| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Adem Gharsallaoui | -- | 4385 | 2022-04-18 16:32:27 | | | |

| 2 | Peter Tang | -5 word(s) | 4380 | 2022-04-19 03:24:00 | | |

Video Upload Options

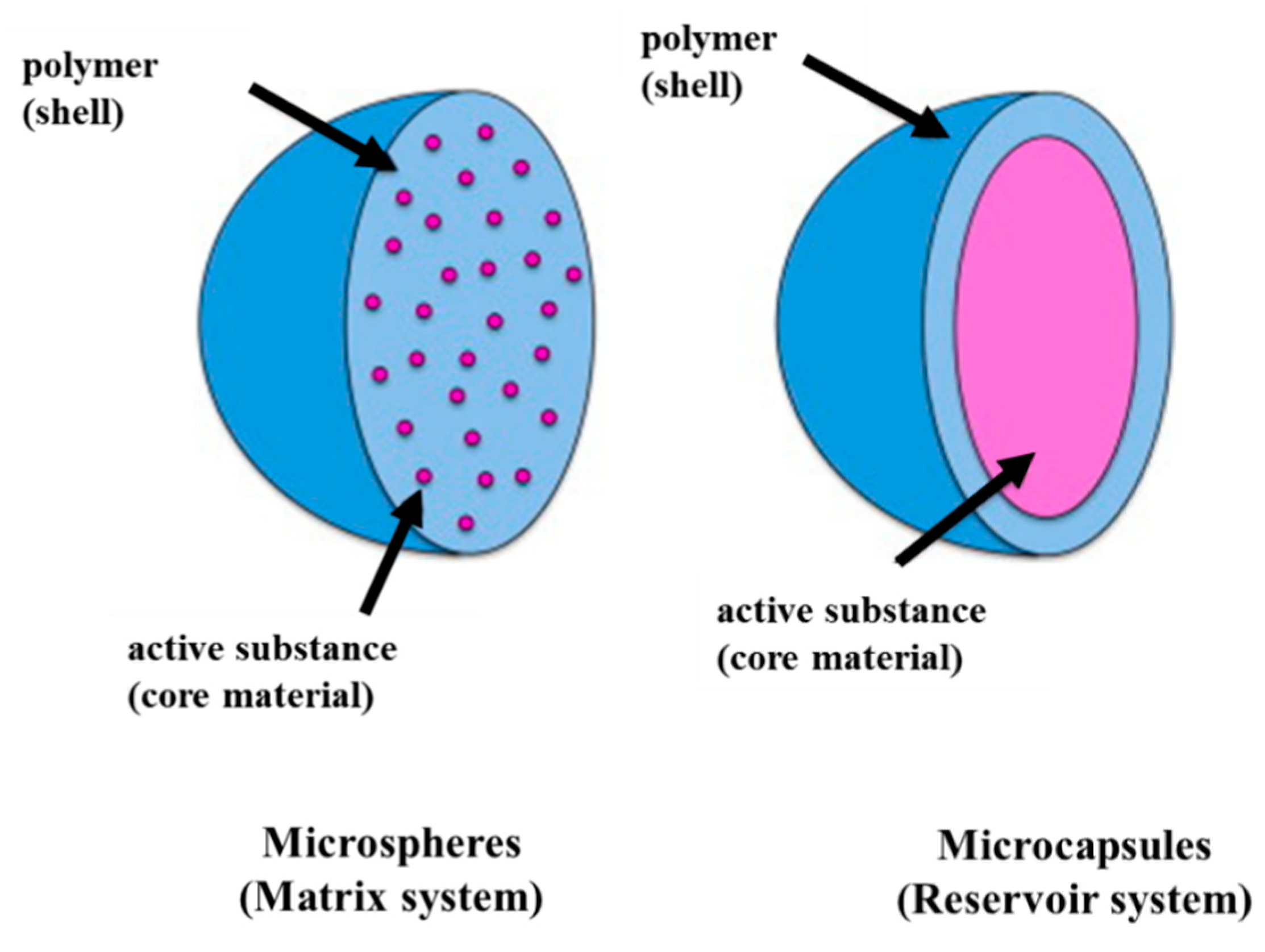

Encapsulation is defined as the process in which an active substance (core material) is enveloped into another substance (shell/matrix/wall material) to elaborate particles with a specific geometry at the nanometer (nanoencapsulation), micrometer (microencapsulation) or millimeter scale. Some natural food antimicrobials with strong antimicrobial activity and low toxicity have been considered as alternatives for current commercial food preservatives. Nonetheless, these natural food antimicrobials are hardly applied directly to food products due to issues such as food flavor or bioavailability. Recent advances in microencapsulation technology have the potential to provide stable systems for these natural antibacterials, which can then be used directly in food matrices.

