The manufactured industrial pieces have often the external surfaces being in contact with harsh environment. The turbine blades are submitted to hot gas, the implanted prostheses to body liquids, etc. The protection of these surfaces can be realized using films and coatings. The latters have an important function of rendering the life in service of industrial piece longer, belong however, generally, to another group of materials with very different properties than the piece itself. For example, ceramic coatings are applied frequently on metal and alloys and some intermediate layers should be added between substrate and top coating. This is the concept of "functionally graded coatings" reviewed for the technology of thermal spraying in present entry basing onto paper Appl. Sci. 2020, 10, 5153; doi:10.3390/app10155153. The excerpt of this paper shows the chapters related to the applications of functionally graded coatings and their perspectives of development together with selected cited references.

- thermal spray coatings

- functional graded coatings

- application of thermal spray coatings

Major Applications of Functionally Graded Coatings

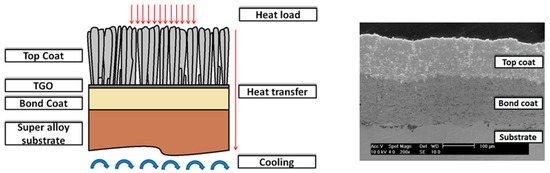

Thermal Barrier Coatings

-

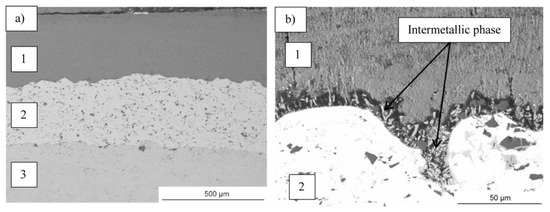

First concept consists of gradual change from fracture-resistant BC layer to heat-resistant TC layer by initial mixing the feedstock powders or by injecting feedstock by different injectors. It resulted in a significant decrease of residual stresses and in improvement of adhesion between subsequent layers leading to the long-term performance of TBC. The concept could be realized by mixing the zirconia and MCrAlY alloy powders and then spraying the mixtures [7,8]. The authors found out that some interlamellar discontinuities were formed in the final structure because of different properties of the mixed feedstock. Other authors used the mechanically pre-alloyed MCrAlY and 8YSZ powders with different ratios. The APS deposition of powders prepared in that way enabled high deposition rate, uniform coating density, and chemical homogeneity to be achieved [9,10]. The use of two injectors for 8YSZ and MCrAlY powders separately was another idea [11,12]. The coatings sprayed in this way were almost crack-free and their chemical composition changed gradually across the thickness without a distinct interface between layers. A new idea is the deposition of functionally graded TBCs using spraying of hybrid powder-suspension feedstock. The authors report about gradual change of TBC microstructure from dense bond coat to columnar top coat. The TBC showed high resistance against oxidation at high-temperature test and high resistance against thermal shocks.

-

Second concept consists of gradual change of chemical composition in TC. At least two different ceramics are used as layers. The outer one made of ceramics with high phase stability and low thermal conductivity, like e.g., alumina. The bottom ceramic layer should have high toughness, high fatigue performance, and low thermal conductivity. This specification corresponds to e.g., yttria stabilized zirconia such as 8YSZ [12,13].

-

APS and SPS deposited 8YSZ/La2Zr2O7 coatings [14];

-

APS deposited 8YSZ/Gd2Zr2O7 coatings ;

-

APS deposited La2Ce2O7/8YSZ [15];

-

APS deposited LaMgAl11O19/8YSZ bilayers [16].

Biomedical

Photo-Catalysis

Applications in Printing Industry (Corona and Anilox Rolls)

Other Applications

Perspectives of Development of Functionally Graded Coatings

Polymers as Substrates

New Applications of FGC

References

- Clarke, D.R.; Oechsner, M.; Padture, N.P. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012, 37, 891–898.

- Łatka, L. Thermal barrier coatings manufactured by suspension plasma spraying—A review. Adv. Mater. Sci. 2018, 18, 95–117.

- Evans, H.E. Oxidation failure of TBC systems: An assessment of mechanisms. Surf. Coat. Technol. 2011, 206, 1512–1521.

