Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hisham Alidrisi | + 1262 word(s) | 1262 | 2021-11-21 10:21:40 | | | |

| 2 | Vicky Zhou | + 1262 word(s) | 1262 | 2021-11-21 11:15:05 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Alidrisi, H. Efficiency-Based Global Green Manufacturing Innovation Index. Encyclopedia. Available online: https://encyclopedia.pub/entry/16227 (accessed on 08 February 2026).

Alidrisi H. Efficiency-Based Global Green Manufacturing Innovation Index. Encyclopedia. Available at: https://encyclopedia.pub/entry/16227. Accessed February 08, 2026.

Alidrisi, Hisham. "Efficiency-Based Global Green Manufacturing Innovation Index" Encyclopedia, https://encyclopedia.pub/entry/16227 (accessed February 08, 2026).

Alidrisi, H. (2021, November 21). Efficiency-Based Global Green Manufacturing Innovation Index. In Encyclopedia. https://encyclopedia.pub/entry/16227

Alidrisi, Hisham. "Efficiency-Based Global Green Manufacturing Innovation Index." Encyclopedia. Web. 21 November, 2021.

Copy Citation

Manufacturing Innovation Index (GGMII) was developed by formulating an input-oriented data envelopment analysis model. Criteria such as the value added to the gross domestic product (GDP), corresponding CO2 emissions, and unemployment rates were examined in order to represent the economic, environmental, and social dimensions of SD, respectively. Other scientific and technological dimensions were also considered. The data corresponding to all ten of the criteria were collected from World Bank Open Data.

green manufacturing innovation index

global index

green innovation index

sustainability

World Bank

United States

China

1. Introduction

Innovation-based economic growth is considered a vital strategy for attaining economic success in employment and overall prosperity. The environmental degradation associated with such advancements has resulted in the appearance of several environmentally friendly concepts, such as green/sustainable development (SD) [1]. The rapid development of green innovation worldwide is contributing significantly to almost all kinds of industries [2]. However, attempts to research such promising concepts are still in need of unbounded and continued support [3]. Even though the recent literature on the Green Innovation Index (GII) has provided various investigations relevant to different aspects of innovation, some key technological and/or practical issues have not yet been handled appropriately.

