Through the transformation that the electrical sector has been passing by, improvements in asset management and the guarantee of sustainable and quality services have become essential aspects for power companies. Thus, the digitalization of energy utilities presents itself as an important and crucial process. A concept that involves a variety of innovative trends is the digital twin. It consists of a 3D virtual replica of existing physical objects and real-time monitoring of certain measures. By developing a digital twin in the electrical power grid, a virtual replica of the network is obtained providing network virtual maps, 3D asset models, dynamic and real-time data of grid assets, and IoT sensing. All these data can feed a platform where AI-based models and advanced field operation technologies and solutions will be applied. With a Network Digital Twin©development, applications involving on-field activities can be improved through augmented reality (AR) and virtual reality (VR) to enhance workforce operations.

1. Introduction

The emerging of new technologies and the arrival of the Fourth Industrial Revolution have favored the development of intelligent cities concept

[1] and transformed the electrical sector on the way

[2]. Thus, a need for technological development through intelligent management of assets and distribution network infrastructures surges

[1][2][3][4]. In 2002, the term digital twin (DT) was introduced by Michael Grieves and immediately showed great innovative potential to be applied in electric power utilities due to the potential such tools have to bring improvement for the electric power grid operation, by reducing unplanned interruptions and improving the maintenance process of active network assets

[5]. According to Gabor et al.

[6], the DT is a special simulation, built on specialized knowledge and real data collected to perform a more accurate simulation at different scales of time and space. One can say that DT is a digital representation that can portray a system, a process, or a service

[7]. Thus, it indicates being a good tool for the improvement of labor services at the human interface (HI) layer of energy utilities.

DT is commonly known as a replica, or a virtual model of an object or physical structure

[8]. Its scanning process occurs through data, sensors, scanners, and simulators, which make it possible to monitor, optimize, and control those assets in real-time

[9]. According to

[10], the DT has three main milestones: the year of its conception (2003), which is described as the training stage; the first published theoretical work (2011), which initiated the so-called incubation stage; and, finally, the first published practical work (2014), demarcating the growth stage

[11].

The DT implementation brings great benefits to the electrical company. It provides faster inspection of the network and more control in the assets management and efficiency for the anomalies identification

[12]. Furthermore, it increases safety and productivity during field activities.

Enel conceived the Network Digital Twin©(NDT) and applied this technology for the first time in Brazil, within the scope of the R&D project called Urban Futurability (UF), which is an innovation project engaging local stakeholders and communities in a living lab where the electricity network works as a platform to originate, enable, and develop new urban services and sustainable living