1. Introduction

2. Encapsulation Methods

|

Microencapsulation Method |

Wall Material |

Antimicrobial Agent |

Encapsulation Efficiency |

Main Results |

References |

|---|---|---|---|---|---|

|

Inclusion |

β-cyclodextrin |

Eugenol |

- |

The eugenol-βCD complexes showed enhanced antibactieral activity compared to free eugenol (a concentration of eugenol higher than 5.03 mmol L−1 inhibited the growth of Staphylococcus aureus and Escherichia coli) |

[11] |

|

Inclusion (KN-FD) |

HPBCD |

Carvacrol |

78.09% for KN, and 83.74% for FD |

Encapsulated carvacrol showed a lower minimum concentration (300 μg/mL) than free carvacrol (1000 μg/mL) for both bacteria, Escherichia coli and Salmonella enterica |

[12] |

|

Inclusion (KN-FD) |

β-cyclodextrin |

Thymol and thyme oil |

71 to 83% |

β- cyclodextrine inclusion complexes were able to inhibit Escherichia coli at lower concentrations (0.37 mg/mL) than free oils. |

[13] |

|

Inclusion (by spray drying and precipitation methods) |

HPBCD, β-CD |

Lemongrass volatile oil |

56–60% and 26–29% using β-CD and HP-β-CD, respectively |

More effective inclusion of lemongrass oil with beta-CD |

[14] |

|

Inclusion |

Β-cyclodextrin, HE-β-CD, HP-β-CD |

Eugenol |

- |

The inclusion process was deduced to be an exothermic and enthalphy-driven process |

[15] |

|

Spray drying |

Low methoxyl pectin |

Lysozyme |

- |

Higher pectin concentrations (above 0.5 g/L) preserved lysozyme structure and activity |

[16] |

|

Spray drying |

Gum arabic, starch, maltodextrin, inulin |

Rosemary EO |

- |

The combination of modified starch and inulin was shown to be a viable substitute for gum arabic in foods |

[17] |

|

Spray drying |

Modified starch, gum arabic, maltodextrin |

Oregano EO |

- |

The inlet air temperature and the emulsion feed rate significantly affected the powder recovery, moisture content and the oil retention |

[18] |

|

Spray drying |

Zein |

Nisin |

- |

Encapsulated nisin was more effective than free antimicrobials in inhibiting the growth of L. monocytogenes |

[19] |

|

Simple coacervation |

PVA crosslinked by glutaraldehyde |

Lemongrass EO |

- |

When SDS at 0.03 wt.% was used, no agglomeration was observed |

[20] |

|

Simple coacervation |

Gelatin microparticles crosslinked with glutaraldehyde |

Holy basil EO (HBEO) |

95.41% |

Extended shelf-life of microencapsulated HBEO up to 18 months at 25 °C |

[21] |

|

Complex coacervation |

Gelatin–gum arabic crosslinked with genipin |

Mustard seed EO |

- |

Genipin-hardened microcapsules exhibited strong chemical stability with a particle size of mainly 5–10 μm |

[22] |

|

Complex coacervation |

Soy protein–pectin |

Propolis extract |

72.01% and 66.12% for formulations with 2.5 and 5.0 g/100 mL of colloids, respectively |

This process preserves the phenolic and flavonoids compounds with antioxidant activity and inhibitory activity of S. aureus |

[23] |

|

Complex coacervation |

Whey protein isolate–chitosan |

Garlic extract |

51% to 61% |

The CH/WPI complexes are revealed to be good alternatives for use as wall systems |

[24] |

|

Single emulsion diffusion method |

Poly lactic acid (PLA) |

Nisin |

12 to 16% |

The encapsulation efficiency was enhanced with the increase in nisin loading in the aqueous solution |

[25] |

|

Emulsion diffusion |

Polycaprolacton (PCL) |

Eugenol |

100%, 90.9% and 89.1% for PCL, β-CD eugenol and 2-HP-β-CD eugenol, respectively |

