| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Monohar Hossain Mondal | + 3346 word(s) | 3346 | 2022-01-04 14:10:26 | | | |

| 2 | Conner Chen | Meta information modification | 3346 | 2022-01-19 03:11:47 | | |

Video Upload Options

Natural emulsion stabilizers are polymers of amino acid, nucleic acid, carbohydrate, etc., which are derived from microorganisms, bacteria, and other organic materials. Plant and animal proteins are basic sources of natural emulsion stabilizers. Pea protein-maltodextrin and lentil protein feature entrapment capacity up to 88%, (1–10% concentrated), zein proteins feature 74–89% entrapment efficiency, soy proteins in various concentrations increase dissolution, retention, and stability to the emulsion and whey proteins, egg proteins, and proteins from all other animals are applicable in membrane formation and encapsulation to stabilize emulsion/nanoemulsion. In pharmaceutical industries, phospholipids, phosphatidyl choline (PC), phosphatidyl ethanol-amine (PE), and phosphatidyl glycerol (PG)-based stabilizers are very effective as emulsion stabilizers. Lecithin (a combination of phospholipids) is used in the cosmetics and food industries. Various factors such as temperature, pH, droplets size, etc. destabilize the emulsion. Therefore, the emulsion stabilizers are used to stabilize, preserve and safely deliver the formulated drugs, also as a preservative in food and stabilizer in cosmetic products. Natural emulsion stabilizers offer great advantages because they are naturally degradable, ecologically effective, non-toxic, easily available in nature, non-carcinogenic, and not harmful to health.

1. Emulsion and Emulsion Stabilizer

1.1. Emulsion and Emulsification

| Properties | Emulsions | Nanoemulsions | References |

|---|---|---|---|

| Droplet size | Lager than nanoemulsions | 20–200 nm | [3] |

| Stability | Thermodynamically unstable | Thermodynamically stable | [4] |

| Formation | By high shear homogenization methods | Micro-fluidization of emulsions | [5] |

| Viscosity | Higher viscosity than nanoemulsions | Lower viscosity than emulsions | [5] |

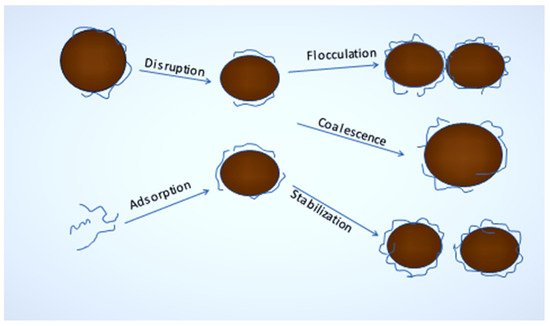

1.2. Stabilization and Destabilization of Nanoemulsion

1.3. Synthesis and Application of Nanoemulsion

| Sources | Emulsification Techniques | Droplet Size | References |

|---|---|---|---|

| Fluids | Ultrasonic emulsification | 24.21 ± 0.11 nm | [17] |

| Pastes | Emulsion inversion point method | <300 nm | [18] |

| Fogs | High-pressure homogenization | 200–600 nm | [19] |

| Gels | Microfluidization | <100 nm | [20][21] |

| Fine liquid and solid particles in the air | Vertex mixing | 282 nm | [22][23] |

| Topical | High-pressure homogenization | 50–100 nm | [24] |

| Oral | Microfluidization | 22 ± 4.0 nm | [25] |

| Intravenous | High-pressure homogenization | 89.23 ± 7.2 nm | [26] |

| Intranasal, pulmonary, and ocular | High-pressure homogenization | 8.4 ± 12.7 nm | [27] |