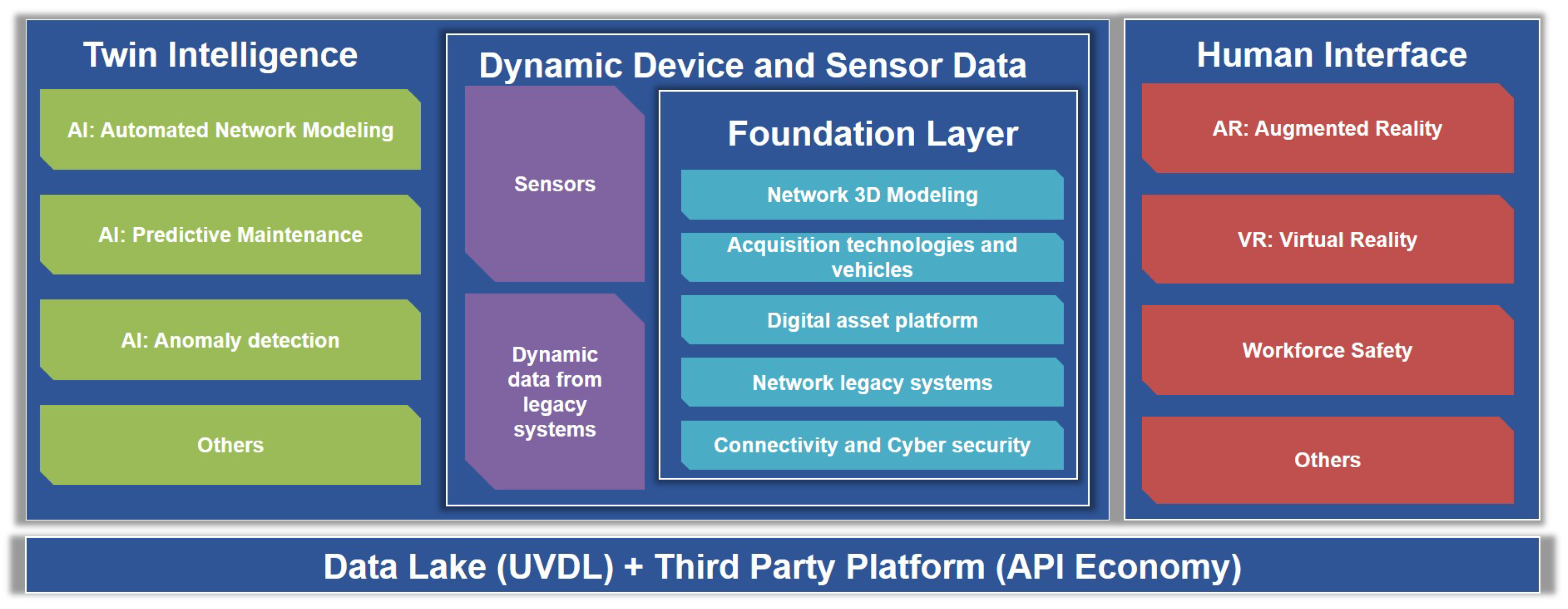

[13]. The project area extends through Vila Olímpia, a neighborhood in São Paulo, where thousands of people live and work every day. To better develop the NDT©in Brazil, four layers were designed through the project: the Dynamic Devices—which includes the foundation layer, the Twin Intelligence, and the HI layers.

Figure 1 illustrates those layers and their sublayers.

Figure 1. NDT© layers developed during the UF Project.

The foundation layer is the basis for digital network modeling. It includes the global 3D modeling repository, systems methodologies to gather on-field images such as vehicle usage, a digital platform development and legacy system integration, data universalizing, and cybersecurity criteria. The layer of dynamic devices and sensors data increases the vision of the previous layer with the real-time monitoring of assets through the internet of things (IoT) devices, providing a dynamic DT. The artificial intelligence (AI) layer aims to automate activities that are currently carried out manually, such as anomaly detection and register update. This layer includes vegetation management and shift from corrective to predictive maintenance. In the HI layer, there is virtual and remote assistance through augmented reality (AR) and new tools for field force empowerment, e.g., thermal cameras, smart bluetooth badges, remote assistance with AR features, and the use of virtual reality (VR) for training. While the foundation and dynamic and sensor layers are the basis of NDT© development, the twin intelligence and HI Layers are the DT on-field application. Among the layers, a universal virtual data lake unifies the information shared within all the DT applications. The third-party platform aims to share the information with stakeholders who can use it to increase network digitalization.

Regarding the Twin Intelligence work front, the UF project published three papers: the aim of

[14][15] is to present the concept of Predictive Maintenance 4.0, the building blocks of a predictive system architecture, its applications in the electricity sector, and its benefits as an innovative technology. In

[16], the authors describe the potential to use an UAV in scanning almost three hundred underground structures (transforming chambers and manholes) for initial tests, with the possibility of expanding the use to thousands of other structures.

2. Application and Its Benefits

2.1. On-Field Operational Activities

On the power systems on-field activities, tasks as inspection of assets, listing and checking asset operational conditions, etc., are common in the daily workforce operation. These operations are used to make decisions about activities in the grid, such as equipment replacement, remodeling the electrical network, or even trimming trees that may interfere with the electrical grid. All those activities are reinforced and improved with digital tools.

