Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Seyyed Masoud Kargar | + 3091 word(s) | 3091 | 2022-03-09 05:23:55 | | | |

| 2 | Amina Yu | + 29 word(s) | 3120 | 2022-03-18 02:28:37 | | | | |

| 3 | Amina Yu | Meta information modification | 3120 | 2022-03-21 04:33:42 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kargar, S.M. Atlas of Piezoelectric Energy Harvesters in Oceanic Applications. Encyclopedia. Available online: https://encyclopedia.pub/entry/20694 (accessed on 07 February 2026).

Kargar SM. Atlas of Piezoelectric Energy Harvesters in Oceanic Applications. Encyclopedia. Available at: https://encyclopedia.pub/entry/20694. Accessed February 07, 2026.

Kargar, Seyyed Masoud. "Atlas of Piezoelectric Energy Harvesters in Oceanic Applications" Encyclopedia, https://encyclopedia.pub/entry/20694 (accessed February 07, 2026).

Kargar, S.M. (2022, March 17). Atlas of Piezoelectric Energy Harvesters in Oceanic Applications. In Encyclopedia. https://encyclopedia.pub/entry/20694

Kargar, Seyyed Masoud. "Atlas of Piezoelectric Energy Harvesters in Oceanic Applications." Encyclopedia. Web. 17 March, 2022.

Copy Citation

Piezoelectric energy harvesters provide many different application scenarios by having flexibility in their structures, coupling modes, sizes and so on.

piezoelectric

energy harvesting

ocean

energy conversion

atlas

1. Oceanic Piezoelectric Energy Harvesters

1.1. Piezoelectricity

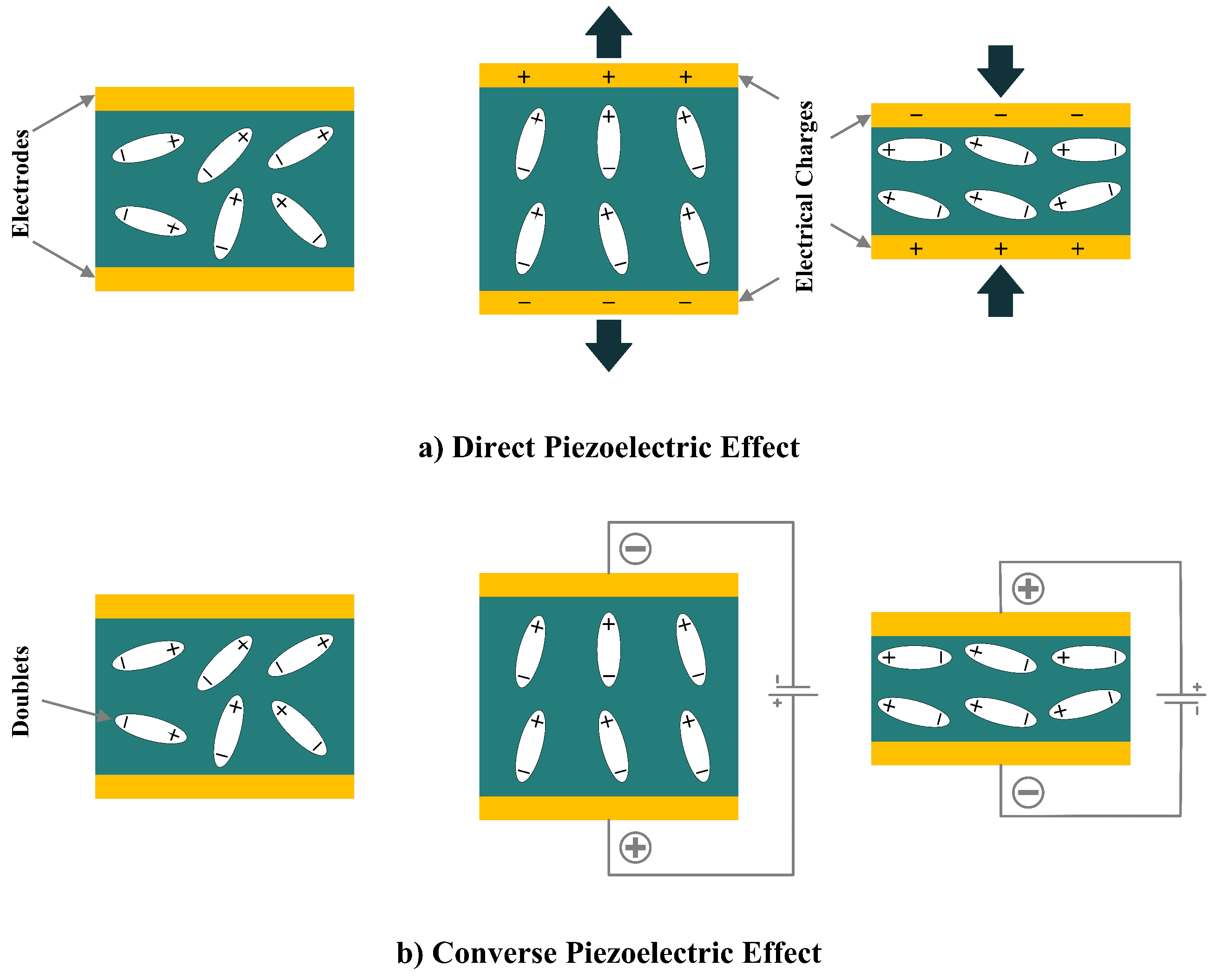

In 1880, the term piezoelectricity was introduced by brothers Pierre and Jacques Curie [1], which has been intensively studied in recent years for different sensory and actuation applications in different fields. Later, in 1881, the brothers Curie validated their work on the inverse piezoelectric effect with experiments [2]. Stressing a piezoelectric material would result in a change in its atomic configuration, which forms dipole moments. This phenomenon is called the direct piezoelectric effect, in which the piezoelectric material generates electricity as a reaction to the applied force. Therefore, if a periodic force (tension or compression) is applied to the material, an alternative current (AC) voltage will be the output. On the other hand, if the piezoelectric material is electrically polarized, the converse piezoelectric effect appears in which the piezoelectric material extends/contracts as a result of the applied electrical voltage. It should be noted that in the inverse piezoelectric effect, lengthening or shortening of the piezoelectric material depends on the polarity and the applied poling voltage and can be reversed if the voltage direction is reversed [3]. Both the direct and converse effects of piezoelectricity are shown in Figure 1.

Figure 1. Piezoelectric Effect; (a) Direct Piezoelectric Effect; (b) Converse Piezoelectric Effect.

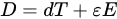

There are many diverse applications for both direct and inverse piezoelectric effects, where the direct effect is utilized in the case of sensors and energy harvesters, and the inverse effect is used in actuators. These effects are governed by piezoelectric constitutive equations as [4]:

where D, d, T, E, X, and s, represent electrical displacement, piezoelectric coefficient, stress, the permittivity of the material, electric field, strain, and mechanical compliance, respectively.

1.2. Piezoelectric Materials

Active materials that can generate electricity as a reaction to small mechanical stress are called piezoelectric materials. The type of material for energy harvesting applications is of high importance to the performance and functionality of the harvester. Researchers have investigated numerous types of materials, such as organic, inorganic, composite, and bio-inspired materials, for piezoelectric energy harvesters [4]. Among them, PZT and PVDF are the most widely used materials for energy harvesting in oceanic applications. PZT, which is also known as Lead Zirconate Titanate, is a polled ferroelectric ceramic with the highest frequency of applications in piezoelectric energy harvesters. Even though the PZT is one of the major materials in energy harvesting, its drawbacks, such as its drastic brittle nature and fatigue growth possibility in high-frequency loadings, limited its widespread usage in energy harvesting. On the other hand, to overcome the demerits of PZT, PVDF, also known as polyvinylidene fluoride, is developed to improve the efficiency of piezoelectric energy harvesters [5]. Although PZT can produce more electricity when subjected to the same stress as PVDF, unlike PVDF, it cannot bear high stress. PVDF shows a higher tensile strength value, which is about 2.6 times higher than PZT’s strength value [3]. The low stiffness, large tensile strength, and high flexibility of PVDF make it a unique choice for many applications, specifically in ocean energy harvesters. Apart from PZT and PVDF, macro-fiber composites (MFC) are also used in some of the literature in ocean applications, which show great performance in energy harvesting from the ocean.

1.3. Coupling Modes

Piezoelectric materials present a kind of flexibility in their configurations, which makes them unique in energy harvesting applications. Based on the desired configuration in a particular application, piezoelectric materials’ configurations can be altered by changing their electrode pattern, poling direction, and strain direction. Moreover, to tune the resonant frequency between the material and the energy source, volume and layers can be changed, and a pre-load force can be added [6].