- Ali, I.; Sokołowski, P.; Grund, T.; Pawłowski, L.; Lampke, T. Oxidation behavior of thermal barrier coating systems with Al interlayer under isothermal loading. In Proceeding of the 20th Chemnitz Seminar on Materials Engineering—20 Werkstofftechnisches Kolloquium (previous editions: WTK-2016, WTK-2017), Chemnitz, Germany, 14–15 March 2018.

- Sampath, S.; Herman, H.; Shimoda, N.; Saito, T. Thermal spray processing of FGMs. MRS Bull. 1995, 20, 27–31.

- Jian, C.Y.; Hashida, T.; Takahashi, H.; Saito, M. Thermal shock and fatigue resistance evaluation of functionally graded coating for gas turbine blades by laser heating method. Compos. Eng. 1995, 5, 879–889.

- Ge, W.A.; Zhao, C.Y.; Wang, B.X. Thermal radiation and conduction in functionally graded thermal barrier coatings. Part I: Experimental study on radiative properties. J. Heat Mass Transf. 2019, 134, 101–113.

- Kokini, K.; DeJonge, J.; Rangaraj, S.; Beardsley, B. Thermal shock of functionally graded thermal barrier coatings with similar thermal resistance. Surf. Coat. Technol. 2002, 154, 223–231.

- Samani, T.; Kermani, M.; Razavi, M.; Farvizi, M.; Mobasherpour, I. A comparative study on the microstructure, hot corrosion behavior and mechanical properties of duplex and functionally graded nanostructured/conventional YSZ thermal barrier coatings. Mater. Res. Express 2019, 6, 115063.

- Carpio, P.; Rayón, E.; Salvador, M.D.; Lusvarghi, L.; Sánchez, E. Mechanical properties of double-layer and graded composite coatings of YSZ obtained by atmospheric plasma spraying. J. Therm. Spray Technol. 2016, 25, 778–787.

- Khoddami, A.M.; Sabour, A.; Hadavi, S.M.M. Microstructure formation in thermally sprayed duplex and functionally graded NiCrAlY/Yttria-Stabilized Zirconia coatings. Surf. Coat. Technol. 2007, 201, 6019–6024.

- Lashmi, P.G.; Ananthapadmanabhan, P.V.; Unnikrishnan, G.; Aruna, S.T. Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. J. Eur. Ceram. Soc. 2020, 40, 2731–2745.

- Viswanathan, V.; Dwivedi, G.; Sampath, S. Engineered multilayer thermal barrier coatings for enhanced durability and functional performance. J. Am. Ceram. Soc. 2014, 97, 2770–2778.

- Chen, H.; Liu, Y.; Gao, Y.; Tao, S.; Luo, H. Design, preparation, and characterization of graded YSZ/La2Zr2O7 thermal barrier coatings. J. Am. Ceram. Soc. 2010, 93, 1732–1740.

- Guo, H.; Wang, Y.; Wang, L.; Gong, S. Thermo-physical properties and thermal shock resistance of segmented La2Ce2O7/YSZ thermal barrier coatings. J. Therm. Spray Technol. 2009, 18, 665–671.

- Chen, X.; Gu, L.; Zou, B.; Wang, Y.; Cao, X. New functionally graded thermal barrier coating system based on LaMgAl11O19/YSZ prepared by air plasma spraying. Surf. Coat. Technol. 2012, 206, 2265–2274.

- Kirbiyik, F.; Gok, M.G.; Goller, G. Microstructural, mechanical and thermal properties of Al2O3/CYSZ functionally graded thermal barrier coatings. Surf. Coat. Technol. 2017, 329, 193–201.

- Gok, M.G.; Goller, G. Production and characterisation of GZ/CYSZ alternative thermal barrier coatings with multilayered and functionally graded designs. J. Eur. Ceram. Soc. 2016, 36, 1755–1764.

- Li, C.-J.; Li, Y.; Yang, G.-J.; Li, C.-X. A novel plasma-sprayed durable thermal barrier coating with a well-bonded YSZ interlayer between porous YSZ and bond coat. J. Therm. Spray Technol. 2012, 21, 383–390.

- Li, H. Thermal sprayed bioceramic coatings: Nanostructured hydroxyapatite (HA) and HA-based composites. In Biological and Biomedical Coatings Handbook; Zhang, S., Ed.; CRC Press: Boca Raton, FL, USA, 2011.

