Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Alejandro Moure Abelenda | + 1648 word(s) | 1648 | 2022-01-21 03:05:04 | | | |

| 2 | Camila Xu | Meta information modification | 1648 | 2022-01-21 08:55:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Moure Abelenda, A. Wood Ash Based Treatment of Anaerobic Digestate. Encyclopedia. Available online: https://encyclopedia.pub/entry/18600 (accessed on 08 February 2026).

Moure Abelenda A. Wood Ash Based Treatment of Anaerobic Digestate. Encyclopedia. Available at: https://encyclopedia.pub/entry/18600. Accessed February 08, 2026.

Moure Abelenda, Alejandro. "Wood Ash Based Treatment of Anaerobic Digestate" Encyclopedia, https://encyclopedia.pub/entry/18600 (accessed February 08, 2026).

Moure Abelenda, A. (2022, January 21). Wood Ash Based Treatment of Anaerobic Digestate. In Encyclopedia. https://encyclopedia.pub/entry/18600

Moure Abelenda, Alejandro. "Wood Ash Based Treatment of Anaerobic Digestate." Encyclopedia. Web. 21 January, 2022.

Copy Citation

The anaerobic digestion (AD) was first applied to deal with the sewage sludge (SS) produced during the primary and secondary treatment of wastewater, but its use to deal with agro-waste and the MSW with around 70% of organic material has been subsequently encouraged.

anaerobic digestion

greenhouse gas mitigation

phosphate leaching

1. Introduction

The growth of the human population and the change in their diet (e.g., more consumption of animal products) imply devoting more land to food production at an alarming rate [1]. The problem of our current agricultural practices is not limited to land management but also to the unsustainable consumption of essential nutrients for plants, such as phosphorus [2][3]. The fluctuation in prices helps preserve the long-term availability of these mineral resources [4]. In the present situation, the development of profitable strategies for utilizing the waste materials is the only way to achieve sustainable development of the society [5]. Once a material is regarded as waste, its utilization is constrained by regulations [6]. In Europe, all waste-derived products must comply with Directive 2018/851, but there are shortcuts to achieve end-of-waste (EoW) status. Generally, when a residue is produced in large amounts and has a composition suitable for a particular application, the European parliament applies EoW regulations that do not need to be transposed by the governments of each member state [7].

The production of digestate was around 180 million tons per year in the EU28, before the UK withdrawal in 2020 [8]. In the UK, 7.5 million tons of anaerobic digestate and 2.7 million tons of compost were produced in 2018 [9]. A common policy is being developed to improve the management of all nitrogenous materials employed as soil amendments [10][11]. In 2009 [12], the EU27 produced 256 million tons of municipal solid waste (MSW). Much more animal manure is applied to land as a soil amendment than anaerobic digestate because of the high CAPEX and OPEX associated with implementing anaerobic digestion (AD) in the farms [13]. The biological treatment of organic residues via AD is a promising technology for energy recovery in the form of biogas and the production of fertilizers [14]. The AD was first applied to deal with the sewage sludge (SS) produced during the primary and secondary treatment of wastewater, but its use to deal with agro-waste and the MSW with around 70% of organic material has been subsequently encouraged [15][16]. The AD technology fits with the current trends of using the biorefinery to sustainably satisfy the needs of society, which used to be covered by the petrochemical industry [17].

Vassilev et al. [18] estimated that approximately 476 million tons of biomass ash could be generated worldwide annually if the average ash content is 6.8% and the burned biomass is assumed to be 7 billion tons. This amount resembles the 780 million tonnes of coal ash generated every year [18]. According to Pitman [19], the wood ash (WA) production could be estimated by considering that 1% of the wood incinerated is left as ash. According to the UK Forestry Commission [20], 2.68 million tons of wood fuel were used in 2016. Even considering the combustion of other types of biomass, the amount of biomass ash currently produced in the UK is lower than that coming from the coal power plants. In 2016, the amount of coal ash produced in the UK was around 6 million tons [21]. However, this scenario is changing, and by 2025 the amount of biomass ash is expected to be greater than that of coal ash [22]. In 2007, Sweden produced 0.3 million tons of WA, and most of this material was disposed of in landfills [23]. The preparation of a blend of organic manure and ash to enhance the circular economy has been addressed in the literature from several points of view:

