1. Introduction

According to the reports of the International Energy Agency (IEA), despite the destabilization of global energy consumption due to the pandemic, electricity demand will reach pre-pandemic levels in 2022, and continue to increase [

1]. Analogous to the increase in demand on land, the demand for electricity on board ships will also increase, due to the ongoing electrification of ships and a growing number of electricity-based technologies [

2,

3,

4], the implementation of which contributes to the International Maritime Organization’s (IMO) goal of reducing greenhouse gas emissions by 2050 [

5] while increasing energy efficiency. Consequently, the increasing demand requires improvements in two areas: power generation and power distribution. It should be noted that, due to functional similarities, the advances in land-based distribution systems can also be considered as improvements in shipboard distribution systems, focusing on increasing efficiency and reliability, as it is an independent, closed system that can be considered as an islanded microgrid at sea [

6]. The inefficiency of the power distribution system, if not at an appropriate level, can outweigh the efficiency of the power generation system, which is why it is important to link the improvements in both areas. Switchgear, as an essential component of the distribution system, is used to control, protect, and isolate power systems, as well as disconnect equipment for repair, maintenance, and testing purposes. Considering the role of switchgear and the usually high current flow loads to which the equipment is subjected, especially in medium voltage networks, maintenance strategies are required, the optimization of which would be of great benefit for real-time condition monitoring and diagnosis [

7]. The procedures now mostly rely on predefined maintenance intervals and observing the thermal effects by means of manual IR temperature measurements. With this in mind, several studies and experiments have been conducted to leverage the recent beneficial results of deep learning-based methods and Internet-of-Things (IoT) to create solutions for efficient power distribution monitoring. In [

8], deep learning was used to diagnose power quality disturbances in electric power systems to reduce existing delayed actions based on mathematical calculations. The implementation resulted in over 99% accuracy using simulated data. Another study, [

9], proposed a high-throughput, low-latency deep-learning-based approach in an edge device to detect high-impedance faults on overhead power lines in real time. The approach was validated under laboratory conditions and showed reduced detection latency and high detection accuracy of 96.67%. Additionally, in [

10], an intelligent device was presented for monitoring polluted high voltage insulators in overhead transmission lines to prevent power outages before they occurred. The device was tested under laboratory conditions and achieved an accuracy of 91.66%. Although the advantages of such a system are numerous (simplicity, low cost, ease of use, etc.), the limitation lies in the problems of the internet network, and the adjustment of the reference current leakage depending on the pollution of the area where the lines are installed. In order to quantify the research focus in this area, the highly regarded Web of Science (WoS) database was searched for studies on switchgear digitization and intelligent fault diagnosis techniques from the last decade. With respect to the topic of this paper, the core collection of WoS, or more specifically, the Science Citation Index Expanded (SCIE) and the Social Science Citation Index (SSCI), were selected. In addition, only articles and reviews were considered, and publication years were limited from 2011 to 2021. The selection of keywords was of great importance, and due to the wide variety of connotations for the searched topic, it was difficult to include all relevant keywords. In this paper, the search format “object” (e.g., switchgear, grid, etc.) + “interest” (e.g., diagnostics, digitization, etc.) was used, and the query is as follows:

