Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Inês Moreira | + 1994 word(s) | 1994 | 2021-06-21 06:19:16 | | | |

| 2 | Bruce Ren | -21 word(s) | 1973 | 2021-06-28 10:21:17 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Moreira, I. Multiple Scale Fibrous systems Heating. Encyclopedia. Available online: https://encyclopedia.pub/entry/11372 (accessed on 08 February 2026).

Moreira I. Multiple Scale Fibrous systems Heating. Encyclopedia. Available at: https://encyclopedia.pub/entry/11372. Accessed February 08, 2026.

Moreira, Inês. "Multiple Scale Fibrous systems Heating" Encyclopedia, https://encyclopedia.pub/entry/11372 (accessed February 08, 2026).

Moreira, I. (2021, June 28). Multiple Scale Fibrous systems Heating. In Encyclopedia. https://encyclopedia.pub/entry/11372

Moreira, Inês. "Multiple Scale Fibrous systems Heating." Encyclopedia. Web. 28 June, 2021.

Copy Citation

Different types of heating systems have been developed lately, representing a growing interest in both the academic and industrial sectors. Based on the Joule effect, fibrous structures can produce heat once an electrical current is passed, whereby different approaches have been followed. For that purpose, materials with electrical and thermal conductivity have been explored, such as carbon-based nanomaterials, metallic nanostructures, intrinsically conducting polymers, fibers or hybrids.

heating

Joule effect

polymers

fibers

composites

textiles

thermal conductivity

1. Introduction

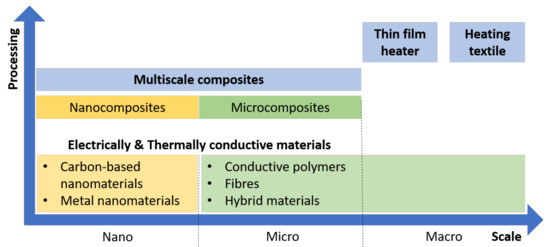

Heating technologies have been highly studied lately for distinct applications that go from smart textiles/wearables and thermotherapy to defreezing/defogging applications. Heating is considered passive when it depends on light irradiation of solar energy. As previously reviewed [1], photothermal heating uses inorganic nanomaterials, semiconducting polymers or ceramics to emit absorbed energy as heat. In contrast, active heaters can be developed by using conductive materials, relying on the Joule heating upon the application of low voltages. They can be produced in different configurations that go from thin film heaters to heating textiles, and from nano- to macroscale (Figure 1).

Figure 1. Schematic diagram of the multiscale approaches to heating technologies.

All the technologies end up using the same kind of conductive materials. Apart from metals and metal oxides, metallic nanostructures, carbon-based materials and inherently conductive polymers are highly promising and have been used in several research studies. Different techniques have been explored throughout the years to improve the thermal and/or electrical conductivity of materials, including the addition of fillers to a polymeric matrix. These fillers can be in the form of fibers, particles or flakes, homogeneously distributed within the polymer matrix [2].

2. Intrinsically Conductive Materials

2.1. Carbon-Based Nanomaterials

Despite being relatively recent, there are numerous studies on the use of carbon-based nanomaterials for practical applications due to their electrical, optical and thermal properties. In particular, graphene and carbon nanotubes have been used for thermal engineering thanks to their high thermal conductivity (see Table 1) [3]. These are two carbon allotropes with sp2-hybridized carbon atoms but different structures. Du et al. published a detailed review that explains the fundamentals of graphene and carbon nanotubes (CNTs) [4], in addition to their application on transparent conductive films for optoelectronic devices.

Table 1. Thermal conductivities of generally used materials.

| Materials | Category | Thermal Conductivity (W m−1 K−1) |

Ref. |

|---|---|---|---|

| Carbon fiber | Carbon-based | 400–650 | [5] |

| Carbon nanotubes | Carbon-based | 3000 | [5] |

| Graphite | Carbon-based | 100–400 | [6] |

| Graphene nanoplatelets | Carbon-based | 2000–6000 | [7] |

| Graphene sheets | Carbon-based | ~5000 | [8] |

| Single-walled carbon nanotubes | Carbon-based | 2000 | [8] |

| Multi-walled carbon nanotubes | Carbon-based | 3000 | [8] |

| Aluminum | Metal | 247 | [9] |

| Copper | Metal | 398 | [9] |

| Gold | Metal | 315 | [9] |

| Silver | Metal | 427 | [9] |

| Silver nanowires | Metal nanostructure | 191.5 | [10] |

| Polyacetylene | Conductive polymer | 0.4–13 | [11] |

| Polypyrrole (PPy) | Conductive polymer | 0.11–0.25 | [11] |

| Polyaniline (PANi) | Conductive polymer | 0.04–0.14 | [11] |

| Polythiophene | Conductive polymer | 0.2–4.4 | [11] |

| Poly(3,4-ethylenedioxythiophene):Polystyrenesulfonate (PEDOT:PSS) | Conductive polymer | 0.16–0.39 | [11] |