| Cosmetic industry | Ultrasonic emulsification | 6–10 nm | [28] |

| Pesticide industry | Low-energy emulsification | ~30 nm | [29] |

2. Polysaccharides Chemical Structure and Their Properties

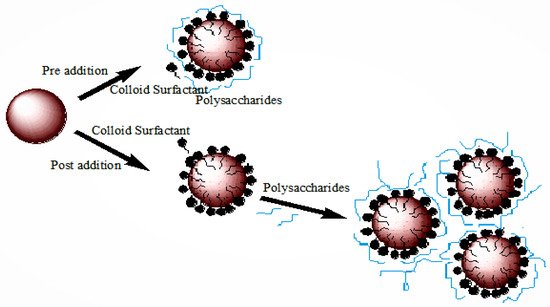

2.1. Synthesis of Polysaccharides Emulsion

2.2. Glycosyl with Polysaccharides

3. Food Protein and Food Protein Emulsions

3.1. Animal Protein and Plant Protein

3.2. Effectiveness of Plant Protein

3.3. Pea Protein Entrapment Efficiency

3.4. Other Plant Protein and Entrapment Efficiency

3.5. Modification of Protein into Functional Components

4. The Stability Factors of Proteins Nanoemulsions

4.1. Encapsulation and Encapsulation Efficiency

4.2. Emulsifying Properties of Proteins

- (a)

-

Surface hydrophobicity: The percentage of hydrophobic proteins exposed on the surface of proteins measures how much of the protein can adsorb to the oil phase. The presence of hydrophobic sites buried inside proteins can be revealed by partial denaturation, which can increase their emulsifying ability [72].

- (b)

-

The flexibility of proteins: It is a self-rearrangement property of proteins, when it is adsorbed at the oil–water (O/W) interface, most of the hydrophilic mass favors the watery parts and the hydrophobic mass favors the oily parts by reducing the attractive force between two liquids [73]. According to the composition of protein, hydrophilic loops of amino acids may enlarge away from the O/W interface in the form of waterish parts, slowing the reaction [73].

- (c)

- (d)

-

When encapsulating, a high solubility of proteins is preferable in order to allow higher movement in the O/W interface and higher continuous phase viscosities [72].

- (e)

-

The factor influences in the protein solubility are the pH of the solvent, the ionic character, and the attractive or repulsive forces between closer globules showing emulsion instability or stability. When the solvent pH is not near the isoelectric point of proteins or when ionic conditions are low, charge repulsion can enhance emulsion stability [75].

4.3. Protein from Rice Bran as an Emulsifier

References

- Pal, A.; Mondal, M.H.; Adhikari, A.; Bhattarai, A.; Saha, B. Scientific information about sugar-based emulsifiers: A comprehensive review. RSC Adv. 2021, 11, 33004–33016.

- El Asjadi, S.; Nederpel, Q.A.; Cotiuga, I.M.; Picken, S.J.; Besseling, N.A.M.; Mendes, E.; Lommerts, B.J. Biopolymer scleroglucan as an emulsion stabilizer. Colloids Surf. A Physicochem. Eng. Aspects 2018, 546, 326–333.

- Solans, C.; Izquierdo, P.; Nolla, J.; Azemar, N.; Garcia-Celma, M.J. Nano-emulsions. Curr. Opin. Colloid Interface Sci. 2005, 10, 102–110.

- Azeem, A.; Rizwan, M.; Ahmad, F.J.; Iqbal, Z.; Khar, R.K.; Aqil, M.; Talegaonkar, S. Nanoemulsion components screening and selection: A technical note. Aaps Pharmscitech. 2009, 10, 69–76.

- Salvia-Trujillo, L.; Rojas-Graü, A.; Soliva-Fortuny, R.; Martín-Belloso, O. Physicochemical characterization and antimicrobial activity of food-grade emulsions and nanoemulsions incorporating essential oils. Food Hydrocoll. 2015, 43, 547–556.

- Zhang, Y.; Shang, Z.; Gao, C.; Du, M.; Xu, S.; Song, H.; Liu, T. Nanoemulsion for Solubilization, Stabilization, and In Vitro Release of Pterostilbene for Oral Delivery. Aaps Pharmscitech. 2014, 15, 1000–1008.

- Jiang, S.P.; He, S.N.; Li, Y.L.; Feng, D.L.; Lu, X.Y.; Du, Y.Z.; Yu, H.Y.; Hu, F.Q.; Yuan, H. Preparation and characteristics of lipid nanoemulsion formulations loaded with doxorubicin. Int. J. Nanomed. 2013, 8, 3141–3150.

- Devalapally, H.; Zhou, F.; McDade, J.; Goloverda, G.; Owen, A.; Hidalgo, I.J.; Silchenko, S. Optimization of PEGylatednanoemulsions for improved pharmacokinetics of BCS class II compounds. Drug Deliv. 2013, 22, 467–474.

