Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Nanoscience & Nanotechnology

Piezoelectric and triboelectric nanogenerators have been widely studied for their advantages of easy design/manufacturing, small size, and flexibility. Nanogenerators that are developed based on the coupled piezoelectric and triboelectric effects (PTCNG) can make full use of the mechanical energies and achieve both higher output and sensing performance.

- piezoelectric-triboelectric nanogenerator

- coupled effect

- structure integration

1. Introduction

Currently, artificial intelligence technology and Internet of Things (IoTs) are playing important roles in industry and people’s lives, from managing inventories to improving personalized shopping experiences and assisting in data mining, even transforming how people do business today [1]. Intelligent electronic devices such as wearable devices [2,3,4,5], implantable devices [6,7,8], medical robots, and other products are showing explosive growth and helping people control and detect various aspects of the surrounding environment [9], human health, and energy harvesting [10,11,12]. However, because the composition of artificial intelligence and IoTs require numerous sensors with high performance, low power consumption, and especially, stable and sustainable operation, which is the key to realize the full power of IoTs, traditional electrochemical sensor power sources are facing challenges in this era due to their limited endurance and energy storage capacity [13,14,15].

As a kind of emerging energy-harvesting technologies, nanogenerators, such as triboelectric nanogenerators (TENG) and piezoelectric nanogenerators (PENG), are proposed for scavenging mechanical energies from our ambient environment and transforming them into electricity in a distributed manner [16]. TENGs are fabricated based on electrostatic inductive coupling and the triboelectric effect, while PENG is developed based on the piezoelectric effect and generating alternating currents from the polarization, both with advantages of a high output voltage, simple fabrication, lightweight, and small sizes [17,18,19,20].

Since Wang et al. proposed the concept of a hybrid nano-energy-harvesting device for collecting mechanical energy and solar energy in 2009, the strategy of hybridizing or coupling multi-effects together has been widely applied to the design of nanogenerators for collecting single or multiple types of energy [21,22,23]. Among the various all-in-one multi-energy-harvesting devices, the synergism between piezoelectric and triboelectric effects is especially attractive due to the easiness to integrate that comes from their similarity in both structure and operation principle, which means they can be integrated together with a simpler structure, higher efficiency, and other complementary characteristics.

Generally, PTCNG structures are divided into three types [24,25,26,27,28,29,30]. In the two-end structure, piezoelectric and triboelectric characteristics are provided by one material. Electrostatic charges are directly added to the material surface, increasing the potential difference between the two surfaces of the film. In the three-terminal structure, TENG and PENG share one electrode, which can increase the triboelectric charge on the PENG electrode. For the four-terminal structure, PENG and TENG work independently. In addition, the polarity of piezoelectric material can be flexibly modulated, which can improve the conversion efficiency of the generator [31]. Previous studies have proved that PENG has the best energy conversion efficiency in the resonant state, which can be mutually coordinated with TENG to activate the resonant mode and reduce the output phase difference to achieve effective hybridization of PENG and TENG [32,33]. At the same time, PENG and TENG have the characteristic of complementary frequency, and both have high stable output power and conversion efficiency under weak low-frequency external stimulation, and thus may achieve efficient and stable mechanical energy collection [28,34]. In addition, due to the wide selection of piezoelectric and triboelectric materials, the impedance matching between PENG and TENG is not difficult, which can reduce the additional energy loss [35]. This helps the two-part work in concert with easy integration, enhanced overall charge density, high flexibility, light weight, and small size. Besides, both the responsivity and specific detectivity of sensors that are developed on the coupled device can be enhanced due to the frequency complementarity and multi-signal division. Consequently, spatially resolved force detection may be realized by recording the different output voltage signals as a mapping figure in smart devices [36,37].

