| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Eduardo Javier Elizondo Martinez | + 2178 word(s) | 2178 | 2020-05-29 08:51:21 | | | |

| 2 | Rita Xu | -360 word(s) | 1818 | 2020-06-10 10:44:56 | | | | |

| 3 | Rita Xu | -24 word(s) | 1794 | 2020-10-27 09:52:06 | | |

Video Upload Options

Alternative materials to replace cement in pavements have recently been widely studied with the purpose of decreasing the environmental impacts that the construction industry generates. In this context, the implementation of sustainable urban drainage systems has grown, especially with porous pavements, with the intention to reduce water and environmental impacts. In the present investigation, the addition of alternative materials to minimize the use of cement in porous concrete pavements is evaluated. Starting from a partial substitution of Portland cement with metakaolin, experimental geopolymer concretes were produced with metakaolin and waste basalt powder according to several dosages. Two sets of mixtures were analyzed to evaluate the Porous Concrete Design (PCD) methodology for porous concrete mixtures with alternative materials. A deep analysis was proposed for the evaluation of the mechanical and volumetric properties of the mixtures. Results demonstrated that replacing 5% of cement with metakaolin can increase both permeability and indirect tensile strength. Geopolymer mixtures can achieve permeability significantly higher than the traditional porous concrete, but this decreases their indirect tensile strength. However, considering the promising results, an adjustment in the mix design of the geopolymer mixtures could increase their mechanical properties without negatively affecting the porosity, making these materials a suitable alternative to traditional porous cement concrete, and a solution to be used in urban pavements.

1. Introduction

1.1. Porosity and Permeability

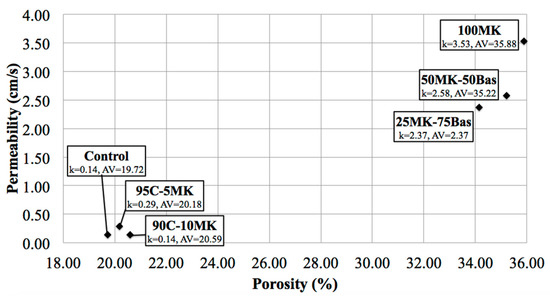

The total porosity (AV) and permeability (k) results are shown in Figure 1.

Figure 1. Porosity and permeability general results.

It can be observed that the geopolymer mixtures achieved permeability results over 90% higher than the Control mixture because of the porosity parameter used in order to control the VMAs. If the mixtures with cement (Control, 95C-5MK, and 90C-10MK) had been designed with a higher porosity, the mortar amount would have been lower, making the adhesion between the aggregate particles poor and, therefore, weak.

In addition, the use of basalt powder in the geopolymer mixtures tended to clog the air voids in the sample, decreasing the permeability capacity. The addition of 50% of basalt powder decreased the permeability by 27%, and with 75% of basalt powder the decrement was equal to 33%. Nevertheless, both AV and permeability results were considerably high for the geopolymer mixtures with basalt powder.

In the case of replacing part of the cement with metakaolin (95C-5MK and 90C-10MK), results demonstrated that the porosity increased and permeability resulted. In this scenario, replacing 5% of cement with metakaolin doubled the permeability. However, the increase in the metakaolin amount of 10% can be considered excess, where the mortar tended to cover the aggregates more and permeability started to decrease, showing the same results as the Control mixture. It can be stated that the replacement of cement with metakaolin over 5% seemed to negatively affect the permeability of the mixture. Nevertheless, according to the National Center for Asphalt Technology, a minimum permeability of 100 m/day (0.012 cm/s) is suggested for open-graded friction courses [1][2]. Therefore, all the mixtures overcame that parameter, even the Control mixture with the lowest permeability (0.14 cm/s). In addition, the behavior of the mixtures demonstrated that at higher porosity, permeability tended to increase, a performance in compliance with some authors’ results [3][4].

1.2. Density and Indirect Tensile Strength

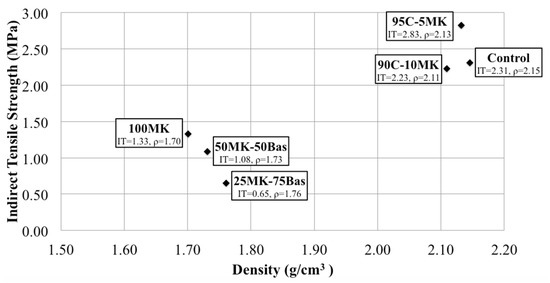

The density (ρ) and indirect tensile strength (IT) results are presented in Figure 2.