The emulsion–diffusion method was more effective for eugenol encapsulation to protect against light oxidation during storage time |

[26] |

|

s/o/w emulsion–evaporation extraction |

Poly (lactic-co-glycolic) (PLGA) |

Lysozyme |

73% |

More hydrophilic polymers were less prone to protein adsorption |

[27] |

|

Alginate microbeads |

Calcium alginate–cellulose nanocrystals (CNC) |

Nisin |

- |

The beads containing nisin significantly reduced the L. monocytogenes counts after 28 days of storage compared with free nisin |

[28] |

|

Alginate microbeads |

Calcium–Alginate |

Clove, thyme and cinnamon EOs |

90 to 94% |

Encapsulation in Ca-alginate microspheres could effectively reduce the evaporation rate of EOs |

[29] |

|

Alginate microbeads |

Sodium alginate–guar gum |

Nisin |

36.35% |

The encapsulation efficiency of nisin under optimal conditions was 36.65% |

[30] |

|

Ionic gelation |

Sodium alginate |

Propolis extract |

99.3% |

Na-alginate encapsulation increased the bioavailability of propolis extract |

[31] |

|

SAS |

PLGA and CaCo3 |

Lysozyme |

~60% |

The supercritical CO2 process offers optimal conditions for protein stability and integrity and permitted the retention of 90% of the biological activity of lysozyme |

[32] |

|

Liposome |

PC, PC/PG |

Nisin |

89–91, 78–83 and 72–78% for PC/PG 6:4, PC/PG 8:2 and PC, respectively |

Liposomes formulated with PC and PG appeared to be relatively stable to pasteurization protocols |

[33] |

|

Liposome and emulsification method |

Lecithin–chol Alginate, chitosan or starch |

Plant herbs, spices and lyzozyme |

- |

Particles with co-encapsulated herbs and lysozyme are more active against different types of bacteria |

[34] |

|

Vibrating technology |

alginate |

Nisin |

75% |

Microcapsules efficiently protected nisin from protease activity and retarded nisin release |

[35] |

3. Microencapsulation of Natural Food Antimicrobials

3.1. Essential Oils

3.2. Propolis

3.3. Antimicrobial Peptides

4. Food Applications of Encapsulated Antimicrobials

|

Antimicrobial Agents |

Wall Material |

Encapsulation Method |

Food Products |

Target Microorganism |

Main Results |

References |

|---|---|---|---|---|---|---|

|

Nisin |

Gum arabic |

Spray drying |

Milk |

L. monocytogenes, B. cereus |

Spray-dried commercial nisin had an antimicrobial effect under refrigeration (90 days) |

[66] |

|

Clove oil |

Β-CD–porous structure |

Spray drying |

Meat products |

Mold spores |

Encapsulated clove oil had a strong heat resistance and a high antiseptic effect on meat products |

[67] |

|

Grape seed extract/carvacrol |

Chitosan |

Ionic gelation |

Salmon |

Psycrophilic, mesophilic bacteria, Pseudomonas spp. |

Prepapred microcapsules increased the shelf-life of refrigerated salmon to 4–7 days of storage |

[68] |

|

Coconut shell liquid smoke |

Dextrin |

Spray-drying |

Tilapia meat |

TPC |

Formulated microcapsules could reduce quality deterioration on fresh fish meat |

[69] |

|

Curcumin |

Gelatin–porous starch |

Spray-drying |

Tofu/bread/cooked pork |

Mold spores |

Compared with free curcumin, microcapsules reduced mold spores from (34.4 ± 2.5) to (52.3 ± 4.1)% |

[70] |

|

Nisin |

Zein |

Spray drying |

milk |

L. monocytogenes |

Capsules were more effective than free antimicrobials in inhibiting the growth of L. monocytogenes in 2% reduced fat milk at 25 °C |

[19] |

|

Rosemary EO |

Modified starch–maltodextrin |

Spray drying |

Fresh dough |

Fungi and yeast |

The encapsulated rosemary essential oil provided long-term antimicrobial activity when applied to fresh dough |

[71] |

|

Nisin |

Alginate–cellulose nanocrystals (CNC) microbeads |

Alginate microbead |

RTE meat |

L. monocytogenes |

Microencapsulation of nisin (63 μg/mL) increased the lag phase of bacterial growth up to 28 days |

