There are two types of milk whey obtained from cheese manufacture: sweet and acid. It retains around 55% of the nutrients of the milk. Milk whey is considered as a waste, creating a critical pollution problem, because 9 L of whey are produced from every 10 L of milk. Some treatments such as hydrolysis by chemical, fermentation process, enzymatic action, and green technologies (ultrasound and thermal treatment) are successful in obtaining peptides from protein whey. Milk whey peptides possess excellent functional properties such as antihypertensive, antiviral, anticancer, immunity, and antioxidant, with benefits in the cardiovascular, digestive, endocrine, immune, and nervous system.

1. Introduction

One of the most debated topics in food processing is the recycling of the by-products and their applications as a high value-added product. Milk whey represents a clear example of a by-product obtained from cheese production. This material can be considered as a contaminant and at the same time, the source of protein hydrolysates. Whey is a yellowish to greenish clear liquid obtained after milk coagulation during the cheese-making process. Whey represents about 85–95% of the volume of milk volume and contains over 55% of milk nutrients such as minerals, proteins, and lactose

[1][2]. Sweet and acid whey are obtained when the coagulation of milk is carried out by enzymatic action (rennet) or the addition of acids posteriorly

[3][4]. The most abundant nutrients in whey are: lactose, soluble proteins, lipids, and mineral salts (see

Table 1). With the additional presence of some neutral salts such as NaCl, KCl, and calcium salts (primarily phosphate), among others. Aside from these nutrients, whey also contains lactic and citric acids, non-protein nitrogen compounds such as urea and uric acid, and B group vitamins

[3][5].

Table 1. Comparison of sweet and acid whey components

[6].

| Characteristics |

Sweet Whey |

Acid Whey |

| pH |

>5.6 |

<5.6 |

| Water |

93–94% |

94–95% |

| Protein (g/L) |

6–10 |

6–8 |

| Lactose (g/L) |

46–52 |

44–46 |

| Minerals (g/L) |

2.5–4.7 |

4.3–7.2 |

| Obtained by |

Enzymatic action |

Organic acids |

Whey is considered as a waste by-product from the production of cheese. The production of 1 kg of cheese generates approximately 9 kg of whey [7]. It is discarded without treatment to public sewage systems, creating a critical pollution problem. Unfortunately, only 50% of the whey produced globally is used to formulate products. Whey has been traditionally dumped into common water ducts or used to feed livestock. The treatment and re-use of whey is very important as it is one of the most polluting food by/co-product streams; its biochemical oxygen demand (BOD) is around 435,000 ppm and its chemical oxygen demand (COD) is 460,000 ppm [5][8]. Current environmental regulations are forcing cheese makers to treat whey before disposal. The continued growth of the cheese industry, the necessity for reduction in pollutants in the effluent, and the need to maximize returns on raw material have encouraged producers and researchers to seek new ways of using cheese whey with a great amount of research focused on converting this liability into an asset [7][8][9][10][11]. The protein content of whey is one of the main advantages of this by-product. It is known that diet is one of the factors that influence human health and the development of diseases. Proteins are important nutrients in foods that can be hydrolyzed into a wide range of peptides during gastrointestinal digestion. Some of these peptides share characteristics that act in the organism as hormones, neurotransmitters, or regulatory peptides [12]. The importance of whey protein peptides is associated with their functional properties. Some studies have demonstrated the action of these peptides as inhibitors of angiotensin converting enzyme (ACE) on the regulation of blood pressure and enhancement of the immune system. These hydrolysates also help to increase dopamine, improving memory in patients from the geriatric area. In the food industry, whey protein peptides present antimicrobial, antioxidant activities, and also emulsifying properties. All functional properties of whey protein hydrolysates are related to their molecular weight. These properties are in a latent state during the formation of the protein structure complex and is only activated when that structure is broken or hydrolyzed by different methods such as enzymatic action, chemical hydrolysis, and through the application of emerging technologies such as ultrasound and heat treatments [13][14][15][16].

