Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | KeChrist Obileke | + 3195 word(s) | 3195 | 2022-03-19 04:59:13 | | | |

| 2 | Vicky Zhou | -57 word(s) | 3138 | 2022-03-29 08:27:24 | | | | |

| 3 | Vicky Zhou | Meta information modification | 3138 | 2022-03-29 08:29:20 | | | | |

| 4 | Helen Onyeaka | Meta information modification | 3138 | 2022-04-07 10:10:06 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Obileke, K.; Onyeaka, H. Starch-Based Biodegradable Films for Food Packaging. Encyclopedia. Available online: https://encyclopedia.pub/entry/21131 (accessed on 04 March 2026).

Obileke K, Onyeaka H. Starch-Based Biodegradable Films for Food Packaging. Encyclopedia. Available at: https://encyclopedia.pub/entry/21131. Accessed March 04, 2026.

Obileke, Kechrist, Helen Onyeaka. "Starch-Based Biodegradable Films for Food Packaging" Encyclopedia, https://encyclopedia.pub/entry/21131 (accessed March 04, 2026).

Obileke, K., & Onyeaka, H. (2022, March 28). Starch-Based Biodegradable Films for Food Packaging. In Encyclopedia. https://encyclopedia.pub/entry/21131

Obileke, Kechrist and Helen Onyeaka. "Starch-Based Biodegradable Films for Food Packaging." Encyclopedia. Web. 28 March, 2022.

Copy Citation

The use of biodegradable packaging material as an alternative to conventional petrochemical-based polymers is based on the environmental issues associated with conventional materials. Starch-based biodegradable films can be applied in food packaging. It was evident that starch stands out among biopolymers due to its abundance and cost effectiveness.

starch

biodegradable film

food packaging

environmental impact

shelf life

1. Introduction

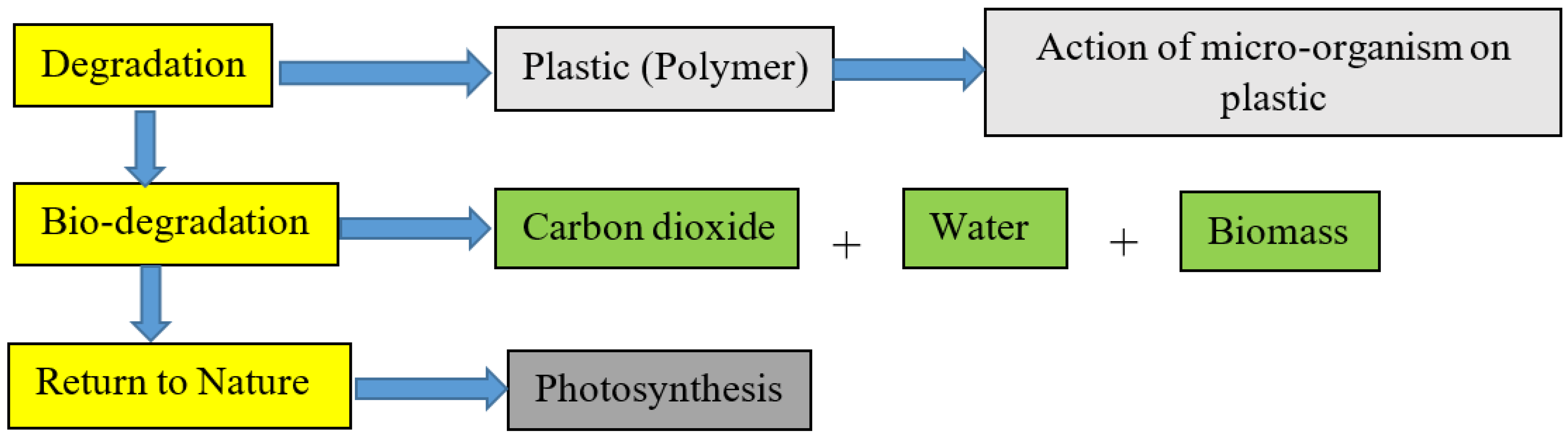

The use of plastic for food packaging in the food industry has shown an annual growth rate of 5% over recent decades. At present, plastic is recorded as the second most widely used material for food packaging [1]. This packaging process is essential as it prevents foods from being infected by microbes, thereby prolonging their shelf life. Real product shelf life is governed not only by microbiological control but also by chemical and physical control of products, connected to the maintenance of desirable sensory properties throughout storage. Food packaging is an essential part of the food industry sector. However, the food packaging sector is now in pursuit of lightweight biodegradable packaging for reducing materials use, waste, and transportation costs. The process of biodegradation (see Figure 1) is engineered by the activities of microorganisms present in the environment. During this process, microorganisms consume degradable plastics, thereby producing carbon dioxide, water, and biomass that is returned to nature by the bio cycle process [2].

Figure 1. The process of biodegradation.