[28] |

|

Nisin Z |

Proliposome H |

Liposome |

Cheddar cheese |

L. innocua Lactobacillus spp. L. casei subsp. casei |

Nisin-containing liposomes could provide a powerful tool to improve nisin stability and availability in the cheese matrix |

[72] |

|

Lactoferrin |

Corn oil–butter fat–polyglycerol polyricinoleate |

Emulsification |

Bologna slices |

Carnobacterium viridans |

Microencapsulated lactoferrin had greater antimicrobial activity against Carnobacterium viridans than the free one |

[73] |

References

- Barberis, S.; Quiroga, H.G.; Barcia, C.; Talia, J.M.; Debattista, N. Chapter 20—Natural Food Preservatives Against Microorganisms. In Food Safety and Preservation; Grumezescu, A.M., Holban, A.M., Eds.; Academic Press: Cambridge, MA, USA, 2018; pp. 621–658.

- Fratianni, F.; Nazzaro, F.; Marandino, A.; Fusco, M.R.; Coppola, R.; Feo, V.D.; Martino, L.D. Biochemical composition, antimicrobial activities, and anti–quorum-sensing activities of ethanol and ethyl acetate extracts from Hypericum connatum Lam. (Guttiferae). J. Med. Food 2013, 16, 454–459.

- Tiwari, B.K.; Valdramidis, V.P.; O’Donnell, C.P.; Muthukumarappan, K.; Bourke, P.; Cullen, P.J. Application of natural antimicrobials for food preservation. J. Agric. Food Chem. 2009, 57, 5987–6000.

- Zanetti, M.; Carniel, T.K.; Dalcanton, F.; dos Anjos, R.S.; Riella, H.G.; de Araújo, P.H.; de Oliveira, D.; Fiori, M.A. Use of encapsulated natural compounds as antimicrobial additives in food packaging: A brief review. Trends Food Sci. Technol. 2018, 81, 51–60.

- Ye, Q.; Georges, N.; Selomulya, C. Microencapsulation of active ingredients in functional foods: From research stage to commercial food products. Trends Food Sci. Technol. 2018, 78, 167–179.

- Martins, I.M.; Barreiro, M.F.; Coelho, M.; Rodrigues, A.E. Microencapsulation of essential oils with biodegradable polymeric carriers for cosmetic applications. Chem. Eng. J. 2014, 245, 191–200.

- Paulo, F.; Santos, L. Design of experiments for microencapsulation applications: A review. Mater. Sci. Eng. C 2017, 77, 1327–1340.

- Delshadi, R.; Bahrami, A.; Assadpour, E.; Williams, L.; Jafari, S.M. Nano/microencapsulated natural antimicrobials to control the spoilage microorganisms and pathogens in different food products. Food Control 2021, 128, 108180.

- Castro-Rosas, J.; Ferreira-Grosso, C.R.; Gómez-Aldapa, C.A.; Rangel-Vargas, E.; Rodríguez-Marín, M.L.; Guzmán-Ortiz, F.A.; Falfan-Cortes, R.N. Recent advances in microencapsulation of natural sources of antimicrobial compounds used in food—A review. Food Res. Int. 2017, 102, 575–587.

- Kaur, R.; Kaur, L. Encapsulated natural antimicrobials: A promising way to reduce microbial growth in different food systems. Food Control 2021, 123, 107678.

- Piletti, R.; Bugiereck, A.M.; Pereira, A.T.; Gussati, E.; Dal Magro, J.; Mello, J.M.M.; Dalcanton, F.; Ternus, R.Z.; Soares, C.; Riella, H.G. Microencapsulation of eugenol molecules by β-cyclodextrine as a thermal protection method of antibacterial action. Mater. Sci. Eng. C 2017, 75, 259–271.

- Kamimura, J.A.; Santos, E.H.; Hill, L.E.; Gomes, C.L. Antimicrobial and antioxidant activities of carvacrol microencapsulated in hydroxypropyl-beta-cyclodextrin. LWT-Food Sci. Technol. 2014, 57, 701–709.

- Tao, F.; Hill, L.E.; Peng, Y.; Gomes, C.L. Synthesis and characterization of β-cyclodextrin inclusion complexes of thymol and thyme oil for antimicrobial delivery applications. LWT-Food Sci. Technol. 2014, 59, 247–255.

