Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sravendra Rana | -- | 1469 | 2022-06-09 13:35:37 | | | |

| 2 | Jessie Wu | Meta information modification | 1469 | 2022-06-10 03:06:12 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Rana, S.; Kumar, A.; Guadagno, L. Applications of Carbon Fiber-Reinforced Polymer Composites. Encyclopedia. Available online: https://encyclopedia.pub/entry/23883 (accessed on 13 January 2026).

Rana S, Kumar A, Guadagno L. Applications of Carbon Fiber-Reinforced Polymer Composites. Encyclopedia. Available at: https://encyclopedia.pub/entry/23883. Accessed January 13, 2026.

Rana, Sravendra, Ajay Kumar, Liberata Guadagno. "Applications of Carbon Fiber-Reinforced Polymer Composites" Encyclopedia, https://encyclopedia.pub/entry/23883 (accessed January 13, 2026).

Rana, S., Kumar, A., & Guadagno, L. (2022, June 09). Applications of Carbon Fiber-Reinforced Polymer Composites. In Encyclopedia. https://encyclopedia.pub/entry/23883

Rana, Sravendra, et al. "Applications of Carbon Fiber-Reinforced Polymer Composites." Encyclopedia. Web. 09 June, 2022.

Copy Citation

Carbon fiber-reinforced polymer (CFRP) composites are used in a variety of applications such as aircraft, automobiles, body armors, and the sports sector owing to their ultra-strong and lightweight characteristics.

carbon fibers

graphene oxide

aircraft

1. Introduction

Owing to their low specific weight, high stiffness, superior temperature and corrosion resistance, and ease of processability, carbon fiber-reinforced polymeric (CFRP) composites are used in broad range of applications from aerospace to marine industries [1]. CFRPs display excellent tensile strength; however, the brittleness, crack-prone matrix and the fiber–matrix interface with a weak adhesion usually lead to a failure of the composite structures in terms of delamination and catastrophic failure [2][3]. In this direction, carbon nanostructured forms (CNFs) can help to overcome these criticalities. The use of CNFs in bulk epoxy resins and their composites has been pursued by many authors, not only to increase the mechanical performance of the resulting composites but also to confer them functional properties, such as de-icing, self-sensing, and self-healing, or to save energy during the manufacturing process [4][5][6][7]. Multi-wall carbon nanotubes (MWCNs) have been successfully incorporated in CFRCs, imparting them electrical conductivity, whose value depends on the process adopted for the manufacturing [8][9]. Graphene-based nanoparticles are expected to further improve, with respect to CNTs, some functional properties depending on the thermal conductivity of the composite (thermal management), and to reduce the humidity content in composites based on epoxy resins [10]. For these reasons, many authors have made tremendous efforts to obtain graphene in the form of single layers, for example, training to completely exfoliate graphite particles (to reach almost 100% of exfoliation). Despite the large efforts made to obtain and employ perfect and almost single graphene layers, no high-performance materials, in terms of electrical properties and related functional properties, have been obtained. This is because defect-free single graphene layers tend to reassemble during the steps of nanocomposite manufacturing. To avoid reassembling arrangements, functionalization procedures are needed. This allows the attaching of chemical groups to the graphene layers able to prevent the re-assembling because of steric and energy factors. If the functionalization is performed through functional groups covalently bonded to the single graphene layers, the reassembling phenomena are prevented, but the change in the hybridization state of the carbon atoms, from sp2 to sp3, in single layers results in the partial loss of the phenomenon of electron delocalization of carbon nanoparticles and, as a consequence, in the