Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ahmed Mohssen Abdelmagid | -- | 1268 | 2022-07-25 23:25:57 | | | |

| 2 | Rita Xu | Meta information modification | 1268 | 2022-07-26 03:18:41 | | | | |

| 3 | Rita Xu | + 3 word(s) | 1271 | 2022-07-29 10:53:36 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Abdelmagid, A.M.; Gheith, M.; Eltawil, A. The Truck Appointment Scheduling Problem. Encyclopedia. Available online: https://encyclopedia.pub/entry/25499 (accessed on 28 February 2026).

Abdelmagid AM, Gheith M, Eltawil A. The Truck Appointment Scheduling Problem. Encyclopedia. Available at: https://encyclopedia.pub/entry/25499. Accessed February 28, 2026.

Abdelmagid, Ahmed M., Mohamed Gheith, Amr Eltawil. "The Truck Appointment Scheduling Problem" Encyclopedia, https://encyclopedia.pub/entry/25499 (accessed February 28, 2026).

Abdelmagid, A.M., Gheith, M., & Eltawil, A. (2022, July 25). The Truck Appointment Scheduling Problem. In Encyclopedia. https://encyclopedia.pub/entry/25499

Abdelmagid, Ahmed M., et al. "The Truck Appointment Scheduling Problem." Encyclopedia. Web. 25 July, 2022.

Copy Citation

Scheduling the arrival of external trucks in container terminals is a critical operational decision that faces both terminal managers and trucking companies. This issue is crucial for both stakeholders since the random arrival of trucks causes congestion in the terminals and extended delays for the trucks.