2. Hydrolyzed Protein from Milk Whey as High Value-Added Compounds

The valorization of a waste product can be defined as a process that transforms waste through physical, thermal, chemical, or biological methods in order to create products that can be incorporated as part of the circular economy into production chains. Whey valorization focuses mainly on the concentration and transformation of lactose, proteins, or any other nutrients into new value-added compounds

[17][18]. Some value-added compounds from whey have been extracted from different biotechnological approaches such as enzymatic, microbial, thermal, galacto-oligosaccharide probiotics (GOS), lactose fatty acid esters, biocolorants, aroma compounds, and bacterial cellulose

[19].

Galacto-oligosaccharides (GOS) are a well-known class of probiotics or substrates that are selectively utilized by host microorganisms, conferring a health benefit

[20]. GOS have various benefits to human health including the selective stimulation of the beneficial intestinal bacteria growth, maintenance of the normal flora balance in the intestine, increased calcium absorption, and decreased serum cholesterol levels and cancer risks. The health-promoting effects of GOS include immunomodulation, lipid metabolism, mineral absorption, weight management, and obesity-related issues, among others

[21][22][23].

Lactose fatty acid esters are odorless, non-toxic, and biodegradable compounds of high importance for the food, cosmetics, and pharmaceutical industries. Lactose fatty acid esters have been recognized for their superior properties as attractive substitutes of synthetic surfactants, excellent emulsifying and stability properties in food products. Additionally, they present antimicrobial activity against many foodborne pathogens as well as medicinal properties such as anticancer activity

[24][25][26].

Carotenoids are one of the most important natural pigments and can usually be extracted from plants. However, cheese whey, or deproteinized cheese whey, has been used for the production of carotenoids by using various microorganisms (

Blakeslea trispora,

Mucor azygosporus,

Rhodotorula rubra) for the fermentation of various carbon sources such as glucose, sucrose, and xylose. Carotenoids possess biological functions such as antioxidant activity, reduction in cardiovascular diseases, anti-diabetic, anti-cancer, and anti-inflammation activities. The interest in the carotenoids from whey focuses on the use of low-cost substrates to reduce the production costs

[27][28][29]. Fermentation is also an alternative way for the production of natural aroma compounds from milk whey and involves the use of several yeast strains such as

Metschnikowia pulcherrima,

Bacillus licheniformis,

Wickerhamomyces pijperi, and

Saccharomyces cerevisiae [30][31][32][33].

Bacterial cellulose (BC) is a biopolymer with important physiochemical properties such as water holding capacity, hydrophilicity, high degree of polymerization, mechanical strength, crystallinity, and porosity. All these BC characteristics represent a wide range of potential applications starting from the food industry and biomedicine to electronics and cosmetics. Bacterial cellulose extracted from whey through enzymatic and acidic pre-treatments can be considered as a cheaper growth medium for BC production due to the low-cost of raw materials as well as its enhanced BC yields

[34], reducing environmental pollution from dairy waste. BC has been used as an edible antimicrobial food coating increasing shelf life as well as a healthy food supplement for patients with gastrointestinal disorders, obesity, cardiovascular diseases, and diabetes. BC is considered as a multifunctional food ingredient because it can be used to improve the rheology of foods as a fat replacer ingredient for the production of both low-calorie and low cholesterol food products

[35][36].

