Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Sara Filippi and Version 2 by Dean Liu.

Molecular weight distributions are widely used to evaluate the effects of aging or modifiers in bituminous binders. As with polymers, the most common techniques to obtain the distributions can be subdivided into two main groups, depending on whether or not they use a solvent.

- bitumen

- apparent molecular weight distribution

- gel permeation chromatography

1. Introduction

The molecular weight distribution (MWD) influences the rheological and mechanical properties of viscoelastic materials, such as bitumen. For this reason, there is an increasing use of the MWD in the scientific literature related to asphalt paving, where it is correlated with the composition, performance, aging susceptibility and compatibility with additives and polymers [1]. The MWD can be determined by several experimental techniques, such as size-exclusion chromatography (SEC), field-flow fractionation and mass spectrometry [2]. Of these, the most popular in terms of bitumen is SEC, also known as gel permeation chromatography (GPC) [3][4][3,4]. In GPC, the data are collected in a diluted state, where the interactions among molecules are eliminated or at least strongly inhibited by the solvent. This therefore provides a distribution that corresponds to a disaggregate state and contributes little to the open debate on the complex structure of binders [5].

It would thus be helpful to obtain the distribution directly in bulk, as in the “inverse mechanical” approach, which uses rheological data, which are typically collected in the linear viscoelastic region. The idea is that the viscoelastic functions contain the complete spectrum of relaxation times, which can thus be deconvoluted into an MWD [6][7][8][6,7,8]. The procedure uses different viscoelastic functions and requires a correlation between the operating variable (i.e., reduced frequency, shear rate, time) and the molecular weight (MW).

One of the criteria adopted to derive such a correlation is to obtain a similar MWD from the GPC and inverse mechanical method. In other words, the calibration curves in the inverse mechanical approach are tuned in order to unify the results obtained with the two techniques [9][10][9,10]. This is somewhat questionable because molecules that tend to aggregate can be interpreted as a single entity in bulk and as multiple components in solution.

2. Applications

GPC has been used in several studies on bituminous binders, and the arecent review by Ma et al. provides a thorough overview of the available literature [1]. Here, rwesearchers briefly analyze a few examples to show the differences and characteristics of the solution and bulk distributions.2.1. Aging

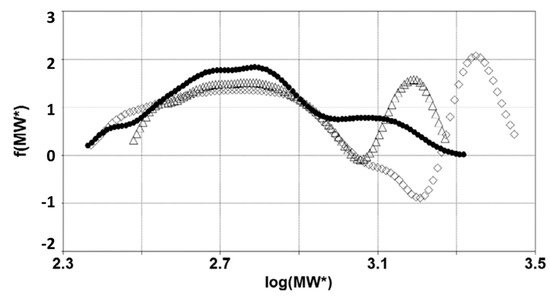

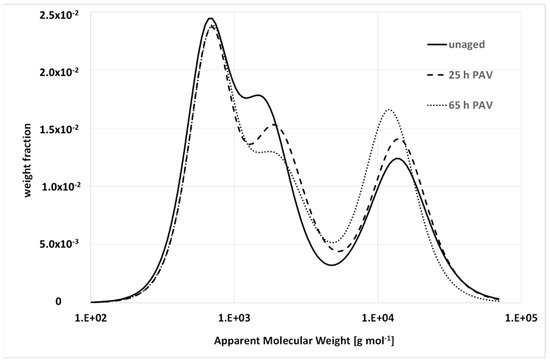

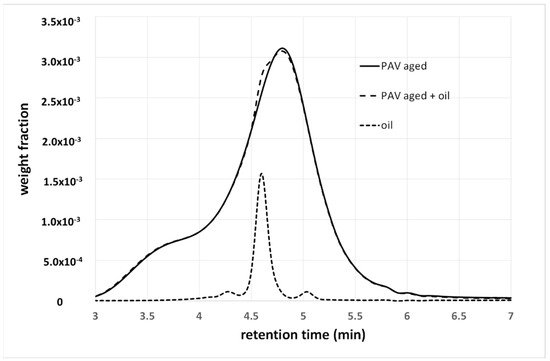

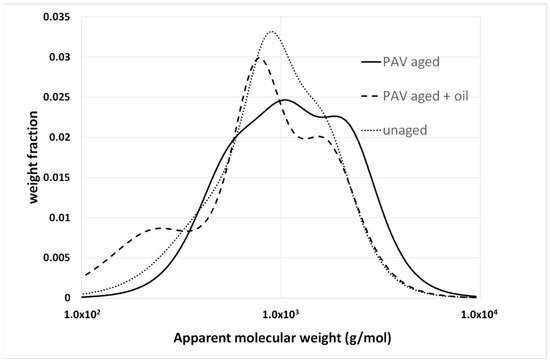

Oxidative aging is one of the main causes of long-term pavement deterioration, and there is a vast amount of literature on this topic in the field of asphalt [11][12][13][34,35,36]. From the AMWD perspective, the difference between bulk and solution characterization is of paramount importance. Partial oxidation of bituminous molecules determines the formation of new functional groups, and, above all, carbonyl (C=O) and sulfoxides (S=O) [12][35]. These functional groups alter the polarity of the molecules, and thus their contribution to the cohesive energy of the material, as well as their degree of association with the surrounding molecules. In fact, oxidative aging is often characterized by a sort of shifting to a fraction with a higher polarity (for example, an increase in resins and asphaltenes with a decrease in the aromatic content with saturates, which tend to remain stable). This has a significant effect on the bulk properties that macroscopically show the hardening of the materials, with a consequent reduction in their strain tolerance. In contrast, the new functional groups have a modest effect on the molecular weight of the molecules. Therefore, the BMWD is expected to be more sensitive to aging than the SMWD. This is highlighted in Figure 16 and Figure 27, which show the effects of artificial aging on the SMWD and BMWD for the same unmodified base bitumen.