truck scheduling problem

container terminal

truck appointment system

1. Introduction

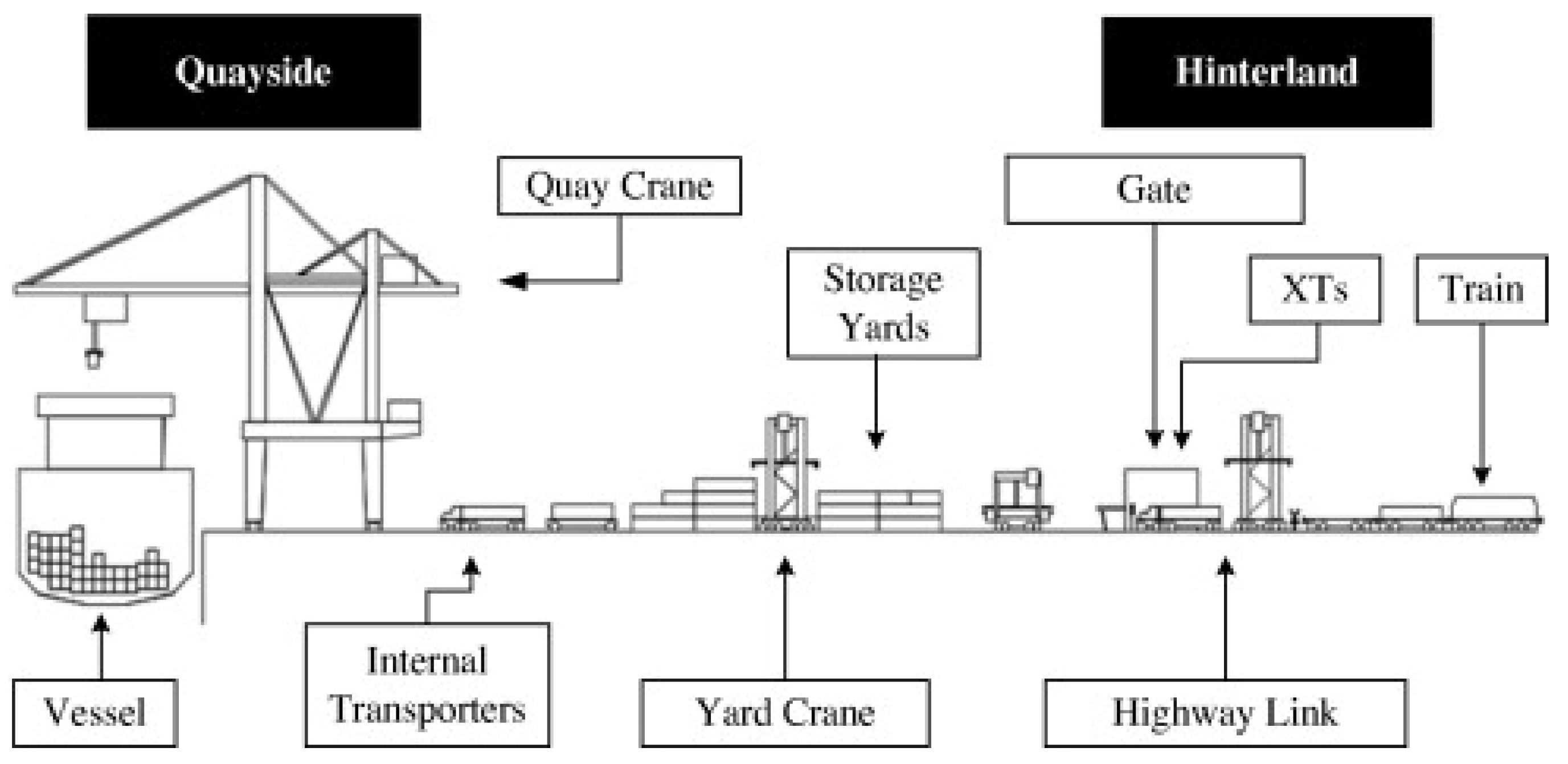

The rapid growth in the worldwide shipping industry has made the process of exchanging all kinds of goods easier. Containerized shipping has become the standard model of exchanging goods in global supply chains. The core advantages of depending on a sustainable freight mean of transport can be summed up as cost-effectiveness, time-saving, and higher reliability. Trucks are mainly responsible for the transportation operations from/to the container terminal. According to the International Chamber of Shipping [1], almost 90% of raw materials, foods, vehicles, manufacturing equipment, and products are shipped by sea around the world. Containerized trade using vessels is considered the lifeblood of the worldwide economy. Therefore, Container Terminals (CTs) have received a great deal of attention from researchers and responsible authorities who seek to manage their activities. CTs constitute a complicated network aiming to move goods among the world countries [2]. CTs consist of three essential areas: the landside, the yard area, and the seaside. Transport areas commonly link those three vital areas. The seaside has a group of quay cranes that perform discharging/charging inbound/outbound operations on deck, respectively. Internal trucks play an essential role in moving containers from/to the quayside to/from the yard area. Yard cranes are used for discharging containers transported by internal trucks. These containers are stacked in the yard area for a dwell time until they are carried by external trucks. External trucks are dedicated to picking up/delivering containers from/to the CT. At the landside area, external trucks are inspected, and handling containers takes place [3]. Figure 1 depicts the main areas of a CT and the cycle of the trucks while performing the dispatching tasks [4].

Figure 1. Schematic diagram representing the typical layout of a container terminal. (XTs: refers to external trucks) [4].

