| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Lila Sigdel | + 2575 word(s) | 2575 | 2021-08-11 11:09:35 | | | |

| 2 | Ron Wang | -1061 word(s) | 1514 | 2021-08-27 03:11:34 | | |

Video Upload Options

Integral bridges are a class of bridges with integral or semi-integral abutments, designed without expansion joints in the bridge deck of the superstructure. The significance of an integral bridge design is that it avoids durability and recurring maintenance issues with bridge joints, and maybe bearings, which are prevalent in traditional bridges. Integral bridges are less costly to construct.

1. Introduction

Traditionally, bridges are designed and constructed with expansion joints and bearings to accommodate the expansion and contraction of the bridge due to temperature and stress changes. However, expansion joints and bearings need regular maintenance and replacement due to cyclical deck movement, traffic loading, trapped debris, and salt and moisture intrusion [1][2]. Degradation of expansion joints is a persistent cause of costly maintenance and rectification work [3]. Failure to maintain the bridge joints and bearings could cause overstress and structural distress in the bridge structure, which must be avoided. Rectification work is often disruptive to traffic flow and causes an increase in travel time that also incurs socio-economic costs for road users. Although conventional or jointed bridges still outnumber integral bridges, the overall trend of bridge construction towards integral bridges is increasing to avoid the recurring maintenance issues related to bridge joints and bearings.

Integral bridges have been used since 1938 in Ohio, the United States of America (USA) [4]. During the construction boom of the National Interstate Highway System, in the late 1950s and mid-1960s, several USA states began to use integral bridges as a construction choice for bridges. In 1980, the American Federal Highway Association (FHWA) recommended bridges to be constructed as integral bridges for steel bridges with overall lengths up to 90 m, cast-in-place concrete bridges up to 150 m and post-tensioned bridges up to 183 m [5]. According to Tabatabai et al. [6], approximately 70% of the USA State Department of Transportation (DOT) have already included integral bridges in their jurisdictions. In 1996, the British Highway Agency recommended adopting an integral bridge design approach for any bridge with a length of up to 60 m [7]. Integral bridges in other regions and countries, e.g., Europe, Japan, Canada, China and Oceania, also witnessed rapid development in the last few decades.

Under cyclic thermal, environmental and mechanical loading, the bridge superstructure expands and contracts. Movements particularly in the bridge deck of integral bridges will cause the bridge abutment to displace directionally into and away from the approach fill with each cycle. The movements of the abutment and substructure mobilise significant soil–structure interaction (SSI) effects [8][9][10][11], such as stress variations, soil densification, stress ratcheting [12][13][14], heave, settlement and/or slumping of the backfill soil [15][16], which in turn affect the overall performance of integral bridges. Stress ratcheting is the phenomenon that increases the lateral earth pressure applied on the abutments due to cyclic movements transferred from the bridge deck [12]. Pile-supported systems will also be affected by the abovementioned issues of integral bridge. The repeated actions of deck movements, much of which is induced by temperature changes, may be transferred to the piles, changing the soil properties around the pile. Many researchers have reported that the overall pile–soil interaction is dependent on various factors including pile type, pile orientation, pile flexibility, soil properties around piles and substructure stiffness [17][18][19][20]. Cyclic displacements and moments transferred to pile foundations are at risk of causing pile fatigue failure [21]. The complexities associated with pile–soil interaction ultimately affect the overall performance of the integral bridge including the bridge approach. Despite this, Philip [22] reported that only two states in the USA consider the pile stress due to thermal movements, while other states neglect this aspect in the integral bridge design.

It is quite evident from literature that different countries and jurisdictions are using a variety of design guidelines and practices to deal with the geotechnical issues for abutments and pile foundations. Therefore, this paper aims to present a comprehensive review of the design guidelines and the literature relevant to the recommended practices corresponding to the geotechnical aspects of integral bridges incorporating the effects of SSI. In the literature, a variety of definitions and terminologies have also been used to describe integral bridges. This can sometimes cause confusion to the reader. Hence, this paper begins with a discussion on different terminologies and definitions used for integral bridges to establish the context for the review.

