Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Metallurgy & Metallurgical Engineering

Thermomechanical Controlled Processing (TMCP), the initial microstructure and mechanical properties of rolled products made of high-strength steels, have a significant influence on the properties and reliability of welded structures for low temperature and cryogenic service.

- metallurgy

- high-strength cold-resistant and cryogenic steels

- thermomechanical controlled processing

- weldability

1. Introduction

High-strength cold-resistant and cryogenic steels are widely used for icebreakers, gas carriers, hydrogen storage, hydrocarbon production and transportation, wind turbines, offshore platforms, railroads, and the automotive industry. The history of traditional high-strength steel (HSS) metallurgy began with the creation of low-alloy Si-Mn ferritic–pearlitic steels with a carbon content of <0.2% [1,2,3]. The micro-alloying of V, Nb, Ti, and Thermomechanical Controlled Processing (TMCP) allowed the achievement of a fine-grained microstructure, increasing strength and impact toughness with a decrease in carbon content < 0.15% [1,2,3].

Subsequent development of TMCP and the application of accelerated cooling with tempering allowed for obtaining ferritic–bainitic and ferritic–martensitic microstructures of steels with reduced carbon content <0.1%. This microstructure has a fine-dispersed morphology with distributed and dispersed carbides and carbonitrides, and has a high impact toughness. Micro-alloying, optimization of TMCP, microstructure refinement, dispersion hardening, refining, and reduction of the anisotropy of rolled steel are used to improve plasticity and impact toughness of high-strength steels. Modern HSS have bainitic, bainitic–martensitic, martensitic–bainitic, and martensitic microstructures with low carbon content up to 0.05–0.02%. The production and development of high-strength steels are closely related to welding metallurgy and weldability, as arc and laser welding are used to make structures.

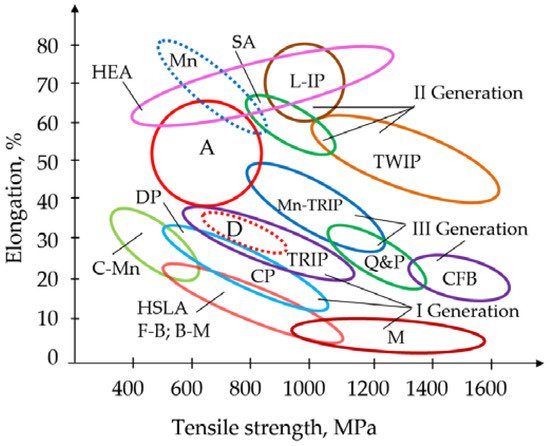

Research on the metallurgy and weldability of high-strength steels is actively developing all over the world. The main trends are increasing strength and impact toughness of steels, improving quality, and reducing the cost of alloying in steelmaking [4,5,6,7]. Among traditional and advanced high-strength steels for low-temperature and cryogenic service, about 15 groups of low- and high-alloy steels should be distinguished, as shown in Figure 1.

Figure 1. Mechanical properties of HSS and AHSS (Advanced High-Strength Steels) high-strength cold-resistant and cryogenic steels.

Figure 1 contains the following designations: C-Mn—pearlitic steels; HSLA—high-strength low-alloy steels; F-B—ferritic–bainitic steels; B-M—bainitic–martensitic steels; DP (Dual-Phase)—two-phase steels; CP—complex phase steels; D—duplex steels; TRIP (Transformation-Induced-Plasticity)—metastable steels with induced plasticity; M—martensitic steels; TWIP (Twinning-Induced Plasticity)—austenitic high-manganese steels with induced plasticity; Mn-TRIP—medium-manganese TRIP steels; Q&P (Quenching and Partitioning)—martensitic–austenitic steels; CFB—carbide-free bainitic steels; A—austenitic steels; SA—superaustenitic steels; L-IP—lightweight steels with induced plasticity; Mn—high-manganese austenitic steels; HEA—high-entropy alloys.

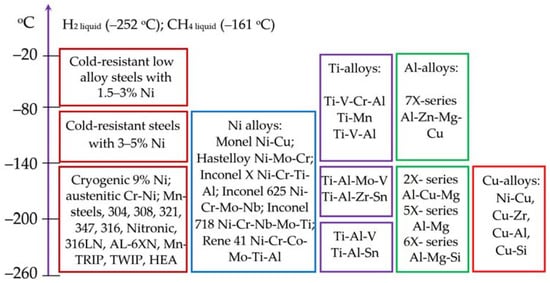

Advanced steels have high strength, corrosion resistance, and high viscoplasticity at low temperatures, and can be considered as alternatives to Ni-, Ti-, Al-, and Cu-alloys for low temperature and cryogenic service, including hydrogen storage systems, as shown in Figure 2.

Figure 2. Steels and alloys for low-temperature and cryogenic service.

