Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Amir Poursaee | -- | 2486 | 2022-06-15 17:06:44 | | | |

| 2 | Dean Liu | -3 word(s) | 2483 | 2022-06-16 03:07:20 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Poursaee, A.; Ross, B. Chloride-Induced Corrosion of Carbon Steel in Cracked Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/24073 (accessed on 07 February 2026).

Poursaee A, Ross B. Chloride-Induced Corrosion of Carbon Steel in Cracked Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/24073. Accessed February 07, 2026.

Poursaee, Amir, Brandon Ross. "Chloride-Induced Corrosion of Carbon Steel in Cracked Concrete" Encyclopedia, https://encyclopedia.pub/entry/24073 (accessed February 07, 2026).

Poursaee, A., & Ross, B. (2022, June 15). Chloride-Induced Corrosion of Carbon Steel in Cracked Concrete. In Encyclopedia. https://encyclopedia.pub/entry/24073

Poursaee, Amir and Brandon Ross. "Chloride-Induced Corrosion of Carbon Steel in Cracked Concrete." Encyclopedia. Web. 15 June, 2022.

Copy Citation

Corrosion is an electrochemical reaction consisting of anodic and cathodic half-cell reactions. Micro-cell corrosion refers to the situation where active dissolution and the corresponding cathodic half-cell reaction occur in adjacent parts of the same metal. For a steel reinforcing bar in concrete, the surface of the corroding steel can act as a mixed electrode containing both anode and cathode regions connected by the bar itself. Macro-cell corrosion can also form on a single bar exposed to different environments within the concrete or where part of the bar extends outside the concrete. In both cases, the concrete pore solution functions as an electrolyte.

