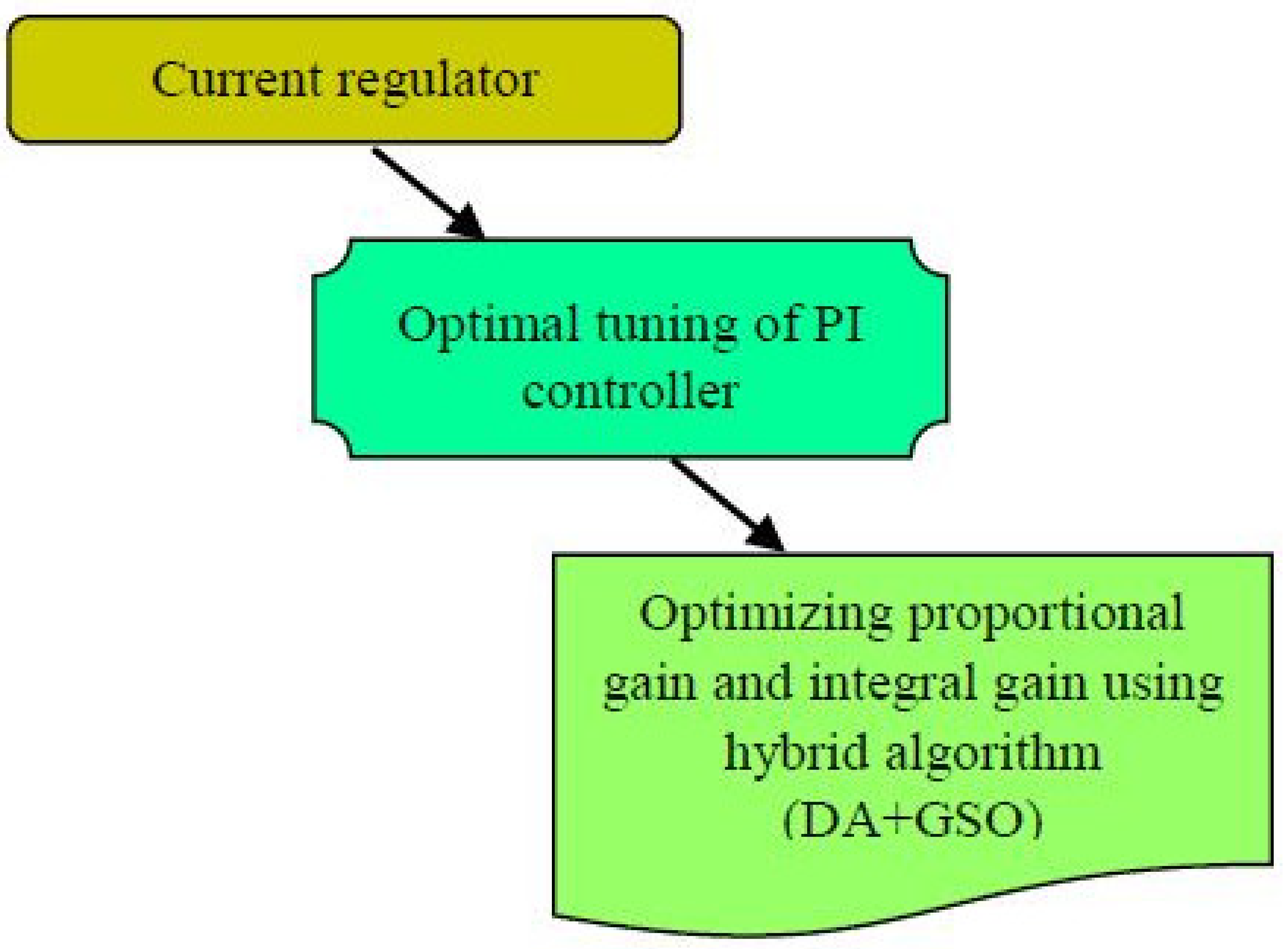

Induction motors tend to have better efficiency on rated conditions, but at partial load conditions, when these motors operate on rated flux, they exhibit lower efficiency. In such conditions, when these motors operate for a long duration, a lot of electricity gets consumed by the motors, due to which the computational cost as well as the total running cost of industrial plant increases. Squirrel-cage induction motors are widely used in industries due to their low cost, robustness, easy maintenance, and good power/mass relation all through their life cycle. A significant amount of electrical energy is consumed due to the large count of operational units worldwide; hence, even an enhancement in minute efficiency can direct considerable contributions within revenue saving, global electricity consumption, and other environmental facts. Hybrid dragonfly algorithm is a model of induction motor drive is taken, in which the proportional integral (PI) controller is tuned. The optimal tuning of gains of a PI controller such as proportional gain and integral gain is conducted. The tuning procedure in the controller is performed in such a condition that the efficiency of the induction motor should be maximum. Moreover, the optimization concept relies on the development of a new hybrid algorithm, the so-called Scrounger Strikes Levy-based dragonfly algorithm (SL-DA), that hybridizes the concept of dragonfly algorithm (DA) and group search optimization (GSO).

- induction motor

- PI controller

- speed control

- dragonfly algorithm

1. Introduction