Figure 16. SMWD for a 35/50 Pen-grade base bitumen, before and after being subjected to a pressure-aging vessel (PAV).

2.2. Additives or Modifiers

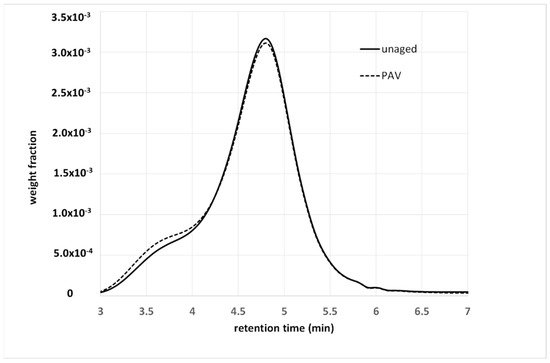

Many types of additives may be used to improve or restore the physical properties of bituminous binders, and, again, the SMWD and BMWD provide different information. Let reusearchers consider the case of rejuvenators, for example, which are vegetable oil added to an aged binder. Figure 38 shows the GPC spectra of a PAV-aged 50/70 penetration-grade binder, before and after the addition of a rejuvenating vegetable oil, as well as that of the oil.

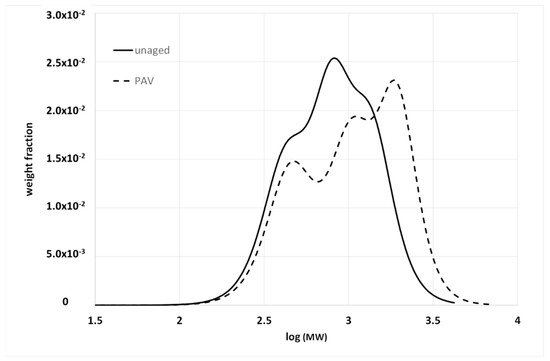

Figure 49. BMWDs of original PAV-aged and rejuvenated 50/70 binder.

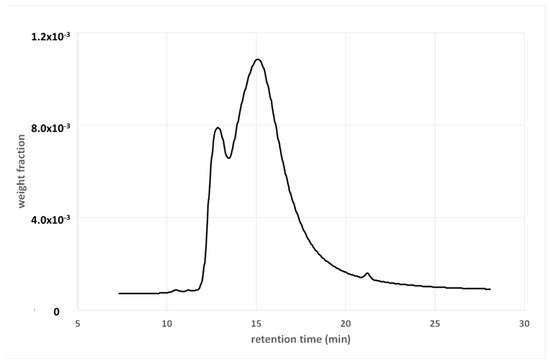

2.3. Polymer-Modified Bitumen (PMB)

The use of polymers to modify bitumen is well known. The polymer-modified bitumen (PMB) obtained is a blend of two constituents with very different average molecular weights, and, thus, in theory, they are easy to identify in the MWD. This is why GPC can assess the presence of polymers when there is a rapid elution peak that corresponds to the polymer, which is clearly distinguishable from the signal associated with the bitumen molecules [19][20][37,38]. The weight fraction of the polymer corresponds to the relative area of the peak in the spectrum, but this calculation can be quite difficult due to the small amount of loaded polymer. Moreover, due to both the presence of short chains in the polymer and interactions with the stationary phase, the polymer and bitumen signals cannot be completely separated. This can happen, for example, in the case of HS-SEC, which confirms that the appropriate operating conditions are necessary, depending on the aims of the analysis. A moderate flow rate and a highly diluted solution favor the separation of the peaks and are preferable when polymer content is required. The role of GPC in PMB is thus similar to the above-described example of low-molecular-weight additives. In Figure 510, the signal corresponding to the SBS copolymer is observable between 10 and 12 minutes of retention time.

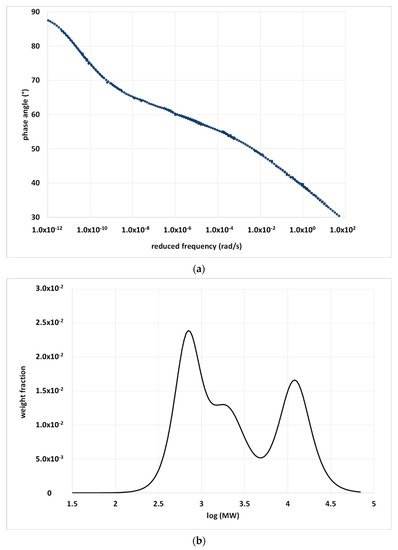

Figure 611.

(

a

) Phase-angle master curve of a PMB containing 5% SBS. (

b

) BMWD obtained from the master curve reported in (