2. The Working Principle of Piezoelectric/Triboelectric Nanogenerator

2.1. Piezoelectric Effect

The piezoelectric effect was discovered by Pierre Curie and others in the research of Rochelle salt, quartz, and other materials. Materials with an asymmetric crystal structure are piezoelectric materials, and common piezoelectric materials can be divided into two categories: inorganic piezoelectric materials and organic piezoelectric materials. Inorganic materials include piezoelectric ceramics and crystals, such as lead zirconate titanate (PZT), barium titanate (BaTiO3), lithium niobate (LiNbO3), zinc oxide (ZnO), and quartz. Meanwhile, representative organic piezoelectric materials are polyvinylidene fluoride (PVDF) fibers/films and their copolymers [38]. The piezoelectric effect of piezoelectric materials occurs because when stress is applied to the surface of the material, the centers of positive and negative charges in the material lattice do not overlap and there is the presence of an electric dipole, and when there is an external stimulus, the disordered electric dipole reverses to form a regular and sequential combination of arrangements, and the centers of positive and negative charges move to the opposite surface of the material, forming a built-in electric field on the two surfaces of the material. This is the phenomenon of polarization [39]. This phenomenon of polarization due to material deformation is called the positive piezoelectric effect [40]. If the direction of the applied force is changed, the polarity of the charge will change. However, for the inverse piezoelectric effect, when the piezoelectric material is pressurized, the electric field force causes the dipole to drive the crystal to deform and produce a polarization phenomenon, to show the stretching behavior of the material surface on a macro-level, which belongs to the inverse piezoelectric effect [41].

2.2. Working Principle of PENG

PENG mainly consists of piezoelectric materials and electrodes, and the working principle of PENG is that when piezoelectric materials are subjected to external stress, the positive and negative charge centers of the piezoelectric materials move and a potential difference is formed on the surface of the materials, leading to the generation of transient currents [16,42,43]. To obtain a higher piezoelectric response, it is necessary to go through a polarization method. Due to the positive and negative polarization properties of the material itself, for example, under the same mechanical stress, GaN will produce positive and negative polarization effects with different polarities, but for ceramic or polymer piezoelectric materials, contact polarization and corona polarization methods are commonly used [44]. Due to the irregular “mosaic” of grains in these two groups of materials, the arrangement of electric domains is haphazard and has no polarity, and the electric domains must be oriented in the direction of the electric field by a high-voltage electric field. Contact polarization is to apply high voltage through electrodes on both sides of a piezoelectric material [45]. Corona polarization is based on the principle of corona discharge. At room temperature, the high-voltage electric field will ionize the plasma in the air during the discharge process, and the oxygen atoms with negative charges will be deposited on the surface of the piezoelectric film under the acceleration of the high-voltage electric field. A large number of negative charge ions are deposited on the film to form a potential difference, which makes the electric dipoles reverse, and they are arranged in a certain order. However, for semiconductors, which do not require an electric field to produce polarization, some semiconductors are ferroelectric, and the ferroelectric phase exhibits a spontaneous ferroelectric polarization rate, changing from a paraelectric phase to a ferroelectric phase during the transition from high to low temperature. After the polarization step, the piezoelectric response is increased [46,47].

Since PENG was first proposed by Wang et al. in 2006, many different structures and materials of PENG have been utilized for the preparation of PENG-based energy-harvesting devices [48]. Nowadays, there is a shift from traditional rigid materials such as piezoelectric ceramics (quartz, PZT, and BTO, etc.) to polymeric (PVDF, PDMS, etc.) materials, including composite materials. The flexible design can satisfy more customer requirements and enables the designers to construct customized module functions. To enhance the performance of PENG [49,50,51], researchers have also proposed various structures, such as the vertical growth structure [52,53,54], horizontal growth structure [55,56,57], and stretchable structure [58,59], where the structural and material progress have led to a significant improvement in the performance and extended the application of PENG in human health monitoring, wearable devices, energy harvesting, etc.