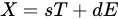

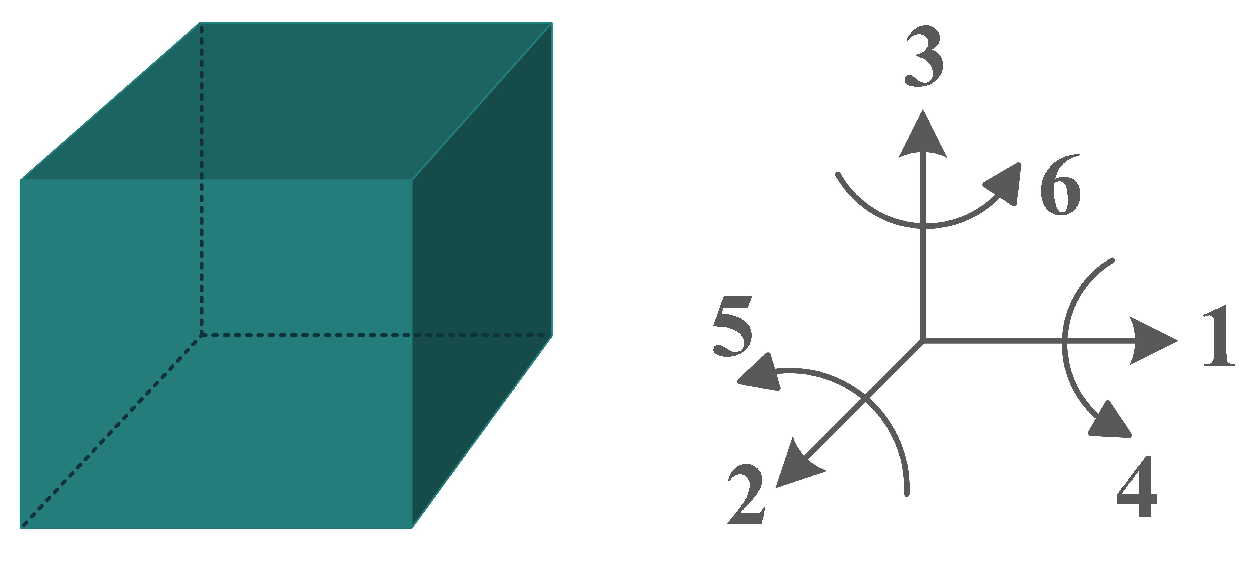

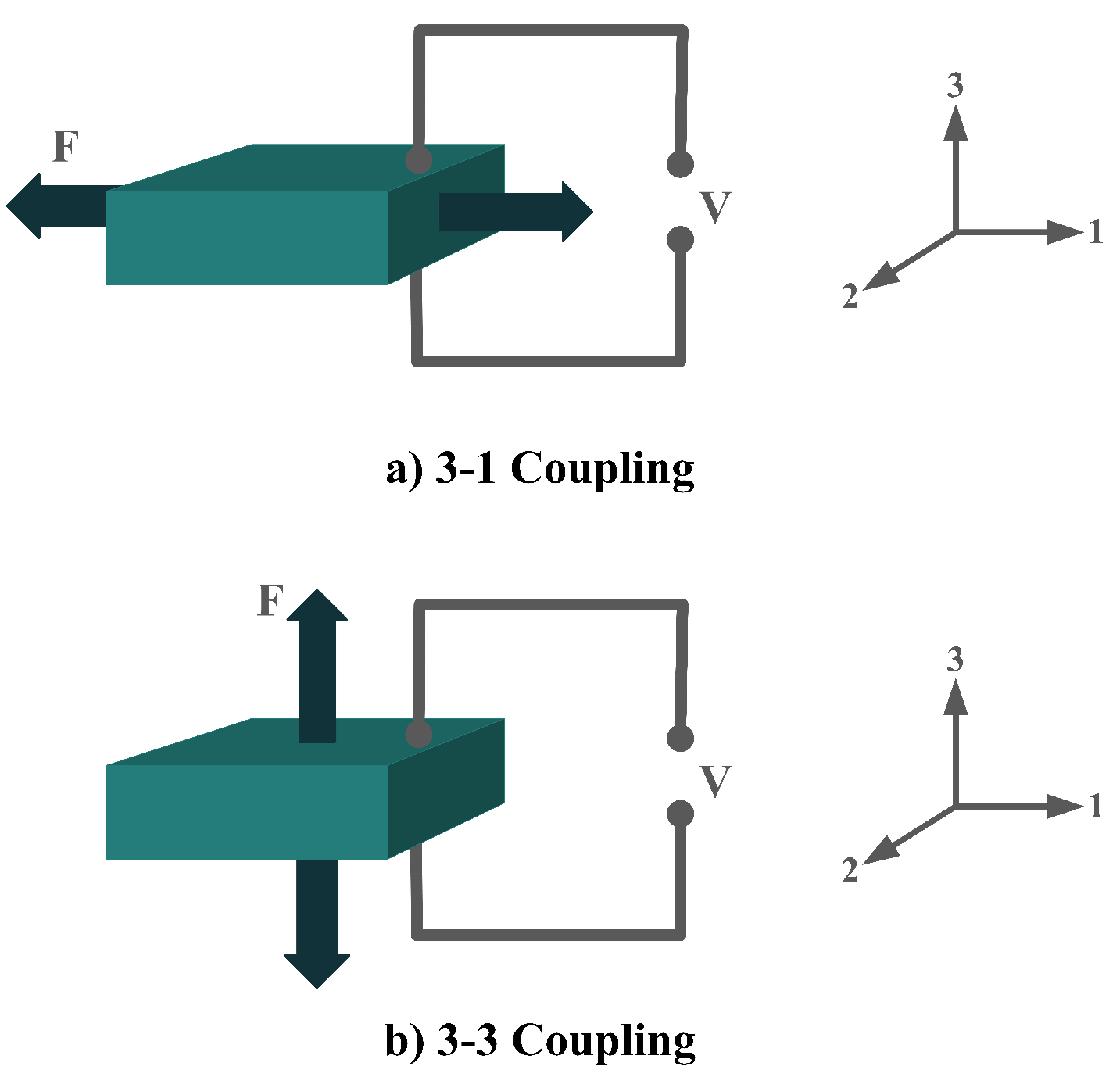

The piezoelectric coefficient (dij) is the ratio of the strain to the electric field, where i denotes the direction of the polarity and j represents the mechanical stress direction. Figure 2 shows piezoelectric material axes for polarization, as well as stress/strain. According to [7], d14, d15, d33, and d31, or simply 1-4, 1-5, 3-3, and 3-1, respectively, are the piezoelectric energy harvesters’ configurations in oceanic applications. However, due to the complex configurations of 1-4 and 1-5 modes, they are less used in oceanic applications compared to 3-3 and 3-1 modes. Figure 3 shows the most utilized configurations, 3-3 and 3-1, in ocean applications. In the 3-3 mode, both the polarity and the mechanical stress are in the same direction, parallel to each other. However, in the case of 3-1, the direction of the mechanical stress is perpendicular to that of polarity [8]. It should also be noted that choosing the right configuration for designing a high-performance piezoelectric energy harvester plays a crucial role and thus should be carefully considered based on the design requirements.

Figure 2. Polarization axes of piezoelectric materials.

Figure 3. Piezoelectric Coupling Modes; (a) 3-1 Coupling Mode; (b) 3-3 Coupling Mode.

1.4. Classification Based on Device Structure

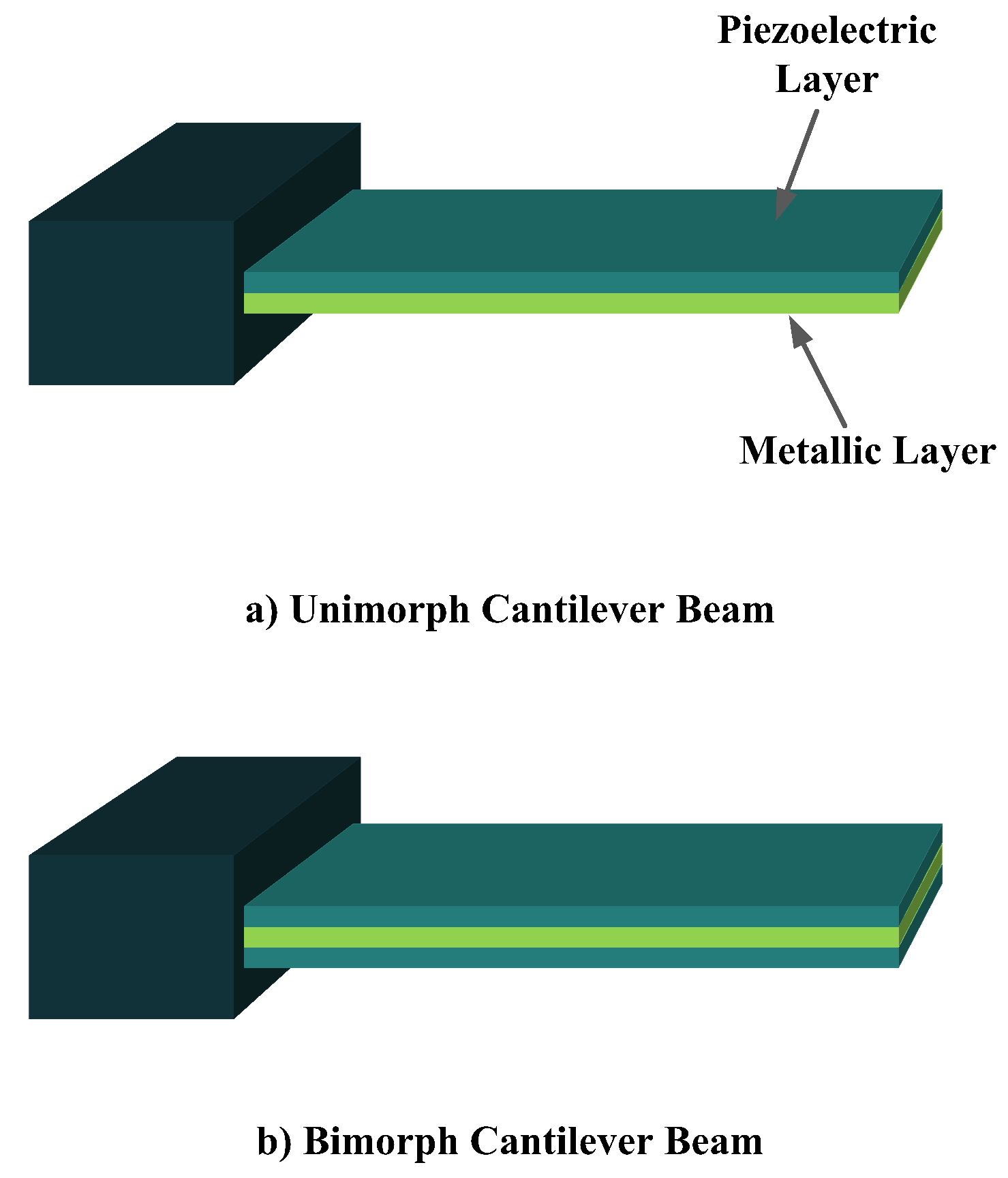

The most common structure for a piezoelectric energy harvesting device is the cantilever beam configuration. This type of harvester employs one or two piezoelectric layers and is called unimorph and bimorph, respectively. Figure 4 shows cantilever beam structures with one and two layers of piezoelectric materials. As can be seen in Figure 4, piezoelectric layers are mostly bonded to a metallic non-piezoelectric material that is fixed at one end and acts as a flexural structure. As it is clear, taking advantage of two layers of piezoelectric materials, bimorph-type cantilever beams are capable of generating more output power compared to unimorph configurations. Therefore, bimorph configurations are of the high frequency of applications in piezoelectric energy harvesters [9][10].

Figure 4. Cantilever Beam Configuration; (a) Unimorph; (b) Bimorph.

Cantilever beam configuration utilizes the 3-1 coupling mode most often. However, there are designs in the literature that have used 3-3 coupling modes for cantilever structures, making use of interdigitated electrode designs. Moreover, it is usual to add a proof mass at the free end of the cantilever beam to tune the resonant frequency of the harvester with the environment [4].

