Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Yoshinori Matsuda | + 1386 word(s) | 1386 | 2022-03-03 10:27:07 | | | |

| 2 | Yvaine Wei | Meta information modification | 1386 | 2022-03-04 03:35:02 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Matsuda, Y. Electrical Trap-and-Kill Fly Traps Using Electrified Insulated Conductors. Encyclopedia. Available online: https://encyclopedia.pub/entry/20187 (accessed on 09 February 2026).

Matsuda Y. Electrical Trap-and-Kill Fly Traps Using Electrified Insulated Conductors. Encyclopedia. Available at: https://encyclopedia.pub/entry/20187. Accessed February 09, 2026.

Matsuda, Yoshinori. "Electrical Trap-and-Kill Fly Traps Using Electrified Insulated Conductors" Encyclopedia, https://encyclopedia.pub/entry/20187 (accessed February 09, 2026).

Matsuda, Y. (2022, March 04). Electrical Trap-and-Kill Fly Traps Using Electrified Insulated Conductors. In Encyclopedia. https://encyclopedia.pub/entry/20187

Matsuda, Yoshinori. "Electrical Trap-and-Kill Fly Traps Using Electrified Insulated Conductors." Encyclopedia. Web. 04 March, 2022.

Copy Citation

Electrostatic insect exclusion is a physical approach to pest control in which an apparatus forming an electric field (EF) is applied to capture pests. The EF producer consisted of a negatively charged polyvinyl chloride membrane-insulated iron plate (N-PIP) and a non-insulated grounded iron plate (GIP) paralleled with the N-PIP. An EF was formed in the space between the plates. The magnitude of electric current from the fly was voltage-dependent, and detrimental effects caused by electricity release became more apparent as the applied voltage increased. Bioelectrical measurements showed that electric current caused acute damage and delayed the death of captured flies.

electric field producer

electricity release

repulsive force

1. Introduction

Electrostatic insect exclusion is a physical pest-control approach in which an apparatus forming an electric field (EF) is applied to capture pests. Previous studies have clarified the insect-capture mechanisms of such tools and evaluated their practicality. Some EF-producing pest-capture systems consist of a negatively charged insulated conductor (metal wire or plate) paralleled with a grounded non-insulated conductor; an EF is generated in the space between them [1]. Electrostatic insect traps were designed to target small, flying insect pests that can pass through conventional insect-proof nets with mesh sizes of 1–1.5 mm. The first designs consisted of an EF screen comprising a layer of insulated conductor wires arrayed in parallel at definite intervals and a parallel grounded metal net [2]. This apparatus was installed on lateral greenhouse windows to prevent pest entry [3][4]. The EF screen technique has been applied in an electrostatic nursery shelter to protect tomato seedlings from whiteflies, leaf miners, aphids, and thrips in an open-window greenhouse environment [5], a portable electrostatic insect sweeper to trap whiteflies colonizing host plants [6], and an electrostatic seedbed cover to capture leaf miners emerging from underground pupae [7]. In this system, a negative voltage generator picks up negative charge from the ground and supplies it to a linked insulated conductor that accumulates negative charge at its outer surface, dielectrically polarizing the insulator cover to generate the negative charge [8]. This negative charge positively polarizes a grounded conductor through electrostatic induction [9]. These opposite charges generates an EF in the space between the opposite poles (i.e., the negatively charged insulated and positively charged grounded conductors).

Charged poles within the EF generate an attractive or repulsive force to other charges in the field [10]; these forces may be involved in insect capture within the apparatus [11][12][13]. The negatively charged insulated conductor pushes free electrons (negative electricity) out of an insect that enters the EF and sends them to the ground via a grounded conductor; such events are detected as a transient electric current from the insect. It can be hypothesized that the insect is subjected to discharge-mediated positive electrification and then attracted to the negatively charged conductor [1]. The force generated during this process is sufficiently strong to prevent insects from escaping the trap, making the electrostatic insect trap practically applicable for a wide range of insect pests [14].

