mater. Pavement Des. 2011, 12, 795–819.

- Petersen, J.C. Quantitative method using differential infrared spectrometry for the determination of compound types absorbing in the carbonyl region in asphalts. Anal. Chem. 1975, 47, 112–117.

- Dorrence, S.M.; Barbour, F.A.; Petersen, J.C. Direct evidence of ketones in oxidized asphalts. Anal. Chem. 1974, 46, 2242–2244.

- Cappello, M.; Polacco, G.; Crépier, J.; Hung, Y.; Filippi, S. Use of Linear Viscoelastic Functions to Estimate the Aging Resistance and Internal Structure of Bituminous Binders. Appl. Sci. 2021, 11, 7483.

- Krolkral, K.; Haddadi, S.; Chailleux, E. Quantification of asphalt binder ageing from apparent molecular weight distributions using a new approximated analytical approach of the phase angle. Road Mater. Pavement Des. 2018, 21, 1045–1060.

- Cappello, M.; Filippi, S.; Hung, Y.; Losa, M.; Polacco, G. Apparent Molecular Weight Distributions for Investigating Aging in Polymer-Modified Bitumen. Adv. Polym. Technol. 2021, 2021, 3660646.

- Mallegni, N.; Cappello, M.; Filippi, S.; Leandri, P.; Polacco, G.; Losa, M. Use of Recycled Oils as Rejuvenators for Bituminous Binders. Chem. Eng. Trans. 2021, 86, 1249–1254.

- Cuciniello, G.; Mallegni, N.; Cappello, M.; Filippi, S.; Leandri, P.; Polacco, G.; Losa, M. Classification and selection of exhausted oils for rejuvenating bituminous blends. Constr. Build. Mater. 2021, 278, 122387.

- Lin, P.; Huang, W.; Tang, N.; Xiao, F.; Li, Y. Understanding the low temperature properties of Terminal Blend hybrid asphalt through chemical and thermal analysis methods. Constr. Build. Mater. 2018, 169, 543–552.

- Luo, S.; Tian, J.; Liu, Z.; Lu, Q.; Zhong, K.; Yang, X. Rapid determination of styrene-butadiene-styrene (SBS) content in modified asphalt based on Fourier transform infrared (FTIR) spectrometer and linear regression analysis. Measurement 2019, 151, 107204.

- Cuciniello, G.; Leandri, P.; Filippi, S.; Presti, D.L.; Polacco, G.; Losa, M.; Airey, G. Microstructure and rheological response of laboratory-aged SBS-modified bitumens. Road Mater. Pavement Des. 2019, 22, 372–396.

- Syroezhko, A.M.; Begak, O.Y.; Fedorov, V.V.; Gusarova, E.N. Modification of Paving Asphalts with Sulfur. Russ. J. Appl. Chem. 2003, 76, 491–496.

- Polacco, G.; Filippi, S.; Merusi, F.; Stastna, G. A review of the fundamentals of polymer-modified asphalts: Asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci. 2015, 224, 72–112.

- Jasso, M.; Stastna, J.; Polacco, G.; Cuciniello, G. Development of internal structure of polymer-modified asphalts via transformations of the reduced frequency. J. Appl. Polym. Sci. 2020, 138, 50037.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

847

Revisions:

2 times

(View History)

Update Date:

11 Aug 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No