- Ratner, B.D.; Hoffman, A.S.; Schoen, F.J.; Lemons, J.E. Biomaterials science: A multidisciplinary endeavor. In Biomaterials Science; Ratner, B.D., Hoffman, A.S., Schoen, F.J., Lemons, J.E., Eds.; Elsevier Academic Press: San Diego, CA, USA, 2013.

- Wang, Y.; Khor, K.A.; Cheang, P. Thermal spraying of functionally graded calcium phosphate coatings for biomedical implants. J. Therm. Spray Technol. 1998, 7, 50–57.

- Khor, K.A.; Wang, Y.; Cheang, P. Thermal spraying of functionally graded coatings for biomedical applications. Surf. Eng. 1998, 14, 159–164.

- Wang, M.; Yang, X.Y.; Khor, K.A.; Wang, Y. Preparation and characterization of bioactive monolayer and functionally graded coatings. J. Mater. Sci. Mater. Med. 1999, 10, 269–273.

- Heimann, R.B. Thermal spraying of biomaterials. Surf. Coat. Technol. 2006, 201, 2012–2019.

- Goller, G. The effect of bond coat on mechanical properties of plasma sprayed bioglass-titanium coatings, Ceram. Int. 2004, 30, 351–355.

- Oktar, F.N.; Yetmez, M.; Agathopoulos, S.; Loper Goerne, T.M.; Goller, G.; Ipeker, I.; Ferreira, J.M.F. Bond-coating in plasma-sprayed calcium-phosphate coatings. J. Mater. Sci. Mater. Med. 2006, 17, 1161–1171.

- Yang, Y.Z.; Tian, J.M.; Tian, J.T.; Chen, Z.Q.; Deng, X.J.; Zhang, D.H. Preparation of graded porous titanium coatings on titanium implant materials by plasma spraying. J. Biomed. Mater. Res. 2000, 52, 333–337.

- Ning, C.Y.; Wang, Y.J.; Chen, X.F.; Zhao, N.R.; Ye, J.D.; Wu, G. Mechanical performances and microstructural characteristics of plasma-sprayed bio-functionally gradient HA-ZrO2-Ti coatings. Surf. Coat. Technol. 2005, 200, 2403–2408.

- Sun, J.; Thian, E.S.; Fuh, J.Y.H.; Chang, L.; Hong, G.S.; Wang, W.; Tay, B.Y.; Wong, Y.S. Fabrication of bio-inspired composite coatings for titanium implants using the micro-dispensing technique. Microsyst. Technol. 2012, 18, 2041–2051.

- Sola, A.; Bellucci, D.; Cannillo, V. Functionally graded materials for orthopedic applications—An update on design and manufacturing. Biotechnol. Adv. 2016, 34, 504–531.

- Schneider, K.; Heimann, R.B.; Berger, G. Plasma-sprayed coatings in the system CaO-TiO2-ZrO2-P2O5 for long-term stable endoprostheses. Mater. Sci. Eng. Technol. 2001, 32, 166–171.

- Levingstone, T.J.; Barron, N.; Ardhaoui, M.; Benyounis, K.; Looney, L.; Stokes, J. Application of response surface methodology in the design of functionally graded plasma sprayed hydroxyapatite coatings. Surf. Coat. Technol. 2017, 313, 307–318.

- Chen, C.C.; Huang, T.H.; Kao, C.T.; Ding, S.J. Characterization of functionally graded hydroxyapatite/titanium composite coatings plasma sprayed on Ti alloys. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 78B, 146–152.

- Cannillo, V.; Lusvarghi, L.; Sola, A. Design of Experiments (DOE) for the optimization of titania-hydoxyapatite functionally graded coatings. J. Appl. Ceram. Technol. 2009, 6, 537–550.

- Tan, Y.; Wang, X.; Wu, Q.; Yan, W. Early peri-implant osteogenesis with functionally graded nanophase hydroxyapatite/bioglass coating on Ti alloys. Key Eng. Mater. 2007, 330–332, 553–556.

- Chen, X.; Zhang, B.; Gong, Y.; Zhou, P.; Li, H. Mechanical properties of nanodiamond-reinforced hydroxyapatite composite coatings deposited by suspension plasma spraying. Appl. Surf. Sci. 2018, 439, 60–65.

