Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Biochemistry & Molecular Biology

Carbohydrate-binding modules (CBMs) are a class of multi-module enzyme proteins and their function is to respond to bind to the carbohydrate substrate. Cellulose-binding domains (CBDs) are the earliest-discovered CBMs which were used to be catergozied based on their sequence homology. However, with the in-depth study of carbohydrate hydrolases, more modules in carbohydrate-active enzymes were discovered that could bind, in addition to cellulose, to other types of carbohydrates such as chitin, glucan, xylan, or starch.

- carbohydrate-binding modules (CBM)

- classification and configuration

- CBM-substrate interactions

1. CBMs: Classification, Sources, Structures, and Functions

CBMs are widely distributed in nature [38] and are present in enzymes secreted by bacteria, fungi, and archaea [39]. Typical fungi sources are Trichoderma reesei [40], Caldanaerobius polysaccharolyticus [41], Rhizopus oryzae [42] and Polymyxa [43]. Fungi have developed to produce a set of glycoside hydrolases (GHs) and oxidoreductive enzymes, the synergistic action of which is required for enzymatic degradation of lignocellulose [44]. Bacteria commonly used in research are Clostridium thermocellum [45], maritima [46], Rhodothermus marinus [47], bacillus halodurans [48] and alcaligenes [49]. There are other microorganisms containing CBMs, such as actinomycetes [50]. Various types of CBMs are obtained from different microorganisms. Additionally, through genetic engineering, different expression vectors are constructed to obtain single or multiple CBMs, and used CBMs for substrate recognition and fiber treatment.

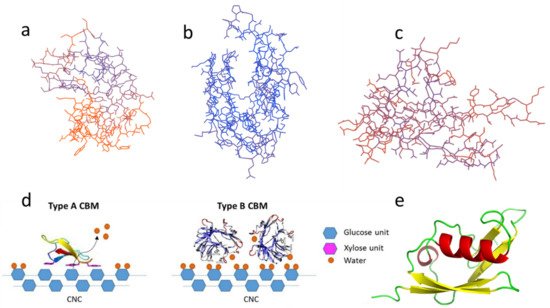

There are many ways to classify CBMs. Based on structural, functional similarities and the different ligand binding sites, CBMs can be divided into three types, namely, ‘surface-binding’ CBMs (type-A), ‘glycan-chain-binding’ CBMs (type-B), and ‘small-sugar-binding’ CBMs (type-C) [51]. For example, desired CBMs can be obtained by genetic engineering (the SUMO nobility tag can be added), as shown in Figure 1e.

Figure 1. Different types of CBM: (a) Type-A, CBM3; (b) Type-B, CBM4; (c) Type-C, CBM9; (d) Schematic of binding of type-A (left) and type-B (right) CBMs on nanocrystalline cellulose (CNC) reprinted from Ref [53] with permission from Elsevier; (e) Type-A CBM1 with SUMO solubilizing label. The above structure diagrams are drawn using the base sequences from Table 1 through the Swiss model and Pymol.

1.1. Type-A CBMs

Type-A CBMs contain a hydrophobic surface, and the binding of CBMs tends to be distributed in a plane or near a plane, binding to the surface of crystal regions of carbohydrate substrate [54]. A schematic diagram of the binding of type-A CBMs on the fiber substrate is shown in Figure 1d. CBM1 and CBM3 are two typical type-A CBMs. Their 3D configurations are illustrated in Figure 1a [53]. CBM1, the smallest CBM currently found in nature, consists of approximately 36 residues and typically contains two or three disulfide bonds and a plane including three aligned aromatic residues along with several polar residues [55,56,57]. Uppsala University reported the first NMR spectrum of the CBM1 synthesized by solid peptide sequences from the most abundant cellulase in Trichoderma [58].

1.2. Type-B CBMs

The crystal structure of type-B CBMs shows that the protein of type-B CBMs often contains grooves or cracks of different depths, which is shown in Figure 1b [59]. They are grooved when the binding sites bind to amorphous cellulose [37] or mannan [60]. The schematic diagram of the binding of general type-B CBMs on the fiber substrate is displayed in Figure 1d [53]. Most type-B CBMs are produced by enzymes secreted by bacteria. The aromatic group only interacts with the free single-chain polysaccharide [45]. The crystal structure of CBM of cellobiohydrolase A derived from Clostridium thermocellum is the first discovered crystal structure of cellulase CBM4 [61]. And Alahuhta, et al. [62] have solved the X-ray structure of CelK CBM4 from C. thermocellum.

1.3. Type-C CBMs

The typical configurations of type-C CBMs, including CBM9, 14, etc., are illustrated in Figure 1c. Type-C CBMs mainly interact with the end of the polysaccharide chain. Due to steric hindrance, only monosaccharides, disaccharides, trisaccharides, or the terminal sugar group of polysaccharides bind to type-C CBMs [3]. Type-C CBMs was first known from lectins, which are widely found in animals, plants, and microorganisms, and can bind to free sugars in solution. A lectin contains multiple CBMs and can selectively bind to a specific glycosyl [63]. At present, there are few related studies on type-C CBMs.

