Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

A battery–supercapacitor hybrid energy storage system is investigated as a solution to reduce the high-power delivery stress on the battery. An optimally-sized system can further enhance the storage and cost efficiency.

- battery

- supercapacitor

- EDLC

- capacity sizing

- embedded system

- energy management

- power distribution

- hybrid battery supercapacitor system

- HESS

- BESS

1. Background

Battery and supercapacitor systems are currently the most promising portable energy storage solutions. The capability of each is synergised when combined in a battery–supercapacitor hybrid energy storage system (HESS). The storage and cost efficiency can be further enhanced when they are optimally sized for practical purposes. The hybridisation reduces the battery size, increases the battery life span, improves the power efficiency, and thus reduces the initial and recurring cost of the battery [1][2][1,2]. The combination of a battery and supercapacitor, thus, has been studied for many applications [3][4][5] [3,4,5]. Several types of topologies have been proposed for the integration of battery–supercapacitor pairs, and experiments are being carried out to verify the feasibility of the various topologies[6][7] [6,7]. The topologies are passive, semi-active, and fully active[1][2][6] [1,2,6]. The difference between these three topologies is the controllability of the system, with the fully active topology having the most controllability. The control strategies for a semi-active HESS and a fully active HESS have been reported, targeting different desired outputs from the hybridisation[8][9][10] [8,9,10]. Two types of fully active HESS topology will be discussed in the current work, and the sizing strategy will be built based on a fully active HESS topology.

The supercapacitor is designed to take the entire high-power load when there is a surge in power demand, and the battery is designed to support the high energy demand of the load. However, in a practical application, such a condition can only be obtained if there is sufficient energy from both the battery and supercapacitor. Thus, when the state-of-charge (SOC) of each energy storage device falls below its usable power spectrum, the HESS can no longer operate in an ideal condition. To solve the problem, the sizing of energy storage based on the individual user’s power and energy demand must be considered.

The general approach to sizing a HESS is based on the average load profile of the selected application [11][11]. Based on this method, the sizing of electric vehicles (EV), photovoltaics (PV), and microgrids[12][13] [12,13] have been studied. In other work, a modified particle swarm optimisation (PSO) algorithm was adopted to optimise the sizing of a battery-only, supercapacitor-only, and a battery–supercapacitor hybrid configuration[14][15] [14,15]. A PSO algorithm takes in different parameters such as the component data, vehicle parameters, and drive cycles as input for the optimal sizing of the energy storage. In the study, the sizing method considered many aspects of the vehicle’s condition for an electric city bus application with a general urban drive cycle. A filter-based approach with an optimal noncausal energy management method was used to minimise the installation and running costs of an EV [16][16]. A multi-objective optimisation algorithm was proposed to minimise the energy storage cost by prolonging the battery life of the EV[12] [12]. This sizing method adopted a state-of-health (SOH) model to maximise the energy storage operation life span. In another study, a sizing method using pinch analysis and design space for a PV-based application was proposed[17] [17]. The proposed method considers the storage time-frame of each energy storage device, with a fuel cell for long-term storage, batteries for medium-term storage, and supercapacitor for short-term storage. In the sizing of a HESS for a forklift application, different operating conditions of a forklift were considered to optimise the sizing of energy storage based on the forklift’s efficiency, volume, and mass [18]. A sizing strategy considering a typical forklift’s general load cycle was also introduced in the study. The same author also used different standardised driving cycles of vehicles (NEDC, ARTEMIS, FTP-75 and WLTP) to size the energy storage[11] [11].

A specific user needing energy storage with different demands can be solved by coupling the real-time data collected by an energy management controller. However, a semi-active HESS faces limited flexibility due to the limited control over the energy storage device compared to a fully active HESS. Therefore, to overcome the problem of sizing that is based on the overall drive cycle of an electric vehicle (EV), a sizing model for a semi-active HESS topology that couples with a real-time energy management controller was developed [6][19]. The sizing of a HESS based on real-time data provides better accuracy. This ensures minimal energy storage capacity wastage and at the same time is capable of ensuring sufficient power delivery.

2. Battery–Supercapacitor HESS Topology

The battery–supercapacitor HESS topologies are categorised into: passive topology, semi-active topology, and fully active topology[2][6] [2,6]. The difference between these three topologies is the controllability of these topologies. The passive topology relies entirely on the physics of the battery–supercapacitor connection and has no control over the battery–supercapacitor’s power flow. The semi-active HESS topology includes a control converter for each energy storage device. Finally, both of the energy storage devices are controlled by a converter in a fully active HESS topology.