General visualization is the first action for initial inspections of the grid, the assets, or even the workforce. This action aims to find visual flaws that may compromise the energy services. Each conclusion for the inspector needs to be followed with a photo registration from their smartphone. That process is necessary to guarantee the safety of the operation. Later, another inspector checks the images on-office. In that situation, the full grid digitalization, through a 3D real-time replica, improves the on-office inspection and refines on-field activity and safety. Some tools that can be used to provide such digitalization are the same used to gather 3D images for the NDT© development, such as handheld scanners, drones equipped with cameras, and tools as those aforementioned.

Concerning asset inspections, thermal equipment is used to find hot spots in the asset which may cause future equipment failure

[17]. Thermal cameras are the way to do it, where drones and even smartphones are suitable to use. Since the workforce uses its smartphone to do their activities, a coupled gadget adaptation can be used through many commercials apparatus of the smartphone. Thermal data outputs are synchronized with real-time sensors and electrical measures in the power systems’ legacy platforms. All the measures, such as sensing, thermal analyses, SCADA/GIS data, etc., lead to an efficient and smart asset maintenance process, where the NDT© provides it through an IoT data platform and real-time on-field activities.

The process of trimming trees is one of the most relevant for the distribution power systems in terms of on-field activities. Trees are responsible for grid transient fault and can lead to permanent consumer power outage

[18]. Daily workforce teams perform trimming on trees that have twigs close to the grid. Usually, these activities are scheduled by consumer complaints or after a fault detection. Using a real 3D replica of the grid and its surrounding environment, an analysis of the situation between trees and network cables without the need for complaints or fault identification can be made. For that analysis, the point cloud and infrared measures are used to represent situations in the critical neighborhood and estimate the twigs’ growth. Thus, the NDT© together with AI increases the grid resilience, avoiding or mitigating unexpected outages.

In the electrical power grid, there are two main grids: the overhead and the underground. The overhead has its assets and structure visible to the workforce, while the underground has its equipment hiding in the ground. This fact encumbers the underground inspection and maintenance routine activities. Even though the underground grid has a confined vault for inspection, and its access is hard and risky. The use of drones to gather images, such as the thermal and high-resolution pictures, is necessary to compare the previous inspection and provide risk-free analyses and diagnoses. In addition, the NDT© replica for the underground grid brings to the workforce the network situation through technologies like AR or simple visualization in its smartphone.

The NDT©has the goal to bring many benefits for the power grid operation. The implementation of such a system is mitigated to a mindset changing in the on-field operational activities, which uses technological trends to do its tasks. The gathered data are stored in a UVDL platform, which provides many opportunities for smart decision-making and foresees assets situation. The on-field inspection is the key point to start an NDT©developing through a foundation layer, and operation & maintenance (O&M) is an area to first appropriate its technology through predictive maintenance. All the final NDT©usage area takes advantage of the automatizing process, high data density in the cloud, and the AI process.

During the UF project prospecting, the aforementioned on-field operational activities are the basis for the NDT©foundation layer development. Nevertheless, one can find many benefits for the future workforce activities and methodology, which will be endorsed with digital tools in a grid digitalization process. The NDT©forming is the first step to a full digital grid.

2.2. Virtual and Augmented Reality

Since the DT is defined as a virtual model of a system, a process, or a service, AR and VR can be used to enhance many off-field activities of the workforce. For instance, according to approaches in

[19], the VR is well fit for workforce training in utilities. Through this technology, the workforce can have an immersive training experience of its activity, without risks or the need to spend scarce materials.

Simple use of VR training in the electrical power sector can be social and occupational, where the electrical company can make the population aware of electrical hazards and provide them with an overview of the electrical grid operations. For example, with the VR, the company can aware the community of the risk of kites touching the grid, and the effect it has on the power grid through an immersive experience. Furthermore, the electrical company becomes a more cooperative integration among its areas, creating a systemic workforce sharing many operational tasks, resulting in assertiveness when one team needs to call another experienced workforce team

[20]. In addition, VR brings interaction and motivation for training and learning.