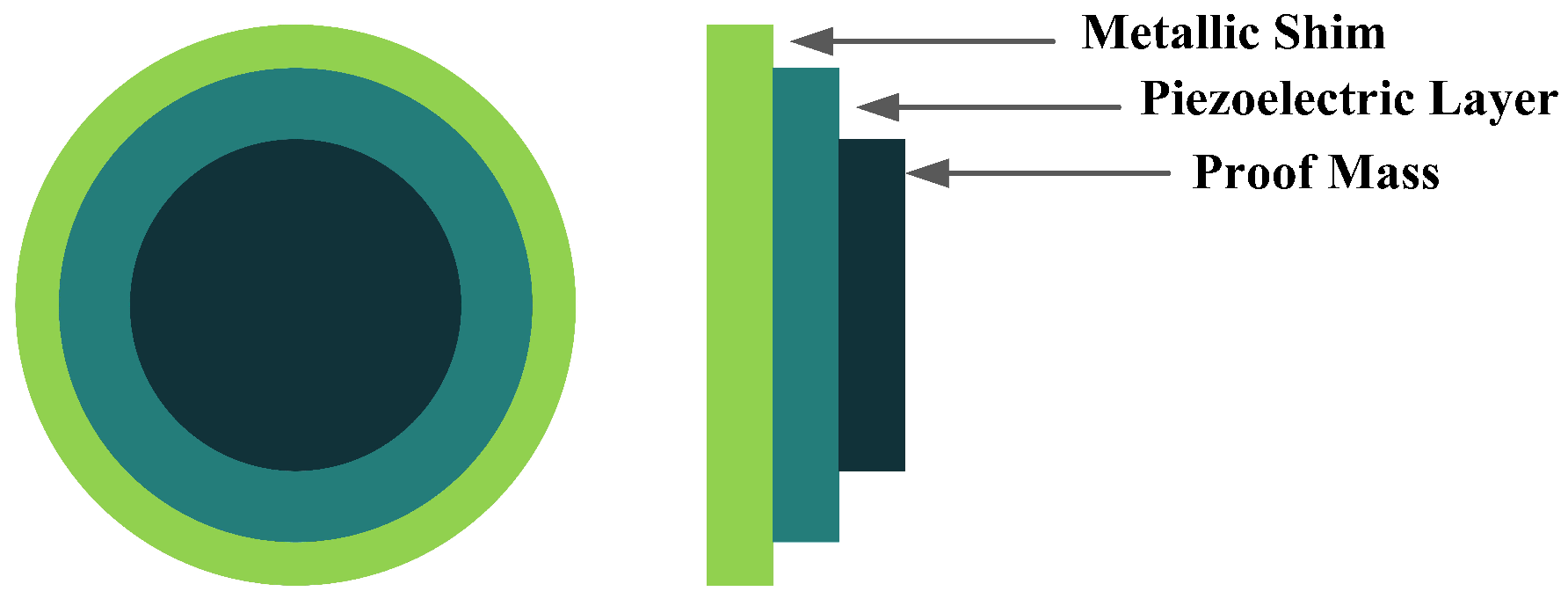

The other configuration, which consists of a piezoelectric layer with a mostly disk shape, is the diaphragm structure. The piezoelectric layer is bonded to a metal shim. In some configurations, to improve functionality under low frequencies and to add a pre-loading unit to the energy harvester, a proof mass is attached to the diaphragm’s core (Figure 5) [11].

Figure 5. Diaphragm Configuration.

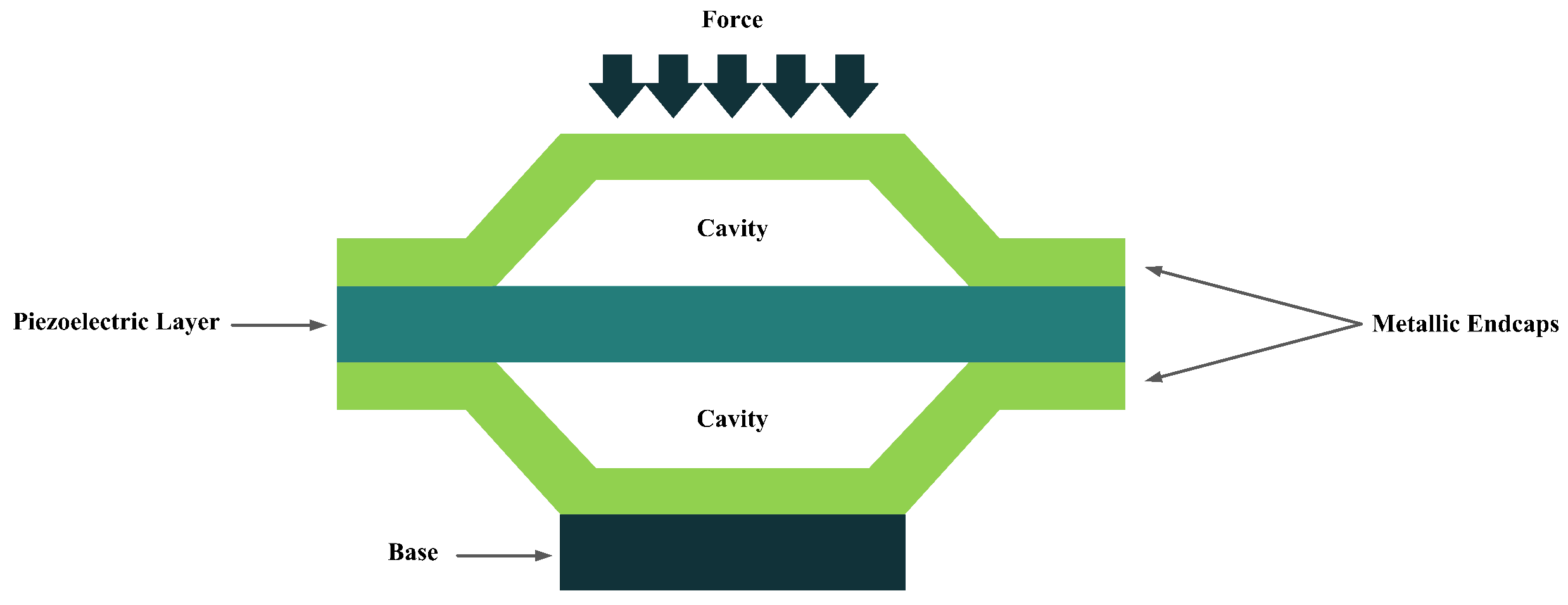

Adding two metallic endcaps in the shape of a cymbal on both sides of a piezoelectric disk would result in a new configuration called the cymbal structure (Figure 6). This configuration is indeed used to improve piezoelectric endurance when it is subjected to higher loads and impact forces. Moreover, the cymbal shape of the endcaps acts as a mechanical amplification unit due to the presence of the cavity in the center [11].

Figure 6. Cymbal Configuration.

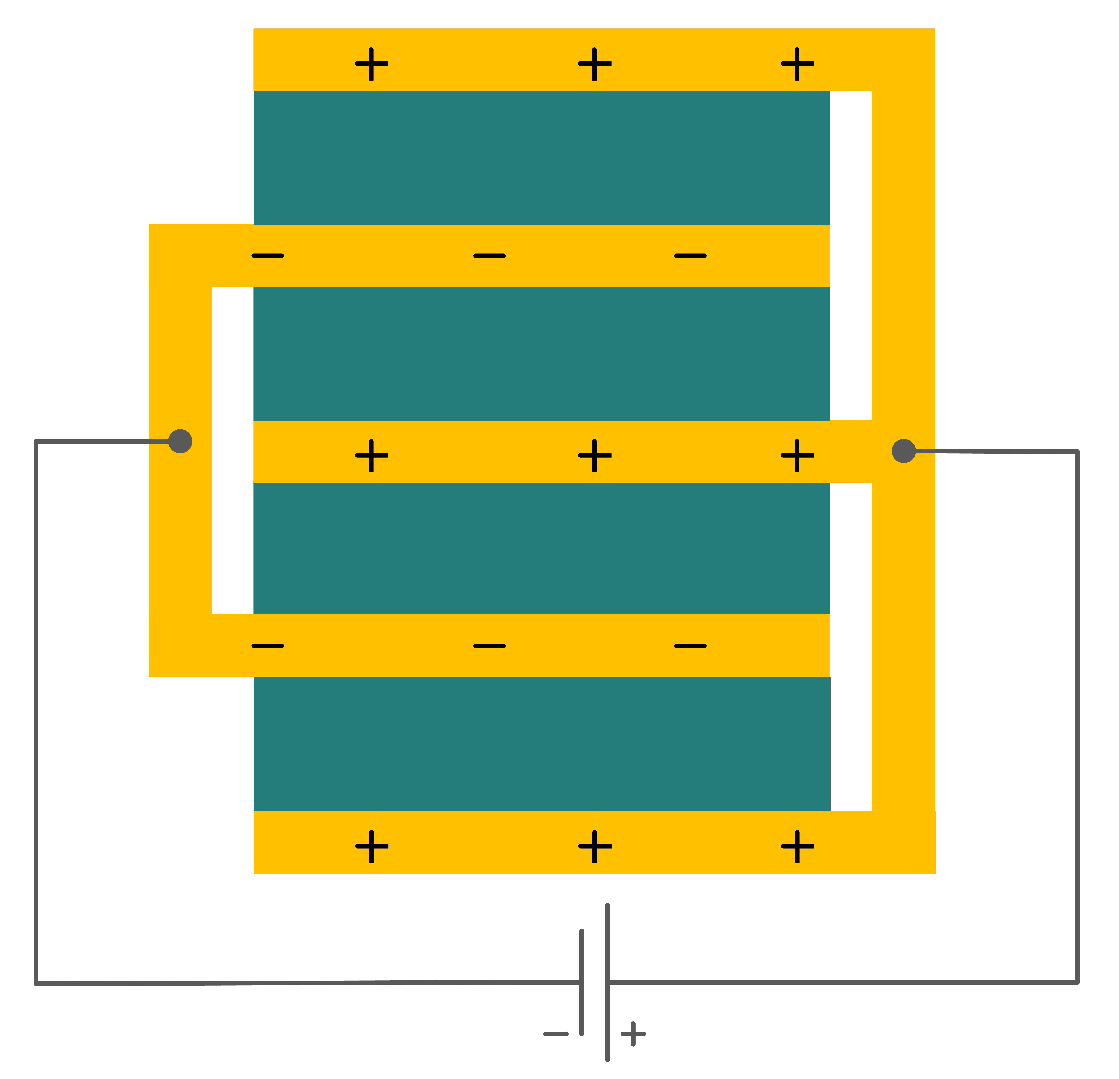

In addition to the other configurations, stacked piezoelectric structures can bear higher pressures. This configuration is made up of multiple layers of piezoelectric material stacked on top of each other. The poling direction of this type should be aligned with the applied force direction, as shown in Figure 7 [10].

Figure 7. Stacked Configuration.

All the aforementioned configurations have their own merits and drawbacks. Each of them may be suitable for numerous applications and unsuitable for many others. Therefore, before employing one of them in an application, their limitations should be carefully studied and considered. In addition to the cantilever beam configuration’s advantages, such as simple structure, low price, suitability for low-frequency applications, and higher mechanical quality factor, they are not able to withstand high impact forces. On the other hand, the cymbal configuration can bear impact forces and provide high energy output. However, the loss of mechanical input energy and being limited to applications requiring high vibration sources are its drawbacks. The circular diaphragm configuration is capable of working in pressure mode operations, but in a vibration mode application, it requires higher resonance frequencies. The stacked configuration is also suitable for working in pressure mode. It can also bear higher mechanical forces and provide higher outputs in the d33 coupling mode. Nevertheless, its high stiffness is among the challenges that should be addressed in the search for a proper application for it [11].

