Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Al Amin bin Mohamed Sultan | -- | 1811 | 2022-05-11 09:40:38 | | | |

| 2 | Lindsay Dong | Meta information modification | 1811 | 2022-05-12 04:02:09 | | | | |

| 3 | Lindsay Dong | Meta information modification | 1811 | 2022-05-13 07:53:00 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Mohamed Sultan, A.A.B.; Qi Hang, Y.; Mahmood, W.; Md Saad, M.S.; Mativenga, P. Product Recycling Desirability Model. Encyclopedia. Available online: https://encyclopedia.pub/entry/22797 (accessed on 08 February 2026).

Mohamed Sultan AAB, Qi Hang Y, Mahmood W, Md Saad MS, Mativenga P. Product Recycling Desirability Model. Encyclopedia. Available at: https://encyclopedia.pub/entry/22797. Accessed February 08, 2026.

Mohamed Sultan, Al Amin Bin, Yoong Qi Hang, Wan Mahmood, Mohd Shamsuri Md Saad, Paul Mativenga. "Product Recycling Desirability Model" Encyclopedia, https://encyclopedia.pub/entry/22797 (accessed February 08, 2026).

Mohamed Sultan, A.A.B., Qi Hang, Y., Mahmood, W., Md Saad, M.S., & Mativenga, P. (2022, May 11). Product Recycling Desirability Model. In Encyclopedia. https://encyclopedia.pub/entry/22797

Mohamed Sultan, Al Amin Bin, et al. "Product Recycling Desirability Model." Encyclopedia. Web. 11 May, 2022.

Copy Citation

Product Recycling Desirability Model (PRDM) was coined as a competent model for prioritizing product selection for recycling due to its successful application in several international cases, including those of the United States, the United Kingdom, the European Union, China, and India. The model’s critical parameters were: (i) the ease with which the product’s components could be disassembled for recycling, (ii) the readiness of the recycling technology in place to carry out the recycling operation; and (iii) the criticality of the materials contained in end-of-life products, which make them prime candidates for recycling.

sustainability

recycling

desirability Model

1. Introduction

End-of-life products pose a significant issue as they are often disposed of in landfills. Recycling to recover usable materials has become a critical strategy for addressing these end-of-life waste issues because it avoids the extraction and refining of virgin raw materials [1][2][3]. It is not uncommon to recover materials such as steel, aluminum, cast iron, and rubber from end-of-life vehicles (ELVs). They may be recovered and repurposed to produce new materials for the manufacture of new vehicles or other products. Rubber tyres, for instance, can be recycled and reprocessed to produce a variety of secondary products [4]. In addition to this, the recycling process is also capable of extracting various valuable materials, including precious metals (i.e., palladium, platinum, gold, and silver) and rare earth elements (REEs).

Recent decades have seen an increase in the demand for REEs as mobile and electronic technology have advanced, with China currently dominating the market. REEs are commonly found in electronic devices and can be recovered from e-waste [5]. For instance, lithium-ion battery recycling could result in the recovery of steel, copper, iron, graphite, and cobalt [6]. By reclaiming materials, manufacturers can reduce costs and landfill usage [7], save up to 13 percent on batteries [8], decrease mining and extraction, and reap a variety of other benefits. However, only a small percentage of these end-of-life wastes are converted into useful products. For example, one percent of REEs and less than three percent of lithium batteries are recycled.

While countries like China and Australia are abundant in REE resources and are dominant exporters, a low recovery rate for REEs poses a threat to consumer countries, such as the United States and countries in the European Union, unless there is enough supply for industrialization. Supply and material restrictions are a problem that can happen in any country of the world, and they have a negative impact on the country’s economy. The challenge of overcoming this type of constraint has been addressed in numerous ways, including reducing a country’s reliance on critical resources. As a result of the urgency of this issue, numerous countries, including the U.S.A., countries in the EU, Japan, and Australia have begun implementing strategies to reduce the risk of breaches of critical infrastructure.