Figure 2. Indirect tensile and density general results.

Here, the geopolymer mixtures obtained lower results if compared to the mixtures with cement, because of the higher porosity. Between the geopolymer mixtures, 100MK showed the highest ITS values, and this was in line with the mechanical properties highlighted in the geopolymer paste characterization. However, in wider terms, the 100MK reached ITS values 42% lower than the Control mixture. Nevertheless, it can be observed that mixtures 100MK and 50MK-50Bas achieved acceptable values of ITS, over 1 MPa, despite the high porosity the sample presented.

In addition, the use of basalt powder demonstrated a weak bond between the geopolymer paste and the aggregate, as the paste became more fluent and went to the bottom of the mold. This clogged the mixture and decreased ITS: 50% of basalt powder in the mixture decreased the ITS by almost 19% if compared to mixture 100MK. Adding basalt powder up to 75% of the cementitious material weight reduced the strength around 51%. It was observed that the lowest cohesion between aggregate particles led to lower ITS results.

In the case of the cement mixtures, ITS results increased by 18% when replacing 5% of cement with metakaolin (95C-5MK) without a relevant variation in the density, compared to the Control mix. The ITS was reduced to almost the same values as the Control mixture when the metakaolin amount increased to 10% (90C-10MK).

Furthermore, to compare the obtained results with other experimental porous concretes, a detailed literature review was carried out. Bringing together the most recent studies on ITS in porous concrete pavements, Table 1 demonstrates the lower and higher results achieved by each author, as well as the w/c, aggregate size, and additional materials employed. ITS values range from 0.02 MPa to 3.09 MPa. Taking this into account, all the experimental mixtures included in this research paper showed acceptable results.

Table 1. Indirect tensile results and materials employed by some authors.

| Author | Ref. | IT1 (MPa) | w/c | Agg1 (mm) | Note |

|---|---|---|---|---|---|

| Torres, A. et al., 2015 | [5] | 1.09–3.09 | 0.33 | 6.35–9.54 | 3 compaction levels and 2 aggregate sizes (limestone) evaluated. |

| Bonicelli, A. et al., 2015 | [6] | 0.02–0.21 | 0.27-0.35 | 3–10 | Addition of sand. |

| Rangelov, M. et al., 2016 | [7] | 1.40–2.90 | 0.24 | 9.5 | Addition of carbon fibers. |

| Adewumi, A. et al., 2016 | [8] | 0.21–1.32 | 0.35-0.40 | 4.50–22 | Different mixtures of coarse aggregate, cement and w/c were used. |

| Brake, N. et al., 2016 | [9] | 0.98–3.04 | 0.27-0.30 | 10 | Type I polycarboxylate superplasticizer and type S viscosity modifying agent were employed. |

| Bonicelli, A. et al., 2016 | [10] | 1.40–2.20 | 0.27-0.35 | - | Monofilament polypropylene and polyethylene fibers used. |

| Hsin-Lun, H. et al., 2018 | [11] | 0.5–2.1 | 0.35 | 19–25 | Portland cement, and co-fired fly ash and blast-furnace slag as replacement of cement were used. |

| Mohd-Ibrahim, M.Y. et al., 2018 | [12] | 2.5–4.3 | 0.34 | 4.75–12.5 | Use of nano black rise husk ash and crushed granites. |

| Tataranni, P. and Sangiorgi, C., 2019 | [13] | 0.48–0.60 | --- | 6.3–12.5 | Use of a polymeric binder, activated with sodium silicate and sodium hydroxide. Synthetic and limestone aggregate. |

| Alshareedah, O. et al., 2019 | [14] | 1.1–1.5 | 0.35 | 4.75–9.5 | Addition of cured carbon fiber composite material. |

| Elizondo-Martinez, E.J. et al., 2020 | [15] | 1.62–2.75 | 0.30 | 4–8 | Combination of superplasticizer, air entraining, and polypropylene fibers for the highest result. |

In addition, considering some authors obtained high ITS values by employing additives, fibers, or other additions (such as sand and certain types of ash) to improve the properties of the mixture, the results obtained in the present investigation demonstrated that the methodology of design, as well as the compaction method used, can achieve very good results, with a range between 0.65 MPa and 2.83 MPa.