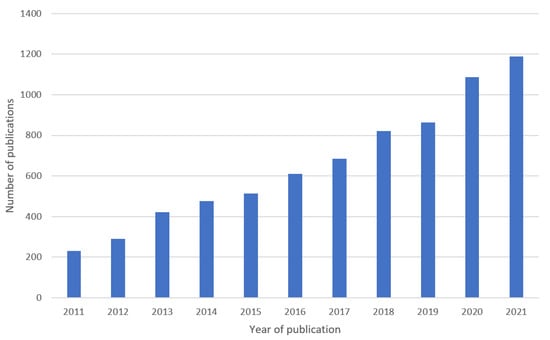

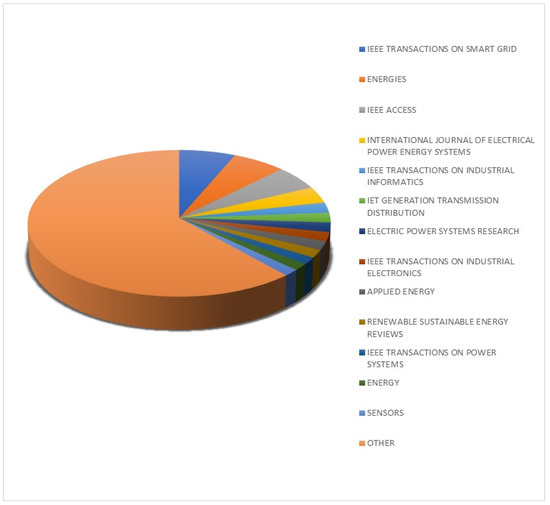

After excluding unrelated topics such as economics, psychology, etc., a total of 7187 documents were collected. The chart in Figure 1 shows the total increase in published papers by year, while Figure 2 shows the major publishers.

Figure 1. Number of publications related to the research topic in the past decade.

Figure 2. Major publishers in the research topic.

Overall, the concept of online condition monitoring using digital sensors and communication protocols, or the concept of digital switchgear (a switchgear in which the information on equipment status, current and voltage measurements, and commands are reliably transmitted over a common communication bus, while the condition monitoring and diagnostic information of the switchgear and its equipment is also digitally available for advanced analysis [

11]), is the most practical tool for maximizing the efficiency of maintenance strategies and all the resulting benefits of digitalization [

12]. However, it also comes with disadvantages [

13], such as the need for solid knowledge of communication networks and adaptation of personnel to digital measurements (software analysis). Another problem posed by the digitalization of the power grid, and in particular by its integration with the IoT, is vulnerability to cyber-attacks due to the increasing reliance on communication networks to support physical process control, a problem that has been recognized and for which a large number of studies already exist, some of which are [

14,

15,

16]. Given the potential importance of distribution system digitization, this scoping review summarizes and appropriately categorizes substation digitization research based on the steps that preceded the emergence of the concept of digital substations. It concludes with current relevant applications, benefits, and recommendations for future work to address the most common problem of forming a framework for direct the comparison of developed algorithms for use in maintenance purposes, and hopefully create a baseline database for switchgear digitalization to guide future research.

2. Applications of Measurement Data Manipulation

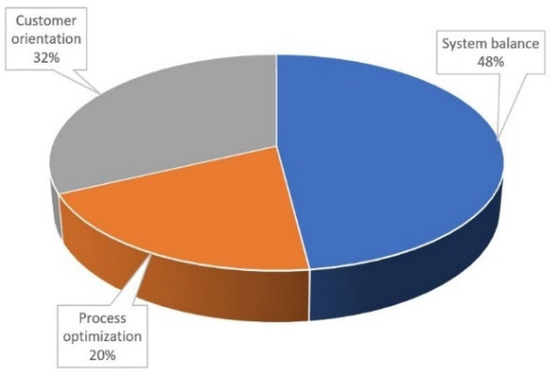

The digital applications used in the “smart grids”, an intertwined term used to describe the digital distribution network, i.e., all distribution components including the switchgear, as investigated in [

41] in 2019, highlight and divide the research conducted in the field of digital applications in condition monitoring and predictive maintenance in distribution networks and its included subcomponents. The results are presented in

Figure 3.

Figure 3. Analysis of digital applications in smart networks.