Although VR can have immediate use socially and administratively, its direct application to training the workforce is not recommended. This is due to the high quality of the electrical workforce, meaning that the procedure repetition or following steps will not aggregate knowledge to them. Thus, to provide efficient use of VR for workforce training, one needs to develop a virtual scenario where the cognition of their workers has to be activated. In order to do it, VR is developed with intelligence, where random risky scenarios are created according to real on-field situations. This development will bring a worker’s reaction training for real adversities and will simulate an escape route for an emergency situation. Such situations are approached theoretically in traditional training, but the practical knowledge only happens upon real risk. Using VR for training, the electrical power sector can better prepare its workforce to act in an emergency, without having to expose its employees in a risky situation. Furthermore, the workforce can have a muscle memory retrained to avoid mechanized movements during the on-field activity

[21].

The AR has different applications in the power sector. The most notorious one is to bring relevant information for on-field activities. Through AR, one can use smart glasses to overlap real images with virtual ones creating an operational system to improve workforce duties

[22]. One application approach on

[23] is the reduction of paperwork on-field. This paperwork, as manual and data sheets, is usually heavy and demands a long time to find important information. Furthermore, this paperwork is out of date and does not bring the electrical power to real conditions. Concerning relevant information, the operational experience exchanging can be better performed with AR, where digital registration can be achieved and replicated through digital content for the new workforce.

Using the NDT© development, with grid 3D modeling, one provides a useful replica of the grid, supplying the workforce with real visualization of electrical structure and quantities, whereas providing an interactive digital way to execute its job. Regarding on-field support, the AR can be well fit for remote assistance. With AR, the remote assistance can be interactive, with the sharing of virtually made drawings in an office, and is overlapped with the real supported equipment. It provides better support, faster problem-solving, and rapid grid restoration.

The AR application can be done with smart glasses, which will provide hands-free for the operational activity. It increases the safety of the employees and results in a better service with attention focused on the equipment. Smartphones are also able to have AR applications, which will have fewer resources but many benefits.

AR and VR are powerful tools to enhance workforce operation capacity, and these applications use the outputs of a DT implementation. There are many possibilities to use VR and AR in the power sector. All the aforementioned is the initial implementation of the UF project and consists of the application performed to prove the NDT© concept into the power electrical systems.

2.3. New Trend’s Nest

The NDT© forming cannot be seen as a closed box of application. As the technological trends advance, the NDT© will increase its potential. For this reason, the NDT© has to be considered as a nest for new trends. Technologies such as AI and machine learning are in great evolution, and their application may bring unknown benefits for utilities. Images recognition, chatterboxes, deep learning processes, smart decision-making algorithms, etc. can ride through the DT forming.

To elucidate some trends, one can point out the augmented intelligence as a way to have a high-level algorithm running together with the operation on-field activities, which will help the workforce to take an optimal operational decision without the need to wait for information sending

[23]. Blockchain is a new trend that is being evaluated and applied in the energy market, the decision-making process, cybersecurity, IoT operations, etc.

[24]. Blockchain can be used for various applications in the electricity sector, such as the automation of transactions within the electricity grid (automatic conclusion of contracts upon fulfillment of a certain condition) and monitoring of energy consumption and production, in addition to being used as a basis for digital transactions in areas such as the electricity market (decentralized settlement of transactions), increasing the options for business models in the sector

[25]. This nest can be the crib for edge and fog computing new applications. With the data lake concept, the IoT can be used at a high level for the power electrical sector

[26]. Together with 5G technology, it will have a fast application with minimum latency

[27].

It is not possible to completely measure the NDT© forming potential. However, with a digitalization wave, the 4.0 industrial revolution, and many technological trends, it makes clear that the power electrical sector evolution is far from completion.