The anaerobic digestates, animal manures, and slurries are appreciated by the farmers as organic soil amendments. Improving the nutrient profile of the digestate might be a way of increasing its value and decreasing the cost of transportation. Moreover, there are more urgent challenges that need to be addressed, such as the pollution associated with the use of these materials [10]. It is necessary to optimize the conditions of the WA-based treatment of the anaerobic digestate to improve the stability of the soil organic amendment, improve the nutrient use efficiency, and reduce the contamination of the environment.

2. Upstream Processing

2.1. State-of-the-Art of AD

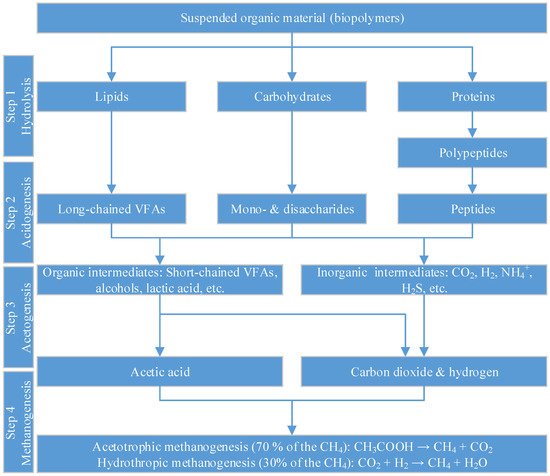

The AD process is also known as bio gasification due to the intervention of microorganisms to convert the components of the organic matter to methane and carbon dioxide. The most accepted model, on how the reactions occur in the anaerobic digester in the absence of oxygen, describes 4 different stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis (Figure 1). The limiting step is hydrolysis, while the methanogenesis is quick, preventing the accumulation of volatile fatty acids (VFA) in the system. In this way, the concentration of VFA in the anaerobic digest ester could be used as an indicator of the correct stationary operation of the bioreactor [17].

Figure 1. Breakdown of the AD process. Modified from Madsen et al. [17]. Reproduced with permission of Renewable and Sustainable Energy Reviews (Elsevier).

2.2. Use of WA as an Additive for Enhancing the AD

The addition of WA to the feedstock of AD can be understood as a way of promoting the stabilization of the anaerobic digestate because the greater the biogas production during the AD, the lower the emission of methane and carbon dioxide occurrence during storage and land application of the soil organic amendments [30]. Furthermore, Alavi-Borazjani et al. [31][32] provided an insight into the feasibility of the utilization of biomass ashes in AD and biogas upgrading. According to Alavi-Borazjani et al. (2020), biomass ashes are cheap sources of alkali suitable for controlling the excessive acidification of anaerobic digesters. Biogas production is also enhanced due to the supplementation with the macro and micronutrient present in biomass ashes, which are required for the anaerobic microbes, and only a reference of WA was mentioned in relation to the biogas upgrading. Raw biogas of approximately 60% methane does not have enough quality for its introduction into the natural gas grid. Most frequently used purification technologies (water/amine scrubbing, pressure swing adsorption, cryogenic distillation, and membrane) require an excessive amount of energy and chemicals. The main targeted compounds to be removed from the biogas are CO2 and H2S. Given the complexity of the WA, there is a knowledge gap on the absorption capacity of bulk WA, and gathering more information to fully appreciate the valorization opportunities of this material is required [31][32].