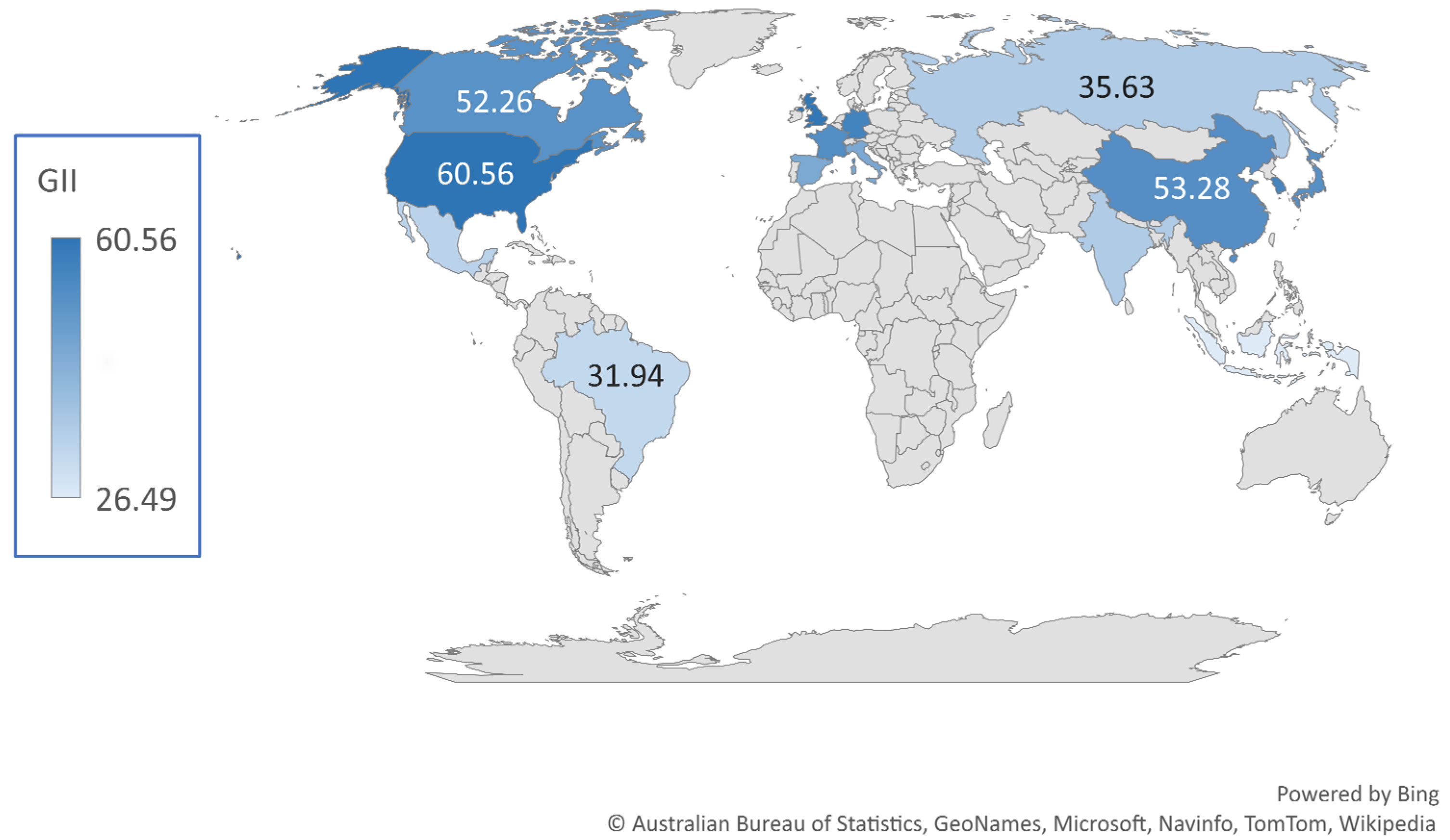

The dilemma of creating a comprehensive GII that considers environmental concerns represents one such critical issue. Even when the latest version of the GII (Figure 1), published in 2020, employed data envelopment analysis (DEA) as a benchmarking tool to measure economies’ multi-dimensional performances with respect to innovation [4], the sustainability dimensions (in particular, the environmental measures) were not explicitly included either as inputs or as outputs. Moreover, the structural relationships among the GII inputs and outputs have been ignored in the recent utilization of DEA in the GII [5]. The potential capability to measure a degree of innovation is more complex than what is being considered and practiced in the current GII [6][7].

Figure 1. Global Innovation Index (GII) for the top 15 manufacturing countries worldwide, based on the manufacturing net value added to the GDP. (Source: data corresponding to each country were collected by the author from the Global Innovation Index report [4]; a licensed Microsoft Excel copy from King Abdulaziz University was then utilized to develop the figure; which is automatically labeled by the following statement: “Powered by Bing © Australian Bureau of Statistics, GeoNames, Microsoft, Navinfo, TomTom, Wikipedia”).

An input-oriented DEA approach was formulated using ten criteria, three of which represented SD in its three generic dimensions, which consider aspects of manufacturing. These three criteria were selected to represent economic, environmental, and social factors: (1) manufacturing in terms of the net value added to the country’s gross domestic product (GDP) measured in US dollars, (2) the CO2 emissions from all manufacturing industries, including construction, as a percentage of the total fuel combustion, and (3) the level of unemployment measured as a percentage of the total labor force. The remaining seven criteria represent the maturity of the manufacturing practices, as all relevant/appropriate scientific and technological World Bank indicators were considered. The extent to which the GII scores had been influenced by the final efficiency scores of these 15 countries was then identified in order to obtain the final GGMII scores for each country.

2. The Different Aspects of Innovation

The different aspects of innovation are presented briefly in this section, in order to highlight the nature of the innovative practices being utilized in the top manufacturing countries. In the United States, innovation in Massachusetts has been investigated for “ecosystems dynamics,” and it has been concluded that the state has great manufacturing capabilities that are providing effective contributions to its leading industries [8], including complex industries such as the automotive industry [9]. The UK Innovation Index has shown that the UK’s intangible investments such as investment in R&D, software, design, training, and organizational capital were key contributors to economic growth. Furthermore, it was concluded that the UK information/communications industry represented the most intangible industry in terms of the value it added to the UK’s economy [10]. In Germany, it has been stressed that organizational characteristics play a significant role in determining the extent to which firms attain innovation [11]. Similarly, in France, numerous innovation-focused studies have been conducted. For instance, innovation has been studied in relation to the influence of the company directors’ characteristics, and it was found that highly educated and independent executives contribute positively to complex decision making, in turn fostering the innovation process and increasing the number of patents that are registered [12].