However, there are certain limitations in the plastic degradation process, because it takes a long time, thus impacting negatively on the environment [3][4]. Some of the environmental impacts of plastics include the contamination of marine and land creatures during photodecomposition. Furthermore, particles of plastics are said to cause injury or death to marine life, thereby disrupting the ecosystem and food chain, leading to potential extinction. Moreover, some of the plastics are also non-recyclable, thus creating environmental burden. Despite the disadvantages associated with plastic disposal, studies have shown that the use of plastic packaging still represents about 37% of the total plastic demand [5][6]. To solve the elongated degradation problem associated with plastics, studies are ongoing for readily biodegradable materials for use as packaging materials for the food industry. Among all the biopolymers, starch-based films stand out because of the abundance and low cost of starch [7]. A biodegradable film derived from starch can become a primary packaging material made from biodegradable polymers and food-grade additives. According to the attestation made by Galus et al. [8], biodegradable films have been employed for the protection and extension of packaged food shelf life. The use of starch-based films in food products is backed by their inherent properties, which include biodegradability, edibility, and abundance. Moreover, biodegradable materials are said to have advantages over plastics in terms of environmental preservation. This is because biodegradable materials degrade after their deposal, creating a new agricultural product [4].

Recent review studies relating to starch-based biodegradable films have been focused on biodegradable polymer trends [9], materials for biodegradable food packaging [10], nanotechnology in food science [11][12], challenges and opportunities for starch-based materials [13], and extraction and sources of starch for biodegradable films [14][15][16][17]. These are interesting topics; however, no reviews have focused on the current state and applications of starch-based biodegradable films for food packaging—a gap in the literature. Therefore, herein covers the topic of the production and processing of starch, the sources of starch, the current industrial applications of starch-based biodegradable films, the properties of starch, the addition of nanomaterials, the embedding of antimicrobial agents, and the evaluation of the shelf life of foods packaged with starch-based biodegradable films. Furthermore, the future perspectives are presented.

2. Starch as a Biodegradable Packaging Material

Starch is a good source of biodegradable material for food packaging, originating from wheat, corn, rice, and potatoes [18]. It is widely viewed as a sustainable substitute to plastics for food packaging. Moreover, various foods, such as fruits, vegetables, snacks, and dry products, can be packaged using starch as a biodegradable film [19]. The three ways starch can be used in producing biodegradable films are as follows: firstly, small amounts of starch can be used in the preparation of starch compositions with other plastics. The essence of this is to improve the biodegradability of traditional, oil-based starch materials. Secondly, the preparation of starch composites with the starch content comprising more than half of the mass. Thirdly, the use of extrusion, processing with mixtures of granular starch in biodegradable preparation processes [20]. The increase in the use of starch-based biodegradable films for food packaging is an outcome of its numerous advantages. These include their contribution to reducing fossil content, their lack of toxins, their origin being plant sources (renewable resources), their biodegradability and biocompatibility, the low cost and abundance of starch, their safety for consumption when used in food packaging, their reduced energy consumption, their role as an eco-friendly disposal solution, and the absence of a net increase in CO2 in the global ecosystem. Despite these advantages and benefits, disadvantages include poor mechanical properties, low water stability, high moisture sensitivity, presence of a poor moisture barrier because of strong hydrophilic behaviour, their brittle behaviour at room temperature, and their high moisture content [1]. To overcome these disadvantages of using starch as a biodegradable material, a thermoplastic starch matrix could be filled with nanofillers, thus improving these properties. In a study by Nafchi et al. [21], the addition of nanoscale particles enhanced the mechanical and barrier properties of starch. Montmorillonite (MMT) nano-clay has been recommended as promising nanoscale filler for biodegradable packaging. Hence, the use of MMT in food packaging can be attributed to its reduced cost, high stability, and high level of effectiveness. [22]. More information on MMT nanoclay is detailed here. Studies have shown that the properties of starch-based films are responsible for its rigidity and reduced flexibility. Hence, other polymers could be used as additive compounds [1]. Different sources of biopolymers, such as polysaccharides, proteins, and lipids, can act as biodegradable films [23].