corrosion

concrete

crack

chlorides

1. Different Types of Cracks

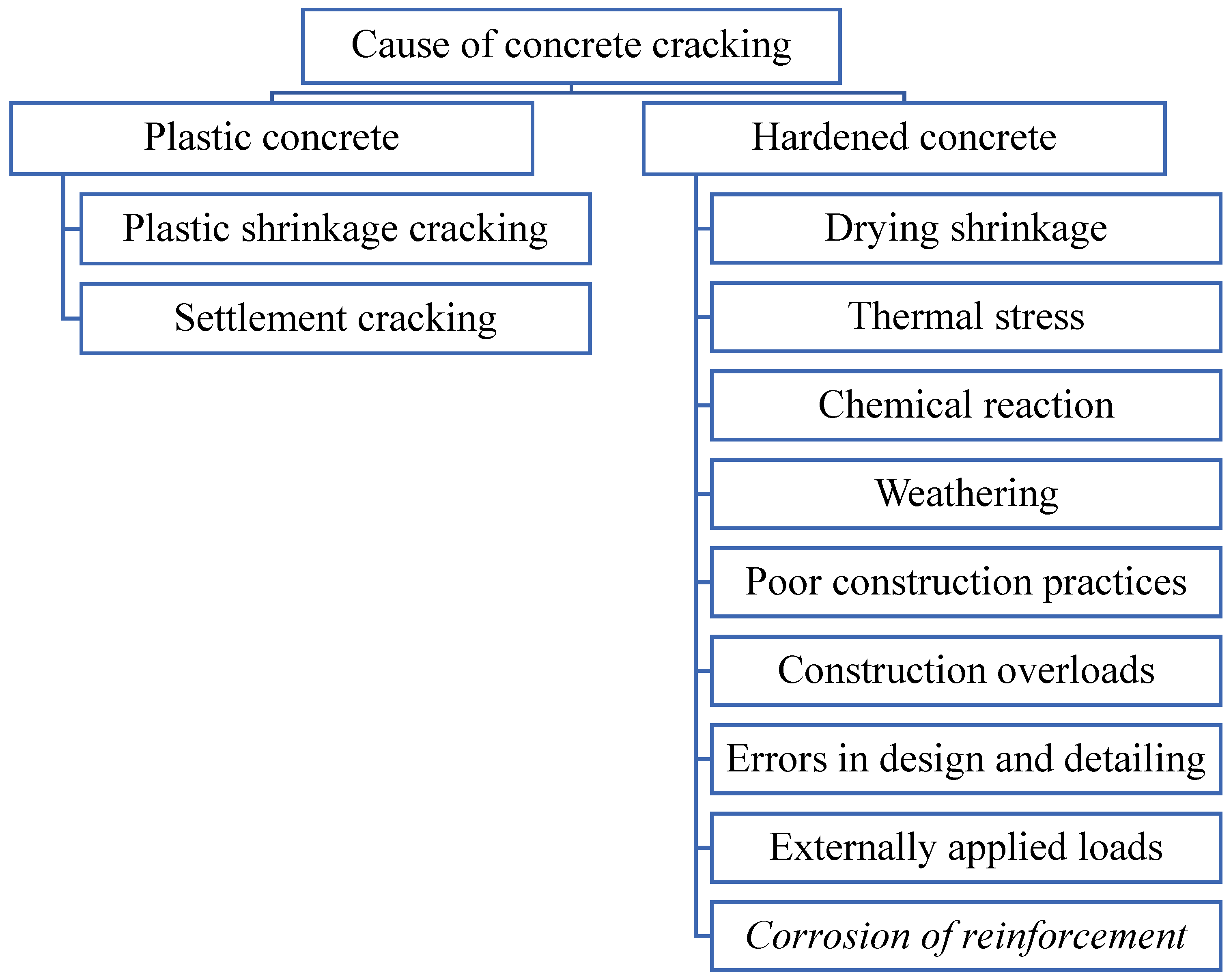

Cracking in reinforced concrete structures occurs due to diverse and complex processes such as physical loads, creep and shrinkage, and thermal stress. Cracks form when the summation of tensile stresses exceeds the concrete tensile strength. According to ACI committee 224, cracking can be classified into two main categories based on the time of the crack occurrence, i.e., cracks occurring before concrete hardening (plastic stage) or after concrete hardening, as shown in Figure 1 [1]. The cracking phenomena can be further subdivided. For example, cracking due to applied loads can be characterized as flexural, shear, or torsional cracks. Cracking can also be characterized by size, location, and severity. Internal microcracking, or non-structural cracks, result from the intrinsic properties of concrete and its ingredients [2].

Figure 1. Causes of concrete cracking.

2. Crack Size

The term “allowable crack width” denotes the range of maximum crack widths acceptable in reinforced concrete members, which should not impair durability or serviceability. “Crack control” includes actions taken during design to limit the quantity and size of cracking and to keep cracks within allowable limits. Even though proper mix design, placement, and curing can prevent or minimize the occurrence of many types of cracks listed previously, concrete cracking is still inevitable during the life span of reinforced concrete structures. Therefore, many building and construction codes include a range of crack limits based on the severity of the exposure conditions and the type of the structure. The crack widths are defined at the surface of the concrete structure under the quasi-permanent load combination. It should be noted that these values are for reinforced concrete, not for pre-stressed concrete.

These guidelines can be used to select reinforcement details to control cracks during the design stage. The guidelines can also be used as thresholds for evaluating concrete cracking in existing structures. There is no consensus regarding the maximum crack widths. For example, the maximum allowable crack width in reinforced concrete members exposed to deicing chemicals is 0.18 mm by ACI Committee 224 and 0.3 mm by Eurocode 2. Two additional points are important regarding allowable crack widths. First, crack widths can change over time, and second, these crack width values are not always a reliable indication of the occurrence of corrosion and deterioration [1]. Thus, these limitations are helpful guidelines and starting points but are not hard and fast rules.