2.3. Stability and Maturity of the WA Amended Anaerobic Digestate

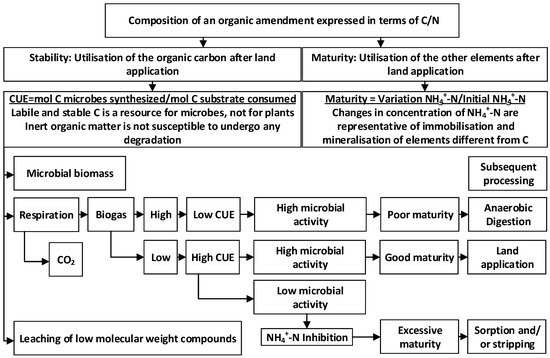

In some UK and European regulations, the terms stability and maturity are used indistinctly to describe the properties of a soil organic amendment [8][33][34]. Stability is related to reactions affecting the fate of carbon, which is the most abundant element in organic materials, and the maturity focuses on all the other elements (Figure 2). Some are nutrients necessary for plant growth (e.g., N, P, K, etc.), while others are phytotoxic compounds (e.g., Cd, Hg, Pb, etc.) that limit seed germination and root development. It is important to mention that the excess of any type of nutrients has a detrimental effect on the soil biota. Because nitrogen is the most abundant of these nutrients, its mineralized form, NH4+-N, could measure maturity [35][36][37].

The aim of determining the stability is to determine the fate of the carbon present in the labile and stable organic matter, since the inert organic matter will not suffer any degradation [38]. As displayed in Figure 2, the carbon could be (a) assimilated by the microorganisms for their growth, (b) lost via respiration, also known as carbon mineralization, and to a lesser extent, (c) lost due to leaching of the low organic molecular weight compounds. The carbon use efficiency (CUE) only accounts for the C used for the microbial growth, hence this parameter could be used to directly measure the stability of an organic amendment for more efficient nutrient management. However, the most common way of determining the stability is by measuring the losses via respiration [8][34][39][40][41], although the test is not carried out in similar conditions to the land application but in AD conditions as per the BMP protocol.

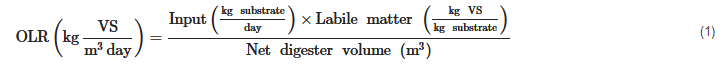

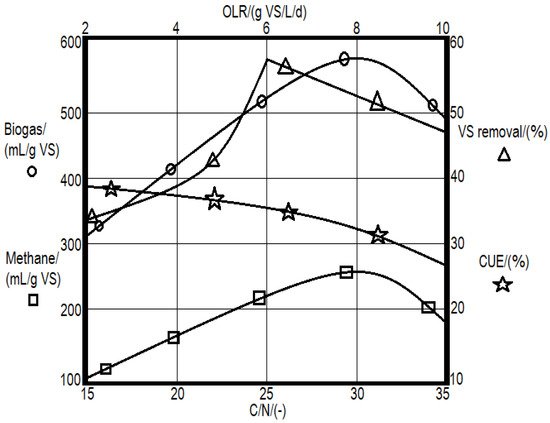

In a BMP test of an organic amendment (Figure 3), the release of biogas due to microbial activity depended on the composition expressed as the C/N and the relative amount of this material with respect to the microbial biomass (i.e., substrate-to-inoculum ratio, S/I), expressed as organic loading rate (OLR) in a continuous reactor. Together with the HRT, the OLR (Equation (1)) is one of the most important parameters in the operation of an anaerobic reactor, and both parameters are used for the design of the anaerobic digester [47][48]. The scale of the OLR for the operation of a continuous reactor, equivalent to the S/I in a batch reactor. Figure 3 included the OLR in the X axis based on the Figures 4 and 5 of Rincón et al. [49], who reported similar trends of biogas release and vs. removal. Reproduced with the permission of Biochemical Engineering Journal (Elsevier). In their original manuscript, the OLR was expressed on chemical oxygen demand (COD) basis, however, it is recommended to use the vs. instead [50].

Figure 3. Application of the concept of CUE from soil science to the AD process. The relation between the CUE and the C/N for terrestrial decomposers was taken from the Figure 1a of Sinsabaugh et al. [46]. Reproduced with the permission of Ecology Letters (John Wiley & Sons). The relation between the biogas yield, the methane yield, and the vs. removal with the C/N for the operation of a discontinuous reactor was taken from Figure 3 of Wang et al. [51], who carried out 30-day AD experiments with a S/I of 0.5 (expressed in terms of VS). Reproduced with the permission of Bioresource Technology (Elsevier).

References

- Banwart, S. Save our soils. Nature 2011, 474, 151–152.

- Elser, J.; Bennett, E. A broken biogeochemical cycle. Nature 2011, 478, 29–31.