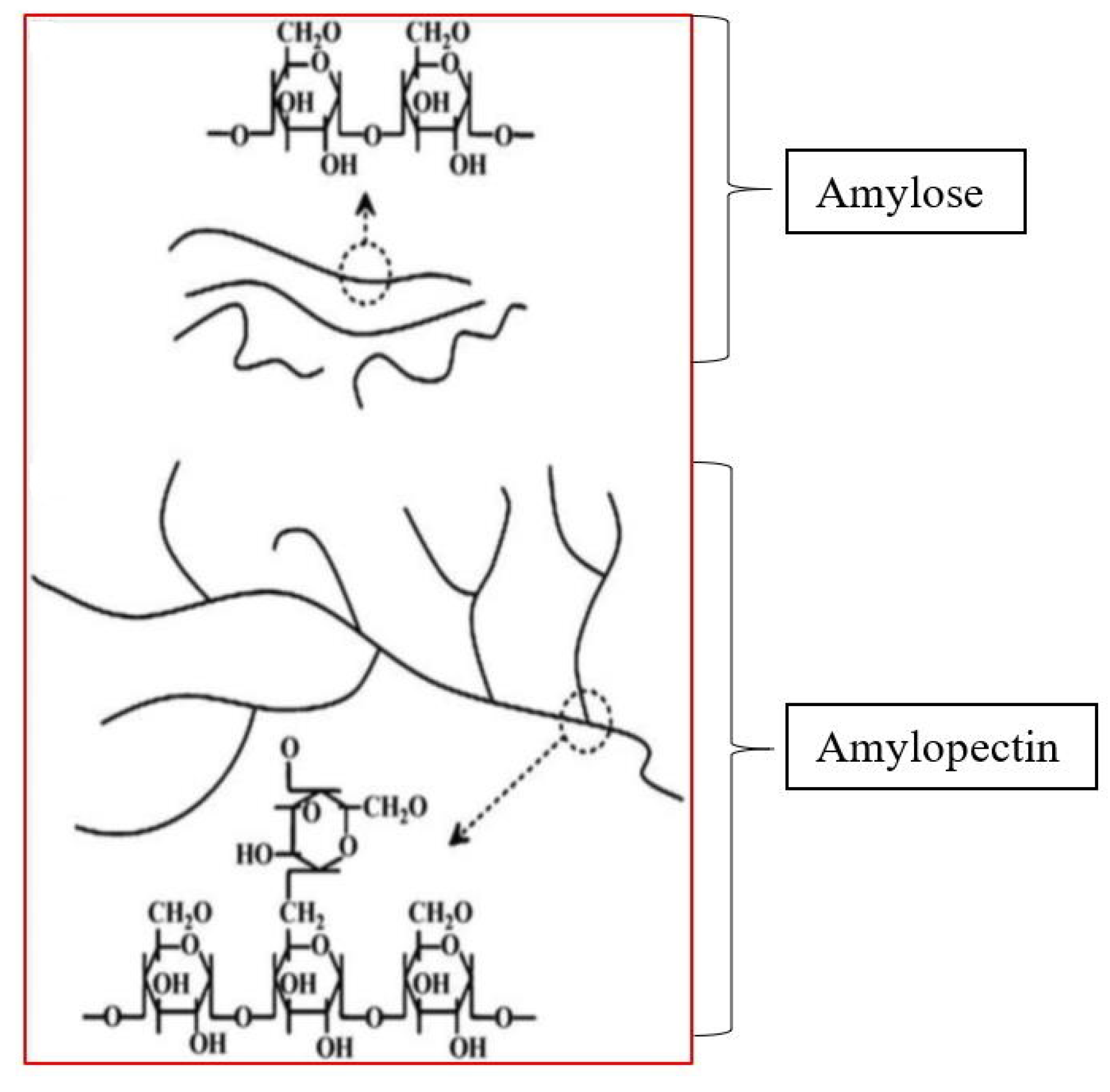

Starch is mainly sourced from plants but can also originate from roots, tubers, cereals, and legumes. Considering its inherent biodegradability, abundance, and annual renewability, starch is a promising natural polymer. Interestingly, previous studies have revealed that starch contains two kinds of microstructures: linear and branched. Hence, it is regarded as a heterogeneous material. The linear structure is known as the amylose (crystallizable form of starch made up of long unbranched polysaccharide chains), while the branched structure is called the amylopectin (non-crystallizable form of starch with branched polysaccharide chain).

Figure 2 shows a chemical representation of amylose and amylopectin starches.

Figure 2. Chemical representation of two kinds of microstructures in starch Modified from Jiang et al. [13].

2.1. The Application of Starch-Based Biodegradable Material

Most of the applications of starch-based biodegradable material in the literature have been carried out at a laboratory scale rather than at an industrial scale. In a study by Molaee Aghaee et al. [24], the researchers packaged a chicken filet using chitosan films containing garlic basic oil amid capacity at a refrigeration temperature. Different levels (0, 0.5, 1.0, and 2.0%) of garlic basic oil was added to the chitosan film arrangement. The chicken filet was examined chemically on days 2, 4, 7, and 10, and it was revealed that the sample films showed a lower pH, which was attributed to unstable nitrogen, thiobarbituric-acid-reactive substances, and peroxide. Thus, it concluded that chemical deterioration components were prevented from developing as a result of the chitosan films used for packaging the chicken.

In another study, the effect of starch protein films on Lactobacillus rhamnous was studied by Soukoulis et al. [25]. The scope focused on compositional, physicochemical, and auxiliary characterization. Starch from local rice and corn was used. In addition to the starch, bovine skin gelatine, sodium caseinate, and soy protein also were also used for the creation of the starch film through probiotics. The findings showed an increment in the practicality of L. rhamnosus by 3–7-fold around the nearness of protein with sodium caseinate. It was concluded by calculating the shelf life of the films. The results showed that, in accordance with the framework of the premise of 6 log practical CFU/g, the measure was extended at 27–96 days and 15–24 days at ice chest or room temperature, respectively.

A comparison study focusing on the main and physical features of chitosan and altered starches of edible films was examined by Garcia et al. [26]. The films’ arrangement was made using a casting strategy that utilises chitosan, waxy, oxidized, and acetylated corn, and their respective blends. Their studies revealed a clearing out of chitosan with a less positive charge, due to the connections between the acetyl bunches, acetylated with carboxyl, and the amino bunches of chitosan. It was also seen that the positive charge diminished because of the interaction with the amino bunches of chitosan, which affected the antimicrobial action. It concluded by mentioning that the adjustment of the starch affects chitosan, thereby driving the diverse of the films’ features.