2. Terminologies and Definitions of Integral Bridges

The diversity in design and construction of integral bridges created various terminologies and definitions. The type of design and construction ultimately has ramifications on the geotechnical aspects of integral bridges. According to the widely accepted definition used by bridge engineers, an integral bridge is one where the bridge deck is without any expansion or contraction, and they can be sub-categorised as an integral abutment bridge (IAB) or a semi-integral abutment bridge (SIAB). A bridge with a fully continuous or integral connection between the deck and the abutment is defined as an IAB. In the literature, IABs are also referred to as fully integral abutment bridges (FIABs). The SIAB, like the IAB, has a continuous deck without joints, but with bearings between abutments and the bridge deck, such that the superstructure is not continuous or monolithic with the abutments. It is noted that the terms IAB and SIAB are quite extensively used in North America.

In European countries, integral bridges are commonly defined as either fully integral bridges or semi-integral bridges [23]. Integral bridges are defined based on the connection between the continuous deck and abutment. There are no expansion joints and bearings in fully integral bridges, and this is analogous to the definition adopted by others for IABs. In the same way, semi-integral bridges are analogous to the definition of SIABs.

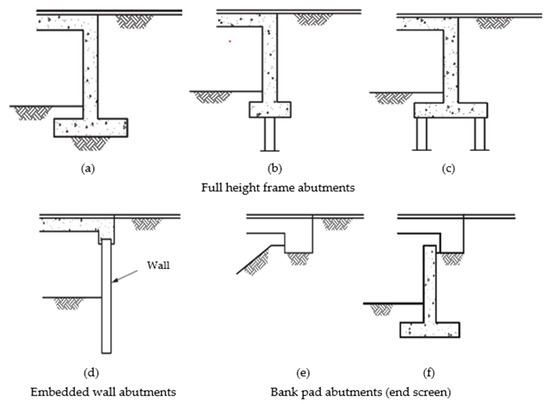

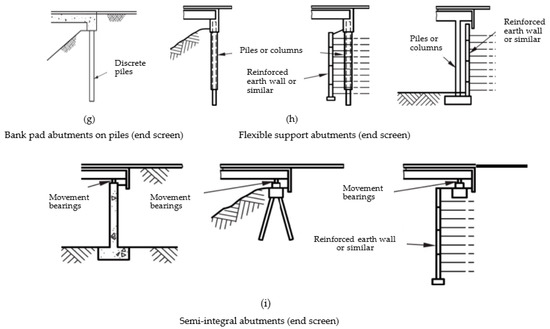

PD 6694-1 [24], published by the British Standards Institution (BSI), defines an integral bridge as a continuous bridge (continuous deck without any joints), which accommodates expansion and contraction of the bridge deck by the movement of the abutments in and out of the backfill. It also classifies the types of integral and semi-integral abutments for the integral construction of the integral bridges. PD 6694-1 categorises three types of abutments for integral construction: full height frame abutments as shown in Figure 1 a –c, embedded wall abutment as shown in Figure 1 d, and end screen abutments as shown in Figure 1 e–i.

The movements in full height frame abutments are accommodated by rotation or flexure of the abutment wall—whereas, in end screen abutments, the abutments can translate in and out of the fill to compensate for the deck movements. PD 6694-1 [24] provides further sub-classifications for end screen abutments: bank pad abutments including those supported on the ground or piles as shown in Figure 1 e–g, flexible support abutments as shown in Figure 1 h, and semi-integral abutments as shown in Figure 1 i. According to PD 6694-1 [24], semi-integral abutments consist of the movement bearings at the connection between the vertical support at the end of the bridge deck and conventional or embedded walls or reinforced soil abutments. The movement bearing connection accommodates the deck expansion and contraction without transferring the effect to the bridge abutment.

3. Geotechnical Guidelines and Practices for the Design of Integral Bridges

Most of the USA states have defined and discussed the integral and semi-integral abutment as the two types of abutment in integral bridges. Here, integral abutment refers to an abutment of an IAB, while semi-integral abutment refers to an abutment of an SIAB. Alaska has discussed only the SIAB [25], while Idaho [26] and North Dakota [27] have discussed only the IAB in their design manuals. Virginia [28] and Maine [29] have used the term “full integral abutment” instead of “integral abutment”.