3. Concrete Cracking Effects

3.1. Effects of Cracks on Chloride Ingress

It can be seen that a wide variety of results have been achieved regarding the effects of cracks on chloride penetration. One trend in the referenced studies is that chloride penetration is a function of the crack width unless the cracks are very small (no access to chloride through cracks), very large (free access of chlorides through cracks), or in between; increased accessibility develops with increasing crack width. There is no clear consensus on the impact of crack width.

3.2. Influence of Concrete Cracking on Reinforcement Corrosion

The influence of concrete cracking on reinforcement corrosion could be a function of the frequency of cracks (number of cracks per a specific length), crack direction compared to the reinforcement, crack width, and crack length.

3.2.1. Effects of Crack Frequency

Arya and Ofori-Darko conducted a study on 28 135 mm × 100 mm × 1360 mm steel-reinforced concrete beams containing 0, 1, 4, 8, 12, 16, and 20 parallel cracks per meter, with a water-to-cement ratio and concrete cover of 0.65 and 42 mm, respectively [3]. The total sum of the crack widths of each cracked beam was 2.4 mm, i.e., some beam specimens had fewer but wider cracks and others had more but narrower cracks. Beams were sprayed with a 3% NaCl solution for 24 months. The results of all cracked beams, except the one with 20 cracks, showed an increase in the weight loss of the embedded reinforcement with the increase in crack frequency. In the case of the beam with 20 cracks, it was suggested that the cracks were undergoing a self-healing process. The authors hypothesized that the corrosion of the reinforcing steel might be effectively controlled by limiting the number of cracks rather than limiting the surface crack widths.

On the contrary, in the study by Schiessl and Raupach, the opposite behavior was observed where the corrosion rate decreased as the spacing between the cracks decreased (i.e., frequency of cracks increased) [4]. They also reported that the corrosion rate doubled as the crack frequency decreased by half. They suggest that increasing crack quantity resulted in more anodic points and fewer cathodic areas between cracks.

In another study by Blagojević, the corrosion of the embedded steel in cracked concrete beams with different concrete covers of 20, 30, and 40 mm was investigated [5]. The beams with 20 mm, 30 mm, and 40 mm of concrete cover had 9, 8, and 6 active cracks, respectively, with a mean crack width of 0.15 mm for each beam. The results showed that the corrosion of the reinforcement tended to decrease when the crack frequency decreased and the concrete cover increased. It was concluded that the frequency of cracks was a function of concrete cover; therefore, the crack frequency was considered a secondary parameter in steel corrosion.

As can be seen, there is no clear answer regarding the relationship between the crack frequency and the corrosion rate. It appears that corrosion is affected by many interacting variables, including crack frequency and concrete cover.

3.2.2. Effects of Crack Orientation

Concrete cracks can be classified according to their orientation with respect to the reinforcement, i.e., longitudinal (or coincident) cracks that are parallel to the reinforcement and transverse (or intersecting) cracks that are perpendicular to the reinforcement [6][7]. Typically, longitudinal cracks develop as the result of plastic shrinkage, bond failure, and plastic settlement [7][8]. Longitudinal cracks are problematic because they expose a large portion of the embedded reinforcement to the aggressive species, e.g., chlorides, leading to the initiation of corrosion in multiple locations [7][8][9]. Poursaee and Hansson studied the corrosion in concrete beams with longitudinal and transverse cracks and they observed that the corrosion current density was higher in the case of concrete with longitudinal cracks than that with transverse cracks of the same width of 0.1 mm [10]. However, in the reinforced concrete structures with transverse cracks, steel often carries significant tensile stresses, impacting the corrosion rate, as observed by [11][12]. Two possible scenarios of longitudinal cracks are suggested. In the first one, a single bar running parallel to the crack of a corrosion cell (anodic and cathodic reactions) occurs within the crack zone. In the second one, the anodic reaction occurs at the intersecting point of the longitudinal and transverse reinforcement, where they are connected electronically, whereas the cathodic reaction takes place in the reinforcement in the uncracked parts of the concrete. More corrosion activity is expected in the second scenario due to the combined large cathode area in sound concrete and the small anode area at the crack.