1.4. Other Classification Methods

Other classification methods can be based on the family and folding configuration. In terms of configuration, members of the large majority of CBM families are β-conformations, including β-sandwich, β-Strefoil, Cysteine knot, Unique, OD fold, and Hevein fold [64]. What is interesting is that different types of CBMs can coexist in a single protein, which suggests that current classifications may not cover all functional classifications of CBMs found in nature [65]. And more and more CBMs from different sources are being discovered. The structures, functions, and characteristics of CBMs lay a foundation for CBMs to conjugate or fuse with other polymers and eventually apply in substrate recognition and fiber treatment.

2. Fiber Treatment Using CBMs

In recent years, with the boycott of plastic products, the demand for fiber materials has increased. However, due to the insufficient strength (especially wet strength) of packaging, paper straws, and the requirements for cleaner production, new biological treatment have gradually attracted the attention of researchers. Among them, application of single or multiple CBMs in fiber processing has extensively been utilized for improving the fiber properties. Treating cellulose fibers with CBMs can change their interfacial properties [110]. CBMs were fused to engineering enzymes/proteins for improved biological activity; or either used alone or conjugated with other reagents for enhanced wood and fiber treatment performance. Using CBM-based polymers to treat fibers to gain improvement of mechanical properties of fiber (secondary fiber) is an emerging area that should pay much attention [111].

2.1. Use CBMs Alone in Fiber Treatment

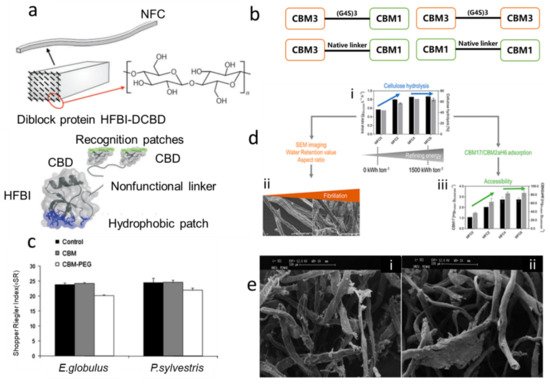

Pala [112] first used separate CBM in papermaking to improve the water filtration and mechanical strength of secondary fiber paper. It showed that CBMs obtained by proteolysis of T. reesei cellulase can alter the drainage capacity of recycled pulp [113]. Shoseyov, et al. [114] and Laaksonen, et al. [115] developed biofunctional CBMs by genetic engineering and obtained paper-based materials with high mechanical strength. The adhesion domain was constructed by CBMs and amphiphilic hydrophobic protein (HFBI), see Figure 3a. A hydrophobic AFM tip can contact and lift a single fusion protein from the functionalized HFBI terminal through hydrophobic interactions between the tip surface and the HFBI hydrophobic patch [115]. Shi, et al. [116] constructed four recombinant CBMs, CBM3-GS(polypeptide (G4S)3)-CBM1, CBM3-NL(native linker from CBH1-1)-CBM1, CBM3-GS-CBM3, and CBM1-NL-CBM1, as shown in Figure 3b, the mechanical properties of paper were all enhanced. The folding resistance and tensile strength of paper increased by 27.4% and 15.5% after adding CBM3-GS-CBM3, and after the addition of CBM1-NL-CBM1, the paper tensile strength, elongation, and folding resistance was increased by 12.6%, 8.8%, and 16.7%, respectively. Among them, the improvement of tensile strength and folding resistance facilitate the use of containerboard paper. As shown in Figure 3e, the fiber agglomerations disappeared after CBMs treatment [113]. CBMs destroyed the aggregates dispersed on the larger fiber surface during drying. This is an interfacial phenomenon. CBMs treatment may reduce fiber interaction (fiber separation observed by SEM) through spatial and hydrophobic effects. Therefore, in the wet state, CBMs may have a better effect on fibers. However, the use of CBMs alone is expensive and cannot fufill are the desire requirements. Therefore, the researchers explored of the comination of other treaments along with CBMs to improve the fibers’ properties. Pretreated the fibers with CBMs and refining, then used water retention value (WRV), SEM, and aspect ratio to observe the change of the fiber. The results showed that using CBMs to more accurately conjecture enzyme accessibility, which is shown in Figure 3d, and it was found that refining did not significantly improve enzyme accessibility at the microfiber level of the cellulose substrate. Later, researchers began to study the conjugated additives, to achieve both performance and economic satisfaction.