- Yu, H.; Huang, Q. Improving the Oral Bioavailability of Curcumin Using Novel Organogel-Based Nanoemulsions. J. Agric. Food Chem. 2012, 60, 5373–5379.

- Sun, W.; Ma, X.; Wei, X.; Xu, Y. Nano Composite Emulsion for Sustained Drug Release and Improved Bioavailability. Pharm. Res. 2014, 31, 2774–2783.

- Dickinson, E. Hydrocolloids as emulsifiers and emulsion stabilizers. Food Hydrocoll. 2009, 23, 1473–1482.

- Li, X.; Liu, S.; Wang, Q.; Lu, R. Nanoemulsions as novel oral carriers of stiripentol: Insights into the protective effect and absorption enhancement. Int. J. Nanomed. 2015, 10, 4937.

- Muheem, A.; Shakeel, F.; Jahangir, M.A.; Anwar, M.; Mallick, N.; Jain, G.K.; Warsi, M.H.; Ahmad, F.J. A review on the strategies for oral delivery of proteins and peptides and their clinical perspectives. Saudi Pharm. J. 2016, 24, 413–428.

- Ensign, L.M.; Cone, R.; Hanes, J. Oral drug delivery with polymeric nanoparticles: The gastrointestinal mucus barriers. Adv. Drug Deliv. Rev. 2012, 64, 557–570.

- Darwis, Y.; Ali Khan, A.; Mudassir, J.; Mohtar, N. Advanced drug delivery to the lymphatic system: Lipid-based nanoformulations. Int. J. Nanomed. 2013, 8, 2733.

- Choi, S.J.; McClements, D.J. Nanoemulsions as delivery systems for lipophilic nutraceuticals: Strategies for improving their formulation, stability, functionality and bioavailability. Food Sci. Biotechnol. 2020, 29, 149–168.

- Tan, S.; Stanslas, J.; Basri, M.; Karjiban, R.A.; Kirby, B.; Sani, D.; Basri, H. Nanoemulsion-based Parenteral Drug Delivery System of Carbamazepine: Preparation, Characterization, Stability Evaluation and Blood-Brain Pharmacokinetics. Curr. Drug Deliv. 2015, 12, 795–804.

- Al-Edresi, S.; Baie, S. Formulation and stability of whitening VCO-in-water nano-cream. Int. J. Pharm. 2009, 373, 174–178.

- Makidon, P.E.; Nigavekar, S.S.; Bielinska, A.U.; Mank, N.; Shetty, A.M.; Suman, J.; Knowlton, J.; Myc, A.; Rook, T.; Baker, J.R. Characterization of Stability and Nasal Delivery Systems for Immunization with Nanoemulsion-Based Vaccines. J. Aerosol Med. Pulm. Drug Deliv. 2010, 23, 77–89.

- Lala, R.R.; Awari, N.G. Nanoemulsion-based gel formulations of COX-2 inhibitors for enhanced efficacy in inflammatory conditions. Appl. Nanosci. 2013, 4, 143–151.

- Hussain, A.; Samad, A.; Singh, S.K.; Ahsan, M.N.; Haque, M.W.; Faruk, A.; Ahmed, F.J. Nanoemulsion gel-based topical delivery of an antifungal drug: In vitro activity and in vivo evaluation. Drug Deliv. 2014, 23, 642–657.

- Nasr, M.; Nawaz, S.; Elhissi, A. Amphotericin B lipid nanoemulsion aerosols for targeting peripheral respiratory airways via nebulization. Int. J. Pharm. 2012, 436, 611–616.

- Amani, A.; York, P.; Chrystyn, H.; Clark, B.J. Evaluation of a Nanoemulsion-Based Formulation for Respiratory Delivery of Budesonide by Nebulizers. Aaps Pharmscitech 2010, 11, 1147–1151.

- Mou, D.; Chen, H.; Du, D.; Mao, C.; Wan, J.; Xu, H.; Yang, X. Hydrogel-thickened nanoemulsion system for topical delivery of lipophilic drugs. Int. J. Pharm. 2008, 353, 270–276.

- Khani, S.; Keyhanfar, F.; Amani, A. Design and evaluation of oral nanoemulsion drug delivery system of mebudipine. Drug Deliv. 2015, 23, 2035–2043.