The aim of a study conducted by Gomes et al. [27] was to characterize edible films of S. burchelli phosphate starches, and observe the development of coasting and its application to cherry tomatoes through post-harvest conservation. The following measurements were conducted: the thickness of the film, the solubility in water, and the permeability by water vapour. The methodology involved comparing the conservation of the cherry tomatoes with and without coverage at the following conditions: time—21 days; temperature—10 ± 2 °C; relative humidity—80 ± 5%. It revealed that factors such as reduction in water solubility, increase in permeability, and characteristics of the films were usually affected by the concentration of the glycerol and the type of starch used. In addition, it was reported that fruits with an edible coating showed a greater permeability by water vapour, especially for the conservation of cherry tomatoes. This was attributed to the gradual decrease in the film during storage compared with the control from an experimental point of view. Its objective was successfully established, proving that the concentration of glycerol affects consumable films and should allow for ideal post-harvest use.

Adjouman et al. [28] conducted a study on the water vapour porousness (WVP) of edible films on 4 g cassava starch from Cote d’Ivoire, focusing on the response of the starch in respect to the effect of glycerol (25–30%), shelled nut oil (5–10%), and soybean lecithin (0–5%), all in w/w. Temperature (25 °C) and relative humidity (75%) were monitored and obtained to determine the water vapour porousness. The findings show that glycerol and shelled nut oil increased the WVP, while the soybean lecithin did not affect the WVP. In addition, the following results were obtained for the WVP: glycerol—25%; shelled nut oil—5%; soybean lecithin—5%. In Cote d’Ivore, starch from cassava is said to be a promising starch for nourishment bundling.

Xiaoyang et al. [29] recommended the use of iron yam and maize starch flavoured with fundamental or essential lemon oil (plasticization). The following parameters were examined: physical change, microcosmic features, and antimicrobial of the starches. It reported diminished dampness substances, water vapour porousness, solvency, and malleability quality. These factors reported were a result of the presence of the lemon fundamental oil used. In conclusion, the recommendation was proven as iron yam/maize starch can be used to nourish flavour for the packaging material. This is because of their physical and antimicrobial characteristics. To conclude this section, in order to make starch useful as a packaging material, it certainly seems to require a lot of support through the addition of many other non-starch materials. This addition is highly recommended.

2.2. Application of Starch-Based Nanomaterials

To keep foods from being infected by fungi and bacteria and for the purpose of long-term storage, nanotechnology is essential [1]. Additionally, by integrating nanomaterials into the food industry, food quality and safety can be further improved [30]. According to Singh et al. [31] and Gupta et al. [32], nanomaterials are characterised by three major properties. These include unique properties (high ratio of surface to volume), physiochemical properties (solubility, optical, magnetic, etc.), and thermodynamic properties. Furthermore, materials used in nanotechnology are non-toxic [33], and at high temperatures and pressures, they are stable [34][35]. These properties have contributed to the extension of shelf life and newness of packaged products. Kuswandi and Moradi [36] recommended using different functional nanomaterials to improve the quality of materials used for food packaging, which can prolong the life span of the packaged food and its safety.

According to Joye et al. [37], Khare et al. [38], and Yoksan and Chirachanchai [39], nanotechnology is formed by the combination of nanoparticles to form nanofilms. Nanofilms decrease gas permeability, thereby reducing harmful concentrations of gases such as carbon dioxide (CO2) or oxygen (O2). These gases negatively impact the shelf life of the food products and act as an obstacle that hinders microorganism activities. This acts as one of the advantages of nanomaterials in food packaging. According to Brody [40], Joye et al. [37], Khare et al. [38], and Yoksan and Chirachanchai [39], the use of nanomaterials can lead to a decrease in oxygen and carbon dioxide permeation of up to 80–90%. They pointed out that most food products are oxygen-sensitive. Hence, a packaging gas barrier seems important for the safe horticultural production of most product types. Carbon dioxide is generally not detrimental to foods and is used in gas-flushing-modified atmospheric packaging (MAP) above 20% to selectivity impact aerobics and psychotropic microorganisms. This makes carbon dioxide gas barrier properties in packaging materials very important.