2. EF Production

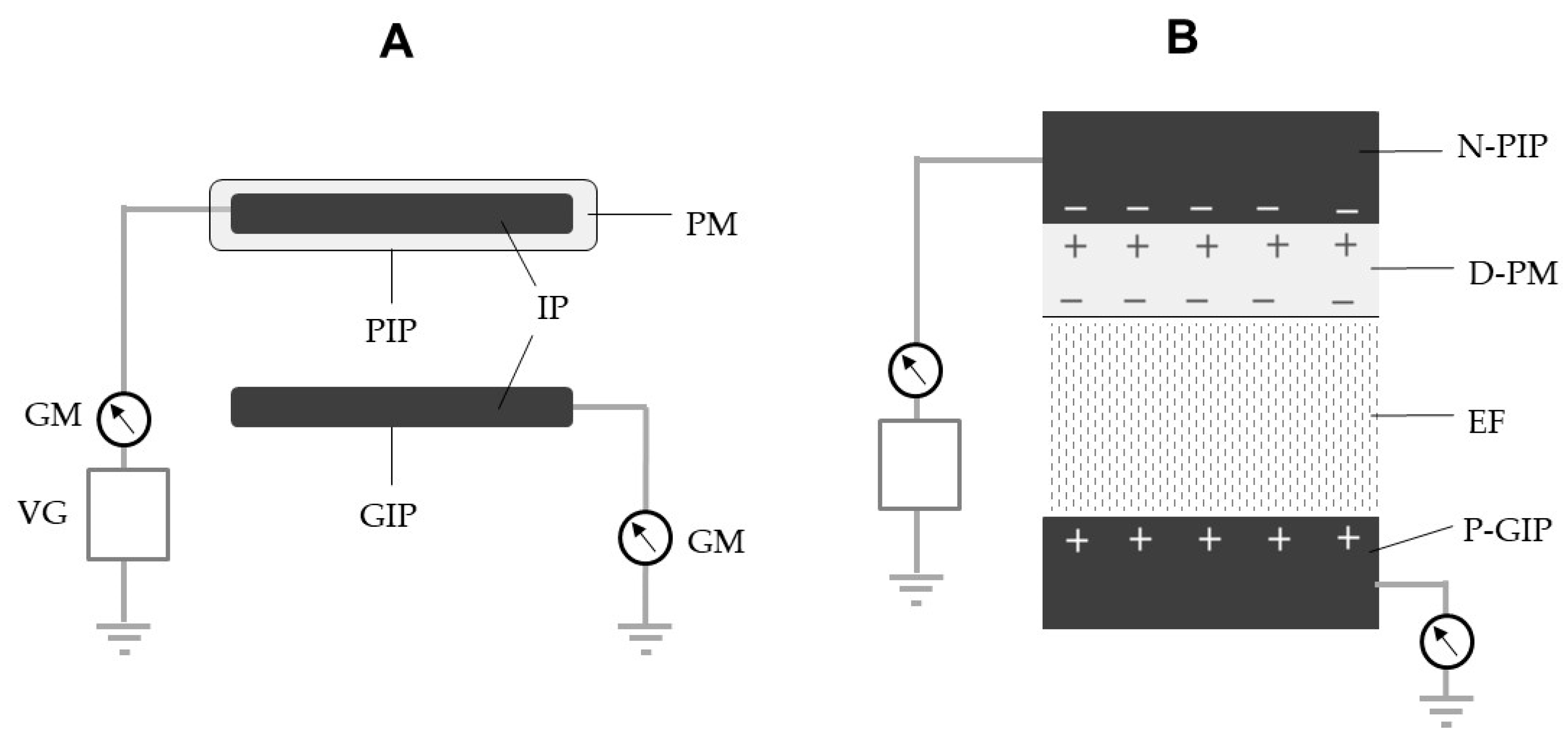

The structure of the EF producer (EFP) is shown in Figure 1A. Two identical iron plates (2 × 10 cm2, 2 mm thickness) were used to construct the EFP; one was coated with a soft polyvinyl chloride (PVC) membrane (1 mm thickness; 109 Ω cm) (Sonoda Seisakusho, Osaka, Japan) for insulation and linked to a negative voltage generator (Max Electronics, Tokyo, Japan), while the other was non-insulated and linked to a grounded line. The plates were arranged in parallel at a distance of 10 mm. A transformer and Cockcroft circuit [15] were integrated so as to enhance the initial voltage (12 V) of the voltage generator to achieve the desired voltages (−1 to −20 kV). With this enhanced voltage, the generator is able to pick up negative electricity from the ground and supply it to a PVC-insulated iron plate (PIP) [16]. Negative electricity accumulates on the surface of the iron plate and polarizes the conductor-side surface (positive) and outer surface of the insulator coating (negative). Eventually, the negative surface charge polarizes the non-insulated grounded iron plate (GIP), so that it is positively charged through electrostatic induction [9]. The opposite charges on the PIP and GIP generate an EF in the space between them (Figure 1B).

Figure 1. Schematic representation of (A) an electric field producer (EFP) and (B) dielectric polarization of a polyvinyl chloride (PVC) membrane used to insulate an iron plate, followed by electrostatic induction of a grounded iron plate paralleled with an insulated iron plate. D-PM, dielectrically polarized PVC membrane; EF, electric field; GIP, grounded iron plate; GM, galvanometer; IP, iron plate; N-PIP, negatively charged iron insulated iron plate; P-GIP, positively polarized grounded plate; PIP, PVC-insulated iron plate (charged conductor); PM, PVC membrane coating (insulator); VG, voltage generator.

3. Attraction of Houseflies to the N-PIP