impoverishment of their electronic properties [11]. To meet this scientific and technical challenge, it is possible to use graphene oxide nanosheets, which are constituted of the stacking of different graphene layers (able to manifest the desired phenomenon of electron delocalization) and polar functional groups on the edges of these thin graphene-based blocks. GO nanoparticles dispersed in the polymeric matrix are expected to also improve the interfacial adhesion between woven carbon fibers and the epoxy matrix during the impregnation process of the woven fibers. In fact, GO nanoparticles are composed of polar groups, especially on the edges of the nanosheets, able to provide strong interaction with the hosting cured epoxy matrix (composed of a large number –OH polar groups) and the “core” part, similar to the structure of CFs, therefore being able to establish attractive interactions with the reinforcing CFs of the woven fibers. This is a hot topic worth investigating for the obvious applicative implications. There are many relevant papers in the literature that have revealed that the presence of GO nanosheets in the epoxy resin should allow the conferring of functional properties to the resin, whereas, in other papers, GO should promote better adhesion between carbon fibers and the polymeric matrix. This research aims to investigate recent advances achieved in this last direction. To improve the interfacial properties of the composites, a resilient interfacial adhesion between the fiber and matrix plays a significant role. In recent years, a series of methods have been introduced to improve the interfacial adhesion between the fiber and matrix such as the coating of fibers, sizing, 3D weaving, and tufting [12]. Unfortunately, these approaches are only applicable to textile laminates made with resin transfer molding (RTM) procedures, and are thus not applicable on prepreg laminates [13][14]. The poor defective surface of carbon fiber lacks the functional groups on its surface and thus has insufficient wettability and interaction with the polymer matrix. Functional groups such as hydroxyl –OH, carboxyl –COOH, and carbonyl –CO are added on the surface of CFs or in the epoxy matrix to boost their functionality as a CFRP reinforcement [15]. The effect of the functionalization of carbon fibers or epoxy with nanoparticles such as carbon nanotubes, nano clay, and graphene nanoplatelets has been investigated in detail [16][17][18][19][20][21][22][23][24][25][26]. However, control of the carbon nanotubes (CNTs) and nano clay dispersion is difficult and not cost-effective. In addition, their agglomeration onto a fiber surface leads to reductions in the glass transition temperature (Tg) and mechanical properties of the developed composites [27]. Recently, to attain good interfacial adhesion, the modified graphene was significantly incorporated in CFRP composites [28]. The improvement in the thermal conductivity of the CFRP by grafting carbon fibers with a 3D graphene network was examined, where an increase in thermal conductivity of about 165% in comparison with that of pure CFRP was observed for the graphene-incorporated composites [29]. The fatigue behavior and mode I fracture toughness of CFRP functionalized by graphene nanoplatelets (GNPs) was investigated, and it was observed that with 0.1% of GNPs, the mean fatigue life and mode I interlaminar fracture toughness increased to 155% and 40%, respectively [30]. A strong interaction was observed in the case of GO-incorporated composites as compared to unfunctionalized graphene sheets-incorporated composites due to the abundance of various functional groups [31]. The use of graphene oxide functionalization with polymers has gained momentum after this development. The functionalization of graphene oxide resulted in an improvement in interfacial adhesion in terms of preventing delamination and crack propagation.