- Pawar, V.K.; Panchal, S.B.; Singh, Y.; Meher, J.G.; Sharma, K.; Singh, P.; Bora, H.K.; Singh, A.; Datta, D.; Chourasia, M.K. Immunotherapeutic vitamin E nanoemulsion synergies the antiproliferative activity of paclitaxel in breast cancer cells via modulating Th1 and Th2 immune response. J. Control. Release 2014, 196, 295–306.

- Ammar, H.O.; Salama, H.A.; Ghorab, M.; Mahmoud, A.A. Nanoemulsion as a Potential Ophthalmic Delivery System for Dorzolamide Hydrochloride. Aaps Pharmscitech 2009, 10, 808–819.

- Yukuyama, M.N.; Ghisleni, D.D.M.; Pinto, T.J.A.; Bou-Chacra, N.A. Nanoemulsion: Process selection and application in cosmetics—A review. Int. J. Cosmet. Sci. 2015, 38, 13–24.

- Wang, L.; Li, X.; Zhang, G.; Dong, J.; Eastoe, J. Oil-in-water nanoemulsions for pesticide formulations. J. Colloid Interface Sci. 2007, 314, 230–235.

- Nie, S.P.; Wang, C.; Cui, S.W.; Wang, Q.; Xie, M.Y.; Phillips, G.O. A further amendment to the classical core structure of gum arabic (Acacia senegal). FoodHydrocoll. 2013, 31, 42–48.

- Enayati, M.; Gong, Y.; Goddard, J.M.; Abbaspourrad, A. Synthesis and characterization of lactose fatty acid ester biosurfactants using free and immobilized lipases in organic solvents. Food Chem. 2018, 266, 508–513.

- Iglauer, S.; Wu, Y.; Shuler, P.; Tang, Y.; Goddard, W.A. Analysis of the Influence of Alkyl Polyglycoside Surfactant and Cosolvent Structure on Interfacial Tension in Aqueous Formulations versus n-Octane. Tenside Surf. Det. 2010, 47, 87–97.

- Patel, S.; Goyal, A. Applications of Natural Polymer Gum Arabic: A Review. Int. J. Food Prop. 2015, 18, 986–998.

- Tadros, T.F. Emulsion Formation and Stability; Wiley: Hoboken, NJ, USA, 2013. ISBN 978352764 7941.

- Plat, T.; Linhardt, R.J. Syntheses and applications of sucrose-based esters. J. Surfactants Deterg. 2001, 4, 415–421.

- Jun-xia, X.; Hai-yan, Y.; Jian, Y. Microencapsulation of sweet orange oil by complex coacervation with soybean protein isolate/gum Arabic. Food Chem. 2011, 125, 1267–1272.

- Tang, C.H.; Li, X.R. Microencapsulation properties of soy protein isolate and storage stability of the correspondingly spray-dried emulsions. Food Res. Int. 2013, 52, 419–428.

- Ducel, V.; Richard, J.; Saulnier, P.; Popineau, Y.; Boury, F. Evidence and characterization of complex coacervates containing plant proteins: Application to the microencapsulation of oil droplets. Colloids Surf. A Physicochem. Eng. Asp. 2004, 232, 239–247.

- Gharsallaoui, A.; Saurel, R.; Chambin, O.; Cases, E.; Voilley, A.; Cayot, P. Utilisation of pectin coating to enhance spray-dry stability of pea protein-stabilised oil-in-water emulsions. Food Chem. 2010, 122, 447–454.

- Karaca, A.C.; Low, N.H.; Nickerson, M.T. Potential use of plant proteins in the microencapsulation of lipophilic materials in foods. Trends Food Sci. Technol. 2015, 42, 5–12.

- Xue, F.; Li, C.; Liu, Y.; Zhu, X.; Pan, S.; Wang, L. Encapsulation of tomato oleoresin with zein prepared from corn gluten meal. J. Food Eng. 2013, 119, 439–445.

- Wang, R.; Tian, Z.; Chen, L. A novel process for microencapsulation of fish oil with barley protein. Food Res. Int. 2011, 44, 2735–2741.

- Jiang, J.; Chen, J.; Xiong, Y.L. Structural and Emulsifying Properties of Soy Protein Isolate Subjected to Acid and Alkaline pH-Shifting Processes. J. Agric. Food Chem. 2009, 57, 7576–7583.

- Augustin, M.A.; Sanguansri, L.; Bode, O. Maillard reaction products as encapsulants for fish oil powders. J. Food Sci. 2006, 71, E25–E32.