- Vaccari, D.A. Phosphorus: A Looming Crisis. Sci. Am. 2009, 300, 54–59.

- Cordell, D.; Drangert, J.O.; White, S. The story of phosphorus: Global food security and food for thought. Glob. Environ. Chang. 2009, 19, 292–305.

- Hsu, E. Cost-benefit analysis for recycling of agricultural wastes in Taiwan. Waste Manag. 2021, 120, 424–432.

- European Parliament. Directive 2018/851 Amending Directive 2008/98/EC on Waste Framework. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv:OJ.L.2018.150.01.0109.01.ENG (accessed on 14 December 2021).

- Corden, C.; Bougas, K.; Cunningham, E.; Tyrer, D.; Kreißig, J.; Zetti, E.; Gamero, E.; Wildey, R.; Crookes, M. Digestate and Compost as Fertilisers: Risk Assessment and Risk Management Options. Available online: https://ec.europa.eu/environment/chemicals/reach/pdf/40039%20Digestate%20and%20Compost%20RMOA%20-%20Final%20report%20i2_20190208.pdf (accessed on 14 December 2021).

- Saveyn, H.; Eder, P. End-of-Waste Criteria for Biodegradable Waste Subjected to Biological Treatment (Compost & Digestate): Technical Proposals. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC87124 (accessed on 14 December 2021).

- Victor, L. AD and Composting Industry Market Survey Report 2020. Available online: https://wrap.org.uk/sites/default/files/2021-01/AD%20%26%20Composting%20Market%20Survey%20Report.pdf (accessed on 14 December 2021).

- Wood, E.; James, K.; Barker, E. Comparison of the Environmental Impacts of Nitrogenous Materials. Available online: https://wrap.org.uk/sites/default/files/2021-01/Nitrogenous%20Materials%20Report%202020.pdf (accessed on 14 December 2021).

- Klages, S.; Heidecke, C.; Osterburg, B.; Bailey, J.; Calciu, I.; Casey, C.; Dalgaard, T.; Frick, H.; Glavan, M.; D’Haene, K.; et al. Nitrogen Surplus—A Unified Indicator for Water Pollution in Europe? Water 2020, 12, 1197.

- Blumenthal, K. Generation and Treatment of Municipal Waste. Available online: https://op.europa.eu/en/publication-detail/-/publication/bd8a43dc-8076-4134-987d-c3081c8311e8 (accessed on 14 December 2021).

- Hou, Y.; Velthof, G.L.; Case, S.D.C.; Oelofse, M.; Grignani, C.; Balsari, P.; Zavattaro, L.; Gioelli, F.; Bernal, M.P.; Fangueiro, D.; et al. Stakeholder perceptions of manure treatment technologies in Denmark, Italy, the Netherlands and Spain. J. Clean. Prod. 2018, 172, 1620–1630.

- Holm-Nielsen, J.B.; Al Seadi, T.; Oleskowicz-Popiel, P. The future of anaerobic digestion and biogas utilization. Bioresour. Technol. 2009, 100, 5478–5484.

- Bond, T.; Templeton, M.R. History and future of domestic biogas plants in the developing world. Energy Sustain. Dev. 2011, 15, 347–354.

- Dagnall, S. UK strategy for centralised anaerobic digestion. Bioresour. Technol. 1995, 52, 275–280.

- Madsen, M.; Holm-Nielsen, J.B.; Esbensen, K.H. Monitoring of anaerobic digestion processes: A review perspective. Renew. Sustain. Energy Rev. 2011, 15, 3141–3155.

- Vassilev, S.V.; Baxter, D.; Vassileva, C.G. An overview of the behaviour of biomass during combustion: Part I. Phase-mineral transformations of organic and inorganic matter. Fuel 2013, 112, 391–449.

- Pitman, R.M. Wood ash use in forestry—A review of the environmental impacts. Forestry 2006, 79, 563–588.

- UK Forestry Commission. Forestry Statistics. Available online: https://www.forestresearch.gov.uk/tools-and-resources/statistics/forestry-statistics/forestry-statistics-2016-introduction/ (accessed on 14 December 2021).