1.5. Power Harvesting System

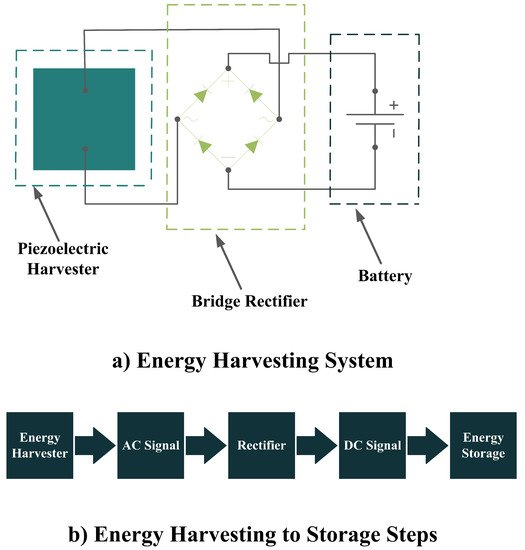

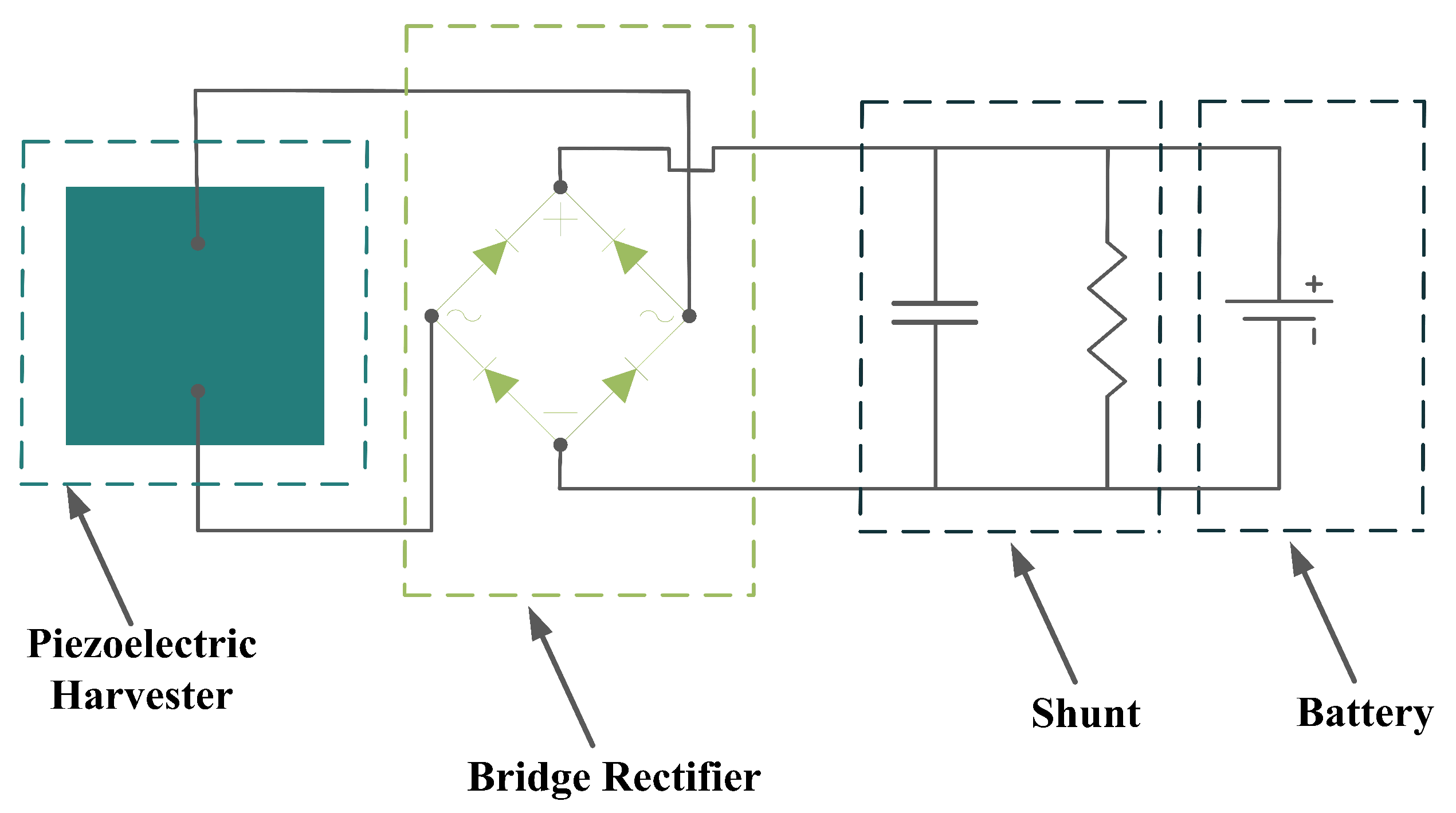

The generated electricity by the piezoelectric energy harvesters needs to be further processed before any collection or storage in a power storage system. However, it should be taken into consideration that power storage systems, such as batteries, require direct current (DC) rather than alternative current (AC). If the piezoelectric harvester acts as a resonator, then the resultant voltage would be a sinusoidal signal, which should be rectified for any further applications. To carry out this operation, an intermediate step needs to be implemented to convert AC signals to DC. To do so, either the Standard Technique or the Synchronized Switch Harvesting on Inductor Technique can be employed [12][13]. By eliminating the ripple voltage, these techniques would smooth out the DC signal, and after regulation by the control system, the signal is ready to be stored in a power storage system. Figure 8 provides an illustration of the power harvesting operation by piezoelectric materials to further simplify the understanding of the process.

Figure 8. Power Harvesting Operation; (a) Energy Harvesting System; (b) Energy Harvesting to Storage Steps.

In addition to the circuit shown in Figure 8, there should be an impedance-matching system in between to guarantee the high performance of the piezoelectric energy harvesters. Matching the electrical parameters with the source, cable, or receiver is of high importance for any electrical transmission line that is involved in the transfer of an electrical signal or power. Therefore, the impedance matching of the electrical parameters should be carefully considered in the design stage of the piezoelectric energy harvesters [14]. According to [14], matching of both acoustic and electrical components in a design should be considered for impedance matching. However, in the case of piezoelectric energy harvesters, the impedance matching of electrical components is more important. Piezoelectric energy harvesters are narrow-banded intrinsically, but a broadband operation is required for energy harvesting, in which acoustic impedance matching is employed to improve the narrow-band operation. However, it increases the electrical impedance and leads to an impedance mismatch between the harvester and the interface device. This mismatch diminishes the electric energy and requires an electrical impedance matching unit to be minimized. To do so, a shunt circuit [15], which is the simplest one for this purpose, can be employed to maximize the output electrical energy (Figure 9). One can refer to [14][15][16][17] for more information regarding the impedance matching of piezoelectric energy harvesters.

Figure 9. Energy Harvesting System with an Impedance Matching Unit (Shunt).

1.6. Ocean Energy Sources for Piezoelectric Energy Harvesters

Marine renewable energies are the source of many different energy converters [18][19]. In the case of piezoelectric energy harvesters, water current, wave motion, and wave impact forces have been employed to extract energy from the ocean and convert it to usable electrical energy to power sensors and some other measurement devices [3]. These sources are very promising and available at all times during the day. Moreover, these energy sources in marine environments have a high density compared to the other sources of renewable energies, such as wind or solar energies [20]. In the following, a short introduction will be given to each of the marine energy sources that piezoelectric energy harvesters are designed for.

1.6.1. Water Currents

To employ piezoelectric energy harvesters to extract power from ocean water currents, the vibration in the water can be converted to electricity. To do so, the piezoelectric energy harvester should be placed in the current stream and be coupled with flow-induced vibration. Vortex-Induced Vibrations (VIV) and Self-Excited Vibrations (SEV) are the two significant flow-induced vibrations that are exploited by piezoelectric energy harvesters [21][22].

To create VIV, a bluff body is located in a water stream, and depending on the characteristics of the bluff body, vortices of a particular size and frequency appear. If, then, the piezoelectric energy harvester is placed behind the body, the generated vortices make it oscillate. This oscillation will generate electricity based on the piezoelectric principle [21].

Through the use of self-excitation of flexible bodies, here most often PVDF materials, SEV-based energy harvesting can be achieved. The bodies are placed in the flow stream and, by a minute increase in flow speed, the body attains self-excitation, which can be further used for electrical energy generation [22].

1.6.2. Wave Motion

Waves in the oceans are generated by the association of forces, such as wind, atmospheric pressure gradients, earthquakes, gravitational attraction, and storms. Moreover, these waves need to be restored using mechanisms such as surface tension, gravity, and Coriolis force. Based on their periods, waves can be classified into seven groups: (1) Capillary waves; (2) Ultra-gravity waves; (3) Gravity waves; (4) Infra-gravity waves; (5) Long-period waves; (6) Ordinary tidal waves; and (7) Trans-tidal waves [23].