In an ideal condition for a battery–supercapacitor HESS system, the supercapacitor should supply all high-power conditions due to its high-power density characteristic. The passive and semi-active HESS topologies have minimal control over the power flow of the HESS and cannot satisfy this condition. Hence, only the fully active topology can assert sufficient control over the entire power flow of each energy storage device to achieve this ideal condition. One of the examples is a novel fully active HESS design that can be used to replace the DC–DC converter, while maintaining the controllability of the system[12] [12]. This is done by using the supercapacitor to support the high power demand of the load, and the battery is completely switched off during the high-power condition. A fully active HESS will be used in the current work.

3. Sizing of Energy Storage

In energy storage sizing, undersized energy storage may affect the overall available operation time of the application, which will result in the subpar performance of the system. Hence, oversizing components is a common practice in most electrical designs. The sizing of a single energy storage system (SESS) is more straightforward. The sizing is carried out based on the average amount of energy needed by the application. However, in a HESS implementation, a multiple energy storage device must be sized accurately to cater for different load demands. If either energy storage device is undersized, the interest of the battery–supercapacitor HESS will be lost, and the system may operate as a SESS instead of a HESS.

The sizing of a battery–supercapacitor HESS can be further improved by reducing the oversized energy storage device and utilising it to improve the other energy storage device[18] [20]. In a practical application, different users have different demands. Some users may have a higher power demand and lower energy demand, while others may have a lower power and higher energy demand.

4. HESS Application

There are three types of possible scenarios that may contribute to sizing inaccuracy in a practical implementation of a fully active HESS, which are:

-

Inter-application load demand difference,

-

Intra-application load demand difference,

-

Uncertain changes in future load demand.

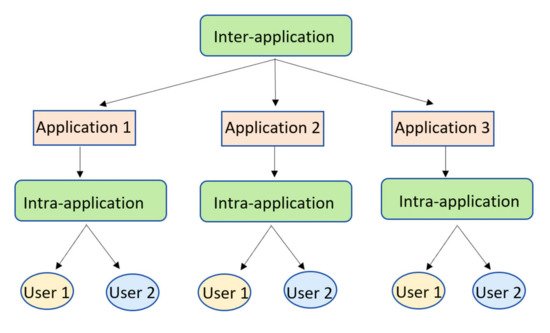

Inter-application refers to two different types of applications. Examples of inter-application are electric buses, residential electrification, industrial electrification, and mobile medical centres. These energy storage systems are different and require different designs to cater to their unique requirements. On the other hand, intra-application represents the same application, but with different load characteristics. Examples of intra-applications are two different electric buses travelling on a different route, different electric vehicles operating in different areas, and different mobile medical centres serving different populations. The inter- and intra-application relationship is shown in Figure 1.

Figure 1. Inter-application and intra-application relationship.

This entry is adapted from the peer-reviewed paper 10.3390/en15103783

References

- Jian Cao; Ali Emadi; A New Battery/UltraCapacitor Hybrid Energy Storage System for Electric, Hybrid, and Plug-In Hybrid Electric Vehicles. IEEE Transactions on Power Electronics 2011, 27, 122-132, 10.1109/tpel.2011.2151206.

- Mid-Eum Choi; Seong-Woo Kim; Seung-Woo Seo; Energy Management Optimization in a Battery/Supercapacitor Hybrid Energy Storage System. IEEE Transactions on Smart Grid 2011, 3, 463-472, 10.1109/tsg.2011.2164816.

- Yu Zhang; Zhenhua Jiang; Xunwei Yu; Control Strategies for Battery/Supercapacitor Hybrid Energy Storage Systems. 2008 IEEE Energy 2030 Conference 2008, 3, 1-6, 10.1109/energy.2008.4781031.

- Wenlong Jing; Chean Hung Lai; Shung Hui Wallace Wong; M. L. Dennis Wong; Battery‐supercapacitor hybrid energy storage system in standalone DC microgrids: areview. IET Renewable Power Generation 2017, 11, 461-469, 10.1049/iet-rpg.2016.0500.

- Thanikanti Sudhakar Babu; Krishnakumar R. Vasudevan; Vigna K. Ramachandaramurthy; Suleiman Bala Sani; Sansubari Chemud; Rosli Mat Lajim; A Comprehensive Review of Hybrid Energy Storage Systems: Converter Topologies, Control Strategies and Future Prospects. IEEE Access 2020, 8, 148702-148721, 10.1109/access.2020.3015919.

- Wenlong Jing; Chean Hung Lai; Wallace S.H. Wong; M. L. Dennis Wong; A comprehensive study of battery-supercapacitor hybrid energy storage system for standalone PV power system in rural electrification. Applied Energy 2018, 224, 340-356, 10.1016/j.apenergy.2018.04.106.