A strong industrial base and a wide range of products and applications are critical to economies around the world, especially in modernised societies. The concept of material security has gained momentum globally as a way to assist regions in securing their raw material supplies, as a means of dealing with future challenges of material supply restrictions.

2. Material Security

Material security is a global economic concern, as it enables the identification of critical materials for a nation’s economy. It is critical in the selection of materials, product design, recycling of materials, and investment decision-making. Material security has been used interchangeably with material criticality, critical mineral security, and mineral resource security in some studies [9][10][11][12]. This has been explored by many researchers in several countries due to increasing demand for raw materials and rising supply risks globally [13][14][15][16].

Countries and businesses employ criticality assessments to identify and prioritize material resources in need of attention, as well as supply chain risk mitigation techniques [16][17]. This encompasses growing and new demand for materials from developing economies; increased need for a larger range of material inputs as a result of new technologies; concentrations of production; supply monopolies; and recognition of mining’s social and environmental effects. Material security is capable of sustaining economies, addressing environmental concerns, lowering industrial costs, and averting future material shortages [18]. This is because assessing material security enables the monitoring of a mineral’s use pattern across industrial sectors and the material’s contribution to the overall economy [10].

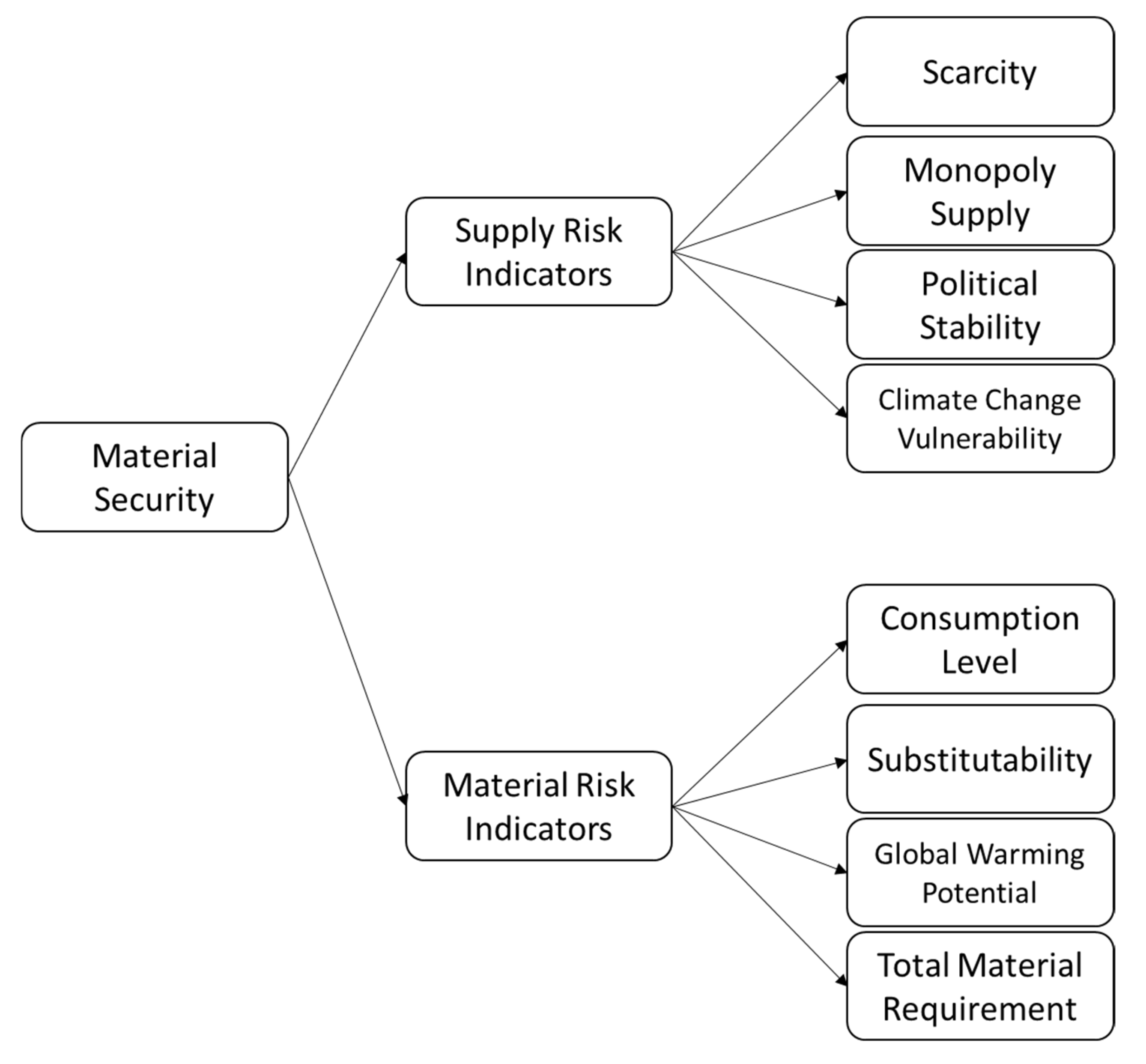

There are two main dimensions that are used to determine critical material: material risk and supply risk [16][19]. Material risk criteria include global consumption level, lack of substitutability, global warming potential, and total material requirement. Supply risk criteria include scarcity, monopoly supply, political instability, and vulnerability to effects of climate change [20]. The material security dimension, with classification of all the indicators under this framework by [21], is shown in Figure 1. There are several determinants that are necessary to assess supply risk, with five main determinants listed in many reports: geological, technical, political, environmental and social, and economic [22]. The geological, technological, and economic elements are comprised of two equally weighted indicators. One examines relative abundance of the metal, and the other percentage of the metal mined [9]. For the environmental and social indicators, these two indicators can influence and inhibit primary production.

Figure 1. The framework of material security dimensions and indicators.

