The use of recycled asphalt pavement (RAP) materials in asphalt concrete pavements (ACP) brings significant cost and environmental benefits. In practice, however, the amount of RAP readily available far exceeds the amount being utilized in ACPs, which still leaves the problem of excess RAP in the environment partially solved. Additionally, ACPs containing RAP materials (i.e., RAP-ACPs) can still be landfilled after they have reached the end of their useful life, which may restore the original environmental waste problem. To address these, researchers have demonstrated different ways to maximize the application of RAP in ACPs. Among them, the use of RAP in pavement preventive maintenance (PPM) treatments and the repeated recycling of RAP-ACPs (i.e., RnAP) are specifically discussed in this review. It is envisaged that, by promoting these two practices, the application and benefits of RAP can be further maximized to improve sustainability. This review also discusses the long-term behavior of RAP-ACP, which is crucial to inspire confidence in the wider application of RAP in ACP. Studies on RAP-PPM have shown that virgin PPM treatments can successfully accommodate RAP materials by adjusting their mix design. So far, research on RnAP has been limited to how multiple-recycling affects the performance properties of the blends, showing improvements in rutting resistance and moisture susceptibility but little effect on linear viscoelasticity and cracking. Overall, the lack of sufficient research is considered to be the biggest challenge in facilitating the implementation of these two sustainable RAP technologies. Little or nothing is known about the bonding mechanisms between RAP and fresh PPM binders, the molecular and chemical changes in RnAP binders, or the functional performance characteristics, actual pavement performance, and long-term performance of both RAP-PPM and RnAP blends. An understanding of these aspects is very relevant to maximize and continue the beneficial reuse of RAP in ACPs while safeguarding human and environmental health.

1. Introduction

Asphalt concrete pavements (ACP) are designed and built to last for a limited period of time, usually between 15 and 35 years. After this period, if the surface layer cannot be repaired, it must be completely removed and replaced. One way of disposing old ACP materials is to dispose of them at a designated landfill or dump site. Landfill disposal is not a sustainable option for obvious reasons, such as environmental concerns and cost issues related to equipment and energy costs. For many years, transport agencies, contractors, engineers, and pavement researchers have shown keen interest in the ACP recycling option because of its many benefits. Firstly, ACP recycling can save significant amounts of money. The National Asphalt Paving Association estimates that the use of recycled pavements in infrastructure could save nearly $2 billion annually [

1]. A major factor in this cost reduction is that ACP recycling uses fewer natural resources, such as stone, aggregate, and asphalt [

2]. Secondly, ACP recycling reduces landfill disposal, which is beneficial to the environment [

3,

4]. In addition, greenhouse gas (GHG) emissions are reduced through ACP recycling, as less virgin asphalt binder is involved [

2]. Performance-wise, previous studies have reported that the final product from ACP recycling is durable. It has better stiffness, which reduces the probability of rutting damage, leading to fewer repairs and maintenance in the future [

1]. However, the effects on fatigue resistance and low-temperature cracking performance are conflicting [

5,

6,

7,

8,

9,

10].

ACP can be recycled by extracting the asphalt binder or aggregate fraction from the old ACP and adding it to the newly produced asphalt mix in a specified quantity, or by incorporating the recycled asphalt pavement (RAP) directly into new asphalt mixtures as it is without separating the binder from the aggregates. The recycled asphalt binder is referred to as the RAP binder and the recycled aggregate is referred to as RAP aggregate. Traditionally, RAP is incorporated into hot- or warm-mix asphalt in amounts no more than 40% [

2], thus leaving behind a surplus in the RAP stockpile that largely remains unutilized. Several efforts have been made to fully exploit RAP in asphalt pavements. Recent studies have shown that it is possible to maximize the use of RAP in ACP with the help of rejuvenating and softening agents, increasing the RAP content to 100% [

11]. However, various concerns have been expressed about the effects of high RAP amounts on mechanical properties such as fatigue cracking, low-temperature cracking, and moisture susceptibility [

4,

12,

13,

14,

15,

16,

17,

18]. In addition, it is not clear how the use of high amounts of RAP can impact the long-term performance of asphalt pavements. Nowadays, alternative options such as RAP application in pavement foundation layers (base and sub-base) is also being considered because it can consume higher volumes of RAP materials [

19]. Improvements in recycling construction techniques such as hot in-place recycling (HIR) and cold in-place recycling methods are also very promising to maximize the application of RAP in ACP [

20,

21,

22,

23].