3.2.3. Effects of Crack Width

Crack width is an important criterion influencing the corrosion of embedded reinforcement steel in concrete. Hence, the influence of crack widths on steel corrosion in concrete has been extensively studied in recent decades. However, the role of cracks and their widths on long-term corrosion (propagation stage) is still debatable.

Uncracked and cracked steel-reinforced concrete specimens with different crack widths of incipient cracks, 0.4 mm and 0.7 mm, and different binder and w/b (water-to-binder) ratios were included in an experimental study by Otieno et al. [13][14]. The specimens were subjected to a pond test with saltwater with 5% NaCl with three days of wetting and four days of drying each week. During exposure, cracks were reopened two times (between weeks 9–10 and 18–19). The entire test program lasted for 31 weeks. It was found that the corrosion in both the initiation and propagation phases was significantly affected by the presence of cracks. Moreover, the corrosion rate was proportional to the increase in the crack width for a given binder type and w/b ratio. For a given w/b ratio, the corrosion rate was higher in the case of ordinary portland cement concrete than it was for slag cement. An acceleration in the steel reinforcement corrosion due to reloading was also observed. The authors suggested that the concrete quality, w/b, and/or cover depth should be taken into account when adopting a crack-width threshold in which the corrosion activity in cracked concrete could be considered the same as in sound concrete.

Sahmaran and Yaman [15] conducted two different tests on pre-cracked mortar. Chloride penetration and the initiation of corrosion were evaluated using a salt ponding test. An accelerated corrosion test was performed by immersing pre-cracked specimens in a 5% NaCl solution and applying a constant voltage of 12 V to determine the effects of cracks on corrosion propagation. Crack widths were generated by flexural loads with a range of cracks from 0.029 to 0.390 mm. The results showed that crack width influenced corrosion initiation and propagation. The chloride diffusivity coefficient was observed to increase with crack widths. In addition, it was noted that a crack width larger than 135 μm had the most significant impact on the initiation and propagation stages. A laboratory study by Schiessl and Raupach [4] showed a considerable influence of crack widths on the chloride-induced corrosion of steel in the short term for widths of 0.3–0.5 mm. In long-term observations, no notable influence of crack widths on the corrosion rate was reported, and the corrosion rate appeared to be controlled by the conditions between the cracks (e.g., concrete cover and composition). Under laboratory conditions, crack healing may play a role, whereas under real conditions this effect may be considerably less (in real structures the cracks open and close due to traffic loads, temperature deviations, shrinkage, etc.). They concluded that crack widths cannot fully address reinforcement corrosion. Jaffer and Hansson studied the corrosion of cracked concrete under load [16]. They found that corrosion formed at the intersection of cracks and rebar only. Their experiments included 36 steel-reinforced concrete beams with two concrete mixes, including ordinary portland cement concrete and high-performance concrete with slag and fly ash. Furthermore, they considered three loading types: dynamic, static, and unloading. Specimens were cracked under three-point bending and then partially immersed vertically in a 3% NaCl solution. Their experiments included wet and dry cycles over 18 months. They concluded that the influence of cracks on the corrosion process is an important criterion in the health monitoring of reinforced concrete structures.

Mohammed et al. [17] carried out a study to investigate how crack width and bar-type influence the corrosion rate. The study used single-crack steel-reinforced mortar specimens and multicrack reinforced concrete beams. The single-crack specimens had crack widths of 0.1 mm, 0.3 mm, and 0.7 mm. The mortar specimens were made with water-to-cement ratios of 0.3, 0.5, and 0.7. Uncracked specimens were also considered study. The specimens were periodically sprayed with a 3.5% NaCl solution and the experiment lasted for 13 weeks. A higher corrosion rate was observed in specimens with larger crack widths in the first two weeks of the experiment; however, after four weeks of exposure, the relationship between crack width and the corrosion rate was not distinct. A negligible current density was reported for the uncracked specimens after 13 weeks. It was concluded that cracks are more consequential for the corrosion of steel reinforcement than crack widths.