Figure 3. (a) A schematic presentation of the structure of the composite, reprinted from Ref [115] with permission from John Wiley and Sons. At the molecular level there are two functional blocks of the fusion protein amphiphilic hydrophobin−cellulose−binding domains (HFBI-DCBD) and its target surfaces; (b) Schematic structures of double CBMs, adapted from Ref [116]; (c) Shopper−Rieler Index of the E. globulus and P. sylvestris fibers treated with CBM, CBM-PEG and untreated, reprinted from Ref [67] with permission from Springer Nature; (d) (i) Impact of increasing refining energies on ease of enzyme−mediated hydrolysis of the microfibrillated cellulose (MFC) substrates. (ii) Impact of the refining energy on the fiber morphology. (iii) Impact of increasing refining energies on cellulose−binding module accessibility to the MFC substrates, reprinted from Ref [87] with permission from American Chemical Society; (e) SEM images of CF11 fibers treated with (i) and without (ii) CBD, reprinted from Ref [113] with permission from American Chemical Society.

2.2. CBMs Conjugated with Other Polymers for Fiber Treatment

CBMs can conjugate with other proteins or polymers because of their flexibility and specificity of CBMs. Protein side-chains contain many groups, such as amino, carboxyl, and hydroxyl groups [117]. Complex can be produced by common methods of blending (electrostatic attraction), and conjugation [118]. Many researchers began to construct conjugated systems of CBMs and polymers. CBM can be conjugated with various compounds such as polyethylene glycol (PEG), and anionic polyacrylamide (APAM) [119]. Machado [67] studied the adsorption of a CBM3 from the Clostridium thermocellum scaffolding protein (Cip A) to cellulose. The Carbohydrate binding domain-polyethylene glycol (CBM-PEG) module was constructed and the effect of this structure on the paper properties was studied (see Figure 3c). CBM-PEG improved the drainage capacity, but does not affect the mechanical properties of the paper which is due to the high water-binding capacity of PEG [120]. CBM-PEG improved the drainability of E. globulus and P. sylvestris pulps without affecting the physical properties of the paper [2]. Kitaoka and Tanaka [119] conjugated the CBM with APAM to improve the fiber binding, the results showed that both the dry tensile index and the wet tensile index were improved. However, both the fiber and the APAM are negatively charged, and the APAM is mostly used as a dispersant in the paper industry, in this case, there is still an improvement in mechanical properties, which can show the superiority of CBM for fiber binding.

The advantages of using independent CBM in fiber processing include the diversity of CBMs and avoiding the strength loss of using whole enzymes due to the catalytic activity of CD. More importantly, the fusion method with other polymers significantly reduces the amount of CBMs required and therefore reduces the costs. However, mass and economical production, preservation, and transportation of CBMs are still critical prerequisites for CBMs’ industrial applications. The current related work is very important because of the increased demand and performance requirements for paper products [121]. Further progress in this area is required to provide more environmentally friendly and more economical additives to improve fiber strength. Meanwhile, there are a few studies on the use of CBMs for nanocellulose materials, such as bacterial cellulose and microcrystalline cellulose materials [122]. This is also a major research direction because the structural properties of CBMs have the potential to alter the brittleness of nanocellulose materials [123]. Nanocellulose materials can be used in Pickering emulsions [124], ultrafiltration membrane [125,126] and paper straws [127].

2.3. Other Functions

In addition to the above effects on cellulose, the fusion of CBMs with other enzymes can also change biochemical characteristics and improve catalytic performance. And the CBMs of some thermophilic bacteria have high stability and belong to the thermostable domain. Studies have shown that fusion of thermostability domains to unstable protein domains can improve the thermostability of the latter [128,129]. Chhabra and Kelly [130] first reported the hyperthermophilic CBM fused to hyperthermophilic endoglucanase. The fusion protein was active on crystalline cellulose and the activity against microcrystalline cellulose was higher than that of the parent endoglucanase at 80 °C. Kavoosi, et al. [131] evaluated the impact of linker design on fusion protein production and performance. Liu, et al. [132] constructed an artificial bifunctional enzyme containing carbonic anhydrase(CA) from Neisseria gonorrhoeae and the CBM from Clostridium thermocellum with His6 tag, which can capture carbon dioxide from flue gas. As for the improvement of catalytic efficiency, Kittur, et al. [133] increased the catalytic activity of xylanase from Thermotoga Maritima for soluble xylan by fusion of CBM2. For optimizing the catalytic activity of Cyclodextrin glycosyltransferase (CGTase). It is an important industrial enzyme for the production of cyclodextrins (CDs) from starch by intramolecular transglycosylation. CGTase of Geobacillus sp. was fused with the CBM20 of the Bacillus circulans strain 251 CGTase [134]. There seemed to be much room for improving its enzymological properties, such as improving its catalytic efficiency and substrate affinity, by replacing the domain of wild-type structural domain with a suitable CBM [135].

This entry is adapted from the peer-reviewed paper 10.3390/polym14091806

This entry is offline, you can click here to edit this entry!