- Weisheimer, V.; Miron, D.; Silva, C.B.; Guterres, S.S.; Schapoval, E.E.S. Microparticles containing lemongrass volatile oil: Preparation, characterization and thermal stability. Die Pharm. Int. J. Pharm. Sci. 2010, 65, 885–890.

- Zhan, H.; Jiang, Z.-T.; Wang, Y.; Li, R.; Dong, T.-S. Molecular microcapsules and inclusion interactions of eugenol with β-cyclodextrin and its derivatives. Eur. Food Res. Technol. 2008, 227, 1507–1513.

- Amara, C.B.; Eghbal, N.; Degraeve, P.; Gharsallaoui, A. Using complex coacervation for lysozyme encapsulation by spray-drying. J. Food Eng. 2016, 183, 50–57.

- Fernandes, R.V.B.; Borges, S.V.; Botrel, D.A. Gum arabic/starch/maltodextrin/inulin as wall materials on the microencapsulation of rosemary essential oil. Carbohydr. Polym. 2014, 101, 524–532.

- Alvarenga Botrel, D.; Vilela Borges, S.; Victória de Barros Fernandes, R.; Dantas Viana, A.; Maria Gomes da Costa, J.; Reginaldo Marques, G. Evaluation of spray drying conditions on properties of microencapsulated oregano essential oil. Int. J. Food Sci. Technol. 2012, 47, 2289–2296.

- Xiao, D.; Davidson, P.M.; Zhong, Q. Spray-dried zein capsules with coencapsulated nisin and thymol as antimicrobial delivery system for enhanced antilisterial properties. J. Agric. Food Chem. 2011, 59, 7393–7404.

- Leimann, F.V.; Gonçalves, O.H.; Machado, R.A.; Bolzan, A. Antimicrobial activity of microencapsulated lemongrass essential oil and the effect of experimental parameters on microcapsules size and morphology. Mater. Sci. Eng. C 2009, 29, 430–436.

- Sutaphanit, P.; Chitprasert, P. Optimisation of microencapsulation of holy basil essential oil in gelatin by response surface methodology. Food Chem. 2014, 150, 313–320.

- Peng, C.; Zhao, S.-Q.; Zhang, J.; Huang, G.-Y.; Chen, L.-Y.; Zhao, F.-Y. Chemical composition, antimicrobial property and microencapsulation of Mustard (Sinapis Alba) seed essential oil by complex coacervation. Food Chem. 2014, 165, 560–568.

- Nori, M.P.; Favaro-Trindade, C.S.; de Alencar, S.M.; Thomazini, M.; de Camargo Balieiro, J.C.; Castillo, C.J.C. Microencapsulation of propolis extract by complex coacervation. LWT-Food Sci. Technol. 2011, 44, 429–435.

- Tavares, L.; Noreña, C.P.Z. Encapsulation of garlic extract using complex coacervation with whey protein isolate and chitosan as wall materials followed by spray drying. Food Hydrocoll. 2019, 89, 360–369.

- Ji, S.; Lu, J.; Liu, Z.; Srivastava, D.; Song, A.; Liu, Y.; Lee, I. Dynamic encapsulation of hydrophilic nisin in hydrophobic poly (lactic acid) particles with controlled morphology by a single emulsion process. J. Colloid Interface Sci. 2014, 423, 85–93.

- Choi, M.-J.; Soottitantawat, A.; Nuchuchua, O.; Min, S.-G.; Ruktanonchai, U. Physical and light oxidative properties of eugenol encapsulated by molecular inclusion and emulsion–diffusion method. Food Res. Int. 2009, 42, 148–156.

- Paillard-Giteau, A.; Tran, V.-T.; Thomas, O.; Garric, X.; Coudane, J.; Marchal, S.; Chourpa, I.; Benoît, J.-P.; Montero-Menei, C.N.; Venier-Julienne, M.-C. Effect of various additives and polymers on lysozyme release from PLGA microspheres prepared by an s/o/w emulsion technique. Eur. J. Pharm. Biopharm. 2010, 75, 128–136.

- Huq, T.; Riedl, B.; Bouchard, J.; Salmieri, S.; Lacroix, M. Microencapsulation of nisin in alginate-cellulose nanocrystal (CNC) microbeads for prolonged efficacy against Listeria monocytogenes. Cellulose 2014, 21, 4309–4321.