- S. Pay; Y. Baghzouz; Effectiveness of battery-supercapacitor combination in electric vehicles. 2003 IEEE Bologna Power Tech Conference Proceedings, 2004, 3, 728-733, 10.1109/ptc.2003.1304472.

- Yen Yee Chia; Lam Hong Lee; Niusha Shafiabady; Dino Isa; A load predictive energy management system for supercapacitor-battery hybrid energy storage system in solar application using the Support Vector Machine. Applied Energy 2015, 137, 588-602, 10.1016/j.apenergy.2014.09.026.

- Lee Wai Chong; Yee Wan Wong; Rajprasad Kumar Rajkumar; Dino Isa; An optimal control strategy for standalone PV system with Battery-Supercapacitor Hybrid Energy Storage System. Journal of Power Sources 2016, 331, 553-565, 10.1016/j.jpowsour.2016.09.061.

- Qiao Zhang; Gang Li; Experimental Study on a Semi-Active Battery-Supercapacitor Hybrid Energy Storage System for Electric Vehicle Application. IEEE Transactions on Power Electronics 2019, 35, 1014-1021, 10.1109/tpel.2019.2912425.

- Theophile Paul; Tedjani Mesbahi; Sylvain Durand; Damien Flieller; Wilfried Uhring; Study and Influence of Standardized Driving Cycles on the Sizing of Li-Ion Battery / Supercapacitor Hybrid Energy Storage. 2019 IEEE Vehicle Power and Propulsion Conference (VPPC) 2019, 1, 1-6, 10.1109/vppc46532.2019.8952494.

- Lei Zhang; Xiaosong Hu; Zhenpo Wang; Fengchun Sun; Junjun Deng; David. G. Dorrell; Multiobjective Optimal Sizing of Hybrid Energy Storage System for Electric Vehicles. IEEE Transactions on Vehicular Technology 2017, 67, 1027-1035, 10.1109/tvt.2017.2762368.

- José Luis Sampietro; Vicenç Puig; Ramon Costa-Castelló; Optimal Sizing of Storage Elements for a Vehicle Based on Fuel Cells, Supercapacitors, and Batteries. Energies 2019, 12, 925, 10.3390/en12050925.

- Amir Ostadi; Mehrdad Kazerani; A Comparative Analysis of Optimal Sizing of Battery-Only, Ultracapacitor-Only, and Battery–Ultracapacitor Hybrid Energy Storage Systems for a City Bus. IEEE Transactions on Vehicular Technology 2014, 64, 4449-4460, 10.1109/tvt.2014.2371912.

- Rui Esteves Araujo; Ricardo de Castro; Claudio Pinto; Pedro Melo; Diamantino Freitas; Combined Sizing and Energy Management in EVs With Batteries and Supercapacitors. IEEE Transactions on Vehicular Technology 2014, 63, 3062-3076, 10.1109/tvt.2014.2318275.

- Ammu Susanna Jacob; Rangan Banerjee; Prakash C. Ghosh; Sizing of hybrid energy storage system for a PV based microgrid through design space approach. Applied Energy 2018, 212, 640-653, 10.1016/j.apenergy.2017.12.040.

- Théophile Paul; Tedjani Mesbahi; Sylvain Durand; Damien Flieller; Wilfried Uhring; Sizing of Lithium-Ion Battery/Supercapacitor Hybrid Energy Storage System for Forklift Vehicle. Energies 2020, 13, 4518, 10.3390/en13174518.

- Taha Sadeq; Chew Kuew Wai; Ezra Morris; Qazwan A. Tarboosh; Omer Aydogdu; Optimal Control Strategy to Maximize the Performance of Hybrid Energy Storage System for Electric Vehicle Considering Topography Information. IEEE Access 2020, 8, 216994-217007, 10.1109/access.2020.3040869.

- Lijun Zhang; Xianming Ye; Xiaohua Xia; Farshad Barzegar; A Real-Time Energy Management and Speed Controller for an Electric Vehicle Powered by a Hybrid Energy Storage System. IEEE Transactions on Industrial Informatics 2020, 16, 6272-6280, 10.1109/tii.2020.2964389.

- Taha Sadeq; Chew Kuew Wai; Ezra Morris; Qazwan A. Tarboosh; Omer Aydogdu; Optimal Control Strategy to Maximize the Performance of Hybrid Energy Storage System for Electric Vehicle Considering Topography Information. IEEE Access 2020, 8, 216994-217007, 10.1109/access.2020.3040869.

This entry is offline, you can click here to edit this entry!