Silver nanoparticles (AgNPs) are widely used for their bacteriostatic or antimicrobial properties. The antibacterial effects of AgNPs have been demonstrated on many bacteria, including bacteria resistant to common antibiotics. They prevent the adhesion and proliferation of bacteria to the surface of materials and suppress microorganisms already adhered. This property is used in the medical field where these materials protect equipment prone to biofilm formation, such as catheters and implants. AgNPs are also used in the treatment of wounds, where they accelerate the conversion of fibroblasts into myofibroblasts (collagen-producing connective tissue cells).

- silver nanoparticles

- polyethyleneterephthalate

- ripple structures

1. Introduction

2. Laser-Promoted Immobilization of Ag Nanoparticles

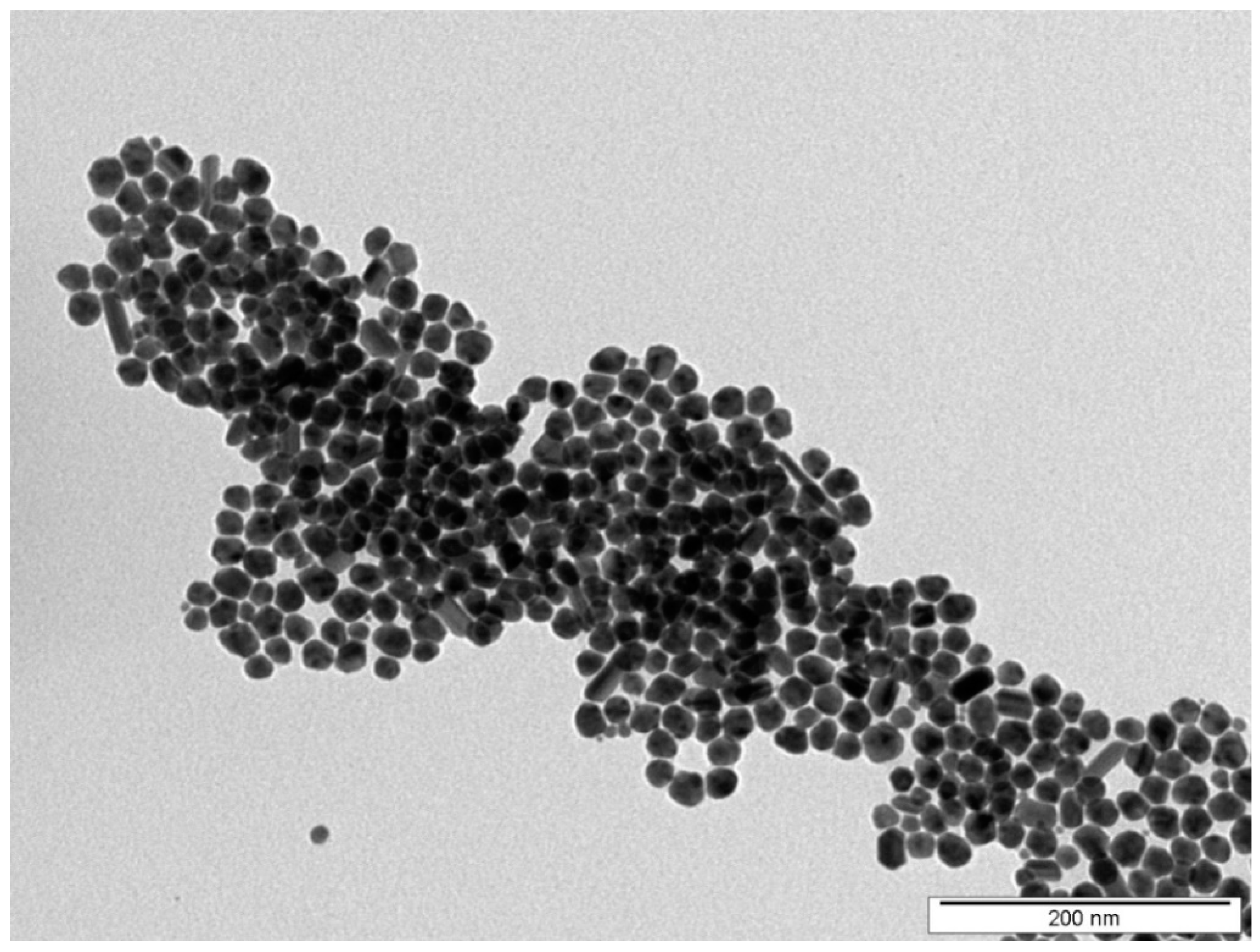

Figure 1. TEM image of synthesized AgNPs used in immobilization process.

