| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Florin Mariasiu | + 3320 word(s) | 3320 | 2021-08-19 09:01:33 | | | |

| 2 | Lindsay Dong | Meta information modification | 3320 | 2021-09-28 03:34:17 | | |

Video Upload Options

In the current context of transition from the powertrains of cars equipped with internal combustion engines to powertrains based on electricity, there is a need to intensify studies and research related to the command-and-control systems of electric vehicles. One of the important systems in the construction of an electric vehicle is the thermal management system of the battery with the role of optimizing the operation of the battery in terms of performance and life.

1. Introduction

2. Battery Thermal Management Systems

2.1. Air-Based BTMS

2.2. Liquid-Based BTMS

2.3. PCM-Based BTMS

2.4. Heat Pipe-Based BTMS

2.5. Hybrid BTMS

3. Conclusions

Air cooling represents the most easily applicable solution for the thermal management of batteries. However, the low specific heat of air still is a major concern when considering its application in full-size battery packs. A possible solution could be the use of active cooling and heating, using an evaporator or heater core. This would allow a reduced dependency on ambient conditions, an increased control over the inlet temperature in the battery pack and therefore a more efficient management of the temperatures inside the pack. Although such a method would increase the heat transfer, the occupied large volume still represents a significant disadvantage. The inlet and outlet scheme and the air flow configuration are also promising research directions, with numerous possible combinations. However, the possibility of implementing these schemes in a full-size battery pack should also be investigated, considering the need to implement the required inlet and outlet channels in the tight package of a vehicle. Regarding the uneven temperature distribution of air cooling, this can be reduced by using air flow channels with variable widths or by distribution pipes.

The large use of prismatic and pouch batteries in commercial vehicles means that liquid cooling plates are one of the most implemented cooling systems in electric vehicles, due to their good heat capacity and compact arrangement. Most research studies focus on various parameters regarding heat transfer and pressure drop, but only a few consider the uneven heat generation in the batteries, which is even more significant for the larger prismatic and pouch batteries. Therefore, more attention in future studies should be accorded to the possibility of implementing bidirectional or reciprocating liquid flows, considering the local heat generation, therefore improving the temperature distribution. In the presented study, examples of improving the temperature uniformity offered by cooling plates are presented using double-layered plates and a better mass distribution in the channels. The heat transfer capacity of conventional liquid cooling systems can further be enhanced using PCM emulsions or liquid metal. For cylindrical batteries, the poor adaptability to indirect liquid cooling is represented by the use of wavy channels, half helical ducts or conduction elements, which significantly increase complexity and add weight to the system.

Adapting the existing refrigerant circuit of the vehicles to serve also for the thermal management of batteries is a concept with a relatively high probability of practical application. The presented studies clearly show the potential of such systems, having a high heat transfer capacity, a capability to cool below ambient temperature and the possibility of heating. Despite these advantages, there are no mentioned studies to analyze the sizing of such a system for a full-size battery pack, nor the necessary changes to the existing air conditioning system to cope with the additional thermal load of the battery. More effort should be directed towards the development of a large-scale system, with precise control algorithms for cabin comfort, battery maximum temperature and temperature uniformity.

The main disadvantages of pure PCMs, namely the low thermal conductivity and leakage problems can be tackled by adding other materials such as EG, AlN, nanosilica, copper mesh foam and others, to form CPCMs. Although the enhancement of pure PCM with additional materials in different concentrations is a promising research direction, the preparation processes are very laborious, as well as time and energy consuming. It could be of interest by how much the preparation of large quantities of CPCM increases the overall costs of full-size battery packs. Moreover, in the case of pouring hot, melted CPCM directly around the batteries, further investigations are needed regarding the possible negative effects on Li-ion batteries.

References

- Climate Strategies & Targets. Available online: https://ec.europa.eu/clima/policies/strategies_en (accessed on 22 April 2021).

- EU Climate Action and the European Green Deal. Available online: https://ec.europa.eu/clima/policies/eu-climate-action_en (accessed on 22 April 2021).

- Fernandez Pales, A.; Bouckaert, S.; Abergel, T.; Goodson, T. Net Zero by 2050 Hinges on a Global Push to Increase Energy Efficiency; International Energy Agency, France, May 2021. Available online: https://www.iea.org/reports/net-zero-by-2050. (accessed on 8 June 2021).

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377.

- Bukhari, S.; Maqsood, J.; Baig, M.Q.; Ashraf, S.; Khan, T.A. Comparison of Characteristics–Lead Acid, Nickel Based, Lead Crystal and Lithium Based Batteries. In Proceedings of the 17th UKSim-AMSS International Conference on Modelling and Simulation (UKSim), Cambridge, UK, 25–27 March 2015; pp. 444–450.