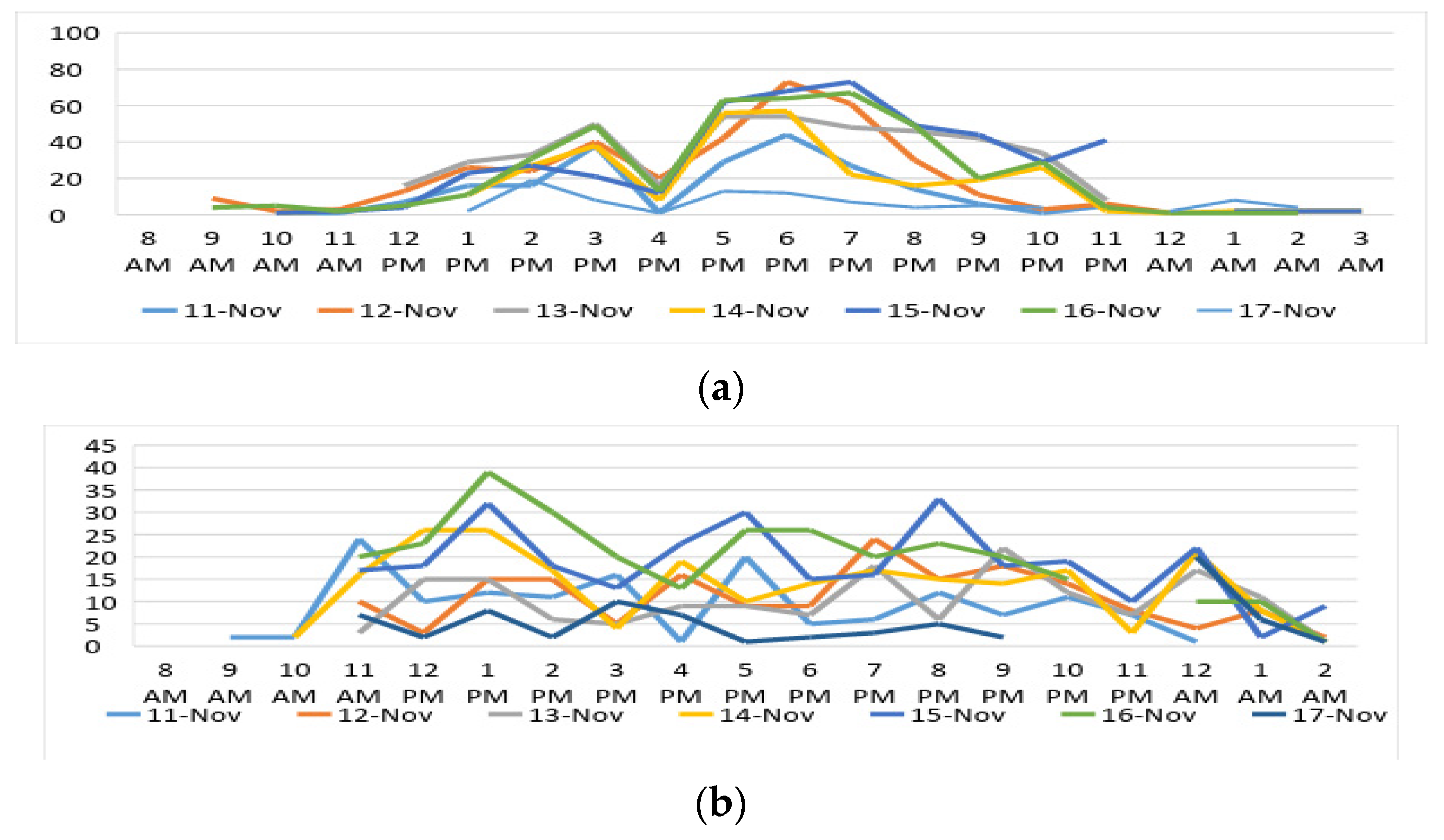

Due to the increasing demand for transporting containers to/from the terminals, trucking companies devote their trucks to performing the loading or dropping off tasks. Having various trucking companies send their trucks during the same time slots results in high arrival rates of trucks. Therefore, congestion levels rise at the terminal gates, causing excessive waiting times for the trucks and resulting in harmful emissions that increase global warming. According to [5], because of the massive amount of emissions, the international maritime organization in 2018 stated that reducing the amount of greenhouse gases resulting from international shipping is a must. After applying some policies and regulations, it is hoped that a reduction in the total amount of CO2 emissions by 50% will be reached in 2050 compared to 2008. Besides, the traffic fluidity of the streets around the terminals may be disrupted. Meanwhile, from the container terminal’s perspective, the bottlenecks that occur during specific time slots throughout the working hours lead to an unbalanced distribution of the workload and consequently reduce the utilization of the terminal’s equipment and its efficiency of serving the received tasks. Figure 2 illustrates typical truck arrival and departure patterns at the port of Alexandria in November 2017 [6]. This figure shows how chaotic the arrival patterns of trucks are during working hours.

Figure 2. Typical external truck (a) departures and (b) arrivals patterns in Alexandria container terminal in November 2017 [6].

In light of the problem of overcrowded trucks in front of the terminal gate and the yard area, container terminals implement Truck Appointment Systems (TAS). The terminal managers are responsible for setting such appointments according to various considerations (e.g., terminal workload, vessel berthing time, quay cranes operation schedule, etc.). The idea is to alleviate the workload in high load time slots [7]. Although the truck appointment system is beneficial for trucking companies, there are some anticipated drawbacks. The main drawback is assigning the trucks to inconvenient appointments for the trucking companies. This is due to the overlap with other tasks that should be performed by the same trucking company. On the other hand, if the container terminal allows the trucks to arrive at the terminal randomly, the terminal managers will lose control of the terminal workload.