The MBO has possessed some challenges, which is its larger sensitivity to parameter variations and the count of arithmetic operations contained within the loss model’s solution. The characterization of SAO in [10][11] is made by its parameter insensitivity. However, it poses some promising challenges such as very slow convergence and high torque ripples to the optimal operating point while distinguished over MBO. In such cases, it has a very large search space and thereby outcomes in large time in the quest for optimal operating conditions. In fact, the optimization algorithm in [12][13] may underestimate the optimal flux with no adaptation of real-time parameters’ mechanisms, which may as well direct the destabilization of the drive system and impact the problem of “motor stalling”, particularly in the existence of an immediate change in load torque. It should be noted that in the full operating region, there is a critical issue in the identification of IM parameters accurately [14][15][16] and simultaneously, even by using the IM parameter stacking algorithms. Over the last few years, researchers have been working on evolutionary algorithms [17] such as genetic algorithms (GA) and swarm-intelligence-based algorithms [18] such as PSO, GSO, DA, FF, and ACO for optimization purposes under different working environments. These meta-heuristic algorithms are very efficient and determine an accurate estimation of optimal solutions compared to conventional algorithms.

This framework has introduced a novel model to maximize the efficiency of induction motors. For this, the objective model is constructed using the speed-control induction motor drive with the tuning of the PI controller. In this PI controller, the optimal tuning of PI controllers such as proportional gain and integral gain is made by introducing a newly hybrid algorithm named SL-DA, which is the hybridization of DA and GSO.