| Diamond | Ceramics | 1000 | [12] |

| Aluminum nitride | Ceramics | 100–300 | [7] |

| Beryllium oxide | Ceramics | 230–330 | [13] |

| Cubic boron nitride | Ceramics | 1000 | [14] |

| Hexagonal boron nitride | Ceramics | 300 | [14] |

| Silicon carbide | Ceramics | 120 | [15] |

| Aluminum oxide (α-Alumina) | Ceramics | 30 | [12] |

The newly discovered graphene is a 2-dimensional sheet of carbon atoms arranged in a honeycomb lattice. Between the carbon allotropes, graphene presents the highest thermal conductivity (around 5000 W m−1 K−1 for single-layer graphene at room temperature). Due to its unique chemical structure, with a densely packed carbon atom arrangement, graphene thermal conduction is thought to occur through phonon waves [16]. This explains why its thermal conductivity is one of the highest of all materials (Table 1), in addition to the fact that it also presents an ultrahigh specific surface area. Graphene nanoplatelets (GNPs) are short stacks of graphene sheets with a platelet shape. Depending on the fabrication method, GNPs can vary in size and thickness and thus the thermal and electrical conductivities can vary considerably. In turn, stacked graphene forms the 3D graphite, which is abundantly available in nature. The atoms are bonded by covalent bonds, the distance between the bonds is approximately 0.412 nm and the distance between the layers of approximately 0.335 nm [17]. Its sp2 configuration explains its high in-plane thermal conductivity [7]. It can be modified into various forms, namely expanded graphite (EG), graphite nanoplatelets, and graphite flakes (GF), that are easily dispersed in polymers [17]. EG is a light and worm-like structure with a thickness of 100 to 400 nm, formed when the graphite-intercalated compounds are exposed to a sudden temperature increase for a short time. Exfoliation of EGs through ultrasonication will produce graphite nanoplatelets, which consist of stacks of graphite layers. The thickness of the graphite nanoplatelets is less than 10 nm and the diameter is in the range of sub-micron to approximately 15 µm [18].

Single-walled carbon nanotubes (SWCNT) have a cylindrical nanostructure formed by rolled-up graphene. They arose as promising for thermal management applications, with thermal conductivity values depending on many factors. Pop and co-workers developed a theoretical study on an individual SWCNT, reporting a thermal conductivity of nearly 3500 Wm−1K−1 at room temperature [19].

2.2. Metallic-Based Nanomaterials

Metals such as aluminum, copper, gold, silver and others, appear as the obvious materials for heating due to their high electrical and thermal conductivities (Table 1). Among all metals, silver presents the highest electrical (6.3 × 107 Sm−1) and thermal conductivity (427 W m−1 K−1) at room temperature. Copper follows silver in terms of properties, but it is less stable in air. In turn, the cost of silver is lower than that of gold and platinum. The engineering of metal nanostructures has attracted a lot of research lately, as a way to manipulate photons and electrons and to produce transparent electrodes for optoelectronic devices, as will be explored later in this review. The main metallic-based nanostructures are metallic meshes, metallic grids and metallic nanowires. Even though the difference between metallic meshes and grids is sometimes confusing in the literature, we hereby consider that metallic meshes do not present an organized conductive direction, while metallic grids present a periodic arrangement of lines.

Metal nanoparticles have unique properties, mainly due to their dimensions and subsequent large ratio of atoms in the particle surface. As opposed to metal nanoparticles, metal nanofibers or metal nanowires present elongated structures that help the electrical current passage. That is the reason why they have been largely investigated as network electrodes for optoelectronic devices, with strictly controlled electrical and optical properties. Copper nanofibers provide around 2–3 orders of magnitude higher aspect ratios than other 1D nanomaterials such as carbon nanotubes or silver nanowires. Silver nanowires have been the most explored nanomaterials, with copper nanowires appearing as an alternative. Some determinant aspects as their dispersing agents, wire geometry and aspect ratio have been fully studied and reviewed over the years [20]. The junctions between the wires in the network are crucial for the conductivity paths, with a well-sintered junction causing a lower junction’s electrical resistance. This leads to overall lower electrical resistance and enhanced electrical and mechanical properties. The thermal conductivity of silver nanowires at room temperature was reduced by 55% from that of bulk silver (see Table 1). Cheng et al. used a unified thermal resistivity method to elucidate the electron scattering mechanism of bulk and silver nanostructures [10]. In bulk silver, the phonon scattering dominates the electron transport, with rare structural scatterings, while in metallic nanostructures, there are grain boundary and surface scatterings. These scatterings limit the electron free path, which contributes to the reduction in thermal and electrical conductivity.