2. Applications of Carbon Fiber-Reinforced Polymer (CFRP) Composites

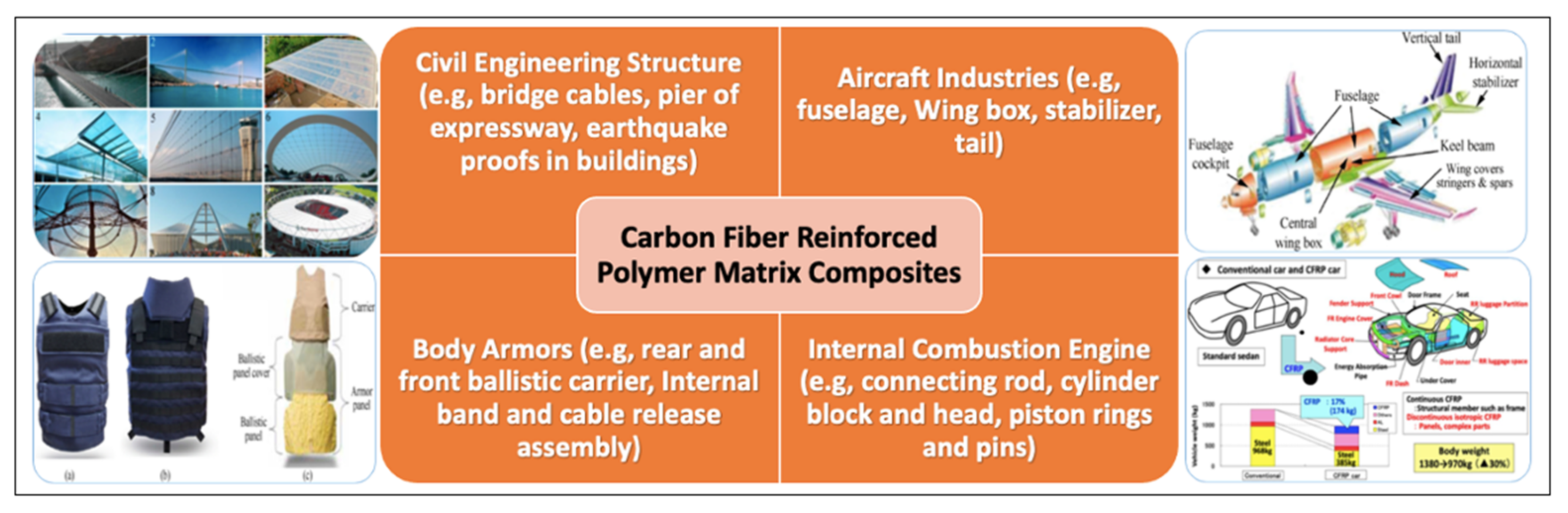

From aerospace to automotive industries, carbon fiber-based polymer composites can contribute a vital role as these applications necessitate a lightweight material with outstanding mechanical performance, high stiffness, corrosion resistance, low coefficient of thermal expansion, chemical resistivity, and excellent electrical and thermal conductivity. Temperature changes and adverse atmospheric conditions, such as saline water and high wind, must be tolerated by the developed composite materials. Multifunctional composites might be quite intriguing in this scenario; thus, combining the excellent mechanical qualities of CF/epoxy composites with other embedded functionalities such as temperature management [4], energy storage, and sensing properties [32] would result in a technical breakthrough in the applicability of carbon-based composites [33]. In the design of airplanes and spacecrafts, the risk of destruction due to impact was well understood. To negotiate these effects, the introduction of CFRP composites is increasing rapidly; for example, an A-320 aircraft has a 21.5% composite usage to its total weight, and a Boeing 787 and Airbus A350 have 50% of its total weight comprised of CFRP for different parts including the tail cone, center wing box, vertical and horizontal tails, and pressure bulkheads. On the other hand, the usage of CFRP composites was also started in the field of military aircraft due to their outstanding performance and the excellent strength-to-weight ratio [34][35]. Figure 1 depicts the sectors for the application of CFRP composites.

The use of CFRP composite laminates has also been initiated in the area of civil engineering and structural parts such as stock cables for bridges and suspension bridges. The cables are used for replacing the conventional steel cables throughout the world due to their nonrelaxing, noncorroding, light-weight quality, and stress-free behavior. Table 1 represents the comparison of properties of CFRP cables in comparison with that of conventional steel cables. It has been found that the CFRP cable shows excellent mechanical performance in terms of elastic modulus, tensile strength, and density [39].

Table 1. Comparison of CFRP and steel cable properties [39].

| Property | Tensile Strength | Elastic Modulus | Elongation at Rupture | Density | Thermal Coefficient of Expansion | Poisson’s Ratio |

|---|---|---|---|---|---|---|

| Steel cable | 1670 N/mm2 | 205,000 N/mm2 | 6.0% | 7850 kg/m3 | 1.2 × 10−5 K−1 | 0.3 |

| CFRP Cable | 2700 N/mm2 | 160,000 N/mm2 | 1.6% | 1600 kg/m3 | 0.2 × 10−6 K−1 | 0.3 |

The automotive sector also started using CFRP composites due to their anisotropic distribution of mechanical properties, advantageous for the fabrication of certain engine components such as conrods R4 (82/71). The material is made up of two monolayer polymers with fibers, oriented differently. The conrod’s main body and cap are constructed of two monolayer polymers that are combined in various quantities [40]. In today’s environment, there is a growing demand for lightweight, flexible, and durable body armor that can provide enhanced ballistic protection, particularly against the increasingly lethal threats that soldiers will face. CNTs and graphene, which are among the world’s strongest and stiffest materials, will certainly contribute in the development of ultra-strong, massive-energy-absorber, lightweight, and robust composites for future body armor construction. High-performance carbon fiber-reinforced polymers functionalized with graphene-based nano-fillers are currently used in ballistic systems as hybrid nanocomposites to construct the ultimate body armor of the future [41].

References

- Kaw, A.K.; Group, F. Mechanics of Composite Materials; CRC Press: Boca Raton, FL, USA; Taylor & Francis: Milton Park, UK, 2006.

- Centre, A.C. The role of delamination in failure of fibre-reinforced composites. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2012, 370, 1850–1870.

- Hao, W.; Tang, C.; Yuan, Y.; Ma, Y. Investigation of dynamic mode I matrix crack- fiber bundle interaction in composites using caustics. Compos. Part B 2016, 92, 395–404.