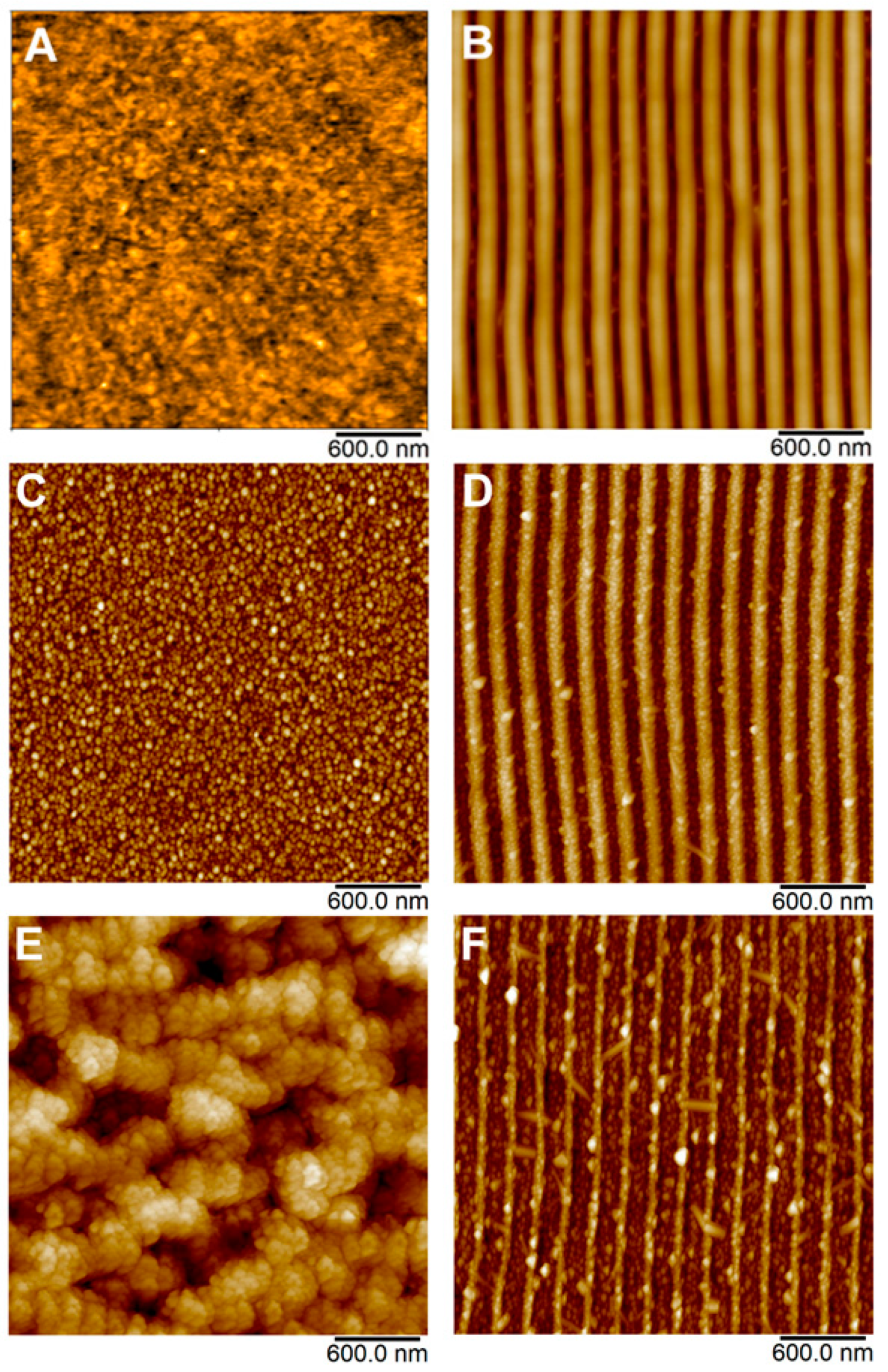

Figure 1. TEM image of synthesized AgNPs used in immobilization process. Figure 2. AFM images of pristine PET (A); laser pre-treated PET with LIPSS structure (B); and PET with immobilized AgNPs on pristine PET (C,E) and PET with LIPSS structure (D,F).

Figure 2. AFM images of pristine PET (A); laser pre-treated PET with LIPSS structure (B); and PET with immobilized AgNPs on pristine PET (C,E) and PET with LIPSS structure (D,F).| Sample | Laser Fluence (mJ cm−2) |