Environmental factors are more likely to restrict material supply than physical scarcity. For example, international and national laws curbing greenhouse gas emissions may come to restrict the more carbon-intensive extraction processes required for a range of minerals.

The assessment determining critical materials can be affected by future demand as well. Future demand is the key determinant of future availability. There are two factors that are used in criticality assessment, which are future demand projections and substitutability [18]. Normally, a material that is listed in a critical material list has a low mining rate and a low recycling rate, so it should improve its resource efficiency to prevent restriction of the material. The supply risk dimension goes beyond output concentration and takes into account other considerations, such as substitutability and recyclability. If a material has high functional substitutability, then this can lower its supply risk [10].

A mineral’s, or material’s, availability will be restricted when there are sudden supply shocks in the supply chain [23]. It can be more serious when there are no substitutes available for specific applications. The study on material criticality has the advantage of providing policymakers with a detailed analysis on the determinants of criticality associated with minerals, as well as the economic importance of minerals [10]. In the UK, a material security database classified 60 critical materials to ensure resource availability for the British economy [20]. The identified critical materials would assist the relevant stakeholders in making recommendations and suggestions for mitigating actions, including the need for investigation, and policies to reduce future supply restrictions [14][22]. This is possible by further working with the identified critical materials together with other relevant models or approaches, such as the Product Recycling Desirability Model [24].

3. Product Recycling Desirability Model

Although numerous approaches to increase recycling rates have been investigated in the literature, the Product Recycling Desirability Model (PRDM) was coined as a competent model for prioritizing product selection for recycling due to its successful application in several international cases, including those of the United States, the United Kingdom, the European Union, China, and India [24]. The model’s critical parameters were: (i) the ease with which the product’s components could be disassembled for recycling, (ii) the readiness of the recycling technology in place to carry out the recycling operation; and (iii) the criticality of the materials contained in end-of-life products, which make them prime candidates for recycling. Equation (1) shows the product desirability calculation by [24]. DDesirability is the desirability recycling index for the selected product and is calculated considering the index of ease to disassemble the end-of-life product, the product’s material security, and the recycling technology readiness index.