François et al. conducted long-term studies to investigate the influence of concrete cracking on reinforcement corrosion [11][12] and the mechanical behavior of reinforced concrete structures in aggressive environments [18]. The program was conducted on 3 m long reinforced concrete beams. The specimens were kept in a confined salt fog of 35 g/L of NaCl in a loaded state. The first two studies were carried out after 12 years and the third after 17 years of exposure. The authors concluded that cracks have no effect on steel reinforcement corrosion development for crack widths less than 0.5 mm. The results showed that the applied load plays a major role in the corrosion and mechanical behavior of reinforced concrete members exposed to aggressive conditions. The authors suggested that service loads lead to microcracking, which allows the ingress of harmful substances. These substances then affect the service life of the structure by initiating corrosion.

Another study by François et al. [19] showed that the crack existence, regardless of width, greatly influenced the corrosion initiation time for steel-reinforced concrete specimens in the NaCl solution. However, there was no notable influence of crack width on long-term corrosion due to the formation of additional cracks due to corrosion. The additional cracks began to dominate the corrosion activity and the process was controlled by mechanical stress intensity.

Dang et al. [20] investigated ring-shaped mortar samples with cracks from 0 to 100 μm. A process of wet and dry cycles with 35 g/L NaCl salt solution was carried out to accelerate reinforcement corrosion. The samples were broken after 1.5 and 2.5 years and visually investigated. The results also showed the importance of cracks in corrosion with no relationship between crack width and corrosion.

The influence of cover cracking on chloride-induced corrosion was experimentally investigated by Li et al. [21] through a 654-day laboratory test on cracked reinforced concrete specimens exposed to a chloride solution. The concrete specimens were made with different crack widths of uncracked, 0.2, 0.3, 0.4, and 0.5 mm, and immersed in a NaCl solution. The results showed that the corrosion rates for the cracked specimens increased with the increasing percentage concentration of chloride and the increasing crack width.

Chen and colleagues [22] studied the corrosion pattern and characteristics of rebars in un- and pre-cracked reinforced concrete beams subjected to natural corrosion for more than three years. They found no correlation between the maximum flexural crack width (nominally 0.1 and 0.4 mm) and the maximum local corrosion level.

Abo Alarab et al. [23] studied the influence of transverse crack opening size on the chloride-induced corrosion of steel bars in cracked concrete with three different crack opening sizes, 0.1, 0.3, and 0.7 mm. The results in the cracked and uncracked specimens showed that, regardless of the crack opening size, corrosion activity was most significant at the location of the crack. However, the corrosion process in specimens with a 0.1 mm crack opening slowed throughout the experiment. It is hypothesized that this is due to the build-up of corrosion products in the cracks. Since chloride ions were already in the vicinity of the steel, filling the crack would lead to a lack of oxygen, slowing the corrosion process. Compared with the specimens with a 0.1 mm crack opening, the corrosion activities in specimens with 0.3 and 0.7 mm crack openings remained relatively steady within the test period. The degree and extent of corrosion were proportional to the crack opening size, with the 0.7 mm crack opening being the highest and the 0.1 mm crack opening being the lowest.

References

- ACI. ACI 224.1R: Causes, Evaluation and Repair of Cracks in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2007.

- Concrete Society. TR22 Non-Structural Cracks in Concrete; Concrete Society: London, UK, 2010.

- Arya, C.; Ofori-Darko, F.K. Influence of crack frequency on reinforcement corrosion in concrete. Cem. Concr. Res. 1996, 26, 345–353.

- Schiessl, P.; Raupach, M. Laboratory studies and calculations on the influence of crack width on chloride-induced corrosion of steel in concrete. Mater. J. 1997, 94, 56–61.

- Blagojević, A. The Influence of Cracks on the Durability and Service Life of Reinforced Concrete Structures in Relation to Chloride-Induced Corrosion. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 2015.