- Paraman, I.; Hettiarachchy, N.S.; Schaefer, C. Glycosylation and deamidation of rice endosperm protein for improved solubility and emulsifying properties. Cereal Chem. 2007, 84, 593–599.

- Wong, B.T.; Day, L.; Augustin, M.A. Deamidated wheat protein-dextran Maillard conjugates: Effect of size and location of polysaccharide conjugated on steric stabilization of emulsions at acidic pH. Food Hydrocoll. 2011, 25, 1424–1432.

- Tang, C.H.; Sun, X.; Foegeding, E.A. Modulation of physicochemical and conformational properties of kidney bean vicilin (phaseolin) by glycation with glucose: Implications for structure–function relationships of legume vicilins. J. Agric. Food Chem. 2011, 59, 10114–10123.

- Jourdain, L.; Leser, M.E.; Schmitt, C.; Michel, M.; Dickinson, E. Stability of emulsions containing sodium caseinate and dextran sulfate: Relationship to complexation in solution. Food Hydrocoll. 2008, 22, 647–659.

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121.

- Li, J.; Bai, Y.; Wang, W.; Tai, X.; Wang, G. Green Glucamine-Based Trisiloxane Surfactant: Surface Activity, Aggregate Behavior, and Superspreading on Hydrophobic Surfaces. ACS Sustain. Chem. Eng. 2019, 7, 4390–4398.

- Teng, F.; He, M.; Xu, J.; Chen, F.; Wu, C.; Wang, Z.; Li, Y. Effect of ultrasonication on the stability and storage of a soy protein isolate-phosphatidylcholine nanoemulsions. Sci. Rep. 2020, 10, 1–9.

- Xu, H.; Chang, C.; Yi, N.; Tao, P.; Song, C.; Wu, J.; Deng, T.; Shang, W. Coalescence, Spreading, and Rebound of Two Water Droplets with Different Temperatures on a Superhydrophobic Surface. ACS Omega 2019, 4, 17615–17622.

- Carpenter, J.; Saharan, V.K. Ultrasonic assisted formation and stability of mustard oil in water nanoemulsion: Effect of process parameters and their optimization. Ultrason. Sonochemistry 2017, 35, 422–430.

- Haahr, A.M.; Jacobsen, C. Emulsifier type, metal chelation and pH affect oxidative stability of n-3-enriched emulsions. Eur. J. Lipid Sci. Technol. 2008, 110, 949–961.

- Suk, J.S.; Xu, Q.; Kim, N.; Hanes, J.; Ensign, L.M. PEGylation as a strategy for improving nanoparticle-based drug and gene delivery. Adv. Drug Deliv. Rev. 2016, 99, 28–51.

- Daraee, H.; Etemadi, A.; Kouhi, M.; Alimirzalu, S.; Akbarzadeh, A. Application of liposomes in medicine and drug delivery. Artif. Cells Nanomed. Biotechnol. 2014, 44, 381–391.

- Yao, C.; Wang, P.; Li, X.; Hu, X.; Hou, J.; Wang, L.; Zhang, F. Near-Infrared-Triggered Azobenzene-Liposome/Upconversion Nanoparticle Hybrid Vesicles for Remotely Controlled Drug Delivery to Overcome Cancer Multidrug Resistance. Adv. Mater. 2016, 28, 9341–9348.

- Li, Y.; Maciel, D.; Rodrigues, J.; Shi, X.; Tomás, H. Biodegradable Polymer Nanogels for Drug/Nucleic Acid Delivery. Chem. Rev. 2015, 115, 8564–8608.

- Teranishi, R.; Matsuki, R.; Yuba, E.; Harada, A.; Kono, K. Doxorubicin Delivery Using pH and Redox Dual-Responsive Hollow Nanocapsules with a Cationic Electrostatic Barrier. Pharmaceutics 2016, 9, 4.

- Biswas, S.; Kumari, P.; Lakhani, P.M.; Ghosh, B. Recent advances in polymeric micelles for anti-cancer drug delivery. Eur. J. Pharm. Sci. 2016, 83, 184–202.

- Cui, Y.; Yang, Y.; Ma, M.; Xu, Y.; Sui, J.; Li, H.; Liang, J.; Sun, Y.; Fan, Y.; Zhang, X. Reductive responsive micelle overcoming multidrug resistance of breast cancer by co-delivery of DOX and specific antibiotic. J. Mater. Chem. B 2019, 7, 6075–6086.