Ra (nm) | SAD (%) |

|---|---|---|---|

| PET (A) | - | 0.78 | 4.93 |

| LIPSS/PET (B) | - | 10.5 | 27.2 |

| AgNPs/PET (C) | 10 | 4.59 | 16.1 |

| AgNPs/PET (D) | 24 | 27.5 | 26.2 |

| AgNPs/LIPSS/PET (E) | 10 | 10.3 | 26.7 |

| AgNPs/LIPSS/PET (F) | 24 | 20.9 | 32.9 |

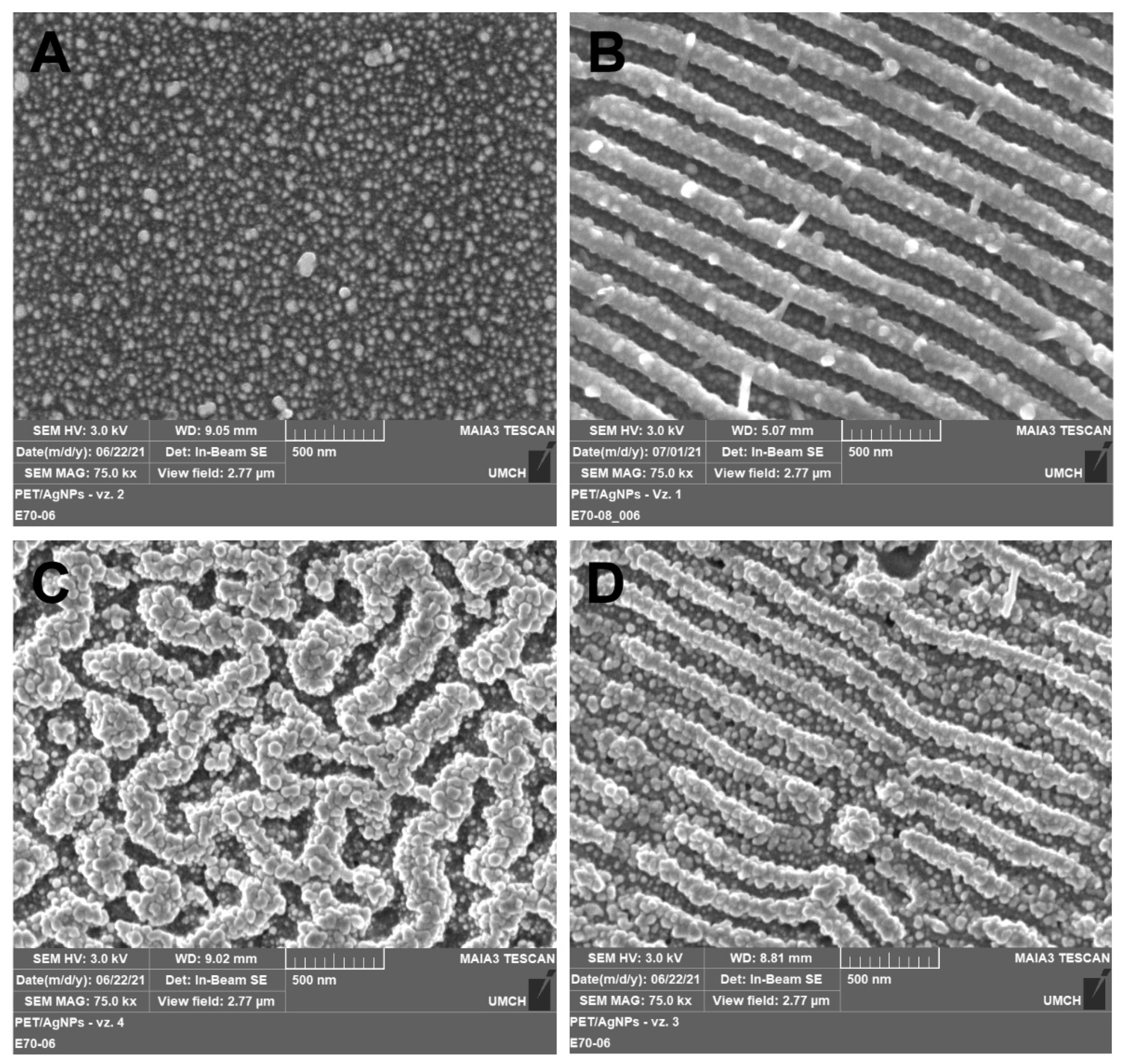

Figure 3. FEGSEM micrographs showing the surface morphology of PET immobilized with AgNPs at laser fluencies of 10 (A,B) and 24 mJ cm−2 (C,D) on pristine PET (A,C) and PET with LIPSS structure (B,D). Micrographs were recorded with an in-beam SE detector at accelerating voltage 3 kV.

Figure 3. FEGSEM micrographs showing the surface morphology of PET immobilized with AgNPs at laser fluencies of 10 (A,B) and 24 mJ cm−2 (C,D) on pristine PET (A,C) and PET with LIPSS structure (B,D). Micrographs were recorded with an in-beam SE detector at accelerating voltage 3 kV.| Sample | Laser Fluence (mJ cm−2) |