- Vertuccio, L.; Foglia, F.; Pantani, R.; Romero-Sánchez, M.D.; Calderón, B.; Guadagno, L. Carbon nanotubes and expanded graphite based bulk nanocomposites for de-icing applications. Compos. Part B Eng. 2021, 207, 108583.

- Spinelli, G.; Lamberti, P.; Tucci, V.; Guadagno, L.; Vertuccio, L. Damage monitoring of structural resins loaded with carbon fillers: Experimental and theoretical study. Nanomaterials 2020, 10, 434.

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Calabrese, E.; Barra, G.; Raimondo, M.; Sorrentino, A.; Binder, W.H.; Michael, P.; Rana, S. Self-healing epoxy nanocomposites via reversible hydrogen bonding. Compos. Part B Eng. 2019, 157, 1–13.

- Guadagno, L.; Sorrentino, A.; Delprat, P.; Vertuccio, L. Design of multifunctional composites: New strategy to save energy and improve mechanical performance. Nanomaterials 2020, 10, 2285.

- Guadagno, L.; Vietri, U.; Raimondo, M.; Vertuccio, L.; Barra, G.; De Vivo, B.; Lamberti, P.; Spinelli, G.; Tucci, V.; De Nicola, F.; et al. Correlation between electrical conductivity and manufacturing processes of nanofilled carbon fiber reinforced composites. Compos. Part B Eng. 2015, 80, 7–14.

- Guadagno, L.; Vertuccio, L.; Naddeo, C.; Raimondo, M.; Barra, G.; De Nicola, F.; Volponi, R.; Lamberti, P.; Spinelli, G.; Tucci, V. Electrical current map and bulk conductivity of carbon fiber-reinforced nanocomposites. Polymers 2019, 11, 1865.

- Guadagno, L.; Raimondo, M.; Vittoria, V.; Bedsole, R.W.; Park, C.; Bogert, P.B. Influence of carbon nanoparticles/epoxy matrix interaction on mechanical, electrical and transport properties of structural advanced materials. Nanotechnology 2017, 28, 094001.

- Guadagno, L.; Vertuccio, L.; Foglia, F.; Raimondo, M.; Barra, G.; Sorrentino, A.; Pantani, R.; Calabrese, E. Flexible eco-friendly multilayer film heaters. Compos. Part B Eng. 2021, 224, 109208.

- Nasser, J.; Zhang, L.; Sodano, H. Laser induced graphene interlaminar reinforcement for tough carbon fiber/epoxy composites. Compos. Sci. Technol. 2021, 201, 108493.

- Koh, T.M.; Isa, M.D.; Feih, S.; Mouritz, A.P. Composites: Part B Experimental assessment of the damage tolerance of z-pinned T-stiffened composite panels. Compos. Part B 2013, 44, 620–627.

- Kumar, A.; Shukla, M. Race Tracking and Related Issues in Liquid Composite Moulding Process. J. Manuf. Sci. Prod. 2014, 14, 209–217.

- Severini, F.; Formaro, L.; Pegoraro, M.; Posca, L. Chemical modification of carbon fiber surfaces. Carbon 2002, 40, 735–741.

- Imran, K.A.; Shivakumar, K.N. Graphene-modified carbon/epoxy nanocomposites: Electrical, thermal and mechanical properties. J. Compos. Mater. 2018, 53, 93–106.

- Yao, X.; Gao, X.; Jiang, J.; Xu, C.; Deng, C.; Wang, J. Comparison of carbon nanotubes and graphene oxide coated carbon fiber for improving the interfacial properties of carbon fiber/epoxy composites. Compos. Part B Eng. 2018, 132, 170–177.

- Chakradhar, K.V.P.; Subbaiah, K.V.; Kumar, M.A. Blended Epoxy/Polyester Polymer Nanocomposites: Effect of ‘Nano’ on Mechanical Properties. Polym. Plast. Technol. Eng. 2012, 51, 92–96.

- Ji, X.; Xu, Y.; Zhang, W.; Cui, L.; Liu, J. Review of functionalization, structure and properties of graphene/polymer composite fibers. Compos. Part A Appl. Sci. Manuf. 2016, 87, 29–45.

- NSahoo, G.; Rana, S.; Cho, J.W.; Li, L.; Chan, S.H. Polymer nanocomposites based on functionalized carbon nanotubes. Prog. Polym. Sci. 2010, 35, 837–867.