2.3. Intrinsically Conductive Polymers

A broad range of available polymers has been documented to have significant electrical conductivity with the addition of dopants. This included polyacetylene, polypyrrole, polyaniline and polythiophene, among others. After polyacetylene has been disregarded commercially due to instability in air, polyaniline and polythiophene have emerged as the most promising in both research and industry, not only due to their stability but also due to their dissolution ability in common solvents. Conductive polymers have attracted much attention due to their advantages, such as recyclability, light weight, low cost, chemical stability and easy processability [11]. Their solution processability, in particular, makes intrinsically conductive polymers highly attractive for flexible electronic devices. The fact that the polymer’s molecular structure can be tuned to control the electrical and mechanical properties of the resulting material is also highly promising.

The correlation between electrical and thermal conductivities in conductive polymers largely differs from the ones in metals, since electrons are not the carriers for electrical nor thermal current [11]. In contrast to the electrically insulating polymers, the thermal conductivity in conductive polymers happens through phonons and charge carriers. As for the insulating polymers, the thermal conductivity in a conductive polymer strongly depends on numerous factors, such as defects or structural faults, its chemical components, side group molecular weight, molecular density distribution, temperature, processing conditions, and others [21]. The presence of defects in polymers can cause phonon scattering at the interface between amorphous and crystalline states, leading to low thermal conductivities [16]. The low thermal conductivities (Table 1) of electrically conductive polymers are thus explained by the same reasons pointed to before. There are a few intrinsically conductive polymers, with a balance between crystallinity and low insulating content, that can be used as conductive thin films or as conductive fillers in nanocomposites [22]. However, engineering of the thermal conductivity is not an easy task, as for crystalline materials, as it depends on several structural factors such as the type and size of fillers, conformation of polymer chains and chain structure [11].

Polythiophene materials, namely Poly(3,4-ethylenedioxythiophene (PEDOT) doped with aqueous polystyrenesulfonate (PSS) (PEDOT:PSS), appeared as one of the most promising intrinsically conductive polymers. It presents the highest reported conductivity among solution-processed polymers [23], which has been reported to increase from 0.8 Scm−1 to 80 Scm−1 in the presence of the solvent DMSO [24]. Indeed, some studies have been published on different techniques to enhance the electrical conductivity of PEDOT:PSS [24][25], including organic solvent, surfactant, salt solution treatments, and others. Romasanta and colleagues have reported a microfluidic method of adding a secondary liquid dopant to alter PEDOT:PSS films locally, boosting the electrical conductivity in a specific area to take advantage of the localized Joule’s effect [26].

2.4. Hybrid Nanomaterials

Hybrid nanomaterials synergistically combine materials of different natures, such as organic and inorganic. They can be highly promising structures that keep the beneficial properties of both inorganic nanoparticles and polymers, e.g., [27]. In addition, multifunctional hybrid nanomaterials can be produced, with the ability to tune their properties through the combination of functional components [28].

3. Fibrous Systems

Conductive fibers have been largely exploited to conduct electricity and provide heating via the Joule effect, but also for sensing and for providing antimicrobial and electromagnetic shielding (EMS) properties.

Carbon fibers have a diameter of 5–10 µm and are composed of carbon atoms bonded together to form a long chain. They have been used in applications in the aerospace and automotive industries, among others, due to their high stiffness, tensile strength, chemical resistance and temperature tolerance. In fact, they present a high ratio of strength to weight and a high ratio of modulus to weight. In addition to their large thermal conductivity (Table 1), they also present a large electrical conductivity (>3300 S/cm) [5]. Even though they are under the category of carbon-based materials in Table 1, they are micromaterials. In addition to providing strength and stiffness to composites, these carbon fibers also introduce new functionalities such as thermal and electrical conductivity, based on their intrinsic properties. The most common types of carbon fibers are polyacrylonitrile (PAN) and pitch carbon fiber [29]. The pitch-based CFs exhibit a thermal conductivity of about 1000 Wm−1K−1 [30], much higher than that of PAN (8–12 W m−1 K−1) [31].