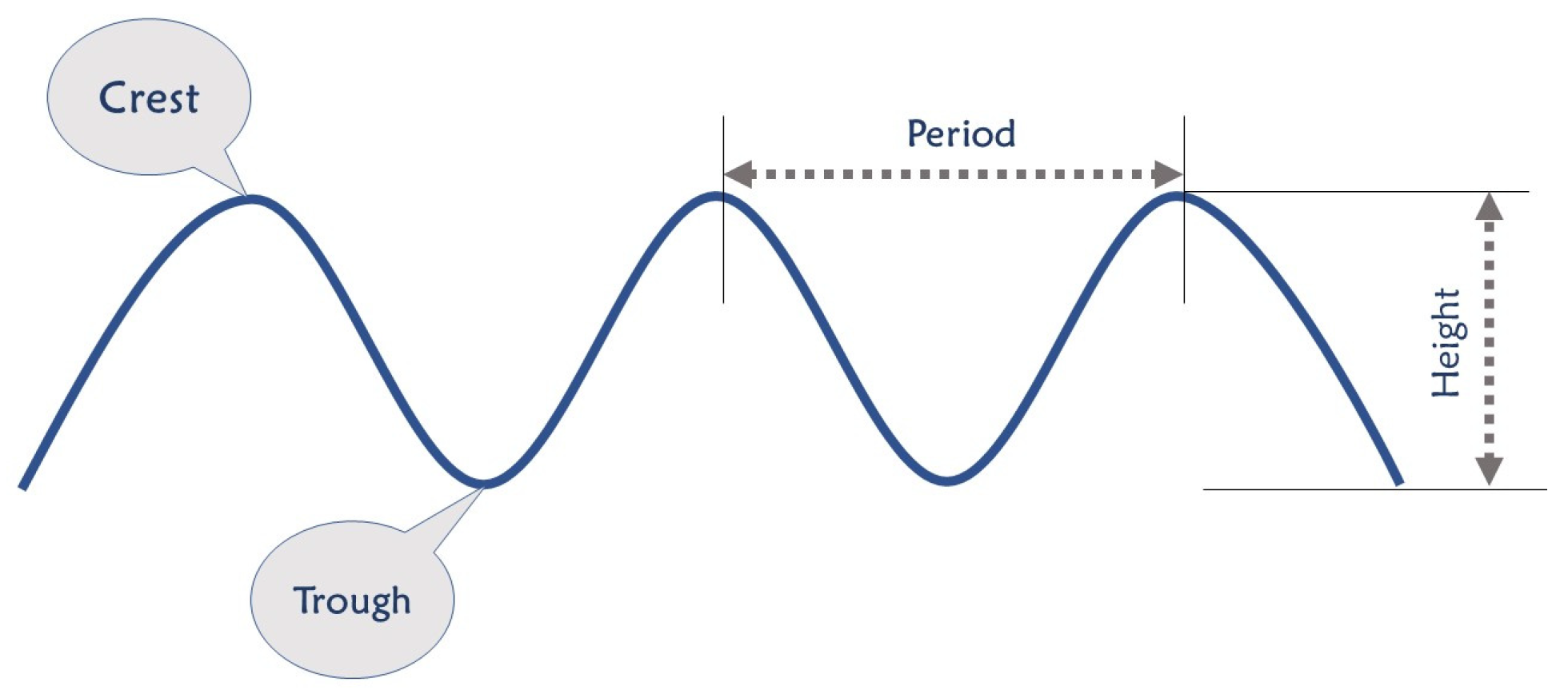

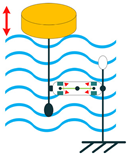

There are two main factors in determining how much energy a wave holds (Figure 10): wave height and the wave’s period [24], meaning the time taken for a wave crest to travel the distance between two wave crests. Waves with a greater height and shorter periods contain more energy. However, unlike water currents where the energy is distributed all along, the waves’ energy density diminishes by the depth and is concentrated near the surface of the ocean. Therefore, the facilities’ tip that captures the wave’s energy should be close to the surface of the ocean [25]. According to [3][26], piezoelectric energy harvesters from wave motion mainly consist of heaving and pitching bodies, the PVDF layer on the surface of the ocean, and fixed bodies on the ocean bottom.

Figure 10. Characteristics of an Oceanic Wave.

1.6.3. Wave Impact

Another feature of the ocean is the impact of the waves on the ocean structure [26]. Mostly, wave impacts are considered destructive forces. However, these waves’ forces on the structures can be advantageous rather than being devastating. In the case that the piezoelectric energy harvesters are placed on the surfaces that are subjected to waves’ impact, they can convert the applied pressure to electricity [3].

1.7. Location

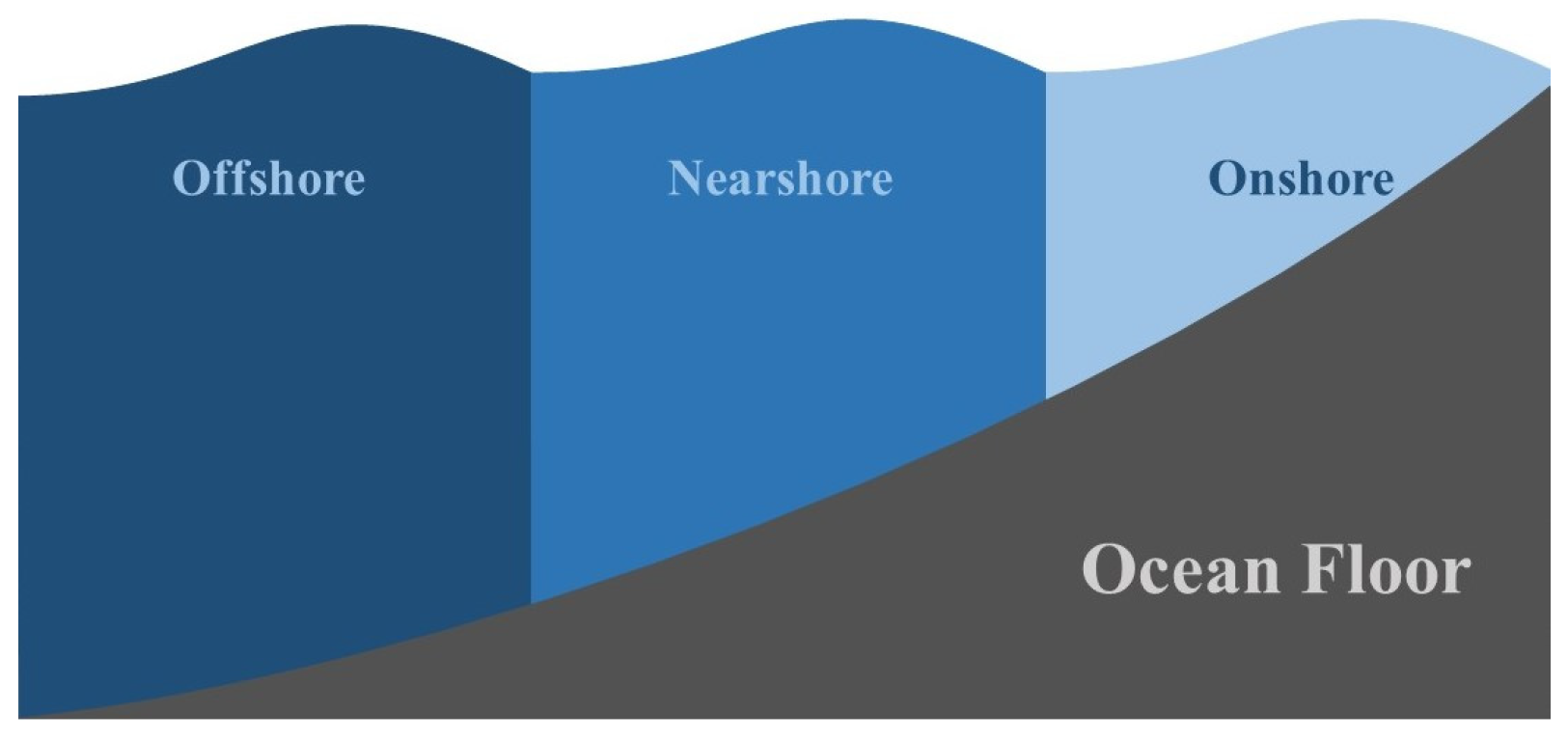

Based on where the marine facilities are working, they can be categorized into three groups; onshore; nearshore; and offshore. Onshore represents regions with 10–15 m water depth, where this value is 15–25 m for nearshore, and is higher than 50 m for offshore. Figure 11 shows the different regions in the ocean [27].

Figure 11. Ocean Regions.

2. The ATLAS

The following comprehensive atlas of 84 designs contains information on the utilized piezoelectric materials, piezoelectric coupling modes, location, power range, energy source, and a schematic of the piezoelectric energy harvesters design in oceanic engineering. It should be noted that all the information is collected exactly from the related references without any judgments and changes. The atlas includes just the information that the research articles provided, and in the cases where there is no information in any of the atlas’s sections, the related unit is free of information. Moreover, the atlas only includes designs for which they have at least provided a simulation or fabricated and tested a prototype. The schematics are sketched in a way to help future designers simply understand the working principles of the state-of-the-art. Table 1 shows the meaning of different colors in the schematics to fully understand the concepts. Table 2, Table 3 show the atlases of cantilever beam-based, diaphragm-based, stacked-based, and cymbal-based designs, respectively. Table 1 shows the meaning of different colors in the schematics to fully understand the concepts. Table 2, Table 3 show the atlases of cantilever beam-based, diaphragm-based, stacked-based, and cymbal-based designs, respectively.

Table 1. Meaning of each color in the atlas.

| Color | Meaning |

|---|---|

|

Buoy |

|

Magnet |

|

Piezoelectric Layer |

|

Water |

| The Other Colors | Non-Piezoelectric Material |

Table 2. Atlas of cantilever beam-based piezoelectric energy harvesters.

| Year and Reference | Material | Coupling Mode | Location | Power Density (W/m3) | Energy Source | Schematics |