Equation (2) illustrates the ease of material separation, DSimplicity, considering mass fraction and distributed materials for parts. Where H is the inverted complexity measure which is known as the simplicity index.

It assesses the ease with which materials in a product can be disassembled quantitatively, as proposed by [25], using a complexity theory. A parameter H

(bits) based on binary separation steps is used to quantify this. This is the collection of individual separations that are gradually required to separate a product’s materials. A product with fewer separation steps would have low material mixing, whereas a product with more separation steps would have higher material mixing.

Material security is the availability and access to the material resources upon which economies rely, as well as the capacity to withstand volatility, increasing scarcity, and rising price [24][26]. The presumption is that there will be no adverse effect on the country’s economy as a result of a shortage or restricted access to the specified substance. Material security is a negative indicator, implying a lack of scarcity in order to achieve the lowest acceptable limit, rather than a positive requirement for abundance. The material security index for recycling, DMSI is shown in Equation (3). Where n is the maximum number of a material type in the product, Mi and MT are the mass of material, or part in a product and total product mass respectively. Si is the material security index of recycling a particular material that is part of a product assembly and Stop is the top scale for the material security index.

Technology Readiness (TRL) is a method for determining technological maturity. TRL looks at program conceptions, technological needs, and proven technological capabilities. The TRL of the United States National Aeronautics and Space Administration (NASA) inspired this notion [27]. TRL refers to a classification of recycling methods for various materials in this model, with the assumption that it can be done for a certain country and geographic region, taking into consideration locally accessible technologies [24].

The recycling technology readiness desirability is represented by parameter DTRL in Equation (4), which takes into account the maturity of recycling technology. Where n is the maximum number of a particular recycling technology used in a product, Mi and MT are the mass of the discrete material in a product or component and the total product mass, respectively.

Once the product recycling desirability index is determined, the various product distributions can be mapped through the ‘What Should be Recycled Model’ to better illustrate their importance for recycling, by considering monetary implication [24]. For instance, car batteries, mobile phones, plastic bottles, and computers are the preferred end-of-life products for recycling in the UK.

References

- Chen, J.M.; Chi, C.Y. Reverse channel choice in a closed-loop supply chain with new and differentiated remanufactured goods. J. Ind. Prod. Eng. 2019, 36, 81–96.

- Sadeghi Ahangar, S.; Sadati, A.; Rabbani, M. Sustainable design of a municipal solid waste management system in an integrated closed-loop supply chain network using a fuzzy approach: A case study. J. Ind. Prod. Eng. 2021, 38, 323–340.

- Tseng, M.L.; Tran, T.P.T.; Ha, H.M.; Bui, T.D.; Lim, M.K. Sustainable industrial and operation engineering trends and challenges Toward Industry 4.0: A data driven analysis. J. Ind. Prod. Eng. 2021, 38, 581–598.

- Bott, R. Environmental benefits of recycling. Wrap 2014, 1, 1–5.

- Joseph, C.V.; Yunus, M.Y.M.; Ismail, N.A.; Kanthasamy, R. Economic potential assessment of neodymium recovery from Malaysia e-waste resource. Mater. Today Proc. 2019, 17, 707–716.

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500.

- Wong, Y.C.; Al-Obaidi, K.M.; Mahyuddin, N. Recycling of end-of-life vehicles (ELVs) for building products: Concept of processing framework from automotive to construction industries in Malaysia. J. Clean. Prod. 2018, 190, 285–302.

- Sonoc, A.; Jeswiet, J.; Soo, V.K. Opportunities to improve recycling of automotive lithium ion batteries. Procedia CIRP 2015, 29, 752–757.

- Graedel, T.E.; Barr, R.; Chandler, C.; Chase, T.; Choi, J.; Christoffersen, L.; Friedlander, E.; Henly, C.; Jun, C.; Nassar, N.T.; et al. Methodology of metal criticality determination. Environ. Sci. Technol. 2012, 46, 1063–1070.