One of the most important events for pest control by an EFP is the attraction of the insect to the negatively charged insulated conductor within the EF [1]. In the present EFP, the attraction of a housefly to the N-PIP was detected in the range from −5.5 to −15 kV. However, at <−7.6 kV, the attracted flies were able to escape from the N-PIP within a short time. Table 1 lists the time required for houseflies to escape following their attraction to the N-PIP of the negatively charged EFP at different voltages.

Table 1. Time (s) required for male and female adult houseflies captured with the negatively charged PIP of the EFP at different voltages to escape from the PIP.

| Sex | Age 1 | Voltage (−kV) Applied to the PIP | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5 | 5.5 | 6 | 6.5 | 7 | 7.5 | 8 | 10 | 12 | 15 | ||

| Male | 7 | n.a. 2 | 2.6 ± 0.7 a | 4.1 ± 0.3 a | 5.2 ± 0.4 a | 6.9 ± 0.3 a | 7.8 ± 0.6 a | n.a.e. 3 | n.a.e. | n.a.e. | n.a.e. |

| 14 | n.a. | 2.7 ± 0.8 a | 4.2 ± 0.4 a | 5.3 ± 0.5 a | 6.8 ± 0.4 a | 7.7 ± 0.5 a | n.a.e. | n.a.e. | n.a.e. | n.a.e. | |

| 21 | n.a. | 2.4 ± 0.7 a | 4.5 ± 0.5 a | 5.4 ± 0.5 a | 6.9 ± 0.6 a | 7.9 ± 0.6 a | n.a.e | n.a.e. | n.a.e. | n.a.e. | |

| Female | 7 | n.a. | n.a. | 3.1 ± 0.3 b | 3.7 ± 0.5 b | 5.3 ± 0.5 b | 5.9 ± 0.3 b | n.a.e. | n.a.e. | n.a.e. | n.a.e. |

| 14 | n.a. | n.a. | 3.2 ± 0.4 b | 3.6 ± 0.5 b | 5.4 ± 0.5 b | 5.9 ± 0.6 b | n.a.e. | n.a.e. | n.a.e. | n.a.e. | |

| 21 | n.a. | n.a. | 3.3 ± 0.5 b | 3.5 ± 0.5 b | 5.2 ± 0.4 b | 5.9 ± 0.6 b | n.a.e. | n.a.e. | n.a.e. | n.a.e. | |

1 Days after eclosion; 2 Flies were not attracted; 3 Flies were attracted to the PIP but not allowed to escape from the trap. 20 insects were used for each sex, age, and applied voltage. Means ± standard deviation were calculated from five experimental replicates. Different letters (a, b) within each column indicate significant differences (p < 0.05) according to Tukey’s test.