Where, in system balance real time condition monitoring and anomaly detection/failure localization, related papers make up 32%, respectively, process optimization digital twin and predictive maintenance-related papers make up 75%. The significant increase of research in the field in the last two decades has seen an exponential growth of predictive maintenance-related papers, while machine learning-infused predictive maintenance papers present around 44% of all related publications between 2020 and 2021 [

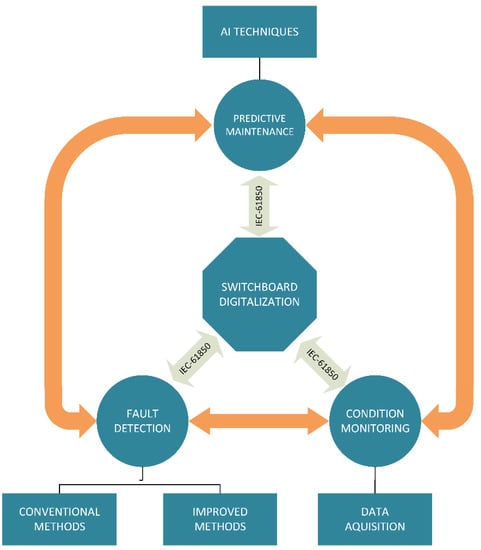

42]. The processes, such as predictive maintenance, fault detection, and condition monitoring, that utilize the measured data (directly or indirectly) are interconnected as each process can either be improved or makes use of the bidirectional flow of information, as shown in

Figure 4.

Figure 4. Interconnection of switchboard digitalization activities.

In the above figure, the orange arrows depict the bidirectional flow of information, and condition monitoring is utilized in the following scheme for data acquisition that is further processed for use with the purpose of fault detection or predictive maintenance. Conversely, the results of the analysis of predictive maintenance or the detection of faults can improve the equipment monitoring by providing data as to optimize the location of sensors or add/remove different types of sensors. In the following subsections, the various applications in each category will be exemplified, but due to significant interconnection they are not always easy to differentiate.

2.1. Condition Monitoring

The process of monitoring multiple conditions of an object (temperature, vibrations, partial discharges, etc.) that are considered to be health indicators, in order to identify changes in operation that indicate the development of a possible fault, is called condition monitoring (CM). It is a significant part of predictive maintenance, as the acquired data is used to optimize and perform scheduled and preventive actions in order to prevent asset failure and unwanted downtime. In the case of a marine switchgear, condition monitoring (and the implied predictive maintenance and fault detection processes) is a viable tool for increasing operational safety, efficiency of the equipment, and reducing major failures risk and the accompanying possibility of arcing faults during maintenance and repair operations that are described in [

43]. The operational advantages of a continuous monitoring system being [

44]:

-

labor-free measurements;

-

accurate data due to real time operational measurements;

-

improved service decision due to failure start/progress information;

-

unnecessary maintenance reduction due to decisions based on data from continuous measurements;

-

prioritization of equipment repair order.

If a full condition monitoring system for switchgear is utilized, such as in [

45], it would yield a reduction of 65% in three-year maintenance tasks, increasing the maintenance cycle by 30% and undoubtedly having a positive impact on cost reduction, and ultimately, ensuring a reliable long term switchgear operation. The safety study of ship power failures [

46], concluded that in many power failures caused by worn or old components, the root sources were actually deficiencies in the maintenance system. In the case of RMS Neudorf from 2016, the power failure was caused by a breaker malfunction, of which the condition was not monitored regularly or was not noticed during inspection. The process of condition monitoring is the solution to preventing such risks during navigation. In future, the digitalization of switchgear can be utilized in the recent trend of “digital twins” with similar solutions, as described in [

47]. Utilization in digital twins is not only limited to switchgear, as the real time operational data can be utilized in the digital twin of a ship; the applications, benefits, and methods of which are revised in [

48]. It should be emphasized that the concept of digital switchgear within the digital twin paradigm is of importance in the simulation of electric power systems, since in most studies the complex dynamics of switchgear are often assumed to be irrelevant and circuit breakers are modeled as switches; an example of this can be found in [

49]. The implementation of real switchgear operation data will positively impact the overall accuracy of the digital twin, especially in the context of digital twins for ships. Additionally, using effective condition monitoring may reduce maintenance tasks by 65%, saving costs in labor and parts, while also reducing the risk of equipment damage during unnecessary inspections, decreasing failure probability, and optimizing the complete maintenance program [

45].