2. The Truck Appointment Scheduling Problem

External truck scheduling is the process of organizing arrivals and departures of trucks according to various factors, e.g., the workload of the quay and yard areas, the available trucks in the trucking company, and the truck densities inside the terminal. Assuming that there is a set of containers that should be delivered/picked up to/from a container terminal, the trucking companies notify the terminal of the arrival time to deliver outbound containers. Likewise, the trucking companies follow the same procedure in picking-up tasks to delivering them to depots. The output of this problem is a schedule of truck appointments that will not violate the preferred arrival times submitted by truck drivers or the terminal workload distribution.

The scheduling of truck appointments is executed by an operating system called TAS. The TAS is a standard communication application that is employed to coordinate between the terminal and the trucking companies. The TAS is used by the terminal planners for determining the best appointment for trucks to come. After submitting an appointment request by a truck driver, the TAS is used to receive the workload levels from the terminal, then calculate the best schedule for drivers to come. Based on this step, the trucking companies organize their plans regarding the expected waiting times in the terminal [8]. The TAS enables the terminal managers to balance the workload level and reduce the congestion, emissions, and total costs resulting from excessive waiting times.

The proposed mathematical model seeks to reduce the total cost that is divided into three components: the container delivery cost, the demurrage cost, and the waiting time cost. According to ref. [9], the container delivery cost can be defined as the cost incurred by the trucking company to deliver containers to customers. This cost includes fuel cost, driving cost, and maintenance cost. The container delivery cost varies as it depends on the time slot at which the container is dispatched to the terminal. If the container is picked up from the terminal during rush hour time slots, the truck will spend more time delivering the container, whereas the truck will reach the depot in less time in smooth traffic conditions.