Ag | C | O |

|---|---|---|---|---|

| PET (A) | - | - | 71.0 | 29.0 |

| LIPSS/PET (B) | - | - | 67.2 | 32.8 |

| AgNPs/PET (C) | 10 | 10.7 | 67.7 | 21.6 |

| AgNPs/PET (D) | 24 | 11.3 | 66.5 | 22.2 |

| AgNPs/LIPSS/PET (E) | 10 | 13.1 | 65.8 | 21.1 |

| AgNPs/LIPSS/PET (F) | 24 | 15.1 | 63.5 | 21.4 |

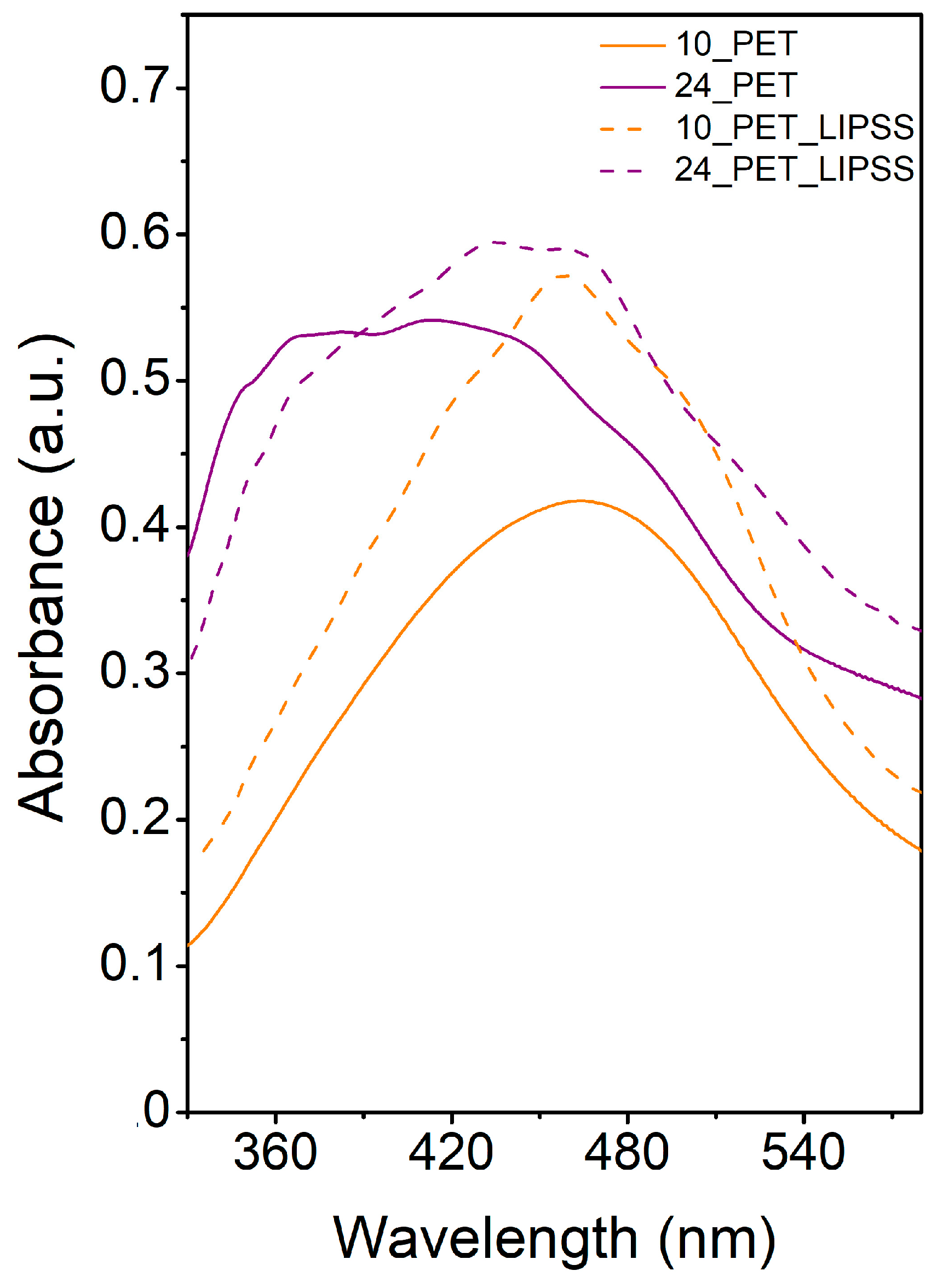

Figure 4. UV-Vis absorption spectra of AgNPs immobilized with the fluence of 10 mJ cm−2 on pristine PET (10_PET) and PET with LIPSS structure (10_PET_LIPSS) and with the fluence of 24 mJ cm−2 on pristine PET (24_PET) and PET with LIPSS structure (24_PET_LIPSS).

Figure 4. UV-Vis absorption spectra of AgNPs immobilized with the fluence of 10 mJ cm−2 on pristine PET (10_PET) and PET with LIPSS structure (10_PET_LIPSS) and with the fluence of 24 mJ cm−2 on pristine PET (24_PET) and PET with LIPSS structure (24_PET_LIPSS).This entry is adapted from the peer-reviewed paper 10.3390/nano12050792

References

- Naghdi, S.; Rhee, K.Y.; Hui, D.; Park, S.J. A Review of Conductive Metal Nanomaterials as Conductive, Transparent, and Flexible Coatings, Thin Films, and Conductive Fillers: Different Deposition Methods and Applications. Coatings 2018, 8, 278.