- Soliman, E.A.; El-Moghazy, A.Y.; El-Din, M.M.; Massoud, M.A. Microencapsulation of essential oils within alginate: Formulation and in vitro evaluation of antifungal activity. J. Encapsulation Adsorpt. Sci. 2013, 3, 48–55.

- Narsaiah, K.; Jha, S.N.; Wilson, R.A.; Mandge, H.M.; Manikantan, M.R. Optimizing microencapsulation of nisin with sodium alginate and guar gum. J. Food Sci. Technol. 2014, 51, 4054–4059.

- Keskin, M.; Keskin, Ş.; Kolayli, S. Preparation of alcohol free propolis-alginate microcapsules, characterization and release property. LWT-Food Sci. 2019, 108, 89–96.

- Tran, M.-K.; Hassani, L.N.; Calvignac, B.; Beuvier, T.; Hindré, F.; Boury, F. Lysozyme encapsulation within PLGA and CaCO3 microparticles using supercritical CO2 medium. J. Supercrit. Fluids 2013, 79, 159–169.

- Taylor, T.M.; Gaysinsky, S.; Davidson, P.M.; Bruce, B.D.; Weiss, J. Characterization of antimicrobial-bearing liposomes by ζ-potential, vesicle size, and encapsulation efficiency. Food Biophys. 2007, 2, 1–9.

- Matouskova, P.; Marova, I.; Bokrova, J.; Benesova, P. Effect of encapsulation on antimicrobial activity of herbal extracts with lysozyme. Food Technol. Biotechnol. 2016, 54, 304–316.

- Maresca, D.; De Prisco, A.; La Storia, A.; Cirillo, T.; Esposito, F.; Mauriello, G. Microencapsulation of nisin in alginate beads by vibrating technology: Preliminary investigation. LWT-Food Sci. Technol. 2016, 66, 436–443.

- Abid, Y.; Gharsallaoui, A.; Dumas, E.; Ghnimi, S.; Azabou, S. Spray-drying microencapsulation of nisin by complexation with exopolysaccharides produced by probiotic Bacillus tequilensis-GM and Leuconostoc citreum-BMS. Colloids Surf. B Biointerfaces 2019, 181, 25–30.

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods—A review. Int. J. Food Microbiol. 2004, 94, 223–253.

- Duman, F.; Kaya, M. Crayfish chitosan for microencapsulation of coriander (Coriandrum sativum L.) essential oil. Int. J. Biol. Macromol. 2016, 92, 125–133.

- Jansen-Alves, C.; Maia, D.S.; Krumreich, F.D.; Crizel-Cardoso, M.M.; Fioravante, J.B.; da Silva, W.P.; Borges, C.D.; Zambiazi, R.C. Propolis microparticles produced with pea protein: Characterization and evaluation of antioxidant and antimicrobial activities. Food Hydrocoll. 2019, 87, 703–711.

- Procopio, F.R.; Oriani, V.B.; Paulino, B.N.; do Prado-Silva, L.; Pastore, G.M.; Sant’Ana, A.S.; Hubinger, M.D. Solid lipid microparticles loaded with cinnamon oleoresin: Characterization, stability and antimicrobial activity. Food Res. Int. 2018, 113, 351–361.

- Guarda, A.; Rubilar, J.F.; Miltz, J.; Galotto, M.J. The antimicrobial activity of microencapsulated thymol and carvacrol. Int. J. Food Microbiol. 2011, 146, 144–150.

- Dima, C.; Cotarlet, M.; Tiberius, B.; Bahrim, G.; Alexe, P.; Dima, S. Encapsulation of coriander essential oil in beta-cyclodextrin: Antioxidant and antimicrobial properties evaluation. Rom. Biotechnol. Lett. 2014, 19, 9128–9140.

- Alves-Silva, J.M.; dos Santos, S.D.; Pintado, M.M.; Pérez-Álvarez, J.A.; Viuda-Martos, M.; Fernández-López, J. In Vitro antimicrobial properties of coriander (Coriandrum sativum) and parsley (Petroselinum crispum) essential oils encapsulated in β-cyclodextrin. In Worldwide Research Efforts in the Fighting against Microbial Pathogens; BrownWalker Press: Irvine, CA, USA, 2013; pp. 168–171.