2. Brief Overview on the Application of RAP in Different Asphalt Pavement Layers

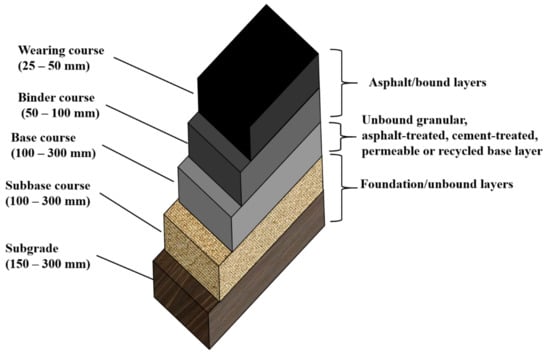

Asphalt pavement is made up of multiple layers, namely: subgrade and sub-base, which constitute the foundation or unbound layers; the base, which can be unbound granular, asphalt-treated, cement-treated, permeable, or recycled [

33]; and the asphalt layers at the surface, as shown in

Figure 1.

Figure 1. Different layers of typical asphalt concrete pavement.

A very important part of the ACP design process is the selection of appropriate pavement materials for the construction of the individual layers. These materials show a complex response when subjected to changes in load, temperature, and moisture. The engineering performance of paving materials depends on the relative composition of their constituents. In order to maximize the benefits of RAP, the transportation departments of several countries around the world—including in China [

34], Japan [

35], South Africa [

24], USA [

36,

37], Europe [

38], Australia, Victoria, New South Wales, Tasmania, and New Zealand [

39]—allow its use in the various layers of ACP. The following subsections provide further details on the use of RAP in different ACP layers.

2.1. RAP Usage in the Asphalt Surface/Bound Layers

The surface layer is the upper layer of the ACP and provides smooth, durable, and wear-resistant characteristics while retaining sufficient friction for road safety. It should also be resistant to water-induced damage, and must be strong enough not to rut under the action of traffic.

The application of RAP material in ACP surfaces has been the subject of intensive research due to its environmental and economic benefits. The greatest use of RAP is in hot-mix asphalt (HMA). It involves mixing RAP with new or ‘virgin’ aggregates, base asphalt binders, and/or rejuvenator in a central hot-mix plant to produce a recycled asphalt mix. The percentage of RAP allowed in surface mixes typically ranges from less than 20% to more than 50%, depending on the agency or country user guidelines.

In China, the utilization of RAP in surface courses is not very common, despite its significant economic and environmental benefits [

40]. Nie [

34] conducted a laboratory study to evaluate the performance of asphalt mixes in terms of fatigue resistance, moisture sensitivity, high-temperature stability and low-temperature cracking. All RAP mixes met the performance requirements, except for 30% of the RAP mixes that failed in terms of moisture resistance and low-temperature cracking. The study was from a research project in China where different concentrations of RAP (0%, 10%, 20%, and 30%) were used in the surface mixes. A 20% RAP content was determined to be the best performance.

Japan’s road sector was already an example of an effective RAP recycling system in 2013. After two years, 99% of the total RAP was reused [

35]. A small amount of RAP was used in the base layer, while the majority was added to the new HMA-WMA mixture, introducing an average of about 47% by weight of RAP [

35].

The South African practice allows up to 40% RAP in ACP surface layers [

24], while in Australia, Victoria, New South Wales, Tasmania, and New Zealand allow RAP contents of at least 15% [

39]. Higher amounts are possible if contractors can demonstrate that they are using appropriate plant technology and quality control procedures [

39]. Other parts of the country, such as Queensland, South Australia, and Western Australia, do not allow the use of RAP for road surfaces [

39].