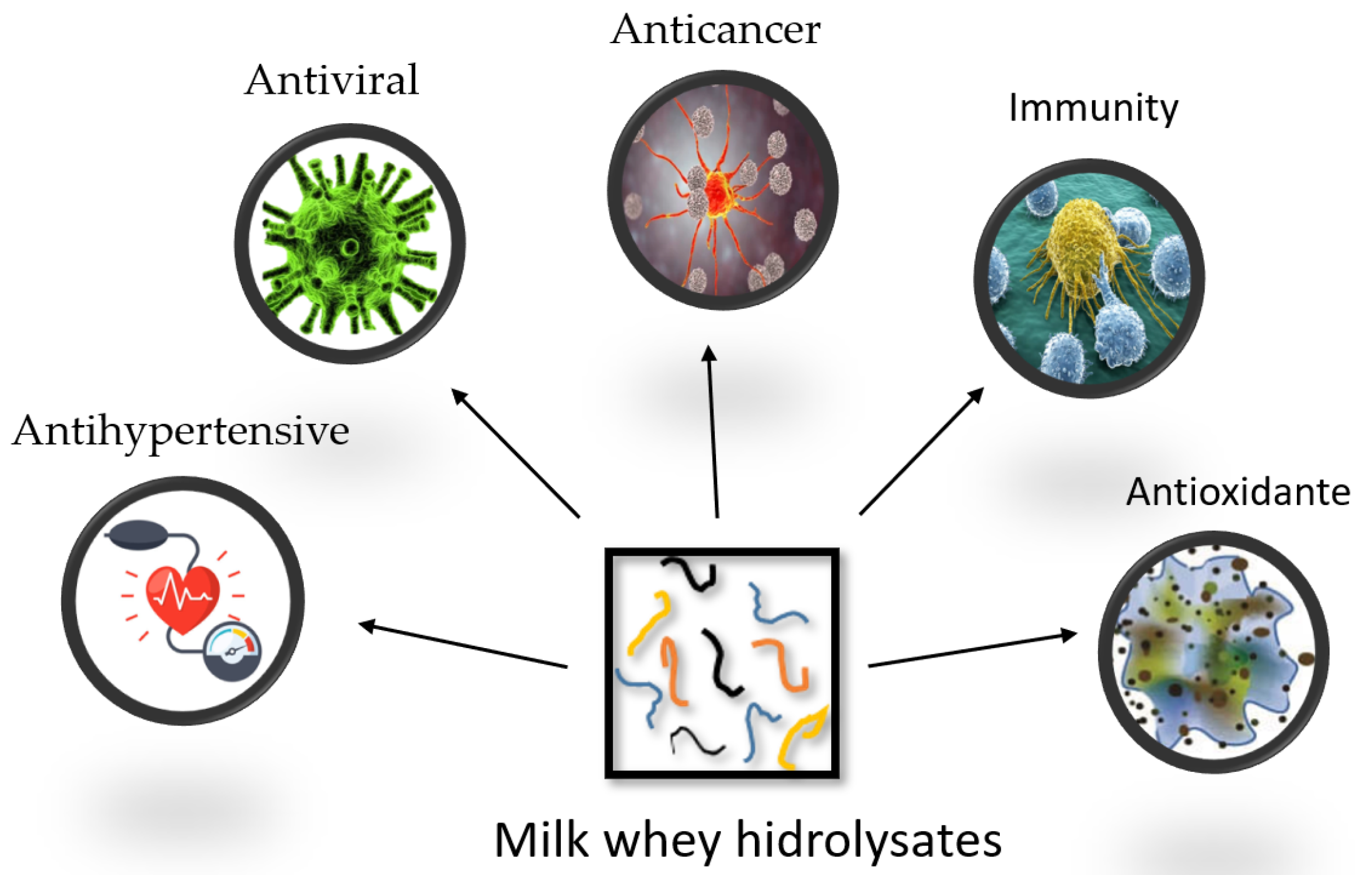

3. Functional Properties of Hydrolyzed Milk Whey Proteins

Milk whey biological functions are mainly related to the cardiovascular, digestive, endocrine, immune, and nervous systems. However, many of the bioactive peptides are encrypted in native whey protein, so in order to liberate these peptides, it is necessary to apply hydrolysis methods that generate milk whey hydrolysates. In recent years, milk whey hydrolysates have been studied due to their potential as a functional ingredient capable of producing beneficial effects on health such as immunity, antioxidant, anticancer, antiviral, and antihypertensive (

Figure 1). At the same time, production of hydrolysates can be an interesting approach in adding value to whey protein, while at the same time protecting the environment from their pollutant effects

[37][38][39][40].

Figure 1. Functional properties of milk whey hydrolysates.