- Naik, I.; Nandgaonkar, M. Review of the approaches and modeling methodology for lithium-ion battery thermal management sustems for electric vehicles. In Advances in Material and Mechanicsl Engineering, Select Proceedings of ICFTMME 2020; Pandey, C., Goyat, V., Goel, S., Eds.; Springer Nature Singapore Pte Ltd.: Singapore, 2021; pp. 75–112.

- Spitthoff, L.; Shearing, P.R.; Burheim, O.S. Temperature, Ageing and Thermal Management of Lithium-Ion Batteries. Energies 2021, 14, 1248.

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A critical review of thermal issues in lithium-ion batteries. J. Electrochem. Soc. 2011, 15, 1–25.

- Ianniciello, L.; Biwolé, P.H.; Achard, P. Electric vehicles batteries thermal management systems employing phase change materials. J. Power Sources 2018, 378, 383–403.

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666.

- Goutam, S.; Timmermans, J.M.; Omar, N.; Van den Bossche, P.; Van Mierlo, J. Comparative study of surface temperature behavior of commercial li-ion pouch cells of different chemistries and capacities by infrared thermography. Energies 2015, 8, 8175–8192.

- Buchmann, I. Battery University. Available online: https://batteryuniversity.com/ (accessed on 12 May 2021).

- Kitoh, K.; Nemoto, H. 100 Wh large size Li-ion batteries and safety tests. J. Power Sources 1999, 81–82, 887–890.

- Ramadass, P.; Haran, B.; White, R.; Popov, B.N. Capacity fade of Sony 18650 cells cycled at elevated temperatures: Part I. Cycling performance. J. Power Sources 2002, 112, 606–613.

- Rugh, J.P.; Pesaran, A.; Smith, K. Electric Vehicle Battery Thermal Issues and Thermal Management Techniques (Presentation); NREL (National Renewable Energy Laboratory): Golden, CO, USA, 2011.

- Jaguemont, J.; Boulon, L.; Dube, Y.; Martel, F. Thermal Management of a Hybrid Electric Vehicle in Cold Weather. IEEE Trans. Energy Convers. 2016, 31, 1110–1120.

- Peng, X.; Chen, S.; Garg, A.; Bao, N.; Panda, B. A review of the estimation and heating methods for lithium-ion batteries pack at the cold environment. Energy Sci. Eng. 2019, 7, 645–662.

- Jaguemont, J.; Omar, N.; Abdel-Monem, M.; Van den Bossche, P.; Van Mierlo, J. Fast-charging investigation on high-power and high-energy density pouch cells with 3D-thermal model development. Appl. Therm. Eng. 2018, 128, 1282–1296.

- Wang, Q.; Jiang, B.; Li, B.; Yan, Y. A critical review of thermal management models and solutions of lithium-ion batteries for the development of pure electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 106–128.

- Jaguemont, J.; Boulon, L.; Dubé, Y. A comprehensive review of lithium-ion batteries used in hybrid and electric vehicles at cold temperatures. Appl. Energy 2016, 164, 99–114.

- de Hoog, J.; Jaguemont, J.; Abdel-Monem, M.; Van Den Bossche, P.; Van Mierlo, J.; Omar, N. Combining an Electrothermal and Impedance Aging Model to Investigate Thermal Degradation Caused by Fast Charging. Energies 2018, 11, 804.

- Hammami, A.; Raymond, N.; Armand, M. Lithium-ion batteries: Runaway risk of forming toxic compounds. Nature 2003, 424, 635–636.

- Kim, J.; Oh, J.; Lee, H. Review on battery thermal management system for electric vehicles. Appl. Therm. Eng. 2019, 149, 192–212.

- Cai, H.; Xu, C.; Liao, Y.; Su, L.; Weng, Z. Mass maldistribution research of different internal flowing channels in the cooling plate applied to electric vehicle batteries. Appl. Sci. 2019, 9, 636.

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005.

- Larsson, F.; Mellander, B.-E. Abuse by External Heating, Overcharge and Short Circuiting of Commercial Lithium-Ion Battery Cells. J. Electrochem. Soc. 2014, 161, A1611–A1617.

- Feng, X.; Zheng, S.; Ren, D.; He, X.; Wang, L.; Cui, H.; Liu, X.; Jin, C.; Zhang, F.; Xu, C.; et al. Investigating the thermal runaway mechanisms of lithium-ion batteries based on thermal analysis database. Appl. Energy 2019, 246, 53–64.

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A review on the key issues for lithium-ion battery management in electric vehicles. J. Power Sources 2013, 226, 272–288.

- Iraola, U.; Aizpuru, I.; Gorrotxategi, I.; Segade, J.M.C.; Larrazabal, A.E.; Gil, I. Influence of voltage balancing on the temperature distribution of a li-ion battery module. IEEE Trans. Energy Convers. 2015, 30, 507–514.