- Deepagan, V.; Kwon, S.; You, D.G.; Nguyen, V.Q.; Um, W.; Ko, H.; Lee, H.; Jo, D.G.; Kang, Y.M.; Park, J.H. In situ diselenide-crosslinked polymeric micelles for ROS-mediated anticancer drug delivery. Biomaterials 2016, 103, 56–66.

- Fan, Z.; Chen, C.; Pang, X.; Yu, Z.; Qi, Y.; Chen, X.; Liang, H.; Fang, X.; Sha, X. Adding Vitamin E-TPGS to the Formulation of Genexol-PM: Specially Mixed Micelles Improve Drug-Loading Ability and Cytotoxicity against Multidrug-Resistant Tumors Significantly. PLoS ONE 2015, 10, e0120129.

- Kataoka, K.; Harada, A.; Nagasaki, Y. Block copolymer micelles for drug delivery: Design, characterization and biological significance. Adv. Drug Deliv. Rev. 2012, 64, 37–48.

- Kutty, R.V.; Feng, S.S. Cetuximab conjugated vitamin E TPGS micelles for targeted delivery of docetaxel for treatment of triple negative breast cancers. Biomaterials 2013, 34, 10160–10171.

- Guo, Y.; Chu, M.; Tan, S.; Zhao, S.; Liu, H.; Otieno, B.O.; Yang, X.; Xu, C.; Zhang, Z. Chitosan-g-TPGS Nanoparticles for Anticancer Drug Delivery and Overcoming Multidrug Resistance. Mol. Pharm. 2013, 11, 59–70.

- Liu, Y.; Wu, J.; Huang, L.; Qiao, J.; Wang, N.; Yu, D.; Zhang, G.; Yu, S.; Guan, Q. Synergistic effects of antitumor efficacy via mixed nano-size micelles of multifunctional Bletilla striata polysaccharide-based copolymer and D-α-tocopheryl polyethylene glycol succinate. Int. J. Biol. Macromol. 2020, 154, 499–510.

- Desai, K.G.H.; Jin Park, H. Recent Developments in Microencapsulation of Food Ingredients. Dry. Technol. 2005, 23, 1361–1394.

- Augustin, M.A.; Hemar, Y. Nano- and micro-structured assemblies for encapsulation of food ingredients. Chem. Soc. Rev. 2009, 38, 902–912.

- McClements, D.; Decker, E.; Weiss, J. Emulsion-Based Delivery Systems for Lipophilic Bioactive Components. J. Food Sci. 2007, 72, R109–R124.

- Subirade, M.; Chen, L. Food-Protein-Derived Materials and Their Use as Carriers and Delivery Systems for Active Food Components. Delivery and Controlled Release of Bioactives in Foods and Nutraceuticals; Elsevier: Amsterdam, The Netherlands, 2008; pp. 251–278.

- Sikorski, Z.E. Functional Properties of Proteins in Food Systems. Chemical and Functional Properties of Food Proteins; Routledge: Oxfordshire, UK, 2001; pp. 113–135.

- Damodaran, S. Protein-Stabilized Foams and Emulsions. Food Proteins and Their Applications; CRC Press: Boca Raton, FL, USA, 2017; pp. 57–110.

- Luyten, H.; Vereijken, J.; Buecking, M. Using proteins as additives in foods: An introduction. In Proteins in Food Processing; Elsevier: Amsterdam, The Netherlands, 2004; pp. 421–441.

- McClements, D.J. Nanoemulsions versus microemulsions: Terminology, differences, and similarities. Soft Matter 2012, 8, 1719–1729.

- Liu, Y.; Liu, C.; Zhang, S.; Li, J.; Zheng, H.; Jin, H.; Xu, J. Comparison of different protein emulsifiers on physicochemical properties of β-carotene-loaded nanoemulsion: Effect on formation, stability, and in vitro digestion. Nanomaterials 2021, 11, 167.

- Chen, W.; Ju, X.; Aluko, R.E.; Zou, Y.; Wang, Z.; Liu, M.; He, R. Rice bran protein-based nanoemulsion carrier for improving stability and bioavailability of quercetin. Food Hydrocoll. 2020, 108, 106042.