- Otieno, M.B.; Alexander, M.G.; Beushausen, H.D. Corrosion propagation in cracked and uncracked concrete. In Concrete Repair, Rehabilitation and Retrofitting II; CRC Press: Cape Town, South Africa, 2008; pp. 157–158.

- Pease, B.J. Influence of Concrete Cracking on Ingress and Reinforcement Corrosion. Ph.D. Thesis, Technical University of Denmark (DTU), Lyngby, Denmark, 2010.

- Shaikh, F.U.A. Effect of cracking on corrosion of steel in concrete. Int. J. Concr. Struct. Mater. 2018, 12, 3.

- Otieno, M. Corrosion Propagation in Cracked and Uncracked Concrete. Ph.D. Thesis, University of Cape Town, Cape Town, South Africa, 2008.

- Poursaee, A.; Hansson, C.M. The influence of longitudinal cracks on the corrosion protection afforded reinforcing steel in high performance concrete. Cem. Concr. Res. 2008, 38, 1098–1105.

- François, R.; Arliguie, G. Effect of microcracking and cracking on the development of corrosion in reinforced concrete members. Mag. Concr. Res. 1999, 51, 143–150.

- François, R.; Arliguie, G. Influence of service cracking on reinforcement steel corrosion. ASCE J. Mater. Civ. Eng. 1998, 10, 14–20.

- Otieno, M.B.; Alexander, M.G.; Beushausen, H.D. Corrosion in cracked and uncracked concrete—Influence of crack width, concrete quality and crack reopening. Mag. Concr. Res. 2010, 62, 393–404.

- Otieno, M.B.; Beushausen, H.D.; Alexander, M.G. Chloride-induced corrosion of steel in cracked concrete—Part I: Experimental studies under accelerated and natural marine environments. Cem. Concr. Res. 2016, 79, 373–385.

- Şahmaran, M.; Yaman, I. Influence of transverse crack width on reinforcement corrosion initiation and propagation in mortar beams. Can. J. Civ. Eng. 2008, 35, 236–245.

- Jaffer, S.J.; Hansson, C.M. The influence of cracks on chloride-induced corrosion of steel in ordinary Portland cement and high performance concretes subjected to different loading conditions. Corros. Sci. 2008, 50, 3343–3355.

- Mohammed, T.; Otsuki, N.; Hisada, M.; Shibata, T. Effect of crack with and bar types on corrosion of steel in concrete. ASCE J. Mater. Civ. Eng. 2001, 13, 194–201.

- François, R.; Castel, A.; Vidal, T.; Vu, N.A. Long term corrosion behavior of reinforced concrete structures in chloride environnement. J. Phys. IV 2006, 136, 285–293.

- François, R.; Khan, I.; Vu, A.N.; Mercado, H.; Castel, A. Study of the impact of localised cracks on the corrosion mechanism. Eur. J. Environ. Civ. Eng. 2012, 16, 392–401.

- Dang, V.H.; François, R.; L’Hostis, V. Effects of pre-cracks on both initiation and propagation of re-bar corrosion in pure carbon dioxide. EPJ Web Conf. 2013, 56, 06006.

- Li, W.; Liu, W.; Wang, S. The effect of crack width on chloride-induced corrosion of steel in concrete. Adv. Mater. Sci. Eng. 2017, 2017, 3968578.

- Chen, E.; Berrocal, C.G.; Lofgren, I.; Lundgren, K. Correlation between concrete cracks and corrosion characteristics of steel reinforcement in pre-cracked plain and fibre-reinforced concrete beams. Mater. Struct. 2020, 53, 33.

- AboAlarab, L.; Ross, B.; Poursaee, A. Influence of transverse crack opening size on chloride-induced corrosion of steel bars in concrete. ASCE J. Bridge Eng. 2020, 25, 04020027.

More

Information

Subjects:

Metallurgy & Metallurgical Engineering

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

16 Jun 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No