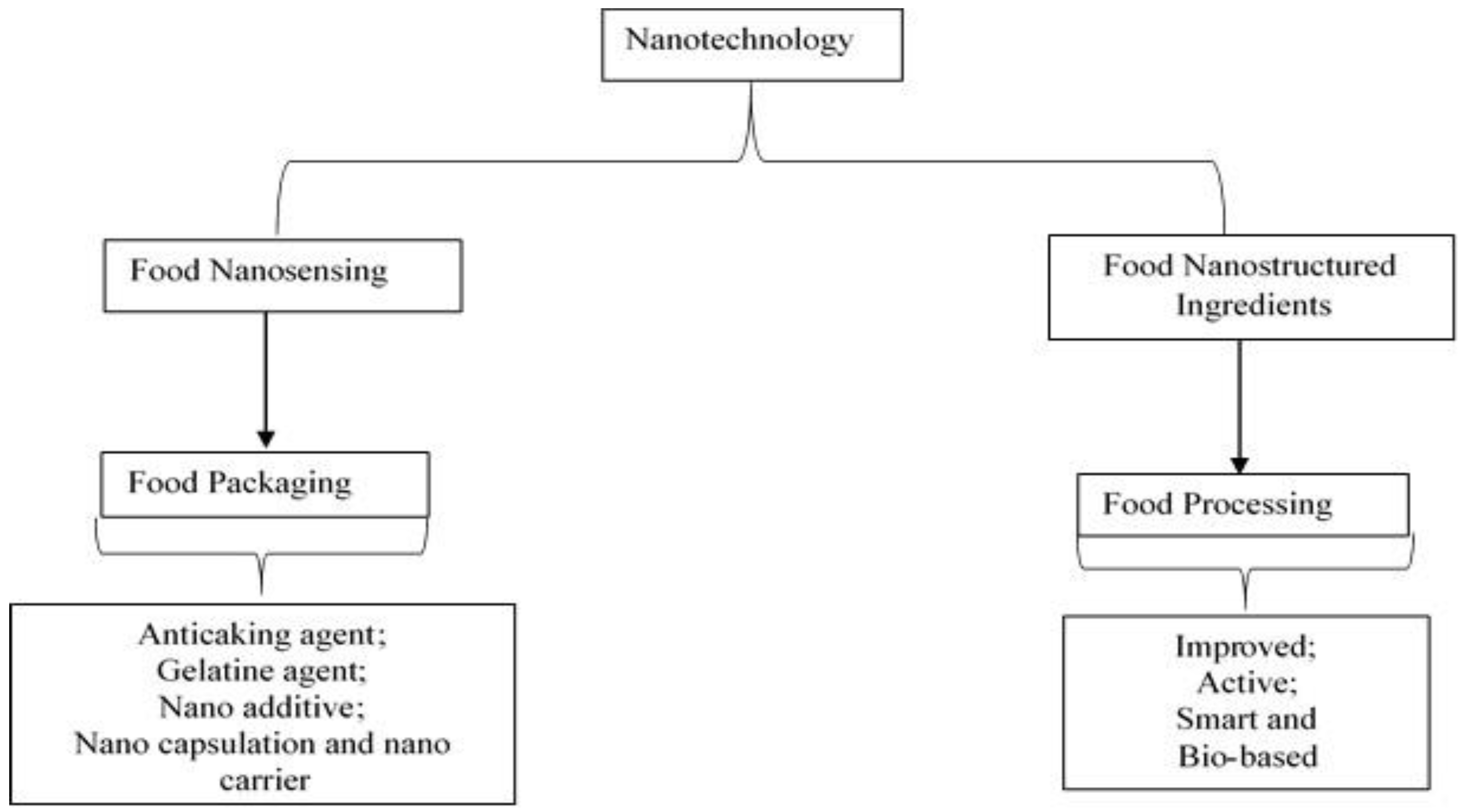

Interestingly, nanotechnology can be classified into food nanosensing and nanostructured food ingredients [41]. Food nanosensing focuses on improving food quality and their safety, while nanostructured food ingredients can be used in a wide range of food processing and packaging applications. Both categories are presented in Figure 3.

Figure 3. Classification of nanotechnology and its applications (modified from Primozic et al. [11]).

Having established the fact that the use of nanomaterials or nanotechnology in food packaging improves food quality and safety, it would be interesting to briefly analyze these materials in starch-based films (starch-based nanomaterials). Material for food packaging using starch-based biodegradable films must be durable. To accomplish this, starch-based nanomaterials are necessary. One main function of the starch-based nanomaterial is to reduce the weakness of the natural polymer in starch [1]. Starch is a promising biopolymer for food packaging, which is affected by water sensitivity and brittleness [41]. The mechanical, UV, and water properties of starch material can be improved by adding nanoparticles [42].

Considering a few studies on starch-based nanotechnology and its effects, the utilization of different concentrations of graphene oxide and its response to starch–graphene oxide composite film was studied by Wu et al. [43]. It revealed that the addition of graphene oxide greatly impacted the packaging material in terms of mechanical properties and water permeability. In a study by Aqlil et al. [44], an investigation into the employment of a graphene-oxide-filled starch/lignin polymer with bio–nanocomposite was conducted. The investigation showed that graphene oxide had a strong influence on the strength of the material and has the potential to reduce water vapour permeability and moisture characteristic of the starch-based film.

3. Challenges Facing Starch-Based Biodegradable Films for Food Packaging

It is necessary to briefly look at the major challenges faced by starch-based biodegradable films for food packaging. Although the disadvantages have been mentioned, poor mechanical behaviour and high water vapour permeability (mass of water vapour transmitted through a film area within a defined time) are the main challenges or drawbacks associated with starch-based biodegradable films. The poor mechanical behaviours are determined by tensile tests and they include the tensile strength, the strain at break, and the elasticity modulus [45]. In relation to high water vapour permeability, the issue of hydrophilicity is concerning. Hydrophilicity is one of the properties derived from the polar characteristics of starch hydroxyl groups and is regarded as an important factor affecting starch-based biodegradable films for food packaging. One of the methods to reduce the hydrophilicity of starch-based biodegradable films is to combine them with lipids. To achieve this, emulsifiers such as polydimethylsiloxane or commercial polysorbate surfactants are applied. According to Cao and Song, [46], Evagelho et al. [47], Kang and Song [48], and Hasan et al. [49], the emulsifier interacts with the starch network. The hydrophobic nature prevents interaction between the starch and water. A more organized network arrangement with increased crystallinity can be used to reduce the hydrophilicity of starch-based biodegradable films. This is possible because of the higher molecular density. Thus, higher solubility has the potential to speed up the biodegradability process and facilitate waste management after disposal [50][51]. Finally, a discussion of the challenges facing starch-based biodegradable films for food packaging would not be complete without talking about the processability of the starch-based films. This process is more difficult to control than it is in the case of conventional plastics. Although the processing of starch has been discussed earlier, it was shown that the amount of water needed emphasises the differences experienced in the techniques used for starch processing. The use of water and high temperature came about as a result of the drawbacks/challenges encountered during the processing of starch. For this reason, there is a need for traditional processing techniques, thereby controlling the process conditions and judicious incorporation of specific additives which are commonly used [45].