For ease of reading, a more detailed summary of the recommendations from several USA state DOTs regarding the types of abutments in integral bridges, limiting criteria for selecting integral bridges, and design parameters and mitigation measures, particularly in respect of geotechnical requirements, are presented in Appendix A , Appendix B , Appendix C and Appendix D .

However, for other types of abutments, such as integral abutments on single rows of piles and embedded wall abutments, and for over-consolidated backfill material, cohesive soil and layered soil, limit equilibrium methods are not adequate. Hence, SSI analysis should be used to calculate the horizontal earth pressure behind integral abutments.

Bridge design engineers in New Zealand generally refer to the Transport Agency (NZTA) Bridge Manual for guidance on the design of integral bridges, including specifications on the lateral earth pressure [30]. The geotechnical provisions for calculating the earth pressure distribution behind the abutments of integral bridges are provided in NZTA’s Bridge Manual and NZTA research report 577 [31] based on the provisions of BA 42/96 [32] and PD 6694-1 [33]. It has further emphasized the parameters that need to be considered for the SSI analysis for full height integral abutments founded on a single row of vertical piles and integral embedded wall abutments (which will be discussed in Section 3.9.1 ).

References

- Biddle, A.; Iles, D.; Yandzio, E. Integral Steel Bridges: Design Guidance; SCI-Pub--163, Steel; Construction Institute: Ascot, UK, 1997.

- Wasserman, E.P.; Walker, J.H. Integral abutments for steel bridges. In Highway Structures Design Handbook; American Iron and Steel Institute: Washington, DC, USA, 1996; Volume II.

- White, H. Integral Abutment Bridges: Comparison of Current Practice between European Countries and the United States of America; Transportation Research and Development Bureau, New York State Department of Transportation: New York, NY, USA, 2007.

- Burke, J.R.M.P. Integral and Semi-Integral Bridges; John Wiley & Sons: Hoboken, NJ, USA, 2009.

- Hassiotis, S.; Roman, E. A survey of current issues on the use of integral abutment bridges. Bridge Struct. 2005, 1, 81–101.

- Tabatabai, H.; Magbool, H.; Bahumdain, A.; Fu, C. Criteria and Practices of Various States for the Design of Jointless and Integral Abutment Bridges. In Third International Workshop on Jointless Bridges; UWM Digital Commons: Seattle, DC, USA, 2017.

- Sandberg, J.; Magnino, L.; Nowak, P.; Wiechecki, M.; Thusyanthan, I. The Integral Bridge Design Concept for the Third Runway at Heathrow, UK; Thomas Telford Ltd.: London, UK, 2020; Volume 173, pp. 112–120.

- Al-Qarawi, A.; Leo, C.; Liyanapathirana, D. Effects of Wall Movements on Performance of Integral Abutment Bridges. Int. J. Geomech. 2020, 20, 1–14.

- Bloodworth, A.; Xu, M.; Banks, J.; Clayton, C. Predicting the Earth Pressure on Integral Bridge Abutments. J. Bridge Eng. 2012, 17, 371–381.

- Fartaria, C. Soil-Structure Interaction in Integral Abutment Bridges; Instituto Superior Téchnico, Universidade Téchinca de Lisboa: Lisbon, Portugal, 2012.

- Shamsabadi, A.; Rollins, K.M.; Kapuskar, M. Nonlinear soil–abutment–bridge structure interaction for seismic performance-based design. J. Geotech. Geoenviron. Eng. 2007, 133, 707–720.

- England, G.L.; Tsang, N.C.; Bush, D.I. Integral Bridges: A Fundamental Approach to the Time–Temperature Loading Problem; Thomas Telford Ltd.: London, UK, 2000.

- England, G. A thermal displacement compensation unit for integral bridges. Pat. Bridge Struct. 2005, 2605437, A1.

- Springman, S.; Norrish, A.; Ng, C. Cyclic Loading of Sand behind Integral Bridge Abutments; TRL Report 146; Transport Research Laboratory: London, UK, 1996.