2.3. Triboelectric Effect

The triboelectric effect can effectively convert mechanical energy into electrical energy based on coupled triboelectrification and electrostatic induction effects. When a material is in frictional contact with another material, the charge between the two materials is transferred, and the charge transfer is accomplished by the thermodynamic movement of electrons from the occupied high-energy state (valence band) to the unoccupied low-energy state (conduction band). To put it simply, a material with a strong ability to obtain electrons will be attracted from another material, and thus electrons gather on the surface of the material, and then when the two materials are separated, an electric potential difference is formed between the two electrodes because a large number of opposite charges have accumulated on the surface of these two materials [60,61,62,63]. The potential difference determines the energy distribution and density of states on the material surface, which is generated by the Fermi energy level of the conducting surface and the effective Fermi energy level of the insulator [64]. The triboelectric layer can generate a large amount of electric charge through periodic contact and separation, and the generated charge can be energy collected after an external circuit. The triboelectric effect is widespread, and many materials in the process of contact-separation produce the corresponding potential difference, so the choice of TENG triboelectric layer materials is very rich, such as wool, melamine, PVC, etc. The polarity of different materials differs, reflecting the different ability of the materials to gain and lose electrons, and the preparation of high-output TENG should use the polarity of the difference between the materials, and thus the friction effect will be stronger [65,66,67,68].

2.4. Working Principle of TENG

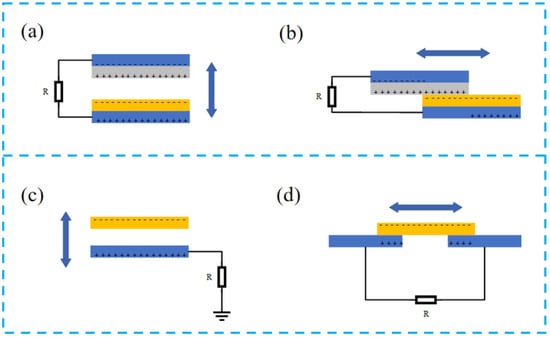

Since TENG was first reported in 2012, much attention has been paid to the collection of randomly generated, irregular, and useless mechanical energy based on Maxwell’s displacement current theory [69,70]. The relative frictional motion of two triboelectric materials generates charges that can be stored through an external circuit for storage. Nowadays, there are four modes of operation of TENG: contact-separation mode, lateral sliding mode, single-electrode mode, and friction-independent mode (Figure 2).

Figure 2. Four fundamental modes of TENG: (a) vertical contact-separation mode, (b) lateral sliding mode, (c) single-electrode mode, and (d) freestanding triboelectric-layer mode.

Contact separation is the more common mode (Figure 2a) of TENG. Under the action of external force, the two dielectric materials frictionally separate and contact in the vertical direction, and the charge generated by friction is gathered in the top electrode and back electrode. Periodic contact-separation movement generates a large number of charges and forms an alternation current flow through the external circuit, and thus the mechanical energy is transformed into electrical energy [62].

The sliding mode is structurally the same as the contact-separation mode (Figure 2b), but the direction of motion of the dielectric layer changes from vertical to horizontal, and the charge is generated during relative sliding. The potential difference between the two electrodes changes with the different contact areas of the dielectric layer, and the potential difference forms a current flow, and a regular AC voltage can be generated through the periodic sliding separation [71].

The single-electrode mode is similar to the vertical contact-separation mode (Figure 2c). In this mode, the ground acts as a reference electrode, and the form of charge generation is also generated by contact separation. In this design, the moving part of the TENG is not connected with any electrode, which substantially simplifies the device fabrication process and improves the operation convenience.

Friction-independent mode (Figure 2d) is generated by the motion of the dielectric layer rubbing the symmetrical electrodes and rubbing the contact parts with each other to produce an asymmetrical potential, allowing the current to flow between the electrodes, but the direction of the current depends on the direction of the motion of the dielectric layer, and the friction-independent mode can adopt either sliding-independent TENG or contact-independent TENG [72].

Nowadays, TENG can be used in various aspects, such as environmental monitoring, biomedical and high-voltage applications, etc. [73,74,75,76,77,78]. Due to the many advantages of TENG, such as diverse material choices, easy-to-design specific structures, low cost, high yield, good stability, and excellent output characteristics, it can bring great power to the development of our society.

This entry is adapted from the peer-reviewed paper 10.3390/nano13030385

This entry is offline, you can click here to edit this entry!