|---|---|---|---|---|---|---|

| 1987 [28] | PVDF | 3-1 | Onshore | - | Wave Motion |  |

| 1987 [29] | PVDF | 3-3 | - | - | Wave Motion |  |

| 2001 [30] | PVDF | 3-1 | - | - | Water Current |  |

| 2004 [31] | PVDF | 3-1 | - | - | Water Current |  |

| 2004 [31] | PZT | 3-1 | - | 70.00 | Water Current |  |

| 2007 [32] | PVDF | 3-1 | Onshore | - | Water Current |  |

| 2009 [33] | - | - | Offshore | 1.64 | Wave Motion |  |

| 2010 [34] | PVDF | 3-3 | Offshore | 15.00 | Water Current |  |

| 2011 [35] | PVDF | - | Offshore | 4.00 × 10−3 | Water Current |  |

| 2012 [36][37] | PVDF | - | Offshore | 0.42 | Wave Motion- Water Current |  |

| 2012 [38] | - | - | - | 1.56 × 10−4 | Water Current |  |

| 2012 [39] | PZT | 3-1 | Onshore | 0.17 | Wave Motion |  |

| 2013 [40] | PZT | 3-3 | - | 0.84 | Water Current |  |

| 2013 [41] | PZT | - | - | 366.00 | Wave Motion |  |

| 2014 [42] | PZT | - | Offshore | 75.00 | Wave Motion |  |

| 2014 [43] | PZT | 3-3 | - | 4.74 | Wave Motion |  |

| 2014 [44] | PVDF | 3-1 | - | - | Water Current |  |

| 2015 [45] | MFC | 3-1 | - | 1.16 × 10−2 | Water Current |  |

| 2015 [46] | PZT | 3-1 | - | 2.24 × 10−2 | Water Current |  |

| 2015 [47] | PZT | - | - | - | Water Current |  |

| 2015 [48] | PVDF | - | - | - | Water Current |  |

| 2015 [49] | PVDF | 3-1 | - | 1.65 × 10−4 | Water Current |  |

| 2015 [50] | PZT | - | Near/Offshore | 1.27 | Wave Motion |  |

| 2015 [51] | - | - | Nearshore | 3.50 × 10−10 | Wave Motion |  |

| 2015 [52] | MFC | - | - | 6.10 × 10−3 | Water Current |  |

| 2016 [53] | PZT | 3-1 | - | 17.31 | Water Current |  |

| 2016 [54] | PZT | 3-3 | Near/Offshore | 206.00 | Wave Motion |  |

| 2016 [55] | PVDF | - | - | 0.58 | Water Current |  |

| 2016 [55] | PZT | - | - | 0.58 | Water Current |  |

| 2016 [56] | PVDF | 3-1 | Near/Offshore | - | Wave Motion |  |

| 2017 [57] | PVDF | 3-1 | Near/Offshore | 2.60 × 10−12 | Water Current |  |

| 2017 [58] | PZT | - | - | 1.40 | Water Current |  |

| 2017 [59] | PZT | - | - | 1.59 × 104 | Wave Motion |  |

| 2017 [60] | PZT | - | - | 143.54 | Wave Motion |  |

| 2017 [61] | PZT | 3-3 | On/Near/Offshore | 260.00 | Wave Motion |  |

| 2017 [62][63] | PZT | 3-1 | - | 3.50 × 10−8 | Water Current |  |

| 2018 [64] | PZT | 3-1 | - | - | Wave Motion |  |

| 2018 [65] | PZT | - | Offshore | 10.34 × 103 | Wave Motion |  |

| 2018 [66] | - | 3-3 | - | 2.40 × 103 | Wave Motion |  |

| 2018 [67] | MFC | 3-1 | - | - | Water Current |  |

| 2018 [68] | - | - | - | 2.56 | Water Current |  |

| 2019 [69] | - | - | - | - | Wave Motion |  |

| 2019 [70] | PZT | 3-3 & 1-5 | - | 0.14 | Water Current |  |

| 2019 [71] | PZT | 3-3 | Offshore | 477.00 | Wave Motion |  |

| 2019 [72] | PZT | 3-1 | - | - | - |  |

| 2019 [73] | PZT | - | Nearshore | 1.06 × 104 | Wave Motion |  |

| 2019 [74] | - | 3-1 | Onshore | - | Wave Impact |  |

| 2019 [75] | PVDF | 3-1 | Offshore | 2.00 × 10−7 | Wave Motion |  |

| 2019 [76] | - | - | - | - | Water Current |  |

| 2019 [77] | MFC | - | - | 7.58 × 10−9 | Water Current |  |

| 2019 [78] | MFC | - | - | - | Water Current |  |

| 2019 [79] | PZT | - | - | - | Water Current |  |

| 2019 [80] | PZT | - | Offshore | 140.00 | Wave Motion |  |

| 2020 [81] | PVDF | - | - | - | Water Current |  |

| 2020 [82] | PZT | 3-1 | - | 7.34 × 10−2 | Water Current |  |

| 2020 [83] | MFC | - | - | - | Water Current |  |

| 2020 [84] | PZT | - | - | - | Wave Motion |  |

| 2020 [85] | PVDF | - | - | - | Water Current |  |

| 2020 [86] | PZT | - | - | 5.74 × 10−8 | Water Current |  |

| 2021 [87] | - | - | - | 12.90 | Wave Motion |  |

| 2021 [88] | PZT | - | - | 8.42 × 10−4 | Water Current |  |

| 2021 [89] | PZT/PVDF | - | Near/Offshore | 10.50 × 102 | Wave Motion |  |

| 2021 [90] | MFC | 3-1 | - | 10.74 × 102 | Water Current |  |

| 2021 [91] | PVDF | 3-1 | - | - | Wave Motion |  |

| 2021 [92] | PZT | - | - | 3.58 × 10−2 | Water Current |  |

| 2021 [93] | - | - | - | 3.20 × 10−3 | Wave Motion |  |

| 2021 [94] | PZT | - | - | 1.63 | Wave Motion |  |

| 2021 [95] | - | - | - | - | Wave Motion |  |

| 2021 [96] | PZT/MFC | - | - | 62.00 × 103 | Wave Motion |  |

| 2021 [97] | PZT | - | Offshore | - | Wave Motion |  |

| 2021 [98] | PZT | - | - | - | Wave Motion |  |

| 2021 [99] | - | - | Nearshore | - | Wave Motion |  |

| 2021 [100] | MFC | 3-3 | - | 8.50 × 10−3 | Wave Motion |  |

Table 3. Atlas of diaphragm-based piezoelectric energy harvesters.

| Year and Reference | Material | Coupling Mode | Location | Power Density (W/m3) | Energy Source | Schematics |

|---|---|---|---|---|---|---|

| 2010 [101] | PVDF | 3-1 | - | 1.90 × 10−2 | Water Current |  |

| 2011 [102] | PZT | 1-5 | - | 7.25 × 10−5 | Water Current |  |

| 2013 [103] | PZT | - | Offshore | 0.34 | Water Current |  |

| 2013 [104] | PZT | - | Offshore | - | Wave Motion |  |

| 2013 [105] | PZT | - | Offshore | - | Wave Motion |  |

| 2018 [106] | PZT | 3-3 | - | - | Water Current |  |

| 2019 [107] | PVDF | - | - | 5.68 × 10−2 | Wave Motion |  |

Table 4. Atlas of stacked-based piezoelectric energy harvesters.

| Year and Reference | Material | Coupling Mode | Location | Power Density (W/m3) | Energy Source | Schematics |

|---|---|---|---|---|---|---|

| 2013 [50] | PVDF | 3-3 | - | - | Wave Impact |  |

| 2017 [108] | PZT | - | Offshore | 600.00 | Wave Impact |  |

| 2021 [109] | PZT | - | - | - | Wave Motion |  |

Table 5. Atlas of cymbal-based piezoelectric energy harvesters.

References

- Athanassoulis, G.A.; Mamis, K.I. Modeling and analysis of a cliff-mounted piezoelectric sea-wave energy absorption system. Coupled Syst. Mech. 2013, 2, 53–83.

- Zhang, B.; Ducharne, B.; Gupta, B.; Sebald, G.; Guyomar, D.; Gao, J. Experimental sea wave energy extractor based on piezoelectric Ericsson cycles. J. Intell. Mater. Syst. Struct. 2017, 29, 1102–1112.

- Chen, S.-E.; Yang, R.-Y.; Wu, G.-K.; Wu, C.-C. A Piezoelectric Wave-Energy Converter Equipped with a Geared-Linkage-Based Frequency Up-Conversion Mechanism. Sensors 2021, 21, 204.

- Bezanson, L.; Thornton, J.; Konchuba, N.; Priya, S. Utilizing deep ocean currents to power extended duration sensors. In Proceedings of the OCEANS 2010 MTS/IEEE SEATTLE, Seattle, WA, USA, 20–23 September 2010; pp. 1–8.

- Zou, H.-X.; Li, M.; Zhao, L.-C.; Gao, Q.-H.; Wei, K.-X.; Zuo, L.; Qian, F.; Zhang, W.-M. A magnetically coupled bistable piezoelectric harvester for underwater energy harvesting. Energy 2021, 217, 119429.

- Kim, H.-M. Electroactive polymers for ocean kinetic energy harvesting: Literature review and research needs. J. Ocean Eng. Mar. Energy 2018, 4, 343–365.

- Kiran, M.R.; Farrok, O.; Abdullah-Al-Mamun, M.; Islam, M.R.; Xu, W. Progress in Piezoelectric Material Based Oceanic Wave Energy Conversion Technology. IEEE Access 2020, 8, 146428–146449.

- Liu, H.; Zhong, J.; Lee, C.; Lee, S.-W.; Lin, L. A comprehensive review on piezoelectric energy harvesting technology: Materials, mechanisms, and applications. Appl. Phys. Rev. 2018, 5, 041306.

- Aabid, A.; Raheman, M.A.; Ibrahim, Y.E.; Anjum, A.; Hrairi, M.; Parveez, B.; Parveen, N.; Mohammed Zayan, J. A Systematic Review of Piezoelectric Materials and Energy Harvesters for Industrial Applications. Sensors 2021, 21, 4145.

- Covaci, C.; Gontean, A. Piezoelectric Energy Harvesting Solutions: A Review. Sensors 2020, 20, 3512.

- Mishra, S.; Unnikrishnan, L.; Nayak, S.K.; Mohanty, S. Advances in Piezoelectric Polymer Composites for Energy Harvesting Applications: A Systematic Review. Macromol. Mater. Eng. 2019, 304, 1800463.

- Guyomar, D.; Badel, A.; Lefeuvre, E.; Richard, C. Toward energy harvesting using active materials and conversion improvement by nonlinear processing. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2005, 52, 584–595.

- Shu, Y.C.; Lien, I.C. A comparison between the standard and SSHI interfaces used in piezoelectric power harvesting. In Active & Passive Smart Structures and Integrated Systems; International Society of Photo Optical: Bellingham, WA, USA, 2007; Volume 6525, p. 652509.

- Rathod, V.T. A Review of Electric Impedance Matching Techniques for Piezoelectric Sensors, Actuators and Transducers. Electronics 2019, 8, 169.

- Liang, J.; Liao, W.H. Impedance matching for improving piezoelectric energy harvesting systems. In Active and Passive Smart Structures and Integrated Systems 2010; SPIE: Bellingham, WA, USA, 2010; Volume 7643, pp. 181–192.

- Wang, M.; Xia, Y.; Pu, H.; Sun, Y.; Ding, J.; Luo, J.; Xie, S.; Peng, Y.; Zhang, Q.; Li, Z. Piezoelectric Energy Harvesting from Suspension Structures with Piezoelectric Layers. Sensors 2020, 20, 3755.

- Jabbar, H.; Jung, H.J.; Chen, N.; Cho, D.H.; Sung, T.H. Piezoelectric energy harvester impedance matching using a piezoelectric transformer. Sens. Actuators A Phys. 2017, 264, 141–150.

- Mustapa, M.A.; Yaakob, O.B.; Ahmed, Y.M.; Rheem, C.-K.; Koh, K.K.; Adnan, F.A. Wave energy device and breakwater integration: A review. Renew. Sustain. Energy Rev. 2017, 77, 43–58.

- López, I.; Andreu, J.; Ceballos, S.; Martínez de Alegría, I.; Kortabarria, I. Review of wave energy technologies and the necessary power-equipment. Renew. Sustain. Energy Rev. 2013, 27, 413–434.

- Jiang, B.; Li, X.; Chen, S.; Xiong, Q.; Chen, B.-F.; Parker, R.G.; Zuo, L. Performance analysis and tank test validation of a hybrid ocean wave-current energy converter with a single power takeoff. Energy Convers. Manag. 2020, 224, 113268.

- Yeung, R. Fluid Dynamics of Finned Bodies—From VIV to FPSO. In Proceedings of the The Twelfth International Offshore and Polar Engineering Conference, Kitakyushu, Japan, 26 May 2002; Volume 12.

- Akcabay, D.; Young, Y.L. Hydroelastic response and energy harvesting potential of flexible piezoelectric beams in viscous flow. Phys. Fluids 2012, 24, 054106.

- Toffoli, A.; Bitner-Gregersen, E.M. Types of Ocean Surface Waves, Wave Classification. In Encyclopedia of Maritime and Offshore Engineering; Carlton, J., Jukes, P., Choo, Y.S., Eds.; Wiley: Hoboken, NJ, USA, 2017; pp. 1–8.

- Guillou, N. Estimating wave energy flux from significant wave height and peak period. Renew. Energy 2020, 155, 1383–1393.