4. Electric Current Generation by a Housefly Attracted to the N-PIP

Flies placed in the EF were exposed to a repulsive force from the N-PIP, such that free electrons in the insect body were pushed out of the fly toward the ground via the GIP. This electricity movement was recorded as a transient electric current from the insect [2][13][3]. Eventually, the insect was positively electrified and attracted to the N-PIP. The outer protective cuticle of many invertebrates can be efficiently electrified due to its conductive nature [17][18][19][20][21][22]. Therefore, insect conductivity was explored in terms of electricity release from the insect body within the EF.

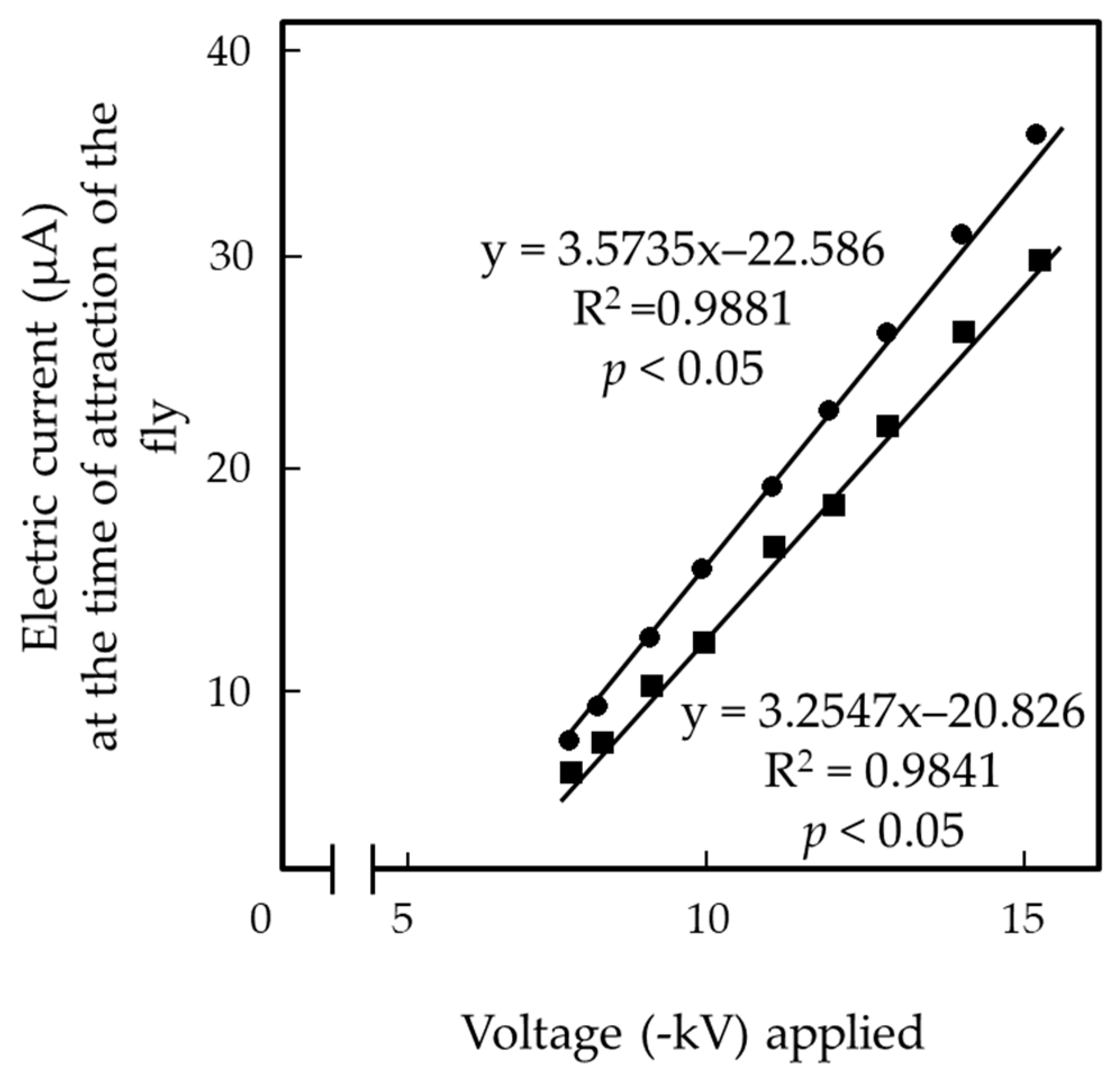

Figure 2 shows the linear relationship between the applied voltage and current magnitude generated by a single fly at the time of attraction over the entire voltage range for insect attraction. Females showed significantly larger current magnitude and a longer current generation duration than males; however, neither current magnitude nor duration differed significantly among flies of different ages within each sex. These results strongly support the hypothesis that houseflies are positively charged due to the release of electricity from the insect body that occurred immediately after its transfer to the EF. Continuously depriving the fly of its electricity appeared to strengthen the force constraining the fly to the N-PIP.

Figure 2. Linear correlation between the voltage applied to the PIP of the EFP and the electric current generated by 7-day-old male and female houseflies upon attraction to the N-PIP.

5. Conclusions

An EF was formed in the space between a negatively charged PIP and GIP within an EF producer. The release of negative electricity from houseflies was detected as they were first attracted, and subsequently confined, to the negatively charged iron plate. This electricity release was detected as the electric current from the fly to the ground via the GIP. The release of electricity from the insect body was dependent upon the applied voltage, and its detrimental effect became increasingly noticeable as the voltage increased.