2. Properties of High-Strength Steels

2.1. High-Strength Low-Alloy Steels

High-strength low-alloy steels (HSLA-steels) have the chemical composition, %: 0.04–0.25 C; 1–2 Mn; 0.4–3.5 Ni; <0.5 alloying elements Si, N, Cr, Mo, Ca, Al, REM, Zr. The formation of intermetallics, carbides, and carbonitrides through the alloying of Cu, Ti, V, and Nb is used for the dispersion hardening of the ferrite matrix. Reducing the grain size increases impact toughness while maintaining a high yield strength of over 460 MPa. The main method of production of these steels is TMCP [1].

High-strength steels are divided into six categories [8,9]: weather-resistant with phosphorus and copper alloying; micro-alloyed ferritic–pearlitic steels with less than 0.1% of the carbides and carbonitrides Nb, Ti, and V for dispersion hardening, grain refinement, and transformation temperature changes; low-alloy steels of controlled rolling from pearlitic C-Mn steels; low-carbon low-alloy bainite steels with acicular ferrite [10]; two-phase martensitic–ferritic steels with high impact toughness; steels with controlled form of nonmetallic inclusions with the alloying of Ca, REM, Zr, and Ti.

2.2. High-Entropy Alloys

Advanced high-entropy alloys, an alternative to cryogenic steels, have the highest plasticity at low temperatures and in cryogenic service in corrosive environments. HEA theory is based on thermodynamic modeling. The entropy of HEA increases with the number of alloying elements. High-entropy alloys have five or more alloying elements with content from 5 to 35 at. pct [27,28]. HEAs are classified as single-phase, multiphase, and amorphous with low and high densities of 2.6–6.7 g/cm3 with the maximum tensile strength of <1500 MPa and elongation of <75% [29,30]. The mechanical properties of HEA are superior to cryogenic nickel alloys and austenitic steels [31]. The metallurgy, weldability, and welding technologies of HEA are developing intensively [27,28].

3. Properties of Advanced High-Strength Steels

Metallurgical innovations are implemented in the development and production of advanced high-strength steels [33,34]. AHSS production is based on TMCP [35,36]. The models and technologies for AHSS are aimed at the automotive industry, therefore, the steels are up to 4 mm thickness. However, the thermophysical-mechanical principles of TMCP, thermodynamic models, and metallurgical technologies of AHSS-making can be applied to steelmaking of higher thicknesses.

Advanced high-strength steels have strengths of more than 500 MPa and a complex microstructure of ferrite, martensite, bainite, and residual austenite [37]. The first generation of AHSS includes dual-phase DP steels with F-M microstructure with the tensile strength of up to 1400 MPa, complex phase CP steels with F-B + P-M-A microstructure with a tensile strength of up to 1300 MPa, martensitic steels with the tensile strength of up to 1600 MPa, TRIP steels with induced plasticity at martensitic transformation of residual austenite during the plastic deformation with F-M/B + A, and a microstructure with the tensile strength of up to 1000 MPa [38]. The second generation includes austenitic high-manganese TWIP steels with induced plasticity through twinning with the tensile strength of up to 1650 MPa, lightweight L-IP steels with induced plasticity with the tensile strength of up to 1150 MPa, and superaustenitic high-manganese steels with the tensile strength of up to 1150 MPa with elongation of up to 60%. The third generation of AHSS includes ultra-high-strength Mn-TRIP steels, Q&P steels with martensitic-austenitic microstructure, and ultra-high-strength carbide-free CFB steels.

4. Problem of Fracture of Steels at Low Temperatures

The main tasks in manufacturing welded structures for low temperature services are to increase reliability and durability and reduce weight and cost. Relevant tasks are increasing the viscoplasticity of steels, reducing the sensitivity to embrittlement and hydrogen cracking, and increasing the cyclic loads at low temperatures. Pous-Romero [59] studied the critical temperature of ductile-brittle transition and the ductile fraction in low-temperature tests of ASTM SA508 Gr.3 low-alloy hull steel, %: <0.25 C; 1.2–1.5 Mn; 0.45–0.6 Mo; 0.4–1 Ni; <0.25 Cr; 0.15–0.35 Si and proved that the impact energy decreases from 230 J at plus 50 °C to 120 J at a critical temperature of minus 50 °C and to 10 J at minus 100 °C with 0% of ductile fracture.

Most fractures in steels occur during the formation and propagation of cracks initiating in local stress concentrations, in dislocation clusters, and at intergranular and interphase boundaries, as well as at nonmetallic sharp-edged shape inclusions [60].

Brittle fractures typically involve little energy absorption and occur by splitting (chipping) as the crack propagates through the atomic plane. Ductile fractures occur during formation of microporous coalescence, in which the initiators of fracture are dispersed inclusions and carbides distributed in the viscous matrix. Decohesive fractures occur during the microfracture along grain boundaries, which have a lower strength than the grain. A decrease in the strength of intergranular boundaries occurs during segregation of brittle and harmful impurities, as well as during the corrosive influence.