1.3. Optimal Mixtures and Performance Requirements

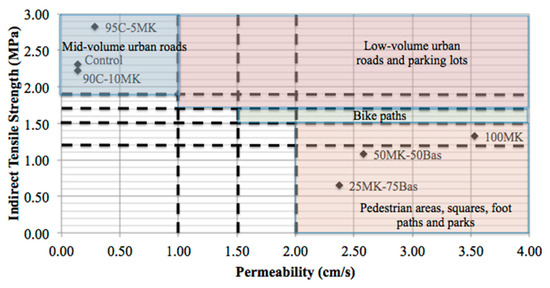

Figure 3 shows the graph proposed by Bonicelli et al. [10], showing the performance requirements for different urban uses of porous concrete pavements and locating results of the present investigation. As stated by the authors, mid-volume urban roads require ITS values over 1.9 MPa, low-volume urban roads and parking lots require instead ITS values between 1.7 and 1.9 MPa and permeability results over 1 cm/s. ITS values between 1.5 and 1.7 MPa and permeability over 1.5 cm/s are recognized as suitable for bike paths, while permeability values over 2 cm/s work better for pedestrian areas, squares, foot paths, and parks.

Figure 3. Performance requirements for different urban uses of porous concrete pavements according to Bonicelli et al., 2016 [10].

As seen in Figure 3, all the cement-base mixtures can be considered suitable for mid-volume urban roads because of the high mechanical properties and relatively low permeability. The geopolymer mixtures are suitable for pedestrian areas, squares, footpaths, and parks because of the high permeability capacity. However, for future research, the reduction in the design AV for geopolymer concrete might improve the final ITS of the mixtures.

1.4. Water Susceptibility of Geopolymer Mixtures

Despite the environmental advantages that porous pavements made with geopolymers can present, the exposure of these materials to water can decrease the strength of the mixtures, as Table 2 shows. Once again, an optimization of the design parameters could decrease the porosity and so increase the VMAs and the final mechanical properties. It is worth noting that in the case of the 100MK mixture, the ITS reduction was not significant (16.67%). For the other experimental mixtures the addition of basalt had a negative effect on the ITS reduction, probably because of the already poor cohesion between particles, which was further limited by the presence of water.

Table 2. Indirect tensile results of geopolymers before and after water exposure.

| Mixture | Indirect Tensile Strength (MPa) | Indirect Tensile Strength after Exposure to Water (MPa) | Strength Reduction (%) |

|---|---|---|---|

| 100MK | 1.33 | 1.10 | 16.67 |

| 50MK-50BAS | 1.08 | 0.65 | 40.13 |

| 25MK-75BAS | 0.65 | 0.45 | 31.37 |

2. Conclusions

Cement production has a big environmental impact and, consequently, alternative materials are being studied to replace it in pavements.

The present research shows a comparison of the functional and mechanical properties of different porous concretes produced with different amounts of metakaolin and alternative geopolymer porous mixtures containing metakaolin and basalt powder.

Based on the discussed results, the following conclusions can be stated:

-

Replacing 5% of cement with metakaolin increases both the ITS and the permeability, but a substitution of 10% of cement with metakaolin reduces both the properties.

-

Cement base mixtures (only with reductions of 5% or 10%) show very high ITS values and acceptable porosity if compared to the geopolymer ones (100% metakaolin).

-

A design porosity of 20% is considered low for the geopolymer mixtures, where, because of the behavior of the paste material, the sample tends to clog. Meanwhile, a design porosity of 30% causes an excessive AV in the material that negatively affects the ITS.

-

The increase in the amount of basalt powder in the mixture lowers the mechanical properties of the sample, both the compressive strength of the mortar cubes and the ITS of the porous samples.

-

According to the results, for geopolymer porous pavements, an amount of 50% or lower of basalt powder in the mixture is recommended to maintain an average mechanical–permeability relation. The amount will depend on the use the pavement is going to have. A high amount can decrease these results considerably.

-

The mechanical properties of geopolymer mixtures with basalt are strongly affected when exposed to water. As the main purpose of porous pavements is to infiltrate water through their structure, adjustments in the design parameters (such as lower porosity and higher VMA) are needed to reduce the water susceptibility.

-

Considering the results obtained with the dosages evaluated, geopolymer mixtures are suitable for pavements with low load, like pedestrian areas, which can comprise a large area in a city, and cement use can be decreased. They also prevent runoff during rain events.

-

Cement-based mixtures, according to the results of the present investigation, can be considered for use in mid-volume urban roads (secondary streets), which represent a high percentage of pavement in a city, decreasing some amount of cement and increasing the permeable capacity of the soil, especially during rain events.

-

Both cement mixtures with metakaolin and mixtures with geopolymer paste represent good alternatives for sustainable pavements, reducing the use of cement.