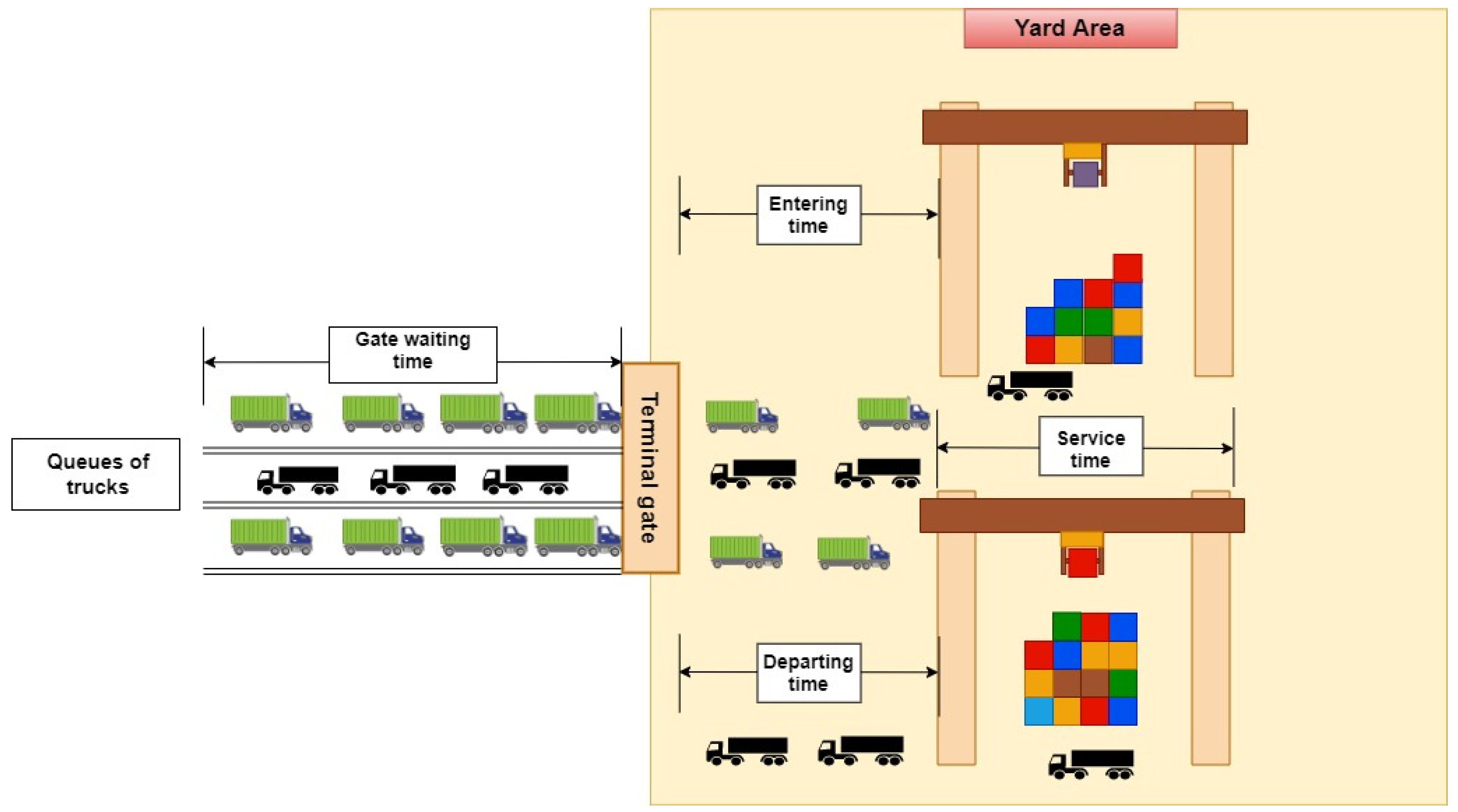

On the other hand, the demurrage cost is a penalty applied per time unit if an inbound container is picked-up after its free of charge period specified by the terminal, or if an outbound container is loaded before its free of charge period. According to the stevedoring tariff document of the Pusan East Container Terminal, the demurrage fee is imposed when an inbound container is stored for more than four days, which is free of charge. Also, the shippers have three days to load outbound containers for free [9]. Finally, the waiting time cost pertains to the entry/exit time to/from the terminal, respectively as well as the service time. Figure 3 illustrates the times spent by external trucks to deliver or pick up a container.

Figure 3. The times spent by trucks to perform the different tasks of container handling.

In the proposed case, the CT consists of seven-yard blocks. The working hours are divided into 24-time slots, and the terminal capacity is 30 trucks. The terminal manager controls the truck quota at each time slot. In this case, the maximum number per time slot is 10. It is assumed that there is one trucking company that executes the dispatching tasks of containers to the terminal.

References

- International Chamber of Shipping. Available online: https://www.ics-shipping.org/shipping-facts/shipping-and-world-trade (accessed on 20 March 2019).

- Steenken, D.; Voß, S.; Stahlbock, R. Container terminal operation and operations research-a classification and literature review. OR Spectr. 2004, 26, 3–49.

- Caballini, C.; Mar-Ortiz, J.; Gracia, M.; Sacone, S. Optimal truck scheduling in a container terminal by using a Truck Appointment System. In Proceedings of the 2018 21st International Conference on Intelligent Transportation Systems (ITSC), Maui, HI, USA, 4–7 November 2018; pp. 2525–2530.

- Taner, M.E.; Kulak, O.; Koyuncuoğlu, M.U. Layout analysis affecting strategic decisions in artificial container terminals. Comput. Ind. Eng. 2014, 75, 1–12.

- Pierre, C.; Francesco, P.; Theo, N. Towards low carbon global supply chains: A multi-trade analysis of CO2 emission reductions in container shipping. Int. J. Prod. Econ. 2019, 208, 17–28.

- Azab, A.; Karam, A.; Eltawil, A. A simulation-based optimization approach for external trucks appointment scheduling in container terminals. Int. J. Model. Simul. 2020, 40, 321–338.

- Giuliano, G.; O’Brien, T. Reducing port-related truck emissions: The terminal gate appointment system at the Ports of Los Angeles and Long Beach. Transp. Res. Part D Transp. Environ. 2007, 12, 460–473.

- Riaventin, V.N.; Kim, K.H. Scheduling appointments of truck arrivals at container terminals. Int. J. Ind. Eng. 2018, 25, 590–603.

- Yi, S.; Scholz-Reiter, B.; Kim, T.; Kim, K.H. Scheduling appointments for container truck arrivals considering their effects on congestion. Flex. Serv. Manuf. J. 2019, 31, 730–762.

More

Information

Subjects:

Engineering, Industrial

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.2K

Revisions:

3 times

(View History)

Update Date:

29 Jul 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No