- Akimoto, H.; Tanaka, K.; Kim, Y.Y. Drag-type cross-flow water turbine for capturing energy from the orbital fluid motion in ocean wave. Renew. Energy 2015, 76, 196–203.

- Athanassoulis, G.A.; Mamis, K.I. Modeling and analysis of a cliff-mounted piezoelectric sea-wave energy absorption system. Coupled Syst. Mech. 2013, 2, 53–83.

- Farrok, O.; Ahmed, K.; Tahlil, A.D.; Farah, M.M.; Kiran, M.R.; Islam, M.R. Electrical Power Generation from the Oceanic Wave for Sustainable Advancement in Renewable Energy Technologies. Sustainability 2020, 12, 2178.

- Hausler, E.; Stein, L. Hydromechanical and physiological mechanical-to-electrical power converter with PVDF film. Ferroelectrics 1987, 75, 363–369.

- Burns, J.R. Ocean Wave Energy Conversion Using Piezoelectric Material Members. U.S. Patent 4,685,296, 11 August 1987.

- Taylor, G.W.; Burns, J.R.; Kammann, S.A.; Powers, W.B.; Welsh, T.R. The Energy Harvesting Eel: A small subsurface ocean/river power generator. IEEE J. Ocean. Eng. 2001, 26, 539–547.

- Pobering, S.; Schwesinger, N. A Novel Hydropower Harvesting Device. In Proceedings of the 2004 International Conference on MEMS, NANO and Smart Systems (ICMENS’04), Banff, AB, Canada, 25–27 August 2004; pp. 480–485.

- Zurkinden, A.S.; Campanile, F.C.; Martinelli, L. Wave Energy Converter through Piezoelectric Polymers. In Proceedings of the Proceedings of the COMSOL Users Conference 2007, Grenoble, France, 23–24 October 2007.

- Murray, R.; Rastegar, J. Novel two-stage piezoelectric-based ocean wave energy harvesters for moored or unmoored buoys. In Active and Passive Smart Structures and Integrated Systems 2009; SPIE: Bellingham, WA, USA, 2009; Volume 7288, pp. 184–195.

- Mutsuda, H.; Kawakami, K.; Kurokawa, T.; Doi, Y.; Tanaka, Y. A Technology of Electrical Energy Generated From Ocean Power Using Flexible Piezoelectric Device. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010; pp. 313–321.

- Mutsuda, H.; Kawakami, K.; Hirata, M.; Doi, Y.; Tanaka, Y. Study on Wave Power Generator Using Flexible Piezoelectric Device. In Proceedings of the ASME 2011 30th International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011; pp. 267–273.

- Mutsuda, H.; Watanabe, R.; Hirata, M.; Doi, Y.; Tanaka, Y. Elastic Floating Unit With Piezoelectric Device for Harvesting Ocean Wave Energy. In Proceedings of the ASME 2012 31st International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; pp. 233–240.

- Mutsuda, H.; Watanabe, R.; Azuma, S.; Tanaka, Y.; Doi, Y. Ocean Power Generator Using Flexible Piezoelectric Device. In Proceedings of the ASME 2013 32nd International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013.

- Molino-Minero-Re, E.; Carbonell-Ventura, M.; Fisac-Fuentes, C.; Mànuel-Làzaro, A.; Toma, D.M. Piezoelectric energy harvesting from induced vortex in water flow. In Proceedings of the 2012 IEEE International Instrumentation and Measurement Technology Conference Proceedings, Graz, Austria, 13–16 May 2012; pp. 624–627.

- Okada, N.; Fujimoto, H.; Yabe, S.; Murai, M. Experiments on floating wave-power generation using piezoelectric elements and pendulums in the water tank. In Proceedings of the the 2012 Oceans—Yeosu, Yeosu, Korea, 21–24 May 2012; pp. 1–8.

- Kim, K.-B.; Kim, C.I.; Jeong, Y.H.; Cho, J.-H.; Paik, J.-H.; Nahm, S.; Lim, J.B.; Seong, T.-H. Energy Harvesting Characteristics from Water Flow by Piezoelectric Energy Harvester Device Using Cr/Nb Doped Pb(Zr,Ti)O3Bimorph Cantilever. Jpn. J. Appl. Phys. 2013, 52, 10MB01.

- Xie, X.D.; Wang, Q.; Wu, N. Potential of a piezoelectric energy harvester from sea waves. J. Sound Vib. 2014, 333, 1421–1429.

- Xie, X.D.; Wang, Q.; Wu, N. Energy harvesting from transverse ocean waves by a piezoelectric plate. Int. J. Eng. Sci. 2014, 81, 41–48.

- Woo, M.S.; Baek, K.H.; Kim, J.H.; Kim, S.B.; Song, D.; Sung, T.H. Relationship between current and impedance in piezoelectric energy harvesting system for water waves. J. Electroceram. 2015, 34, 180–184.

- Gao, X.; Xu, Z.; Gu, J.; Pan, F.; Dong, X. A study of piezoelectric generator based on the flow around a blunt body. In Proceedings of the 2014 17th International Conference on Electrical Machines and Systems (ICEMS), Hangzhou, China, 22–25 October 2014; pp. 2877–2881.

- Song, R.; Shan, X.; Lv, F.; Li, J.; Xie, T. A Novel Piezoelectric Energy Harvester Using the Macro Fiber Composite Cantilever with a Bicylinder in Water. Appl. Sci. 2015, 5, 1942.

- Song, R.; Shan, X.; Lv, F.; Xie, T. A study of vortex-induced energy harvesting from water using PZT piezoelectric cantilever with cylindrical extension. Ceram. Int. 2015, 41, S768–S773.

- Sarker, M.R.; Mohamed, A.; Mohamed, R. Cantilever beam vibration from fluid interactions with triangular shape blunt body for energy harvesting application. In Proceedings of the 2015 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2015; pp. 6–10.

- Feifei, P.; Zhike, X.; Long, J.; Xiu, G. Designed simulation and experiment of a piezoelectric energy harvesting system based on flow around blunt bodies. In Proceedings of the 2015 18th International Conference on Electrical Machines and Systems (ICEMS), Pattaya, Thailand, 25–28 October 2015; pp. 2104–2107.

- Shan, X.; Song, R.; Liu, B.; Xie, T. Novel energy harvesting: A macro fiber composite piezoelectric energy harvester in the water vortex. Ceram. Int. 2015, 41, S763–S767.

- Wu, N.; Wang, Q.; Xie, X. Ocean wave energy harvesting with a piezoelectric coupled buoy structure. Appl. Ocean Res. 2015, 50, 110–118.

- Toma, D.M.; del Rio, J.; Carbonell-Ventura, M.; Masalles, J.M. Underwater energy harvesting system based on plucked-driven piezoelectrics. In Proceedings of the OCEANS 2015—Genova, Genova, Italy, 18–21 May 2015; pp. 1–5.

- Cha, Y.; Chae, W.; Kim, H.; Walcott, H.; Peterson, S.D.; Porfiri, M. Energy harvesting from a piezoelectric biomimetic fish tail. Renew. Energy 2016, 86, 449–458.

- Li, H.; Tian, C.; Lu, J.; Myjak, M.J.; Martinez, J.J.; Brown, R.S.; Deng, Z.D. An Energy Harvesting Underwater Acoustic Transmitter for Aquatic Animals. Sci. Rep. 2016, 6, 33804.

- Viet, N.V.; Xie, X.D.; Liew, K.M.; Banthia, N.; Wang, Q. Energy harvesting from ocean waves by a floating energy harvester. Energy 2016, 112, 1219–1226.

- Kamenar, E.; Zelenika, S.; Blažević, D.; Maćešić, S.; Gregov, G.; Marković, K.; Glažar, V. Harvesting of river flow energy for wireless sensor network technology. Microsyst. Technol. 2016, 22, 1557–1574.

- Renzi, E. Hydroelectromechanical modelling of a piezoelectric wave energy converter. Proc. R. Soc. A Math. Phys. Eng. Sci. 2016, 472, 20160715.

- Mutsuda, H.; Tanaka, Y.; Patel, R.; Doi, Y.; Moriyama, Y.; Umino, Y. A painting type of flexible piezoelectric device for ocean energy harvesting. Appl. Ocean Res. 2017, 68, 182–193.

- Shan, X.; Deng, J.; Song, R.; Xie, T. A Piezoelectric Energy Harvester with Bending–Torsion Vibration in Low-Speed Water. Appl. Sci. 2017, 7, 116.

- Xie, X.D.; Wang, Q. A study on an ocean wave energy harvester made of a composite piezoelectric buoy structure. Compos. Struct. 2017, 178, 447–454.

- Hwang, W.S.; Ahn, J.H.; Jeong, S.Y.; Jung, H.J.; Hong, S.K.; Choi, J.Y.; Cho, J.Y.; Kim, J.H.; Sung, T.H. Design of piezoelectric ocean-wave energy harvester using sway movement. Sens. Actuators A Phys. 2017, 260, 191–197.

- Viet, N.V.; Wang, Q.; Carpinteri, A. Development of an ocean wave energy harvester with a built-in frequency conversion function. Int. J. Energy Res. 2018, 42, 684–695.

- An, X.; Song, B.; Tian, W.; Ma, C. Numerical simulation of Vortex Induced Piezoelectric Energy Converter (VIPEC) based on coupled fluid, structure and piezoelectric interaction. In Proceedings of the OCEANS 2017—Aberdeen, Aberdeen, UK, 19–22 June 2017; pp. 1–5.

- An, X.; Song, B.; Tian, W.; Ma, C. Design and CFD Simulations of a Vortex-Induced Piezoelectric Energy Converter (VIPEC) for Underwater Environment. Energies 2018, 11, 330.

- Dessi, D.; Leonardi, G.; Passacantilli, F. Energy Harvesting From Waves Using Piezoelectric Floaters. In Proceedings of the ASME 2018 37th International Conference on Ocean, Offshore and Arctic Engineering, Madrid, Spain, 17–22 June 2018.

- Nabavi, S.F.; Farshidianfar, A.; Afsharfard, A. Novel piezoelectric-based ocean wave energy harvesting from offshore buoys. Appl. Ocean Res. 2018, 76, 174–183.

- Nguyen, V.; Wang, Q. Ocean Wave Energy Pitching Harvester with a Frequency Tuning Capability. Energy 2018, 162, 603–617.

- Salazar, R.; Taylor, G.; Khalid, M.S.U.; Abdelkefi, A. Optimal design and energy harvesting performance of carangiform fish-like robotic system. Smart Mater. Struct. 2018, 27, 075045.

- Aramendia, I.; Fernandez-Gamiz, U.; Zulueta Guerrero, E.; Lopez-Guede, J.M.; Sancho, J. Power Control Optimization of an Underwater Piezoelectric Energy Harvester. Appl. Sci. 2018, 8, 389.