4. Conclusions and Outlook

Herein succinctly accounted for the current state of research and applications of starch-based biodegradable films for food packaging. It was motivated by the necessity of finding a substitute (biodegradable starch film) for the conventional synthetic plastic currently in use. Although biodegradable starch films are associated with poor properties, the utilisation of nanomaterials tends to enhance the brittleness and physical behaviour of the films for food packaging. While nanotechnology offers various potentials in food packaging—as a result of its functions from bio-based packaging to smart packaging in the food sector, as well as improving food quality and safety—further study is recommended to ascertain the advantages and disadvantages of using nanotechnology in food packaging materials. The issue of moisture sensitivity was identified as a limitation in the use of starch-based materials for food packaging. As further observed, the tensile strength and adequate water vapour permeability of the films can be attributed to the hydrophilic nature of starch. This makes starch-based films susceptible to moisture uptake. Hence, to enhance the resistance of starch-based materials to moisture and mechanical properties, various blending and composting techniques are required, such as coating (acrylate-epoxidized soybean oil). Addition of acrylate-epoxidized soybean oil reduces moisture sensitivity and increases the gas permeability of the starch-based films. To improve the surface adhesion or bonding between starch and acrylate-epoxidized soybean oil coating, polyethylenimine (PEI) is recommended. With regards to the evaluation of shelf life, food materials packed using starch-based films provide a platform for microbial spoilage of stored foods. To avoid this, it is recommended that the use of essential oils with antimicrobial and antibacterial potentials or properties should be employed. This provides a remedy to such limitations.

Further work should focus on improving the performance of starch-based films by reducing their moisture sensitivity, while considering the balance between different chemical treatments for reducing moisture sensitivity and biodegradability. It was observed that studies regarding starch-based materials in other applications, such as in use as fertilizers and in water treatments, have a lot of potential and interest. Therefore, there is a need for researchers and academics to examine this direction.

References

- Sadeghizadeh-Yazdi, J.; Habibi, M.; Kamali, A.A.; Banaei, M. Application of edible and biodegradable starch-based films in food packaging: A systematic review and meta-analysis. Curr. Res. Nutr. Food Sci. 2019, 7, 624–637.

- Making Plastic Environmental Friendly; EPI Environmental Products Inc Vancouver Canada. 2014. Available online: https://www.foresightusa.com/single-post/2014/11/04/biodegradable-plastics-let-s-clear-up-the-confusion (accessed on 28 January 2022).

- Sorrentino, A.; Gorrasi, G.; Vittoria, V. Potential perspectives of bio nanocomposites for food packaging applications. Trends Food Sci. Technol. 2007, 18, 84–95.

- Xu, Y.X.; Kim, K.M.; Hanna, M.A.; Nag, D. Chitosane starch composite film: Preparation and characterization. Ind. Crops Process 2005, 21, 185–192.

- Plastics Europe. Plastics: The Facts 2015. An Analysis of European Plastics Production, Demand and Waste Data; Plastics Europe: Brussel, Belgium, 2015.

- Kalia, V.C.; Raizada, N.; Sonakya, V. Bioplastics. Sci. Ind. Res. 2000, 59, 433–445.

- Jiménez, A.; Fabra, M.J.; Talens, P.; Chiralt, A. Edible and Biodegradable Starch Films: A Review. Food Bioprocess Technol. 2012, 5, 2058–2076.

- Galus, S.; Kadzi_nska, J. Food applications of emulsion-based edible films and coatings. Trends Food Sci. Technol. 2015, 45, 273–283.

- Malathi, A.N.; Santhosh, K.S.; Nidoni, U. Recent trends of biodegradable polymer: Biodegradable films for food packaging and application of Nanoparticles in biodegradable food packaging. Curr. Trends Technol. Sci. 2014, 3, 73–79.

- Issa, A.; Ibrahim, S.A.; Tahergorabi, R. Sweet potato starch/clay nanocomposite: New material for emerging biodegradable food packaging. MOJ Food Process Technol. 2016, 3, 313–315.

- Primožič, M.; Knez, Ž.; Leitgeb, M. (Bio)Nanotechnology in Food Science—Food Packaging. Nanomaterials 2021, 11, 292.

- Huang, Y.; Mei, L.; Chen, X.; Wang, Q. Recent Developments in Food Packaging Based on Nanomaterials. Nanomaterials 2018, 8, 830.

- Jiang, T.; Duan, Q.; Zhu, J.; Liu, H.; Yu, L. Starch-based biodegradable materials: Challenges and opportunities. Adv. Ind. Eng. Polym. Res. 2020, 3, 8–18.