The effect of temperature on impact toughness is determined by Charpy tests. Fracture toughness decreases with a temperature reduction and the occurrence of an embrittlement of steels. The brittle fracture of steels occurs at a critical low temperature in the ductile-brittle transition temperature range. A significant number of physical and analytical models have been developed to describe fracture micromechanics [61]. Microstructural factor, volume, size, and distribution of dispersed phases, intermetallics, nonmetallic inclusions, impurities of S, P, absorption of H, O, N, diffusion of H, S, C, and phase transformations during heat input in welding and heat treatment are important in the models and mechanisms of fractures.

5. Improvement of Viscoplasticity of Steels

Theoretical foundations for improving the viscoplasticity of steels are based on the studies by R. Hadfield, J. Chipman, A. Samarin, A. Baikov, E. Bain, A. Cottrell, H. Bhadeshia, N. Liakishev, and I. Gorynin [84,85,86,87]. TMCP and the formation of nonmetallic inclusions leads to residual stresses at the interface between the inclusion and the steel matrix, due to different coefficients of thermal expansion and mechanical properties. The local stresses in the nonmetallic inclusions of Mg-Al-O, Al-Ca-O-S, and TiN, especially with sharp-edged shapes, can reach 750–2000 MPa, which leads to the fracture of brittle inclusions and the appearance of cracks [88].

As shown by the Electron Backscatter Diffraction (EBSD) analysis, parameters of TMCP and the hardening of Cu-containing HSLA steels can lead to coagulation and irregular distribution of Cu precipitates. This reduces the isotropy of rolled steel and the weldability of high-strength steels, especially with errors in welding parameters [89]. The composition, morphology, and micromechanical properties of nanoparticles smaller than 1 nm, including Cu precipitates, NiAl, Ni2AlMn, Ni2AlTi, Ni3Ti, NbC, and Mo2C intermetallics should be considered to improve impact toughness at low temperatures and weldability. For the isotropy of high-strength steels, the development of a synergistic combination of nanoparticles in the nanoscale hardening mechanism is required [90].

Reducing the ductile-brittle transition temperature to minus 120 °C and improving the weldability of high-strength cold-resistant steels can be achieved through developing methods of the microstructural design of rolled products and welded joints based on X-ray microstructure tomography [91,92]. An important field is the physical thermomechanical modeling to build CCT diagrams to determine the optimal concentrations of alloying elements, Cr, Nb, V, Ni, Ti, Mo, and N [93]. An increase in the viscoplasticity of steels is also achieved through the refinement of the primary austenitic grain, through the control of solubility and distribution of dispersion carbides, nitrides, and complex carbonitrides, VC, VN, TiC, TiN, Nb (C, N), and NbTi (C, N) [94,95].

6. Weldability of High-Strength Steels

Laser welding of boron-containing ultra-high-strength steel Docol PHS CR 2000 leads to the formation of a softening layer in the heat-affected zone (HAZ) when heating in the temperature range Ac1-Ac3. The microstructure of this layer consists of tempered martensite, and tensile strength is 33% lower compared to that of the base metal [104]. In addition to the softening effect, a hardening effect may occur in the HAZ. During hybrid laser-arc welding of S960QL steel, the hardness in HAZ increases to 436 HV with 383 HV in the weld metal and 350 HV in the base metal [105].

Kang et al. [106] studied the MAG welding of DP590 GA, SAE 1008, HSLA HR 420, DP600 HR, Boron, Boron-HSLA, DQSK, TRIP780 GI, and DP780 GI steels and dissimilar joints. Typical weld fractures during cyclic tests occur along the weld metal, in HAZ, and in areas of high stress concentration. Steel thickness, stress concentrators in the structure, and the shape of the welds have a significant influence on the fracture of samples during cyclic tests. The main problem in the welding of DP steels is also the hardening and softening effect in the heat-affected zone. During laser welding of 0.15C-1.7Mn-steel, softening in the low-temperature HAZ (LT-HAZ) reached 20% due to martensite tempering. In the high-temperature HAZ (HT-HAZ), strength increased up to 28% due to martensite formation compared with base metal [107]. Formation of a martensitic layer near the weld metal and softening results in fractures under static, impact, and cyclic dynamic loads. As the tensile strength of DP steel increases up to 1000 MPa, the softening increases up to 25–78% [108,109,110]. During laser welding of DP 980, the softening layer strength decreases by 41%, which is the main cause of fractures under cyclic and vibration loads [111].

To control the welding thermal cycle and microstructure of DP 590 steel, the change in laser pulse frequency can be used [112]. Twin-spot laser welding is used to reduce the cooling rate and hardening when welding DP, CP, and TRIP steels [113,114]. Changing the ratio of power of two laser beams allows one to optimally distribute the heat input, reducing the width of HAZ, the volume of martensite, and the weld hardness by 10%. These effects are important for improving the isotropy of welded joints. Martin-Root [115] investigated the laser welding of CP 980 steel. The hardness in the HT-HAZ increased from 460 to 520 HV.

This entry is adapted from the peer-reviewed paper 10.3390/met11121891

This entry is offline, you can click here to edit this entry!