- Calo, J.R.; Crandall, P.G.; O’Bryan, C.A.; Ricke, S.C. Essential oils as antimicrobials in food systems—A review. Food Control 2015, 54, 111–119.

- Hill, L.E.; Gomes, C.; Taylor, T.M. Characterization of beta-cyclodextrin inclusion complexes containing essential oils (trans-cinnamaldehyde, eugenol, cinnamon bark, and clove bud extracts) for antimicrobial delivery applications. LWT-Food Sci. Technol. 2013, 51, 86–93.

- Liolios, C.C.; Gortzi, O.; Lalas, S.; Tsaknis, J.; Chinou, I. Liposomal incorporation of carvacrol and thymol isolated from the essential oil of Origanum dictamnus L. and in vitro antimicrobial activity. Food Chem. 2009, 112, 77–83.

- Tiveron, A.P.; Rosalen, P.L.; Franchin, M.; Lacerda, R.C.C.; Bueno-Silva, B.; Benso, B.; Denny, C.; Ikegaki, M.; Alencar, S.M. Chemical characterization and antioxidant, antimicrobial, and anti-inflammatory activities of South Brazilian organic propolis. PLoS ONE 2016, 11, e0165588.

- Andrade, J.K.S.; Denadai, M.; de Oliveira, C.S.; Nunes, M.L.; Narain, N. Evaluation of bioactive compounds potential and antioxidant activity of brown, green and red propolis from Brazilian northeast region. Food Res. Int. 2017, 101, 129–138.

- Zancanela, D.C.; Herculano, R.D.; Funari, C.S.; Marcos, C.M.; Almeida, A.M.F.; Guastaldi, A.C. Physical, chemical and antimicrobial implications of the association of propolis with a natural rubber latex membrane. Mater. Lett. 2017, 209, 39–42.

- Busch, V.M.; Pereyra-Gonzalez, A.; Šegatin, N.; Santagapita, P.R.; Ulrih, N.P.; Buera, M.P. Propolis encapsulation by spray drying: Characterization and stability. LWT 2017, 75, 227–235.

- Bruschi, M.L.; Cardoso, M.; Lucchesi, M.B.; Gremião, M.P.D. Gelatin microparticles containing propolis obtained by spray-drying technique: Preparation and characterization. Int. J. Pharm. 2003, 264, 45–55.

- Durán, N.; Marcato, P.D.; Buffo, C.M.S.; Azevedo, M.M.M.D.; Esposito, E. Poly (ε-caprolactone)/propolis extract: Microencapsulation and antibacterial activity evaluation. Die Pharm. Int. J. Pharm. Sci. 2007, 62, 287–290.

- Almeida, E.T.C.; da Silva, M.C.D.; Oliveira, J.M.S.; Kamiya, R.U.; Arruda, R.E.S.; Vieira, D.A.; Silva, V.C.; Escodro, P.B.; Basílio-Júnior, I.D.; do Nascimento, T.G. Chemical and microbiological characterization of tinctures and microcapsules loaded with Brazilian red propolis extract. J. Pharm. Anal. 2017, 7, 280–287.

- Neves, M.V.M.; Silva, T.M.S.; Lima, E.O.; Cunha, E.V.L.; Oliveira, E.J. Isoflavone formononetin from red propolis acts as a fungicide against Candida sp. Braz. J. Microbiol. 2016, 47, 159–166.

- Hazam, P.K.; Goyal, R.; Ramakrishnan, V. Peptide based Antimicrobials: Design Strategies and Therapeutic Potential. Prog. Biophys. Mol. Biol. 2018, 142, 10–22.

- Ciumac, D.; Gong, H.; Hu, X.; Lu, J.R. Membrane targeting cationic antimicrobial peptides. J. Colloid Interface Sci. 2019, 537, 163–185.

- Etchegaray, A.; Machini, M.T. Antimicrobial lipopeptides: In vivo and in vitro synthesis. In Microbial Pathogens and Strategies for Combating Them: Science, Technology and Education; Formatex Research Center: Badajoz, Spain, 2013.

- Kumariya, R.; Garsa, A.K.; Rajput, Y.S.; Sood, S.K.; Akhtar, N.; Patel, S. Bacteriocins: Classification, synthesis, mechanism of action and resistance development in food spoilage causing bacteria. Microb. Pathog. 2019, 128, 171–177.