- Agyepong, J.K.; Barimah, J. Physiochemical properties of starches extracted from local cassava varieties with the aid of crude pectolytc enzymes from Saccharomyces cerevisiae (ATCC 52712). Afr. J. Food Sci. 2018, 12, 151–164.

- Altemimi, A.B. Extraction and optimization of potato starch and its application as a stabilizer in yogurt manufacturing. Foods 2018, 7, 14.

- Cornejo-Ramírez, Y.I.; Martínez-Cruz, O.; Del Toro-Sánchez, C.L.; Wong-Corral, F.J.; Borboa-Flores, J.; Cinco-Moroyoqui, F.J. The structural characteristics of starches and their functional properties. CyTA-J. Food 2018, 16, 1003–1017.

- Horstmann, S.W.; Lynch, K.M.; Arendt, E.K. Starch Characteristics Linked to Gluten-Free Products. Foods 2017, 6, 29.

- Kolybaba, M.; Tabil, L.; Panigrahi, S.; Crerar, W.; Powell, T.; Wang, B. Biodegradable Polymers: Past, Present, and Future; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2006.

- Pelissari, F.M.; Grossmann, M.V.E.; Yamashita, F. Antimicrobial, mechanical, and barrier properties of cassava starch–chitosan films incorporated with oregano essential oil. J. Agric. Food Chem. 2009, 57, 7499–7504.

- Flieger, M.; Kantorova, M.; Prell, A.; Rezanka, T. Biodegradable plastics from renewable sources. Folia Microbiol. 2003, 48, 27–44.

- Nafchi, A.M.; Nassiri, R.; Sheibani, S. Preparation and characterization of bio nanocomposite films filled with Nano rod-rich zinc oxide. Carbohydr. Polym. 2013, 96, 233–239.

- Park, H.W.; Lee, W.K.; Park, C.Y. Environmentally friendly polymer hybrids: Part, I. Mechanical, thermal, and barrier properties of thermoplastic starch/clay nanocomposites. J. Mater. Sci. 2003, 38, 909–915.

- Benbettaïeb, N.; Debeaufort, F.; Karbowiak, T. Bioactive edible films for food applications: Mechanisms of antimicrobial and antioxidant activity. Crit. Rev. Food Sci. Nutr. 2019, 59, 3431–3455.

- Molaee Aghaee, E.; Kamkar, A.; Akhondzadeh Basti, A.; Khanjari, A.; Kontominas, M. Effect of packaging with Chitosan biodegradable films formulated with Garlic essential oil (Allium sativum L.) on the chemical properties of chicken fillet. Iran. J. Health Environ. 2015, 8, 379–390.

- Soukoulis, C.; Singh, P.; Macnaughtan, W.; Parmenter, C.; Fisk, I.D. Compositional and physicochemical factors governing the viability of Lactobacillus rhamnosus GG embedded in starch-protein based edible films. Food Hydrocoll. 2015, 52, 876–887.

- Escamilla-García, M.; Reyes-Basurto, A.; García-Almendárez, B.; Hernández-Hernández, E.; Calderón-Domínguez, G.; Rossi-Marquez, G.; Regalado-González, C. Modified Starch-Chitosan Edible Films: Physicochemical and Mechanical Characterization. Coatings 2017, 7, 224.

- Gomes, M.A.; Palmiro, D.; Ascheri, R.; Campos, A. Characterization of edible films of Swartziaburchelli phosphate starches and development of coatings for post-harvest application to cherry tomatoes. Semin. Ciências Agrárias 2016, 37, 1897–1910.

- Adjouman, Y.D.; Nindjin, C.; Tetchi, F.A.; Dalcq, A.C.; Amani, N.G.; Sindic, M. Water Vapor Permeability of Edible Films Based on Improved Cassava (Manihot esculenta Crantz) Native Starches. J. Food Process. Technol. 2017, 8, 665.

- Song, X.; Cheng, L.; Tan, L. Edible iron yam and maize starch convenient food flavoring packaging films with lemon essential oil as plasticization. Food Sci. Technol. 2019, 39, 971–979.

- He, X.; Deng, H.; Hwang, H.-M. The current application of nanotechnology in food and agriculture. J. Food Drug Anal. 2019, 27, 1–21.

- Singh, T.; Shukla, S.; Kumar, P.; Wahla, V.; Bajpai, V.K.; Rather, I.A. Application of nanotechnology in food science: Perception and overview. Front. Microbiol. 2017, 8, 1501.

- Gupta, A.; Eral, H.B.; Hatton, T.A.; Doyle, P.S. Nano emulsions: Formation, properties and applications. Soft Matter 2016, 12, 2826–2841.

- Roselli, M.; Finamore, A.; Garaguso, I.; Britti, M.S.; Mengheri, E. Zinc oxide protects cultured enterocytes from the damage induced by Escherichia coli. J. Nutr. 2003, 133, 4077–4082.

- Mohamadian, N.; Ghorbani, H.; Wood, D.A.; Khoshmardan, M.A. A hybrid nanocomposite of poly (styrene-methyl methacrylateacrylic acid)/clay as a novel rheology-improvement additive for drilling fluids. J. Polym. Res. 2019, 26, 33.