References

- Toyoda, H.; Matsuda, Y. Basic concept for constructing an electric field screen. In Electric Field Screen; Principles and Applications; Toyoda, H., Ed.; Nobunkyo Production: Tokyo, Japan, 2015; pp. 3–17.

- Matsuda, Y.; Nonomura, T.; Kakutani, K.; Takikawa, Y.; Kimbara, J.; Kasaishi, Y.; Kusakari, S.; Toyoda, H. A newly devised electric field screen for avoidance and capture of cigarette beetles and vinegar flies. Crop Prot. 2011, 30, 155–162.

- Nonomura, T.; Matsuda, Y.; Kakutani, K.; Kimbara, J.; Osamura, K.; Kusakari, S.; Toyoda, H. An electric field strongly deters whiteflies from entering window-open greenhouses in an electrostatic insect exclusion strategy. Eur. J. Plant Pathol. 2012, 134, 661–670.

- Kakutani, K.; Matsuda, Y.; Nonomura, T.; Kimbara, J.; Kusakari, S.; Toyoda, H. Practical application of an electric field screen to an exclusion of flying insect pests and airborne conidia from greenhouses with a good air penetration. J. Agric. Sci. 2012, 4, 51–60.

- Takikawa, Y.; Matsuda, Y.; Nonomura, T.; Kakutani, K.; Kusakari, S.; Okada, K.; Toyoda, H. An electrostatic nursery shelter for raising pest and pathogen free tomato seedlings in an open-window greenhouse environment. J. Agric. Sci. 2016, 8, 13–25.

- Takikawa, Y.; Matsuda, Y.; Kakutani, K.; Nonomura, T.; Kusakari, S.; Okada, K.; Kimbara, J.; Osamura, K.; Toyoda, H. Electrostatic insect sweeper for eliminating whiteflies colonizing host plants; a complementary pest control device in an electric field screen-guarded greenhouse. Insects 2015, 6, 442–454.

- Nonomura, T.; Toyoda, H. Soil surface-trapping of tomato leaf-miner flies emerging from underground pupae with a simple electrostatic cover of seedbeds in a greenhouse. Insects 2020, 11, 878.