4. Applications of Milk Whey Proteins Hydrolysates

Whey hydrolysates are commonly applied to a wide range of food applications (dairies, bakeries, meet products, beverages, food supplements or functional foods) due to their nutritional validity, functional activities, and cost effectiveness. Whey hydrolysates are also used to replace other proteins, improving the functional properties of many food products. Whey protein hydrolysates are important in food processing due to their technological properties including oil and water holding, emulsifying capacity, foam capacity, and solubility. They can promote the formation of volatile compounds in food products regardless of whether they are added in small quantities

[41][42][43][44].

Whey-based beverages such as dairy, not dairy, fermented, or non-fermented show functional activity because of their highly nutritional and digestible properties associated with the presence of hydrolysates as well as their functional properties such as antioxidant, antimicrobial, antihypertensive, and others (see

Table 2)

[45][46].

Mann et al.

[46] prepared a flavored milk beverage with the addition of whey hydrolysates and good antioxidant activity attributed to the existence of several peptides contained in it. Additionally, Arranz et al.

[47] developed a whey protein-based beverage with the same characteristics and no effect on apparent viscosity and stability of the beverage. Ferreira et al.

[48] prepared a whey-raspberry flavored beverage that presented antioxidant capacity and ACE inhibition. Some no dairy beverages have been developed with hydrolysates that very often contain citrus fruits (mainly orange, followed by lemon, rarely grapefruit) as well as mango, passionfruit, pear, apple, and strawberry. The addition of milk whey hydrolysates in these types of beverages increased sensory and physicochemical properties such as flavor, odor, low sedimentation, and storage stability

[49][50][51]. The addition of milk whey hydrolysates with antioxidant and antimicrobial activities into a beverage appears to create an exciting link between food science and therapeutic nutrition

[45]. However, the use of high amounts of hydrolysate could result in negative effects in appearance and aroma

[44].

Several researchers have investigated the application of milk whey hydrolysates as a food supplement. These studies have demonstrated that consumption of whey hydrolysates and other sources of protein hydrolysates such as soy, casein, and wheat presented high protein synthesis in the body

[52][53][54]. Fassina et al.

[55] demonstrated that milk whey hydrolysates are an excellent source of nutritious and commercially available alternative food sources commonly used as a food supplement by athletes. This supplement provides them with essential amino acids and bioactive peptides. Lockwood et al.

[56] concluded that whey protein supplementation increased muscle mass after eight weeks in college-aged males. Hansen and co-workers

[57] demonstrated that consumption of whey protein hydrolysates before an exercise session, followed by ingestion of more protein hydrolysates plus carbohydrates for a training period of six weeks, improved specific mitochondrial protein adaptations compared to the intake of carbohydrates. Additionally, milk whey hydrolysate supplementation showed increments in muscle mass and strength over a 10-week experiment in older post-menopausal women

[58]. Brown and colleagues

[59] reported that milk whey supplementation improved the recovery of muscle function and flexibility, accelerating the repair of damaged skeletal muscle and thus its force generation capacity. The consumption of this type of supplementation may contribute to reduced immunosuppression and excessive inflammation, accelerating muscle function recovery after heavy training

[55][60].

Table 2. Applications of MWH and functionality.

| Product |

Functionality |

Reference |

| Flavored milk beverage |

Antioxidant activity |

[46] |

| Whey MWH food supplementation in post-menopausal women |

Increase muscle mass and strength |

[58] |

| Apple juice |

Low sedimentation |

[49] |

| Beverage enriched white flaxseed oil |

Increased of flavor, odor |

[50] |

| MWH food supplementation in college-aged males |

Increase mixed muscle and protein synthesis |

[56] |

| MWH food supplementation |

Improved recovery of muscle function and flexibility |

[59] |

| Whey-raspberry flavored beverage |

Antioxidant capacity and ACE inhibition |

[48] |

| MWH food supplementation in athletes |

Excellent source of nutritious |

[55] |

| Whey protein-based beverage |

Antioxidant and antimicrobial activity, no affecting physicochemical properties |

[47] |

| Protein supplementation |

Increasing mixed muscle and protein synthesis and lean body mass |

[57] |