According to several studies, China also needs to work on creating a kind of growth that collectively and implicitly considers all of the aspects of green economic growth (i.e., the economic and the environmental dimensions) in order to attain better utilization of its resources [13]. In Spain, knowledge-intensive business services (KIBS) have been investigated in order to study the relationships between various sources of knowledge and innovation authenticity, and it was concluded that R&D was negatively linked with innovation, indicating that the definition of R&D should be clarified in order to ensure better linkages with innovation [14]. In the Korean manufacturing sector, the innovation capabilities of small and medium-sized enterprises (SMEs) have been empirically investigated in order to identify the strategic directions necessary for policymakers to be able to enhance sustainable innovation practices, considering the positive linkage between technological innovation performance and firms’ innovation capabilities [15].

Several aspects of green innovation have been studied in Japan, the United States, and a set of European firms, and one of the conclusions was that R&D efforts focusing on clean production processes strongly affect firms’ maturity levels in terms of their strategic decisions on green investments [16]. Indeed, the positive effect of digitalization on Japanese manufacturing SMEs resulted in better levels of attainment in satisfying customer needs, sales, and profits [17]. In the Italian manufacturing sector, several innovation issues have been discussed in the recent literature, such as the significance of R&D in product innovation within SMEs [18], the relationship between open innovation and human resources [19], the challenges for craft companies relating to digital manufacturing and open innovation [20], the funding of SMEs and their associated innovation strategies [21], and the learning processes that are taking place during the implementation of innovation practices [22].

With the aid of a robust data set, innovation was recently analyzed using two direct measures, R&D spending and the total number of innovations, in order to investigate the case of a Canadian manufacturing company [23]. In Mexico, large amounts of data were collected from 6378 companies in order to understand and interpret the nature of Mexico’s competition with China to penetrate US markets, in particular, the analysis explored the extent to which such competition has enhanced innovation in the Mexican manufacturing sector [24]. The market competition among Mexican companies showed a negative linear relationship with the firms’ innovation capabilities, due to the gaps between leader and follower companies [25]. In Indonesia, innovation was found to represent a critical dilemma, and it needed to be treated promptly in order to resolve issues such as substandard innovation performance indicators, the absence of creativity culture, limited R&D spending, and the absence of a comprehensive national innovation plan [26]. Hence, recent barriers to innovation for Indonesian manufacturing companies have been classified into four categories: markets and institutional situations; human resources and organizational relationships; risks associated with financial issues; and knowledge sharing and collaboration [27]. In order to enhance Russian manufacturing companies’ performance in innovation, science-based collaboration strategies have been discussed in an effort to link academia with industries [28]. Local Indian companies have attained better green innovation practices compared to foreign direct investment (FDI) companies due to a lack of enforcement of regulations on foreign companies in India [29].

References

- Galindo-Martín, M.-A.; Castaño-Martínez, M.-S.; Méndez-Picazo, M.-T. The Relationship between Green Innovation, Social Entrepreneurship, and Sustainable Development. Sustainability 2020, 12, 4467.

- Schiederig, T.; Tietze, F.; Herstatt, C. What Is Green Innovation? A Quantitative Literature Review; Multidisciplinary Digital Publishing Institute: Hamburg, Germany, 2011.

- Andersen, M.M. Eco-innovation–towards a taxonomy and a theory. In Proceedings of the 25th Celebration DRUID Conference, Copenhagen, Denmark, 17–20 June 2008; p. 18.

- Cornell University; INSEAD; WIPO. Global Innovation Index 2020: Who Will Finance Innovations; World Intellectual Property Organization: Geneva, Switzerland, 2021; ISBN 9782381920009.

- Sohn, S.Y.; Kim, D.H.; Jeon, S.Y. Re-evaluation of global innovation index based on a structural equation model. Technol. Anal. Strateg. Manag. 2016, 28, 492–505.

- Nasierowski, W.; Arcelus, F. Interrelationships among the elements of national innovation systems: A statistical evaluation. Eur. J. Oper. Res. 1999, 119, 235–253.

- Bartels, F.L.; Voss, H.; Lederer, S.; Bachtrog, C. Determinants of national innovation systems: Policy implications for devel-oping countries. Innovation 2012, 14, 2–18.

- Reynolds, E.B.; Uygun, Y. Strengthening advanced manufacturing innovation ecosystems: The case of Massachusetts. Technol. Forecast. Soc. Chang. 2018, 136, 178–191.

- Crossa, M.; Wise, R.D. Innovation in the era of generalized monopolies: The case of the US–Mexico automotive industrial complex. Globalizations 2021.