- Feng, X.; Xu, C.; He, X.; Wang, L.; Zhang, G.; Ouyang, M. Mechanisms for the evolution of cell variations within a LiNixCoyMnzO2/graphite lithium-ion battery pack caused by temperature non-uniformity. J. Clean. Prod. 2018, 205, 447–462.

- Kuper, C.; Hoh, M.; Houchin-Miller, G.; Fuhr, J. Thermal management of hybrid vehicle battery systems. In Proceedings of the 24th International Battery, Hybrid and Fuel Cell Electric Vehicle Conference and Exhibition (EVS-24), Stavanger, Norway, 13−16 May 2009; pp. 1–10.

- Pesaran, A.A. Battery Thermal Management in EVs and HEVs: Issues and Solutions. In Proceedings of the Advanced Automotive Battery Conference, Las Vegas, Nevada, USA, 6−8 February 2001; pp. 10–20.

- Zhou, H.; Zhou, F.; Xu, L.; Kong, J. Thermal performance of cylindrical Lithium-ion battery thermal management system based on air distribution pipe. Int. J. Heat Mass Transf. 2019, 131, 984–998.

- Liu, Y.; Zhang, J. Design a J-type air-based battery thermal management system through surrogate-based optimization. Appl. Energy 2019, 252, 113426.

- Jilte, R.D.; Kumar, R.; Ma, L. Thermal performance of a novel confined flow Li-ion battery module. Appl. Therm. Eng. 2019, 146, 1–11.

- Wu, M.S.; Liu, K.H.; Wang, Y.Y.; Wan, C.C. Heat dissipation design for lithium-ion batteries. J. Power Sources 2002, 109, 160–166.

- Wu, W.; Wang, S.; Wu, W.; Chen, K.; Hong, S.; Lai, Y. A critical review of battery thermal performance and liquid based battery thermal management. Energy Convers. Manag. 2019, 182, 262–281.

- Lai, Y.; Wu, W.; Chen, K.; Wang, S.; Xin, C. A compact and lightweight liquid-cooled thermal management solution for cylindrical lithium-ion power battery pack. Int. J. Heat Mass Transf. 2019, 144, 118581.

- Chen, D.; Jiang, J.; Kim, G.H.; Yang, C.; Pesaran, A. Comparison of different cooling methods for lithium ion battery cells. Appl. Therm. Eng. 2016, 94, 846–854.

- Zhao, C.; Zhang, B.; Zheng, Y.; Huang, S.; Yan, T.; Liu, X. Hybrid Battery Thermal Management System in Electrical Vehicles: A Review. Energies 2020, 13, 6257.

- Lv, Y.; Zhou, D.; Yang, X.; Liu, X.; Li, X.; Zhang, G. Experimental investigation on a novel liquid-cooling strategy by coupling with graphene-modi fi ed silica gel for the thermal management of cylindrical battery. Appl. Therm. Eng. 2019, 159, 113885.

- Giuliano, M.R.; Prasad, A.K.; Advani, S.G. Experimental study of an air-cooled thermal management system for high capacity lithium–titanate batteries. J. Power Sources 2012, 216, 345–352.

- Panchal, S.; Khasow, R.; Dincer, I.; Agelin-Chaab, M.; Fraser, R.; Fowler, M. Thermal design and simulation of mini-channel cold plate for water cooled large sized prismatic lithium-ion battery. Appl. Therm. Eng. 2017, 122, 80–90.

- Shang, Z.; Qi, H.; Liu, X.; Ouyang, C.; Wang, Y. Structural optimization of lithium-ion battery for improving thermal performance based on a liquid cooling system. Int. J. Heat Mass Transf. 2019, 130, 33–41.

- Ye, B.; Rubel, M.R.H.; Li, H. Design and optimization of cooling plate for battery module of an electric vehicle. Appl. Sci. 2019, 9, 754.

- Monika, K.; Chakraborty, C.; Roy, S.; Dinda, S.; Singh, S.A.; Datta, S.P. An improved mini-channel based liquid cooling strategy of prismatic LiFePO4 batteries for electric or hybrid vehicles. J. Energy Storage 2021, 35, 102301.

- Patil, M.S.; Seo, J.H.; Panchal, S.; Jee, S.W.; Lee, M.Y. Investigation on thermal performance of water-cooled Li-ion pouch cell and pack at high discharge rate with U-turn type microchannel cold plate. Int. J. Heat Mass Transf. 2020, 155, 119728.

- Jiang, Z.Y.; Qu, Z.G. Lithium–ion battery thermal management using heat pipe and phase change material during discharge–charge cycle: A comprehensive numerical study. Appl. Energy 2019, 242, 378–392.