- Gharsallaoui, A.; Oulahal, N.; Joly, C.; Degraeve, P. Nisin as a food preservative: Part 1: Physicochemical properties, antimicrobial activity, and main uses. Crit. Rev. Food Sci. Nutr. 2016, 56, 1262–1274.

- Cui, H.; Wu, J.; Li, C.; Lin, L. Improving anti-listeria activity of cheese packaging via nanofiber containing nisin-loaded nanoparticles. LWT—Food Sci. Technol. 2017, 81, 233–242.

- Malheiros, P.S.; Daroit, D.J.; Brandelli, A. Food applications of liposome-encapsulated antimicrobial peptides. Trends Food Sci. Technol. 2010, 21, 284–292.

- Kaur, G.; Singh, T.P.; Malik, R.K.; Bhardwaj, A.; De, S. Antibacterial efficacy of nisin, pediocin 34 and enterocin FH99 against L. monocytogenes, E. faecium and E. faecalis and bacteriocin cross resistance and antibiotic susceptibility of their bacteriocin resistant variants. J. Food Sci. Technol. 2014, 51, 233–244.

- Taylor, T.M.; Bruce, B.D.; Weiss, J.; Davidson, P.M. Listeria monocytogenes and Escherichia coli O157: H7 inhibition in vitro by liposome-encapsulated nisin and ethylene diaminetetraacetic acid. J. Food Saf. 2008, 28, 183–197.

- Chan, Y.-H.; Chen, B.-H.; Chiu, C.P.; Lu, Y.-F. The influence of phytosterols on the encapsulation efficiency of cholesterol liposomes. Int. J. Food Sci. Technol. 2004, 39, 985–995.

- Martinez, R.C.R.; Alvarenga, V.O.; Thomazini, M.; Fávaro-Trindade, C.S.; de Souza Sant’Ana, A. Assessment of the inhibitory effect of free and encapsulated commercial nisin (Nisaplin®), tested alone and in combination, on Listeria monocytogenes and Bacillus cereus in refrigerated milk. LWT-Food Sci. Technol. 2016, 68, 67–75.

- Wang, Y.-F.; Jia, J.-X.; Tian, Y.-Q.; Shu, X.; Ren, X.-J.; Guan, Y.; Yan, Z.-Y. Antifungal effects of clove oil microcapsule on meat products. LWT-Food Sci. 2018, 89, 604–609.

- Alves, V.; Rico, B.; Cruz, R.; Vicente, A.A.; Khmelinskii, I.; Vieira, M.C. Preparation and characterization of a chitosan film with grape seed extract-carvacrol microcapsules and its effect on the shelf-life of refrigerated Salmon (Salmo Salar). LWT-Food Sci. 2018, 89, 525–534.

- Ariestya, D.I.; Swastawati, F.; Susanto, E. Antimicrobial activity of microencapsulation liquid smoke on tilapia meat for preservatives in cold storage (±5 °C). Aquat. Procedia 2016, 7, 19–27.

- Wang, Y.-F.; Shao, J.-J.; Zhou, C.-H.; Zhang, D.-L.; Bie, X.-M.; Lv, F.-X.; Zhang, C.; Lu, Z.-X. Food preservation effects of curcumin microcapsules. Food Control 2012, 27, 113–117.

- Teodoro, R.A.R.; Fernandes, R.V.B.; Botrel, D.A.; Borges, S.V.; de Souza, A.U. Characterization of microencapsulated rosemary essential oil and its antimicrobial effect on fresh dough. Food Bioprocess Technol. 2014, 7, 2560–2569.

- Benech, R.-O.; Kheadr, E.E.; Lacroix, C.; Fliss, I. Antibacterial activities of nisin Z encapsulated in liposomes or produced in situ by mixed culture during cheddar cheese ripening. Appl. Environ. Microbiol. 2002, 68, 5607–5619.

- Al-Nabulsi, A.A.; Han, J.H.; Liu, Z.; Rodrigues-Vieira, E.T.; Holley, R.A. Temperature-Sensitive Microcapsules Containing Lactoferrin and Their Action Against Carnobacterium viridans on Bologna. J. Food Sci. 2010, 71, M208–M214.

- Ribeiro-Santos, R.; Andrade, M.; Sanches-Silva, A. Application of encapsulated essential oils as antimicrobial agents in food packaging. Curr. Opin. Food Sci. 2017, 14, 78–84.