- Ming, L.; Hengxu, L.; Hailong, C.; Yuanchao, C.; Liquan, W. Performance Analysis for a Wave Energy Harvester of Piezoelectric Cantilever Beam. J. Coast. Res. 2019, 83, 976–984.

- Gong, Y.; Shan, X.; Yang, Z.; Xie, T. 270-degree arc-shaped piezoelectric energy converter in uniflow fluid environment. IOP Conf. Ser. Mater. Sci. Eng. 2019, 531, 012026.

- Viet, N.V.; Carpinteri, A.; Wang, Q. A Novel Heaving Ocean Wave Energy Harvester with a Frequency Tuning Capability. Arab. J. Sci. Eng. 2019, 44, 5711–5722.

- Bao, B.; Chen, W.; Wang, Q. A piezoelectric hydro-energy harvester featuring a special container structure. Energy 2019, 189, 116261.

- Zhang, J.; Xie, X.; Song, G.; Du, G.; Liu, D. A study on a near-shore cantilevered sea wave energy harvester with a variable cross section. Energy Sci. Eng. 2019, 7, 3174–3185.

- Nabavi, S.F.; Farshidianfar, A.; Afsharfard, A.; Khodaparast, H.H. An ocean wave-based piezoelectric energy harvesting system using breaking wave force. Int. J. Mech. Sci. 2019, 151, 498–507.

- Mutsuda, H.; Tanaka, Y.; Doi, Y.; Moriyama, Y. Application of a flexible device coating with piezoelectric paint for harvesting wave energy. Ocean Eng. 2019, 172, 170–182.

- Gong, Y.; Shan, X.; Luo, X.; Pan, J.; Xie, T.; Yang, Z. Direction-adaptive energy harvesting with a guide wing under flow-induced oscillations. Energy 2019, 187, 115983.

- Sun, W.; Zhao, D.; Tan, T.; Yan, Z.; Guo, P.; Luo, X. Low velocity water flow energy harvesting using vortex induced vibration and galloping. Appl. Energy 2019, 251, 113392.

- Shan, X.; Li, H.; Yang, Y.; Feng, J.; Wang, Y.; Xie, T. Enhancing the performance of an underwater piezoelectric energy harvester based on flow-induced vibration. Energy 2019, 172, 134–140.

- Noh, H.-J.; Lee, J.-S.; Kim, Y.-J. Micro-energy harvesting based on vortex-induced vibration of cross-flow hydroturbine with various cantilever beam configurations. IOP Conf. Ser. Earth Environ. Sci. 2019, 240, 022034.

- Liu, H.-X.; Liu, M.; Chai, Y.-C.; Shu, G.-Y.; Jing, F.-M.; Wang, L.-Q. Piezoelectric Energy Analysis on Diverse Buoy Coupling with Hydrodynamic Parameters. China Ocean Eng. 2019, 33, 279–287.

- Yayla, S.; Ayça, S.; Oruç, M. A case study on piezoelectric energy harvesting with using vortex generator plate modeling for fluids. Renew. Energy 2020, 157, 1243–1253.

- Cao, D.; Ding, X.; Guo, X.; Yao, M. Design, Simulation and Experiment for a Vortex-Induced Vibration Energy Harvester for Low-Velocity Water Flow. Int. J. Precis. Eng. Manuf.-Green Technol. 2021, 8, 1239–1252.

- Shan, X.; Tian, H.; Xie, T. Enhanced performance of piezoelectric energy harvester through three serial vibrators. J. Intell. Mater. Syst. Struct. 2020, 32, 1140–1151.

- Du, X.; Zhao, Y.; Liu, G.; Zhang, M.; Wang, Y.; Yu, H. Enhancement of the Piezoelectric Cantilever Beam Performance via Vortex-Induced Vibration to Harvest Ocean Wave Energy. Shock Vib. 2020, 2020, 8858529.

- Latif, U.; Ali, E.; Uddin, E.; Ali, Z.; Sajid, M.; Shah, S.R.; Younis, M.Y. Experimental investigation of energy harvesting eel in the wake of bluff body under ocean waves. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2020, 235, 81–92.

- Kim, S.; Cho, J.Y.; Jeon, D.H.; Hwang, W.; Song, Y.; Jeong, S.Y.; Jeong, S.W.; Yoo, H.H.; Sung, T.H. Propeller-based Underwater Piezoelectric Energy Harvesting System for an Autonomous IoT Sensor System. J. Korean Phys. Soc. 2020, 76, 251–256.

- Qi, L.; Li, H.; Wu, X.; Zhang, Z.; Duan, W.; Yi, M. A hybrid piezoelectric-electromagnetic wave energy harvester based on capsule structure for self-powered applications in sea-crossing bridges. Renew. Energy 2021, 178, 1223–1235.

- Bao, B.; Wang, Q. Bladeless rotational piezoelectric energy harvester for hydroelectric applications of ultra-low and wide-range flow rates. Energy Convers. Manag. 2021, 227, 113619.

- Kazemi, S.; Nili-Ahmadabadi, M.; Tavakoli, M.R.; Tikani, R. Energy harvesting from longitudinal and transverse motions of sea waves particles using a new waterproof piezoelectric waves energy harvester. Renew. Energy 2021, 179, 528–536.

- Zhao, D.; Zhou, J.; Tan, T.; Yan, Z.; Sun, W.; Yin, J.; Zhang, W. Hydrokinetic piezoelectric energy harvesting by wake induced vibration. Energy 2021, 220, 119722.

- Jiao, P.; Yang, Y.; Egbe, K.I.; He, Z.; Lin, Y. Mechanical Metamaterials Gyro-Structure Piezoelectric Nanogenerators for Energy Harvesting under Quasi-Static Excitations in Ocean Engineering. ACS Omega 2021, 6, 15348–15360.

- Song, R.; Hou, C.; Yang, C.; Yang, X.; Guo, Q.; Shan, X. Modeling, Validation, and Performance of Two Tandem Cylinder Piezoelectric Energy Harvesters in Water Flow. Micromachines 2021, 12, 872.

- Mariello, M.; Fachechi, L.; Guido, F.; De Vittorio, M. Multifunctional sub-100 µm thickness flexible piezo/triboelectric hybrid water energy harvester based on biocompatible AlN and soft parylene C-PDMS-Ecoflex™. Nano Energy 2021, 83, 105811.

- Ucar, H. Patch-based piezoelectric energy harvesting on a marine boat exposed to wave-induced loads. Ocean Eng. 2021, 236, 109568.

- Zheng, S.; Meylan, M.; Zhang, X.; Iglesias, G.; Greaves, D. Performance of a plate-wave energy converter integrated in a floating breakwater. IET Renew. Power Gener. 2021, 15, 3206–3219.

- Salazar, R.; Quintana, R.; Abdelkefi, A. Role of Electromechanical Coupling, Locomotion Type and Damping on the Effectiveness of Fish-Like Robot Energy Harvesters. Energies 2021, 14, 693.

- Yulianti, S.; Kevin, P.; Prakoso, A. The Use of Piezoelectric as Energy Harvester in Breakwater. IOP Conf. Ser. Earth Environ. Sci. 2021, 750, 012016.

- Du, X.; Zhang, M.; Kang, H.; Chang, H.; Yu, H. Theoretical study on a novel piezoelectric ocean wave energy harvester driven by oscillating water column. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–21.

- Alizzio, D.; Bonfanti, M.; Donato, N.; Faraci, C.; Grasso, G.M.; Lo Savio, F.; Montanini, R.; Quattrocchi, A. Design and Performance Evaluation of a “Fixed-Point” Spar Buoy Equipped with a Piezoelectric Energy Harvesting Unit for Floating Near-Shore Applications. Sensors 2021, 21, 1912.

- Tan, D.; Wang, Y.-C.; Kohtanen, E.; Erturk, A. Trout-like multifunctional piezoelectric robotic fish and energy harvester. Bioinspir. Biomim. 2021, 16, 046024.

- Wang, D.A.; Ko, H.H. Piezoelectric energy harvesting from flow-induced vibration. J. Micromech. Microeng. Struct. Devices Syst. 2010, 20, 025019.

- Wang, D.-A.; Liu, N.-Z. A shear mode piezoelectric energy harvester based on a pressurized water flow. Sens. Actuators A Phys. 2011, 167, 449–458.

- Toma, D.M.; Ventura, M.C.; Bresco, D.P.; Lázaro, A.M.; Masalles, J.M. An impacting energy harvester through piezoelectric device for oscillating water flow. In Proceedings of the MARTECH 2013: 5th International Workshop on Marine Technology, Vilanova i la Geltrú, Spain, 19–20 November 2013.

- Viñolo, C.; Toma, D.M.; Manuel, A.; del Río, J. Sea motion electrical energy generator for low-power applications. In Proceedings of the 2013 MTS/IEEE OCEANS—Bergen, Bergen, Norway, 10–14 June 2013; pp. 1–7.

- Viñolo, C.; Toma, D.; Mànuel, A.; del Rio, J. An ocean kinetic energy converter for low-power applications using piezoelectric disk elements. Eur. Phys. J. Spec. Top. 2013, 222, 1685–1698.

- Abrol, S.; Chhabra, D.; Chhabra, D. Experimental Investigations of Piezoelectric Energy Harvesting with Turbulent Flow. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 703–710.

- Huang, W.; Huang, Y. A Study on Piezoelectric Buoy Energy Harvester Based on Orthogonal Experimental Design. In Proceedings of the 2019 IEEE International Conference on Power, Intelligent Computing and Systems (ICPICS), Shenyang, China, 12–14 July 2019; pp. 611–614.

- Zhang, B.; Ducharne, B.; Gupta, B.; Sebald, G.; Guyomar, D.; Gao, J. Experimental sea wave energy extractor based on piezoelectric Ericsson cycles. J. Intell. Mater. Syst. Struct. 2017, 29, 1102–1112. [Google Scholar] [CrossRef]

- Chen, S.-E.; Yang, R.-Y.; Wu, G.-K.; Wu, C.-C. A Piezoelectric Wave-Energy Converter Equipped with a Geared-Linkage-Based Frequency Up-Conversion Mechanism. Sensors 2021, 21, 204. [Google Scholar] [CrossRef]

- Bezanson, L.; Thornton, J.; Konchuba, N.; Priya, S. Utilizing deep ocean currents to power extended duration sensors. In Proceedings of the OCEANS 2010 MTS/IEEE SEATTLE, Seattle, WA, USA, 20–23 September 2010; pp. 1–8. [Google Scholar]

- Zou, H.-X.; Li, M.; Zhao, L.-C.; Gao, Q.-H.; Wei, K.-X.; Zuo, L.; Qian, F.; Zhang, W.-M. A magnetically coupled bistable piezoelectric harvester for underwater energy harvesting. Energy 2021, 217, 119429. [Google Scholar] [CrossRef]

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

3.1K

Revisions:

3 times

(View History)

Update Date:

21 Mar 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No