- Fukuzumi, S.; Yamada, Y. Catalytic activity of metal-based nanoparticles for photocatalytic water oxidation and reduction. J. Mater. Chem. 2012, 22, 24284–24296.

- Díez-Pascual, A.M. Nanoparticle Reinforced Polymers. Polymers 2019, 11, 625.

- Fu, B.; Sun, J.; Cheng, Y.; Ouyang, H.; Compagnini, G.; Yin, P.; Wei, S.; Li, S.; Li, D.; Scardaci, V.; et al. Recent Progress on Metal-Based Nanomaterials: Fabrications, Optical Properties, and Applications in Ultrafast Photonics. Adv. Funct. Mater. 2021, 31, 2107363.

- Naganthran, A.; Verasoundarapandian, G.; Khalid, F.E.; Masarudin, M.J.; Zulkharnain, A.; Nawawi, N.M.; Karim, M.; Che Abdullah, C.A.; Ahmad, S.A. Synthesis, Characterization and Biomedical Application of Silver Nanoparticles. Materials 2022, 15, 427.

- Zare, E.N.; Jamaledin, R.; Naserzadeh, P.; Afjeh-Dana, E.; Ashtari, B.; Hosseinzadeh, M.; Vecchione, R.; Wu, A.; Tay, F.R.; Borzacchiello, A.; et al. Metal-Based Nanostructures/PLGA Nanocomposites: Antimicrobial Activity, Cytotoxicity, and Their Biomedical Applications. ACS Appl. Mater. Interfaces 2020, 12, 3279–3300.

- Prakash, J.; Pivin, J.C.; Swart, H.C. Noble metal nanoparticles embedding into polymeric materials: From fundamentals to applications. Adv. Colloid Interface Sci. 2015, 226, 187–202.

- Barb, R.A.; Hrelescu, C.; Dong, L.; Heitz, J.; Siegel, J.; Slepicka, P.; Vosmanska, V.; Svorcik, V.; Magnus, B.; Marksteiner, R.; et al. Laser-induced periodic surface structures on polymers for formation of gold nanowires and activation of human cells. Appl. Phys. A 2014, 117, 295–300.

- De Guzman, M.R.; Wen, Y.-H.; Du, J.; Yuan, L.; Wu, C.-S.; Hung, W.-S.; Guo, J.-P.; Yao, Y.-L.; Yuan, S.; Wang, R.-Y.; et al. Characterization of antibacterial nanocomposites of polyethylene terephthalate filled with nanosilver-doped carbon black. Polym. Polym. Compos. 2021, 29, 797–806.

- Boboc, M.; Curti, F.; Fleaca, A.M.; Jianu, M.L.; Rosu, A.-M.; Curutiu, C.; Lazar, V.; Chifiriuc, M.C.; Grumezescu, A.M. Preparation and Antimicrobial Activity of Inorganic Nanoparticles: Promising Solutions to Fight Antibiotic Resistance. In Nanostructures for Antimicrobial Therapy; Ficai, A., Grumezescu, A.M., Eds.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 325–340.

- Saravanan, S.; Nethala, S.; Pattnaik, S.; Tripathi, A.; Moorthi, A.; Selvamurugan, N. Preparation, characterization and antimicrobial activity of a bio-composite scaffold containing chitosan/nano-hydroxyapatite/nano-silver for bone tissue engineering. Int. J. Biol. Macromol. 2011, 49, 188–193.

- Paladini, F.; Pollini, M. Antimicrobial Silver Nanoparticles for Wound Healing Application: Progress and Future Trends. Materials 2019, 12, 2540.

- Narayan, N.; Meiyazhagan, A.; Vajtai, R. Metal Nanoparticles as Green Catalysts. Materials 2019, 12, 3602.