In the United States of America (USA), a threshold RAP amount of 30% is recommended for better structural and functional performance of asphalt surface mixtures [

36,

37]. The Federal Highway Administration (FHWA) defines asphalt concrete containing more than 25% RAP (of the total mix weight) as a high RAP content mix [

41]. However, agencies are reluctant to use high RAP content in ACP surface layers due to the drawbacks associated with high RAP. Currently, the addition of limited amounts of aging RAP binder to fresh HMA increases the stiffness of the mixture [

4,

16], which subsequently leads to various forms of cracking such as fatigue cracking and low-temperature cracking. By further increasing the amount of RAP, this problem only becomes more severe. Nevertheless, there are many non-negligible benefits to using high RAP in the surface layer, such as improved resistance to rutting [

42,

43] and water-induced damage [

42], as well as cost and environmental benefits [

2].

Research has shown that, with certain modifications, it is possible to maximize the application of RAP in ACP surface layers without compromising performance. Common techniques that allow the use of high RAP are the use of soft binders, the addition of rejuvenators or softening agents, or the use of WMA additives [

2,

26,

28,

30,

44]. Softening agents usually reduce the viscosity of the aged binder, while rejuvenators help facilitate the rebalancing of the chemical composition in the aged binder that has lost its light molecular weight fraction during construction and use. In any case, the type and quantity of the selected additive should be carefully selected and its effectiveness evaluated by binder and mixture tests [

30].

2.2. RAP Usage in the Base and Sub-Base Layers

The typical base layers can be unbound granular, asphalt-treated, cement-treated, permeable, and recycled [

33]. The sub-base is typically located at the bottom of the base course layer and laid on top of the subgrade, serving to distribute the load over the subgrade [

33]. However, the sub-base is not usually used unless heavy traffic is involved, or if the subgrade is very weak [

33].

Most studies on the application of RAP in ACP have focused on asphalt layers, ignoring the potential of unbound layers (base and sub-base). However, evidences have shown that RAP can also be used in base and sub-base mixtures. The base layer is thicker than the asphalt layer; therefore, more recycled material can be consumed, thus reducing the amount of RAP in stockpiles. Cost-wise, research has shown that by partially replacing virgin aggregates with RAP aggregate in the base and sub-base, material cost savings of approximately 30% can be achieved [

45].

In addition to the economic and environmental benefits, RAP significantly influences the structural behavior and performance of the unbound layers. The modulus of elasticity (M

R), an important parameter in the Mechanistic-Empirical Pavement Design Guide (MEPDG), reflects the potential to resist permanent deformation. For typical unbound aggregates, the modulus of elasticity ranges between 125 MPa and 300 MPa [

46]. However, previous researchers have noted that RAP aggregates tend to have a higher modulus of elasticity than conventional unbound aggregates [

47], which, in turn, can improve rutting resistance. This effect on the mechanical properties and performance of unbound layers is clearly influenced by the amount of RAP in the mixture [

48,

49]. When used as an unbound aggregate, studies have shown that 100% RAP reduces strength and increases the potential for permanent deformation of the unbound base [

50]. Plati and Cliati [

51] reported that 100% RAP material and 50% RAP/50% virgin aggregate (VA) material produced M

R results similar to those investigated for VA, particularly at increased compaction pressures. Others systematically agree that RAP addition to VA (i) reduces dry density [

52], (ii) reduces bearing capacity (as measured by the California Bearing Ratio) [

52], and (iii) increases the modulus of elasticity [

47,

53,

54,

55]. However, the question usually arises as to how to utilize the high RAP amount in the base layer without diminishing the mechanical properties.

It has been shown that stabilized granular materials can allow for high RAP amounts. Mechanical (compaction, geotextiles), chemical, and cementitious (including hydraulic, zeolite, and asphalt cement) stabilization methods are all potentially viable methods, depending on the characteristics of the RAP material and the requirements of the end-use [

19,

55,

56]

This entry is adapted from the peer-reviewed paper 10.3390/polym14214736