References

- Alvarez, A.E.; Martin, A.E.; Estakhri, C.K.; Button, J.W.; Glover, C.J.; Jung, S.H. Synthesis of Current Practice on the Design, Construction, and Maintenance of Porous Friction Courses; Technical Report No. FHWA/TX-06/0-5262-1; Texas Department of Transportation Research and Technology Implementation Office: Austin, TX, USA; Texas Transportation Institute at the Texas A&M University System: College Station, TX, USA, 2006; p. 76.

- Mallick, R.B.; Kandhal, P.S.; Cooley, L.A.; Watson, D.E. Design, Construction and Performance of New Generation Open-Graded Friction Courses; NCAT Report No. 2000-01; National Center for Asphalt Technology (NCAT), Auburn University: Auburn, AL, USA, 2000.

- F Praticò; Antonino Moro; Permeability and Volumetrics of Porous Asphalt Concrete. A Theoretical and Experimental Investigation. Road Materials and Pavement Design 2007, 8, 799-817, 10.3166/rmpd.8.799-817.

- Hakan Yasarer; Yacoub Najjar; Development of Void Prediction Models for Kansas Concrete Mixes Used in PCC Pavement. Procedia Computer Science 2012, 8, 473-478, 10.1016/j.procs.2012.01.088.

- Anthony Torres; Jiong Hu; Amy Ramos; The effect of the cementitious paste thickness on the performance of pervious concrete. Construction and Building Materials 2015, 95, 850-859, 10.1016/j.conbuildmat.2015.07.187.

- Alessandra Bonicelli; Filippo Giustozzi; Maurizio Crispino; Experimental study on the effects of fine sand addition on differentially compacted pervious concrete. Construction and Building Materials 2015, 91, 102-110, 10.1016/j.conbuildmat.2015.05.012.

- Milena Rangelov; Somayeh Nassiri; Liv Haselbach; Karl Englund; Using carbon fiber composites for reinforcing pervious concrete. Construction and Building Materials 2016, 126, 875-885, 10.1016/j.conbuildmat.2016.06.035.

- Adeshina Adewumi; Taoreed Owolabi; Ibrahim O. Alade; Sunday O. Olatunji; Estimation of physical, mechanical and hydrological properties of permeable concrete using computational intelligence approach. Applied Soft Computing 2016, 42, 342-350, 10.1016/j.asoc.2016.02.009.

- Nicholas Brake; Hamid Allahdadi; Fatih Adam; Flexural strength and fracture size effects of pervious concrete. Construction and Building Materials 2016, 113, 536-543, 10.1016/j.conbuildmat.2016.03.045.

- Alessandra Bonicelli; Gilberto Martinez-Arguelles; Luis Guillermo Fuentes Pumarejo; Improving Pervious Concrete Pavements for Achieving More Sustainable Urban Roads. Procedia Engineering 2016, 161, 1568-1573, 10.1016/j.proeng.2016.08.628.

- Hsin-Lung Ho; Ran Huang; Lih-Chuan Hwang; Wei-Ting Lin; Hui-Mi Hsu; Waste-Based Pervious Concrete for Climate-Resilient Pavements. Materials 2018, 11, 900, 10.3390/ma11060900.

- M Y Mohd Ibrahim; Ramadhansyah Putra Jaya; H Mohd Rosli; M H Wan Ibrahim; Mechanical performance of porous concrete pavement containing nano black rice husk ash. IOP Conference Series: Materials Science and Engineering 2018, 290, 12050, 10.1088/1757-899x/290/1/012050.

- Piergiorgio Tataranni; Cesare Sangiorgi; Synthetic Aggregates for the Production of Innovative Low Impact Porous Layers for Urban Pavements. Infrastructures 2019, 4, 48, 10.3390/infrastructures4030048.

- Othman Alshareedah; Somayeh Nassiri; Zhao Chen; Karl Englund; Hui Li; Osama Fakron; Field performance evaluation of pervious concrete pavement reinforced with novel discrete reinforcement. Case Studies in Construction Materials 2019, 10, e00231, 10.1016/j.cscm.2019.e00231.

- Eduardo-Javier Elizondo-Martinez; Valerio Carlos Andrés-Valeri; Jorge Rodriguez-Hernandez; Cesare Sangiorgi; Selection of Additives and Fibers for Improving the Mechanical and Safety Properties of Porous Concrete Pavements through Multi-Criteria Decision-Making Analysis. Sustainability 2020, 12, 2392, 10.3390/su12062392.