- Zhou, Y.; Jin, C.; Li, Y.; Shen, W. Dynamic behavior of metal nanoparticles for catalysis. Nano Today 2018, 20, 101–120.

- Kim, C.; Lee, H. Light-assisted surface reactions on metal nanoparticles. Catal. Sci. Technol. 2018, 8, 3718–3727.

- Wang, Y.; Arandiyan, H.; Scott, J.; Bagheri, A.; Dai, H.X.; Amal, R. Recent advances in ordered meso/macroporous metal oxides for heterogeneous catalysis: A review. J. Mater. Chem. A 2017, 5, 8825–8846.

- Edison, T.J.I.; Sethuraman, M.G. Instant green synthesis of silver nanoparticles using Terminalia chebula fruit extract and evaluation of their catalytic activity on reduction of methylene blue. Process Biochem. 2012, 47, 1351–1357.

- Iqbal, S.; Zahoor, C.; Musaddiq, S.; Hussain, M.; Begum, R.; Irfan, A.; Azam, M.; Farooqi, Z.H. Silver nanoparticles stabilized in polymer hydrogels for catalytic degradation of azo dyes. Ecotoxicol. Environ. Saf. 2020, 202, 110924.

- Begum, R.; Farooqi, Z.H.; Ahmed, E.; Naseem, K.; Ashraf, S.; Sharif, A.; Rehan, R. Catalytic reduction of 4-nitrophenol using silver nanoparticles-engineered poly(N-isopropylacrylamide-co-acrylamide) hybrid microgels. Appl. Organomet. Chem. 2017, 31, e3563.

- Cui, J.; Nogales, A.; Ezquerra, T.A.; Rebollar, E. Influence of substrate and film thickness on polymer LIPSS formation. Appl. Surf. Sci. 2017, 394, 125–131.

- Siegel, J.; Heitz, J.; Svorcik, V. Self-organized gold nanostructures on laser patterned PET. Surf. Coat. Technol. 2011, 206, 517–521.

- Doren, A.; Genet, M.J.; Rouxhet, P.G. Analysis of Poly(Ethylene Terephthalate) (PET) by XPS. Surf. Sci. Spectra 1994, 3, 337–341.

- Abbaszadegan, A.; Ghahramani, Y.; Gholami, A.; Hemmateenejad, B.; Dorostkar, S.; Nabavizadeh, M.; Sharghi, H. The Effect of Charge at the Surface of Silver Nanoparticles on Antimicrobial Activity against Gram-Positive and Gram-Negative Bacteria: A Preliminary Study. J. Nanomater. 2015, 2015, 720654.

- Amendola, V.; Bakr, O.M.; Stellacci, F. A Study of the Surface Plasmon Resonance of Silver Nanoparticles by the Discrete Dipole Approximation Method: Effect of Shape, Size, Structure, and Assembly. Plasmonics 2010, 5, 85–97.

- Chawla, M.; Rubi; Kumar, R.; Sharma, A.; Aggarwal, S.; Kumar, P.; Kanjilal, D. Tailoring Structural Properties of Polyethylene Terephthalate (PET) by 200 keV Ar+ Implantation. In Proceedings of the 3rd Conference on Condensed Matter and Materials Physics (CMMP 2012), Vallabh Vidyanagar, India, 3–5 March 2013; p. 221.

- Krajcar, R.; Siegel, J.; Lyutakov, O.; Slepicka, P.; Svorcik, V. Optical response of anisotropic silver nanostructures on polarized light. Mater. Lett. 2014, 137, 72–74.

- Li, J.; Li, K.; Schuster, C.; Su, R.; Wang, X.; Borges, B.-H.V.; Krauss, T.F.; Martins, E.R. Spatial resolution effect of light coupling structures. Sci. Rep. 2015, 5, 1–8.

- Csete, M.; Bor, Z. Laser-induced periodic surface structure formation on polyethylene-terephthalate. Appl. Surf. Sci. 1998, 133, 5–16.