- Horvath, J.S. Integral-Abutment Bridges: Problems and Innovative Solutions Using EPS Geofoam and Other Geosynthetics; CE/GE-00-2; Manhattan College: Bronx, NY, USA, 2000.

- Horvath, J.S. Lateral pressure reduction on earth-retaining structures using geofoams: Correcting some misunderstandings. In Proceedings of the Earth Retention Conference, Earth Retention Conference (ER), Bellevue, WA, USA, 1–4 August 2010; pp. 862–869.

- Huang, F.; Shan, Y.; Chen, G.; Lin, Y.; Tabatabai, H.; Briseghella, B. Experiment on Interaction of Abutment, Steel H-Pile and Soil in Integral Abutment Jonitless Bridges (IAJBs) under Low-Cycle Pseudo-Static Displacement Loads. Appl. Sci. 2020, 10, 1358.

- Huang, J.; Shield, C.K.; French, C.E. Parametric study of concrete integral abutment bridges. J. Bridge Eng. 2008, 13, 511–526.

- Mitoulis, S.A. Challenges and opportunities for the application of integral abutment bridges in earthquake-prone areas: A review. Soil Dyn. Earthq. Eng. 2020, 135, 106183.

- Razmi, J.; McCabe, M. Analytical and Computational Modeling of Integral Abutment Bridges Foundation Movement due to Seasonal Temperature Variations. Int. J. Geomech. 2020, 20, 04019189.

- Karalar, M.; Dicleli, M. Effect of thermal induced flexural strain cycles on the low cycle fatigue performance of integral bridge steel H-piles. Eng. Struct. 2016, 124, 388–404.

- Philip, B.E. IAB: An Exploratory Study on Integral Abutment Bridges. Int. J. Sci. Res. Dev. 2017, 5, 312–316.

- White, H.; Pétursson, H.; Collin, P. Integral abutment bridges: The European way. Pract. Period. Struct. Des. Constr. 2010, 15, 201–208.

- PD 6694-1:2011+A1:2020. Recommendations for the Design of Structures Subject to Traffic Loading to BS EN 1997-1:2004+A1:2013; BSI (British Standard International): London, UK, 2020.

- Alaska Department of Transportation. Bridge. Design Manual 2017; Alaska Department of Transportation: Juneau, AK, USA, 2017.

- Idaho Department of Transportation. Bridge. Design Manual 2017; Idaho Department of Transportation: Boise, ID, USA, 2019.

- North Dakota Department of Transportation. North. Dakota Bridge. Design Manual 2013; North Dakota Department of Transportation: Bismarck, ND, USA, 2013.

- Virginia Department of Transportation. Manual of the Structure and Bridge. Division 2020; Virginia Department of Transportation: Richmond, VA, USA, 2020.

- Maine Department of Transportations. Bridge. Design Manual 2018; Maine Department of Transportation: Augusta, ME, USA, 2018.

- New Zealand Transport Agency. Bridge. Manual, 3rd ed.; SP/M/022; NZ Transport Agency: Wellington, New Zealand, 2013.

- Al-Ani, M.; Murashev, A.; Palermo, A.; Andisheh, K.; Wood, J.; Goodall, D.; Lloyd, N. Criteria and guidance for the design of integral bridges. In Proceedings of the Institution of Civil. Engineers—Bridge. Engineering; Thomas Telford Ltd.: London, UK, 2018; Volume 171, pp. 143–154.

- HA (Highways Agency). BA 42/96 Design Manual for Roads and Bridges; The Design of Integral Bridges: London, UK, 2003; Volume 1.

- PD 6694-1. Recommendations for the Design of Structures Subject to Traffic Loading to BS EN 1997-1:2004+A1; BSI (British Standard International): London, UK, 2011.

- Massachusetts Department of Transportations. LRFD Bridge. Design Manual—Part. I 2020; Massachusetts Department of Transportation: Boston, MA, USA, 2020.

- Utah Department of Transportation. Utah Bridge. Design Manual 2017; Utah Department of Transportation: Salt Lake City, UT, USA, 2017.