- Azizi, Y.; Sadrameli, S.M. Thermal management of a LiFePO 4 battery pack at high temperature environment using a composite of phase change materials and aluminum wire mesh plates. Energy Convers. Manag. 2016, 128, 294–302.

- Zhang, J.; Li, X.; Zhang, G.; Wang, Y.; Guo, J.; Wang, Y.; Huang, Q.; Xiao, C.; Zhong, Z. Characterization and experimental investigation of aluminum nitride-based composite phase change materials for battery thermal management. Energy Convers. Manag. 2020, 204, 112319.

- Zhang, Z.; Li, Y. Experimental study of a passive thermal management system using copper foam-paraffin composite for lithium ion batteries. Energy Procedia 2017, 142, 2403–2408.

- Faghri, A. Heat Pipe Science & Technology; Taylor & Francis Group: Abingdon, UK, 1995.

- Behi, H.; Karimi, D.; Behi, M.; Jaguemont, J.; Ghanbarpour, M.; Behnia, M.; Berecibar, M.; Van Mierlo, J. Thermal management analysis using heat pipe in the high current discharging of lithium-ion battery in electric vehicles. J. Energy Storage 2020, 32, 101893.

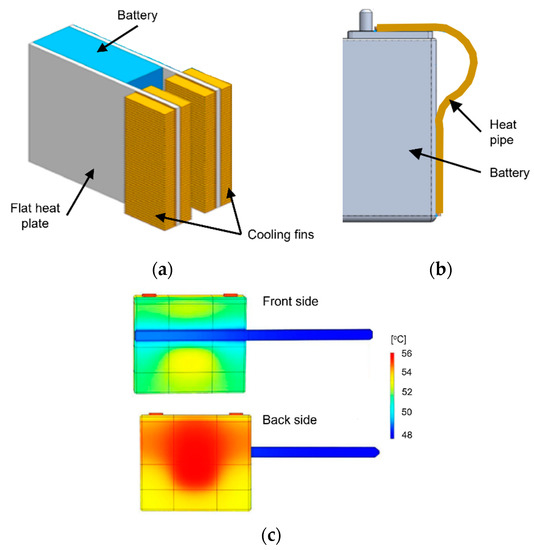

- Zhang, Z.; Wei, K. Experimental and numerical study of a passive thermal management system using flat heat pipes for lithium-ion batteries. Appl. Therm. Eng. 2020, 166, 114660.

- Kleiner, J.; Singh, R.; Schmid, M.; Komsiyska, L.; Elger, G.; Endisch, C. Influence of heat pipe assisted terminal cooling on the thermal behavior of a large prismatic lithium-ion cell during fast charging in electric vehicles. Appl. Therm. Eng. 2021, 188, 116328.

- Liu, F.; Lan, F.; Chen, J. Dynamic thermal characteristics of heat pipe via segmented thermal resistance model for electric vehicle battery cooling. J. Power Sources 2016, 321, 57–70.

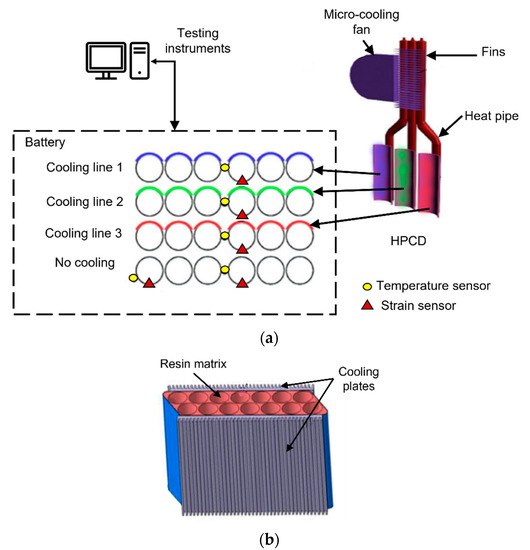

- Feng, L.; Zhou, S.; Li, Y.; Wang, Y.; Zhao, Q.; Luo, C.; Wang, G.; Yan, K. Experimental investigation of thermal and strain management for lithium-ion battery pack in heat pipe cooling. J. Energy Storage 2018, 16, 84–92.

- Ye, X.; Zhao, Y.; Quan, Z. Experimental study on heat dissipation for lithium-ion battery based on micro heat pipe array (MHPA). Appl. Therm. Eng. 2018, 130, 74–82.

- Tran, T.H.; Harmand, S.; Desmet, B.; Filangi, S. Experimental investigation on the feasibility of heat pipe cooling for HEV/EV lithium-ion battery. Appl. Therm. Eng. 2014, 63, 551–558.

- Wang, J.; Gan, Y.; Liang, J.; Tan, M.; Li, Y. Sensitivity analysis of factors influencing a heat pipe-based thermal management system for a battery module with cylindrical cells. Appl. Therm. Eng. 2019, 151, 475–485.