- Fouda, H.; Guo, L.; Yue, Y.; Chen, K.; Elsharkawy, K. Synthesis and Characterization of Hybrid CF/MWCNTS/Epoxy Resin Composite System. IOP Conf. Ser. Mater. Sci. Eng. 2017, 220, 012021.

- Zhang, Q.; Wu, J.; Gao, L.; Liu, T.; Zhong, W.; Sui, G.; Yang, X. Influence of a liquid-like MWCNT reinforcement on interfacial and mechanical properties of carbon fiber filament winding composites. Polymer 2016, 90, 193–203.

- Baek, Y.; Shin, P.; Kim, J.; Park, H.; Devries, K.L.; Park, J. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym. Test. 2020, 81, 106247.

- Ma, P.C.; Siddiqui, N.A.; Marom, G.; Kim, J.K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: A. review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1345–1367.

- Koirala, P.; van de Werken, N.; Lu, H.; Baughman, R.H.; Ovalle-Robles, R.; Tehrani, M. Using ultra-thin interlaminar carbon nanotube sheets to enhance the mechanical and electrical properties of carbon fiber reinforced polymer composites. Compos. Part B 2021, 216, 108842.

- Duongthipthewa, A.; Su, Y.; Zhou, L. Electrical conductivity and mechanical property improvement by low-temperature carbon nanotube growth on carbon fiber fabric with nanofiller incorporation. Compos. Part B 2020, 182, 107581.

- Ambekar, S.D.; Kumar, V. Optimization of flexural strength of CFRP hybrid nano composites containing nanoZnO and nanoclay particles. Int. J. Interact. Des. Manuf. 2019, 13, 0123456789.

- Jian, L. Effect of surface treatment on enhancing interfacial strength of carbon fiber/polyimide composites. J. Thermoplast. Compos. Mater. 2020, 0892705720925141.

- Xu, T.; Zhou, S.; Cui, S.; Song, N.; Shi, L.; Ding, P. Three-dimensional carbon fiber-graphene network for improved thermal conductive properties of polyamide-imide composites. Compos. Part B 2019, 178, 107495.

- Jony, B.; Zainuddin, S. Fatigue analysis and fracture toughness of graphene reinforced carbon fibre polymer composites. Fatigue Fract. Eng. Mater. Struct. 2020, 44, 461–474.

- Salavagione, H.J.; Martínez, G.; Ellis, G. Recent advances in the covalent modification of graphene with polymers. Macromol. Rapid Commun. 2011, 32, 1771–1789.

- Vertuccio, L.; Guadagno, L.; Spinelli, G.; Lamberti, P.; Zarrelli, M.; Russo, S.; Iannuzzo, G. Smart coatings of epoxy based CNTs designed to meet practical expectations in aeronautics. Compos. Part B Eng. 2018, 147, 42–46.

- Paul, R.; Dai, L. Interfacial aspects of carbon composites. Compos. Interfaces 2018, 6440, 1–67.

- Ozkan, D.; Gok, M.S.; Karaoglanli, A.C. Carbon Fiber Reinforced Polymer (CFRP) Composite Materials, Their Characteristic Properties, Industrial Application Areas and Their Machinability. Adv. Struct. Mater. 2020, 124, 235–253.

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326.

- Wan, Y.; Takahashi, J. Development of carbon fiber-reinforced thermoplastics for mass-produced automotive applications in japan. J. Compos. Sci. 2021, 5, 86.

- Abtew, M.A.; Boussu, F.; Bruniaux, P. Dynamic impact protective body armour: A comprehensive appraisal on panel engineering design and its prospective materials. Def. Technol. 2021, 17, 2027–2049.

- Liu, Y.; Zwingmann, B.; Schlaich, M. Carbon fiber reinforced polymer for cable structures-a review. Polymers 2015, 7, 2078–2099.

- Olofin, I.; Liu, R. The Application of Carbon Fibre Reinforced Polymer (CFRP) Cables in Civil Engineering Structures. Int. J. Civ. Eng. 2015, 2, 1–5.

- Myagkov, L.L.; Mahkamov, K.; Chainov, N.D.; Makhkamova, I. Advanced and conventional internal combustion engine materials. In Alternative Fuels and Advanced Vehicle Technologies for Improved Environmental Performance: Towards Zero Carbon Transportation; Woodhead Publishing: Sawston, UK, 2014.

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263.

More

Information

Subjects:

Materials Science, Composites

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

12.7K

Revisions:

2 times

(View History)

Update Date:

10 Jun 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No