- UK Quality Ash Association. UKQAA Ash Availability Report. Available online: http://www.ukqaa.org.uk/information/statistics/ (accessed on 14 December 2021).

- UK Quality Ash Association. About Us. Available online: http://www.ukqaa.org.uk/about/ (accessed on 14 December 2021).

- Andersson, L. Regular Recycling of Wood Ash to Prevent Waste Production. RecAsh. Available online: https://www.osti.gov/etdeweb/servlets/purl/20886561 (accessed on 14 December 2021).

- Guerrero, L.; Da Silva, C.; Barahona, A.; Montalvo, S.; Huiliñir, C.; Borja, R.; Peirano, C.; Toledo, M.; Carvajal, A. Fly ash as stimulant for anaerobic digestion: Effect over hydrolytic stage and methane generation rate. Water Sci. Technol. 2019, 80, 1384–1391.

- Fernández-Delgado Juárez, M.; Waldhuber, S.; Knapp, A.; Partl, C.; Gómez-Brandón, M.; Insam, H. Wood ash effects on chemical and microbiological properties of digestate- and manure-amended soils. Biol. Fertil. Soils 2013, 49, 575–585.

- Ibeto, C.N.; Lag-Brotons, A.J.; Marshall, R.; Semple, K.T. The Nutritional Effects of Digested and Undigested Organic Wastes Combined with Wood Ash Amendments on Carrot Plants. J. Soil Sci. Plant Nutr. 2020, 20, 460–472.

- Fenton, O. Chemical Amendment of Slurry to Control Phosphorus Losses in Runoff. Available online: https://www.teagasc.ie/media/website/publications/2011/5669-Chemical-Amendment-of-Slurry.pdf (accessed on 14 December 2021).

- Zheng, Y.; Ke, L.; Xia, D.; Zheng, Y.; Wang, Y.; Li, H.; Li, Q. Enhancement of digestates dewaterability by CTAB combined with CFA pretreatment. Sep. Purif. Technol. 2016, 163, 282–289.

- Pesonen, J.; Kuokkanen, V.; Kuokkanen, T.; Illikainen, M. Co-granulation of bio-ash with sewage sludge and lime for fertilizer use. J. Environ. Chem. Eng. 2016, 4, 4817–4821.

- Appels, L.; Lauwers, J.; Degrve, J.; Helsen, L.; Lievens, B.; Willems, K.; Van Impe, J.; Dewil, R. Anaerobic digestion in global bio-energy production: Potential and research challenges. Renew. Sustain. Energy Rev. 2011, 15, 4295–4301.

- Alavi-Borazjani, S.A.; Capela, I.; Tarelho, L.A.C. Valorization of biomass ash in biogas technology: Opportunities and challenges. Energy Rep. 2020, 6, 472–476.

- Alavi-Borazjani, S.A.; Tarelho, L.A.C.; Capela, I. A Brief Overview on the Utilization of Biomass Ash in Biogas Production and Purification. Waste Biomass Valorization 2021, 12, 6375–6388.

- Bachmann, N. Design and engineering of biogas plants. In The Biogas Handbook: Science, Production, and Applications; Elsevier: Amsterdam, The Netherlands, 2013; pp. 191–211.

- Linke, B. Kinetic study of thermophilic anaerobic digestion of solid wastes from potato processing. Biomass Bioenergy 2006, 30, 892–896.

- Alburquerque, J.A.; de la Fuente, C.; Bernal, M.P. Chemical properties of anaerobic digestates affecting C and N dynamics in amended soils. Agric. Ecosyst. Environ. 2012, 160, 15–22.

- Astals, S.; Nolla-Ardèvol, V.; Mata-Alvarez, J. Thermophilic co-digestion of pig manure and crude glycerol: Process performance and digestate stability. J. Biotechnol. 2013, 166, 97–104.

- Bernal, M.P.; Alburquerque, J.A.; Moral, R. Composting of animal manures and chemical criteria for compost maturity assessment. A review. Bioresour. Technol. 2009, 100, 5444–5453.

- Strosser, E. Methods for determination of labile soil organic matter: An overview. J. Agrobiol. 2011, 27, 49–60.