Metallic fibers are manufactured fibers composed of metals, either plastic-coated metal, metal-coated plastic or a core completely covered by metal. Whole metallic filaments are fabricated by a continuous heat treatment applied to the metallic wires followed by drawing [32]. Since 1968, Underwood’s technique of producing metallic yarns by spinning a bundle of metallic fibers has been followed [33]. For that, a solid mass of metal is shredded to produce elongated filaments with rough or serrated surfaces. Stainless steel fibers can be used to produce fine stainless-steel yarns, suitable for knitting or weaving and largely used in different heating applications.

The morphological properties of fibrous systems can highly influence the thermal and electrical transport performance. It has been reported that fiber length, diameter and orientation of natural fibers affect mechanical, thermal properties, among others [34].

References

- Park, J. Functional Fibers, Composites and Textiles Utilizing Photothermal and Joule Heating. Polymers 2020, 12, 189.

- Ganguli, S.; Roy, A.K.; Anderson, D.P. Improved Thermal Conductivity for Chemically Functionalized Exfoliated Graphite/Epoxy Composites. Carbon N. Y. 2008, 46, 806–817.

- Balandin, A.A. Thermal Properties of Graphene and Nanostructured Carbon Materials. Nat. Mater. 2011, 10, 569–581.

- Du, J.; Pei, S.; Ma, L.; Cheng, H.M. 25th Anniversary Article: Carbon Nanotube- and Graphene-Based Transparent Conductive Films for Optoelectronic Devices. Adv. Mater. 2014, 26, 1958–1991.

- Khan, M.O.; Leung, S.N.; Chan, E.; Naguib, H.E.; Dawson, F.; Adinkrah, V. Effects of Microsized and Nanosized Carbon Fillers on the Thermal and Electrical Properties of Polyphenylene Sulfide Based Composites. Polym. Eng. Sci. 2013, 53, 2398–2406.

- Ha, S.M.; Lee, H.L.; Lee, S.G.; Kim, B.G.; Kim, Y.S.; Won, J.C.; Choi, W.J.; Lee, D.C.; Kim, J.; Yoo, Y. Thermal Conductivity of Graphite Filled Liquid Crystal Polymer Composites and Theoretical Predictions. Compos. Sci. Technol. 2013, 88, 113–119.

- Leung, S.N. Thermally Conductive Polymer Composites and Nanocomposites: Processing-Structure-Property Relationships. Compos. Part B Eng. 2018, 150, 78–92.

- Chaudhry, A.U.; Mabrouk, A.N.; Abdala, A. Thermally Enhanced Polyolefin Composites: Fundamentals, Progress, Challenges, and Prospects. Sci. Technol. Adv. Mater. 2020, 21, 737–766.

- Chung, D.D.L. Materials for Thermal Conduction. Appl. Therm. Eng. 2001, 21, 1593–1605.

- Cheng, Z.; Liu, L.; Xu, S.; Lu, M.; Wang, X. Temperature Dependence of Electrical and Thermal Conduction in Single Silver Nanowire. Sci. Rep. 2015, 5, srep10718.

- Xu, X.; Zhou, J.; Chen, J. Thermal Transport in Conductive Polymer–Based Materials. Adv. Funct. Mater. 2020, 30, 1–18.

- Chen, H.; Ginzburg, V.V.; Yang, J.; Yang, Y.; Liu, W.; Huang, Y.; Du, L.; Chen, B. Thermal Conductivity of Polymer-Based Composites: Fundamentals and Applications. Prog. Polym. Sci. 2016, 59, 41–85.

- Akishin, G.P.; Turnaev, S.K.; Vaispapir, V.Y.; Gorbunova, M.A.; Makurin, Y.N.; Kiiko, V.S.; Ivanovskii, A.L. Thermal Conductivity of Beryllium Oxide Ceramic. Refract. Ind. Ceram. 2009, 50, 465–468.

- Jeong, S.H.; Song, J.B.; Kim, K.L.; Choi, Y.H.; Lee, H. Enhanced Thermal Properties of Epoxy Composite Containing Cubic and Hexagonal Boron Nitride Fillers for Superconducting Magnet Applications. Compos. Part B Eng. 2016, 107, 22–28.

- Zhou, T.; Wang, X.; Mingyuan, G.U.; Liu, X. Study of the Thermal Conduction Mechanism of Nano-SiC/DGEBA/EMI-2,4 Composites. Polymer 2008, 49, 4666–4672.

- Li, A.; Zhang, C.; Zhang, Y.F. Thermal Conductivity of Graphene-Polymer Composites: Mechanisms, Properties, and Applications. Polymers 2017, 9, 437.