- Samadi, A.; Klingberg, H.; Jauffred, L.; Kjær, A.; Bendix, P.M.; Oddershede, L.B. Platinum nanoparticles: A non-toxic, effective and thermally stable alternative plasmonic material for cancer therapy and bioengineering. Nanoscale 2018, 10, 9097–9107.

- Kuswandi, B.; Moradi, M. Improvement of food packaging based on functional nanomaterial. In Nanotechnology: Applications in Energy, Drug and Food; Siddiquee, S., Melvin, G.J.H., Rahman, M.M., Eds.; Springer: Cham, Switzerland, 2019; pp. 309–344. ISBN 978-3-319-99602-8.

- Joye, I.J.; Davidov-Pardo, G.; McClements, D.J. Nanotechnology in food processing. In Encyclopedia of Food and Health; Caballero, B., Finglas, P.M., Toldrá, F., Eds.; Academic Press: Oxford, UK, 2016; pp. 49–55. ISBN 978-0-12-384953-3.

- Khare, S.; Williams, K.; Gokulan, K. Nanotechnology. In Encyclopedia of Food Microbiology, 2nd ed.; Batt, C.A., Tortorello, M.L., Eds.; Academic Press: Oxford, UK, 2014; pp. 893–900. ISBN 978-0-12-384733-1.

- Yoksan, R.; Chirachanchai, S. Silver nanoparticle-loaded chitosan-starch based films: Fabrication and evaluation of tensile, barrier and antimicrobial properties. Mater. Sci. Eng. C 2010, 30, 891–897.

- Brody, A.L. Case studies on nanotechnologies for food packaging. Food Technol. 2007, 61, 102–107.

- Flore, S.; Famá, L.; Rojas, A.M.; Goyanes, S.; Gerschenson, L. Physical properties of tapioca-starch edible films: Influence of filmmaking and potassium sorbate. Food Res. Int. 2007, 6, 257–265.

- Goudarzi VShahabi-Ghahfarrokhi, I.; Babaei-Ghazvini, A. Preparation of eco-friendly UV-protective food packaging material by starch/TiO2 bio-nanocomposite: Characterization. Int. J. Biol. Macromol. 2017, 95, 306–313.

- Wu, Z.; Huang, Y.; Xiao, L.; Lin, D.; Yang, Y.; Wang, H.; Yang, Y.; Wu, D.; Chen, H.; Zhang, Q.; et al. Physical properties and structural characterization of starch/polyvinyl alcohol/graphene oxide composite films. Int. J. Biol. Macromol. 2018, 123, 569–575.

- Aqlil, M.; Moussemba Nzenguet, A.; Essamlali, Y.; Snik, A.; Larzek, M.; Zahouily, M. Graphene oxide filled lignin/starch polymer bio nanocomposite: Structural, physical, and mechanical studies. J. Agric. Food Chem. 2017, 65, 10571–10581.

- Ribba, L.; Garcia, N.; Accorso, N.D.; Goyanes, S. Disadvantages of starch-based materials, feasible alternatives in order to overcome these limitation. In Starch-Based Materials in Food Packaging; Springer: Singapore, 2017; pp. 37–76, Chapter 3.

- Cao, T.L.; Song, K.B. Effects of gum karaya addition on the characteristics of loquat seed starch films containing oregano essential oil. Food Hydrocoll. 2019, 97, 105198.

- Do Evangelho, J.A.; da Silva Dannenberg, G.; Biduski, B.; El Halal, S.L.M.; Kringel, D.H.; Gularte, M.A.; Fiorentini, A.M.; da Rosa Zavareze, E. Antibacterial activity, optical, mechanical, and barrier properties of corn starch films containing orange essential oil. Carbohydr. Polym. 2019, 222, 114981.

- Kang, J.-H.; Song, K.B. Characterization of Job’s tears (Coix lachryma-jobi L.) starch films incorporated with clove bud essential oil and their antioxidant effects on pork belly during storage. LWT-Food Sci. Technol. 2019, 111, 711–718.

- Hasan, M.; Rusman, R.; Khaldun, I.; Ardana, L.; Mudatsir, M.; Fansuri, H. Active edible sugar palm starch-chitosan films carrying extra virgin olive oil: Barrier, thermo-mechanical, antioxidant, and antimicrobial properties. Int. J. Biol. Macromol. 2020, 163, 766–775.

- Domene-López, D.; Delgado-Marín, J.J.; Martin-Gullon, I.; García-Quesada, J.C.; Montalbán, M.G. Comparative study on properties of starch films obtained from potato, corn and wheat using 1-ethyl-3-methylimidazolium acetate as plasticizer. Int. J. Biol. Macromol. 2019, 135, 845–854.

- Sudheesh, C.; Sunooj, K.V.; Sasidharan, A.; Sabu, S.; Basheer, A.; M, M.N.; Raghavender, C.; Sinha, S.; George, J. Energetic neutral N2 atoms treatment on the kithul (Caryota urens) starch biodegradable film: Physico-chemical characterization. Food Hydrocoll. 2020, 103, 105650.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

6.0K

Entry Collection:

Organic Synthesis

Revisions:

4 times

(View History)

Update Date:

07 Apr 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No