- Gupta, V.; Biswas, T.; Ganean, K. Critical Non-Fuel Mineral Resources for India’s Manufacturing Sector: A Vision for 2030; Department of Science and Technology, Government of India: New Delhi, India, 2016.

- Andersson, P. Chinese assessments of “critical” and “strategic” raw materials: Concepts, categories, policies, and implications. Extr. Ind. Soc. 2020, 7, 127–137.

- Hatayama, H.; Tahara, K. Criticality assessment of metals for japan’s resource strategy. Mater. Trans. 2015, 56, 229–235.

- Wang, P.; Kara, S. Material criticality and circular economy: Necessity of manufacturing oriented strategies. Procedia CIRP 2019, 80, 667–672.

- Kastanaki, E.; Giannis, A. Forecasting quantities of critical raw materials in obsolete feature and smart phones in Greece: A path to circular economy. J. Environ. Manag. 2022, 307, 114566.

- Černý, I.; Vaněk, M.; Maruszewska, E.W.; Beneš, F. How economic indicators impact the EU internal demand for critical raw materials. Resour. Policy 2021, 74, 102417.

- Helbig, C.; Schrijvers, D.; Hool, A. Selecting and prioritizing material resources by criticality assessments. One Earth 2021, 4, 339–345.

- Schrijvers, D.; Hool, A.; Blengini, G.A.; Chen, W.Q.; Dewulf, J.; Eggert, R.; van Ellen, L.; Gauss, R.; Goddin, J.; Habib, K.; et al. A review of methods and data to determine raw material criticality. Resour. Conserv. Recycl. 2020, 155, 104617.

- Speirs, J.; Houari, Y.; Gross, R. Materials Availability: Comparison of material criticality studies—Methodologies and results Working Paper III. UK Energy Res. Cent. 2013, 30, 5–22.

- Schrijvers, D.; Blengini, G.A.; Cimprich, A.; Chen, W.; Correia, V.; Eggert, R.; Gupta, V.; Hagelüken, C.; Hirohata, A.; Ku, A.; et al. Material Criticality: An Overview for Decision-Makers. May 2020. Available online: https://irtc.info/brochure/ (accessed on 25 August 2021).

- Morley, N.; Eatherley, D. Material Security: Ensuring Resource Availability for the UK Economy; C-Tech Innovation Ltd.: Capenhurst, UK, 2008; pp. 1–36.

- Erdmann, L.; Graedel, T.E. Criticality of non-fuel minerals: A review of major approaches and analyses. Environ. Sci. Technol. 2011, 45, 7620–7630.

- Lloyd, S.; Lee, J.; Clifton, A.; Elghali, L.; France, C. Recommendations for assessing materials criticality. Proc. Inst. Civ. Eng. Waste Resour. Manag. 2012, 165, 191–200.

- Mohamed Sultan, A.A.; Mativenga, P.T. Sustainable Location Identification Decision Protocol (SuLIDeP) for determining the location of recycling centres in a circular economy. J. Clean. Prod. 2019, 223, 508–521.

- Sultan, A.A.; Lou, E.; Mativenga, P.T. What should be recycled: An integrated model for product recycling desirability. J. Clean. Prod. 2017, 154, 51–60.

- Dahmus, J.; Gutowski, T. Material Recycling at Product End-of-Life. In Proceedings of the 2006 IEEE International Symposium on Electronics and the Environment, Scottsdale, AZ, USA, 8–11 May 2006; Volume 2, pp. 206–211.

- Eco-Innovation. Glossary of Terms Used in the Eco-Innovation Observatory. European Commission’s Directorate-General for the Environment. 2015. Available online: http://www.eco-innovation.eu/ (accessed on 23 August 2020).

- Straub, J. In search of technology readiness level (TRL) 10. Aerosp. Sci. Technol. 2015, 46, 312–320.

More

Information

Subjects:

Engineering, Environmental

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Entry Collection:

Environmental Sciences

Revisions:

3 times

(View History)

Update Date:

13 May 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No