- Goodridge, P.; Haskel, J.E.; Wallis, G. UK Innovation Index 2014; Imperial College Business School: London, UK, 2015; p. 79.

- Niebuhr, A.; Peters, J.C.; Schmidke, A. Spatial sorting of innovative firms and heterogeneous effects of agglomeration on innovation in Germany. J. Technol. Transf. 2020, 45, 1343–1375.

- Attia, M.; Yousfi, O.; Loukil, N.; Omri, A. Do directors’ attributes influence innovation? Empirical evidence from france. Int. J. Innov. Manag. 2021, 25, 2150010.

- Han, J.; Chen, X.; Sun, Y. Technology or Institutions: Which Is the Source of Green Economic Growth in Chinese Cities? Sustainability 2021, 13, 10934.

- Rodriguez, M.; Doloreux, D.; Shearmur, R. Variety in external knowledge sourcing and innovation novelty: Evidence from the KIBS sector in Spain. Technovation 2017, 68, 35–43.

- Choi, Y.S.; Lim, U. Contextual Factors Affecting the Innovation Performance of Manufacturing SMEs in Korea: A Structural Equation Modeling Approach. Sustainability 2017, 9, 1193.

- Aldieri, L.; Carlucci, F.; Cirà, A.; Ioppolo, G.; Vinci, C.P. Is green innovation an opportunity or a threat to employment? An empirical analysis of three main industrialized areas: The USA, Japan and Europe. J. Clean. Prod. 2019, 214, 758–766.

- Honjo, Y. Competition, Innovation, and Growth in Japan; Springer: Singapore, 2017; ISBN 9789811038631.

- D’Angelo, A.; Baroncelli, A. An investigation over inbound open innovation in SMEs: Insights from an Italian manufacturing sample. Technol. Anal. Strateg. Manag. 2019, 32, 542–560.

- Natalicchio, A.; Petruzzelli, A.M.; Cardinali, S.; Savino, T. Open innovation and the human resource dimension: An investi-gation into the Italian manufacturing sector. Manag. Decis. 2018, 56, 1271–1284.

- Bonfanti, A.; Del Giudice, M.; Papa, A. Italian Craft Firms Between Digital Manufacturing, Open Innovation, and Servitization. J. Knowl. Econ. 2018, 9, 136–149.

- Barbieri, L.; Bragoli, D.; Cortelezzi, F.; Marseguerra, G. Public Funding and Innovation Strategies. Evidence from Italian SMEs. Int. J. Econ. Bus. 2019, 27, 111–134.

- Brancati, R.; Marrocu, E.; Romagnoli, M.; Usai, S. Innovation activities and learning processes in the crisis: Evidence from Italian export in manufacturing and services. Ind. Corp. Chang. 2017, 27, 107–130.

- Koo, B.; Cozzarin, B. Do Large Firms Pursue More Process Innovation? A Case of Canadian Manufacturing Industries. J. Technol. Manag. Innov. 2021, 16, 19–27.

- Meza-González, L.; Sepulveda, J.M. The impact of competition with China in the US market on innovation in Mexican manufacturing firms. Lat. Am. Econ. Rev. 2019, 28, 5.

- Atayde, R.; Garduño, R.; Robles, E.; Zúñiga, P. Market competition and firm productivity and innovation: Responses in Mexican manufacturing industries. Reg. Sci. Policy Pract. 2021, 13, 1185–1214.

- Damuri, Y.R.; Aswicahyono, H.; Christian, D. Innovation policy in Indonesia. Innov. Policy Asean 2018, 98–127. Available online: https://www.eria.org/uploads/media/5.ERIA_Innovation_Policy_ASEAN_Chapter_4.pdf (accessed on 10 October 2021).

- Hartono, A.; Kusumawardhani, R. Innovation Barriers and Their Impact on Innovation: Evidence from Indonesian Manufacturing Firms. Glob. Bus. Rev. 2019, 20, 1196–1213.

- Roud, V.; Vlasova, V. Strategies of industry-science cooperation in the Russian manufacturing sector. J. Technol. Transf. 2018, 45, 870–907.

- Choi, Y.; Lee, H.; Debbarma, J. Are Global Companies Better in Environmental Efficiency in India? Based on Metafrontier Malmquist CO2 Performance. Sustainability 2020, 12, 8359.

More

Information

Subjects:

Operations Research & Management Science; Engineering, Industrial; Engineering, Manufacturing

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Entry Collection:

Environmental Sciences

Revisions:

2 times

(View History)

Update Date:

21 Nov 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No