- Halliday, D.; Resnick, R.; Walker, J. Electric discharge and electric fields. In Fundamentals of Physics; Johnson, S., Ford, E., Eds.; John Wiley & Sons: New York, NY, USA, 2005; pp. 561–604.

- Griffith, W.T. Electrostatic phenomena. In The Physics of Everyday Phenomena, a Conceptual Introduction to Physics; Bruflodt, D., Loehr, B.S., Eds.; McGraw-Hill: New York, NY, USA, 2004; pp. 232–252.

- Jones, E.; Childers, R. Electric charge and electric field. In Physics, 3rd ed.; McGraw-Hill: Boston, MD, USA, 2002; pp. 495–525.

- Kakutani, K.; Matsuda, Y.; Haneda, K.; Nonomura, T.; Kimbara, J.; Kusakari, S.; Osamura, K.; Toyoda, H. Insects are electrified in an electric field by deprivation of their negative charge. Ann. Appl. Biol. 2012, 160, 250–259.

- Matsuda, Y.; Kakutani, K.; Nonomura, T.; Kimbara, J.; Kusakari, S.; Osamura, K.; Toyoda, H. An oppositely charged insect exclusion screen with gap-free multiple electric fields. J. Appl. Phys. 2012, 112, 116103.

- Kakutani, K.; Matsuda, Y.; Haneda, K.; Sekoguchi, D.; Nonomura, T.; Kimbara, J.; Osamura, K.; Kusakari, S.; Toyoda, H. An electric field screen prevents captured insects from escaping by depriving bioelectricity generated through insect movements. J. Electrost. 2012, 70, 207–211.

- Kusakari, S.; Okada, K.; Shibao, M.; Toyoda, H. High voltage electric fields have potential to create new physical pest control systems. Insects 2020, 11, 447.

- Wegner, H.E. Electrical charging generators. In McGraw-Hill Encyclopedia of Science and Technology, 9th ed.; Geller, E., Moore, K., Well, J., Blumet, D., Felsenfeld, S., Martin, T., Rappaport, A., Wagner, C., Lai, B., Taylor, R., Eds.; The Lakeside Press: New York, NY, USA, 2002; pp. 42–43.

- Toyoda, H.; Kusakari, S.; Matsuda, Y.; Kakutani, K.; Xu, L.; Nonomura, T.; Takikawa, Y. Electric field screen structures. In An Illustrated Manual of Electric Field Screens: Their Structures and Functions; Toyoda, H., Ed.; RAEFSS Publishing Department: Nara, Japan, 2019; pp. 9–15.

- Takikawa, Y.; Takami, T.; Kakutani, K. Body water-mediated conductivity actualizes the insect-control functions of electric fields in houseflies. Insects 2020, 11, 561.

- Ishay, J.S.; Shimony, T.B.; Shalom, A.B.; Kristianpoller, N. Photovoltaic effects in the oriental hornet. Vespa Orient. J. Insect Physiol. 1992, 38, 37–48.

- McGonigle, D.G.; Jackson, C.W. Effect of surface material on electrostatic charging of houseflies (Musca domestica L). Pest Manag. Sci. 2002, 58, 374–380.

- McGonigle, D.G.; Jackson, C.W.; Davidson, J.L. Triboelectrification of houseflies (Musca domestica L.) walking on synthetic dielectric surfaces. J. Electrost. 2002, 54, 167–177.

- Honna, T.; Akiyama, Y.; Morishima, K. Demonstration of insect-based power generation using a piezoelectric fiber. Comp. Biochem. Physiol. B Biochem. Mol. Biol. 2008, 151, 460.

- Moussian, B. Recent advances in understanding mechanisms of insect cuticle differentiation. Insect Biochem. Mol. Biol. 2010, 40, 363–375.

More

Information

Subjects:

Entomology

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.5K

Revisions:

2 times

(View History)

Update Date:

19 Apr 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No