2. Hybrid Dragonfly Algorithm

3. Model of AC Sensor-Less Speed Control of Induction Motor Drive

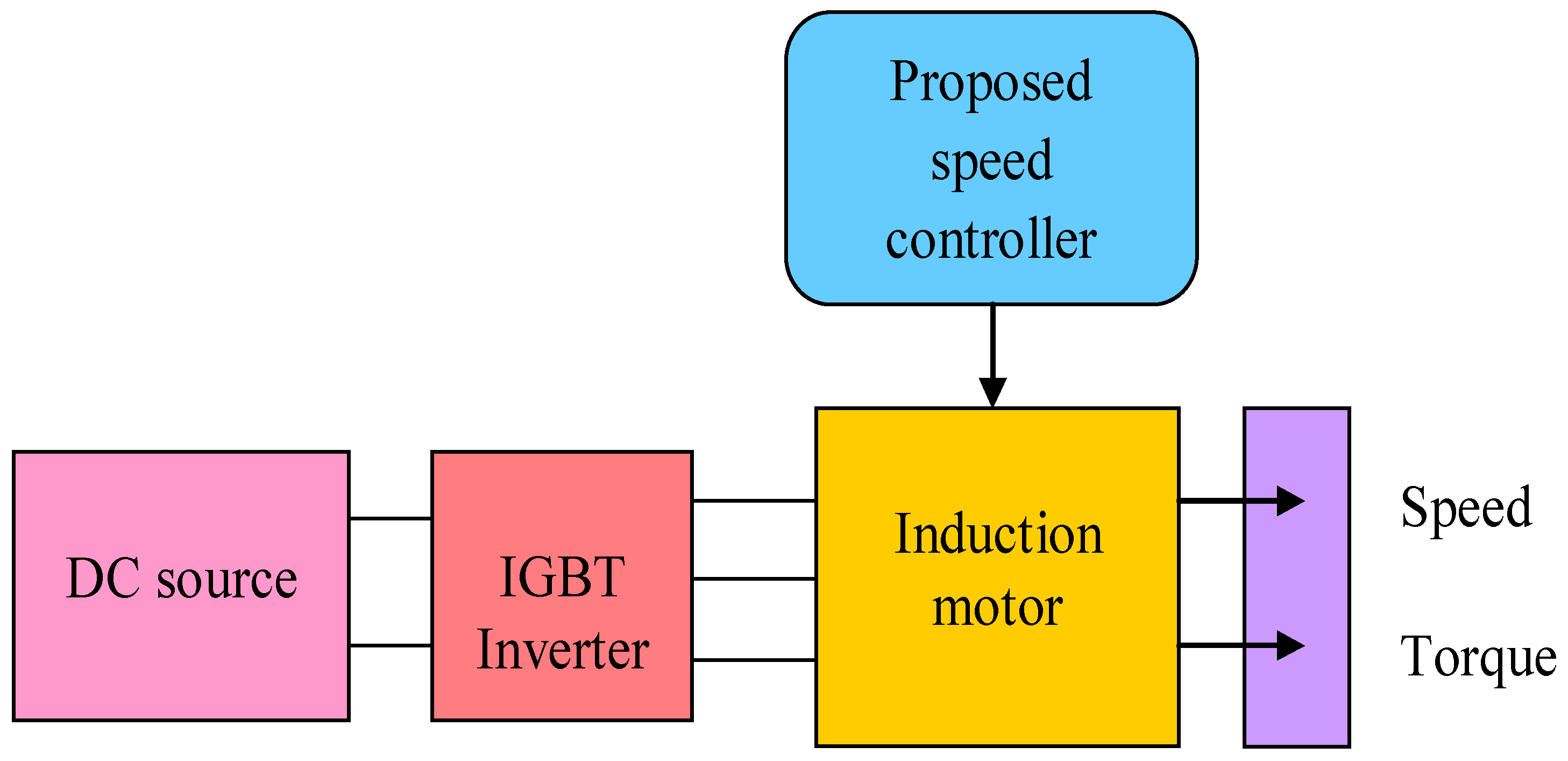

The system consists of a pure DC supply, which needs to be converted into AC by employing an Insulated Gate Bipolar Transistor (IGBT) inverter. An IGBT-based 3-phase inverter is used, which consists of twelve IGBT switches, out of which four IGBT switches per phase are arranged in an H-Bridge configuration. The scheme is depicted in Figure 2. A three-phase asynchronous machine is implemented within the asynchronous machine block, which is termed as single squirrel-cage, wound rotor, or double squirrel-cage. Here, the operation is made in motor mode where motor torque and speed are varied under different conditions. For the conventional method, IM uses the vector control technique where the voltage, current, and torque of a 3-phase induction motor are controlled by time-varying components. The speed is used as a feedback loop in a PI controller at different values of load torque. The proposed speed controller (AC) block exemplifies a PI speed regulator technique for AC machines that is utilized within vector-controlled drives. Here, two operating instances are present: the initial one is having both the outputs of torque as well as the flux references and the second has only the output of the torque reference. The speed of the machine is given in rpm as N; the speed reference of the machine is in rpm and is denoted as N∗. In this, the machine’s torque reference is termed as input, when the parameter of regulation type is fixed as torque. The flux reference is symbolized as Flux∗ and the unit of this is weber. The induction motor speed is controlled by tuning the PI controller; i.e., the proportional and integral gain of the PI controller is fine-tuned via a proposed SL-DA scheme.

This entry is adapted from the peer-reviewed paper 10.3390/s22072594