- Mokhena, T.C.; Mochane, M.J.; Sefadi, J.S.; Motloung, S.V.; Andala, D.M. Thermal Conductivity of Graphite-Based Polymer Composites. In Impact of Thermal Conductivity on Energy Technologies; InTech Open: London, UK, 2018.

- Liu, W.; Do, I.-H.; Fukushima, H.; Drzal, L.T. Influence of Processing on Morphology, Electrical Conductivity and Flexural Properties of Exfoliated Graphite Nanoplatelets-Polyamide Nanocomposites. Carbon Lett. 2010, 11, 279–284.

- Pop, E.; Mann, D.; Wang, Q.; Goodson, K.; Dai, H. Thermal Conductance of an Individual Single-Wall Carbon Nanotube above Room Temperature. Nano Lett. 2006, 6, 96–100.

- Zilberberg, K.; Riedl, T. Metal-Nanostructures-a Modern and Powerful Platform to Create Transparent Electrodes for Thin-Film Photovoltaics. J. Mater. Chem. A 2016, 4, 14481–14508.

- Han, Z.; Fina, A. Thermal Conductivity of Carbon Nanotubes and Their Polymer Nanocomposites: A Review. Prog. Polym. Sci. 2011, 36, 914–944.

- Wang, Y.; Zhu, C.; Pfattner, R.; Yan, H.; Jin, L.; Chen, S.; Molina-Lopez, F.; Lissel, F.; Liu, J.; Rabiah, N.I.; et al. A Highly Stretchable, Transparent, and Conductive Polymer. Sci. Adv. 2017, 3, 1–11.

- Lipomi, D.J.; Lee, J.A.; Vosgueritchian, M.; Tee, B.C.; Bolander, J.A.; Bao, Z. Electronic Properties of Transparent Conductive Films of PEDOT:PSS on Stretchable Substrates. Chem. Mater. 2012, 24, 373–382.

- Kim, J.Y.; Jung, J.H.; Lee, D.E.; Joo, J. Enhancement of Electrical Conductivity of Poly(3,4-Ethylenedioxythiophene)/Poly(4-Styrenesulfonate) by a Change of Solvents. Synth. Met. 2002, 126, 311–316.

- Shi, H.; Liu, C.; Jiang, Q.; Xu, J. Effective Approaches to Improve the Electrical Conductivity of PEDOT:PSS: A Review. Adv. Electron. Mater. 2015, 1, 1500017.

- Romasanta, L.J.; Schäfer, P.; Leng, J. Fluidic Patterning of Transparent Polymer Heaters. Sci. Rep. 2018, 8, 1–7.

- Macchione, M.A.; Biglione, C.; Strumia, M. Design, Synthesis and Architectures of Hybrid Nanomaterials for Therapy and Diagnosis Applications. Polymers 2018, 10, 527.

- Taylor-Pashow, K.M.L.; Della Rocca, J.; Huxford, R.C.; Lin, W. Hybrid Nanomaterials for Biomedical Applications. In Chemical Communications; Royal Society of Chemistry: London, UK, 2010; pp. 5832–5849.

- Ali, Z.; Gao, Y.; Tang, B.; Wu, X.; Wang, Y.; Li, M.; Hou, X.; Li, L.; Jiang, N.; Yu, J. Preparation, Properties and Mechanisms of Carbon Fiber/Polymer Composites for Thermal Management Applications. Polymers 2021, 13, 169.

- Hou, X.; Chen, Y.; Dai, W.; Wang, Z.; Li, H.; Lin, C.T.; Nishimura, K.; Jiang, N.; Yu, J. Highly Thermal Conductive Polymer Composites via Constructing Micro-Phragmites Communis Structured Carbon Fibers. Chem. Eng. J. 2019, 375, 122099.

- Inoue, R.; Arai, Y.; Kubota, Y.; Goto, K.; Kogo, Y. Development of Short- and Continuous Carbon Fiber-Reinforced ZrB2-SiC-ZrC Matrix Composites for Thermal Protection Systems. Ceram. Int. 2018, 44, 15859–15867.

- Raji, R.K.; Miao, X.; Boakye, A. Electrical Conductivity in Textile Fibers and Yarns—Review. AATCC J. Res. 2017, 4, 8–21.

- Webber, H.H.; Wilson, A.H. Metal Filaments Suitable for Textiles. U.S. Patent 3,379,000, 23 April 1968.

- Balla, V.K.; Kate, K.H.; Satyavolu, J.; Singh, P.; Tadimeti, J.G.D. Additive Manufacturing of Natural Fiber Reinforced Polymer Composites: Processing and Prospects. Compos. Part B Eng. 2019, 174, 106956.

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

820

Revisions:

2 times

(View History)

Update Date:

28 Jun 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No