2.2. Fault Detection

Considering the influence of partial discharges on the development of catastrophic failures, determining the source location (of the defect) is of great importance in maintenance and repair procedures. The implementation of sensors in switchgear automates the detection of faults based on real time operational data obtained through condition monitoring. Confirming that partial discharge has occurred is not enough for failure prevention, unless the location of the discharge is provided in order to determinate the insulation state. One possible solution for defect localization is by utilizing transient earth voltage (TEV) sensors, as in [

50], in which the solution is based on the principle that the partial discharge source can be determined by the time difference of arrival method (TDOA) [

51]. The TEV method is the optimal solution in switchgear due to its high sensitivity, uninterrupted power supply, strong anti-interference performance, easy installation, and non-instructive method [

52]. Some examples of various PD localization methods (including data-driven methods using neural networks) are presented and reviewed in [

53,

54].

2.3. Predictive Maintenance

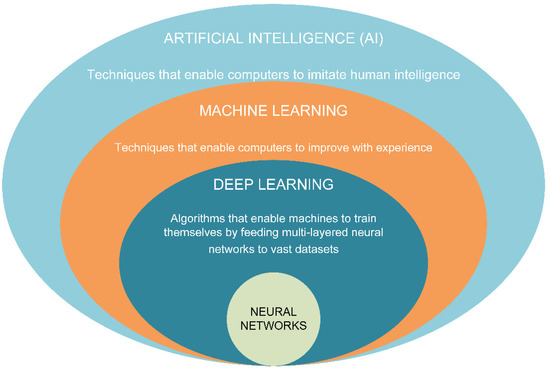

Considering that predictive maintenance leverages operational data (a collection of various operational parameters over an extended period of time) captured through real time condition monitoring (if implemented) and provides a significant amount of data, the need to automate the recognition, classification, and prediction of potential failures/anomalies is obvious. Until recently, the classification and detection of failures, degradation, or defects have been conducted manually, which had the disadvantage of depending on the expertise of staff. More recent trends use artificial intelligence (AI) algorithms to automate all or part of the data analysis process. In the literature, the terms AI, neural networks, machine learning, and deep learning are often used interchangeably, giving the impression that they are not easily distinguishable. In short, machine learning is a subset of AI, while deep learning is a subset of machine learning, with neural networks being the basis of deep learning, which is distinguished by the number of node layers (also called depth), where a deep learning algorithm must have more than three; the subdivision is shown in Figure 5.

Figure 5. Artificial intelligence divisions illustration.

According to [

55], the algorithms most commonly used by data scientists in 2021 were linear and logistic regression, followed by decision trees and random forests, while among more complex methods, gradient boosting machines and convolutional neural networks were the most popular approaches. Some examples of the use of AI in switchgear monitoring are presented in

Table 1.

Table 1. AI utilization in switchgear monitoring.

There are many more applications of AI, but the common outcome is the detection or prediction of faults or the assessment of the condition of assets, which are then used to make decisions about predictive actions to reduce unwanted downtime in the power grid. In recent years, research has shifted primarily to deep learning (DL) because “traditional” machine learning techniques rely on feature extraction using a predefined set of rules, i.e., rely on the programmer’s accuracy. Deep learning provides a solution to this problem as it can use raw data, and feature selection is integrated within the learning process [

67]. A comprehensive review of deep learning in HV applications is given in [

68], which also highlights the shortcomings or future needs of deep learning applications. A key challenge is the lack of real-world measurement data, as this is the basis for the development of any AI/ML/DL algorithm. To put it in context: Continuous measurements for temperature monitoring of switchgears are rare or basically non-existent during their entire operation time, and the breaker switching operation is infrequently performed, which makes it extremely difficult to collect data or detect patterns for training algorithms. One solution to the aforementioned problem is the use of a generative adversarial network (GAN), a deep learning algorithm that enables the generation of more data that mimics real data from a limited set of obtained real/experimental data, as in [

69]. A full summary of the integration of condition monitoring and machine learning algorithms for predictive maintenance is presented using medium voltage switchgear as an example in [

70].

This entry is adapted from the peer-reviewed paper 10.3390/s22207922