- WRAP. BSI PAS 110:2014 Specification for Whole Digestate, Separated Liquor and Separated Fibre Derived from the Anaerobic Digestion of Source-Segregated Biodegradable Materials. 2014. Available online: https://wrap.org.uk/resources/guide/bsi-pas-110-producing-quality-anaerobic-digestate (accessed on 5 January 2022).

- Banks, C.J.; Haeven, S.; Zhang, Y.; Sapp, M. Review of the Application of the Residual Biogas Potential Test. Available online: http://www.organics-recycling.org.uk/uploads/article2652/PAS110%20digestate%20stability%20review.pdf (accessed on 14 December 2021).

- Walker, M.; Banks, C.; Heaven, S.; Frederickson, J. Residual Biogas Potential Test for Digestates. Available online: https://www.wrap.org.uk/sites/files/wrap/Residual%20Biogas%20Potential.pdf (accessed on 28 February 2017).

- Astals, S.; Nolla-Ardèvol, V.; Mata-Alvarez, J. Anaerobic co-digestion of pig manure and crude glycerol at mesophilic conditions: Biogas and digestate. Bioresour. Technol. 2012, 110, 63–70.

- Dijkstra, P.; Salpas, E.; Fairbanks, D.; Miller, E.B.; Hagerty, S.B.; Jan, K.; Groenigen, V.; Hungate, B.A.; Marks, J.C.; Koch, G.W.; et al. High carbon use efficiency in soil microbial communities is related to balanced growth, not storage compound synthesis. Soil Biol. Biochem. 2015, 89, 35–43.

- Geyer, K.M.; Kyker-Snowman, E.; Grandy, A.S.; Frey, S.D. Microbial carbon use efficiency: Accounting for population, community, and ecosystem-scale controls over the fate of metabolized organic matter. Biogeochemistry 2016, 127, 173–188.

- Manzoni, S.; Taylor, P.; Richter, A.; Porporato, A. Environmental and stoichiometric controls on microbial carbon-use efficiency in soils. New Phytol. 2012, 196, 79–91.

- Sinsabaugh, R.L.; Manzoni, S.; Moorhead, D.L.; Richter, A. Carbon use efficiency of microbial communities: Stoichiometry, methodology and modelling. Ecol. Lett. 2013, 16, 930–939.

- UK Government. Quality Protocol: Compost—End of Waste Criteria for the Production and Use of Quality Compost from Source-Segregated Biodegradable Waste. Available online: https://www.gov.uk/government/publications/quality-protocol-for-the-production-and-use-of-compost-from-waste (accessed on 14 December 2021).

- WRAP. PAS 100:2011 Specification for Composted Materials. Available online: http://www.organics-recycling.org.uk/page.php?article=3483#:~:text=PAS%20100%3A2018%20requires%20producers%20to%20set%20up%20a,also%20relates%20to%20the%20new%20%C3%82%C2%91compost%20quality%C3%82%C2%92%20clause (accessed on 15 December 2021).

- Wang, X.; Yang, G.; Feng, Y.; Ren, G.; Han, X. Optimizing feeding composition and carbon—nitrogen ratios for improved methane yield during anaerobic co-digestion of dairy, chicken manure and wheat straw. Bioresour. Technol. 2012, 120, 78–83.

- Rincón, B.; Borja, R.; González, J.M.; Portillo, M.C.; Sáiz-Jiménez, C. Influence of organic loading rate and hydraulic retention time on the performance, stability and microbial communities of one-stage anaerobic digestion of two-phase olive mill solid residue. Biochem. Eng. J. 2008, 40, 253–261.

- Angelidaki, I.; Alves, M.; Bolzonella, D.; Borzacconi, L.; Campos, J.L.; Guwy, A.J.; Kalyuzhnyi, S.; Jenicek, P.; Van Lier, J.B. Defining the biomethane potential (BMP) of solid organic wastes and energy crops: A proposed protocol for batch assays. Water Sci. Technol. 2009, 59, 927–934.

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Entry Collection:

Environmental Sciences

Revisions:

2 times

(View History)

Update Date:

21 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No