- Li, Z.; Khun, N.W.; Tang, X.Z.; Liu, E.; Khor, K.A.; Mechanical, tribological and biological properties of novel 45S5 Bioglass composites reinforced with in situ reduced graphene oxide. J. Mech. Behav. Biomed. Mater. 2017, 65, 77–89.

- Zhang, C.; Xu, H.; Geng, X.; Wang, J.; Xiao, J.; Zhu, P. Effect of spray distance on microstructure and tribological performance of suspension plasma-sprayed hydroxyapatite–titania composite coatings. J. Therm. Spray Technol. 2016, 25, 1255–1263.

- Jaworski, R.; Pawłowski, L.; Pierlot, C.; Roudet, F.; Kozerski, S.; Petit, F. Recent developments in suspension plasma sprayed titanium oxide and hydroxyapatite coatings. J. Therm. Spray Technol. 2010, 19, 240–247.

- Fujishima, A.; Honda, K. Electrochemical photolysis of water at a semiconductor electrode. Nature 1972, 238, 37–38.

- Herrmann, J.-M.; Guillard, C. Photocatalytic degradation of pesticides in agriculturals used waters. C.R. Acad. Sci. 2000, 3, 417–422.

- Fujishima, A.; Rao, T.N.; Tryk, D.A. Titanium dioxide photocatalysis. J. Photochem. Photobiol. C 2000, 1, 1–21.

- Mills, A.; Le Hunte, S. An overview of semiconductor photocatalysis. J. Photochem. Photobiol. A 1997, 108, 1–35.

- Fujishima, A.; Zhang, X.; Tryk, D.A. TiO2 photocatalysis and related surface phenomena. Surf. Sci. Rep. 2008, 63, 515–582.

- Ye, F.; Ohmori, A. The photocatalytic activity and photo-absorption of plasma sprayed. Surf. Coat. Technol. 2002, 160, 62–67.

- Ye, F.; Tsumura, T.; Nakata, K.; Ohmori, A. Dependence of photocatalytic activity on the compositions and photo-absorption of functional TiO2-Fe3O4 coatings deposited by plasma spray. Mater. Sci. Eng. B 2008, 148, 154–161.

- Yu, Q.; Zhou, C.; Wang, X. Influence of plasma spraying parameter on microstructure and photocatalytic properties of nanostructured TiO2-Fe3O4 coating. J. Mol. Catal. A Chem. 2008, 283, 23–28.

- Chen, H.; Lee, S.W.; Kim, T.H.; Hur, B.Y. Photocatalytic decomposition of benzene with plasma sprayed TiO2-based coatings on foamed aluminum. J. Eur. Ceram. Soc. 2006, 26, 2231–2239.

- Ctibor, P.; Pala, Z.; Stengl, V.; Musalek, R. Photocatalytic activity of visible-light-active iron-doped coatings prepared by plasma spraying. Ceram. Int. 2014, 40, 2365–2372.

- Zenh, Y.; Liu, J.; Wu, W.; Ding, C. Photocatalytic performance of plasma sprayed TiO2ZnFe2O4 Surf. Coat. Technol. 2005, 200, 2398–2402.

- Daram, P.; Banjongprasert, C.; Thongsuwan, W.; Jiansirisomboon, S. Microstructure and photocatalytic activities of thermal sprayed titanium dioxide/carbon nanotubes composite coatings. Surf. Coat. Technol. 2016, 306, 290–294.

- Robotti, M.; Dosta, S.; Fernandez-Rodriguez, C.; Hernandez-Rodriguez, M.J.; Cano, I.G.; Pulido Melian, E.; Guilemany, J.M. Photocatalytic abatement of NOx by C-TiO2/polymer composite coatings obtained by low pressure cold gas spraying. Appl. Surf. Sci. 2016, 362, 274–280.

- Liu, Y.; Huang, J.; Ding, S.; Liu, Y.; Yuan, J.; Li, H. Deposition, characterization and enhanced adherence of Escherichia coli bacteria on flame-sprayed photocatalytic titania-hydroxyapatite coatings. J. Therm. Spray Technol. 2013, 22, 1053–1062.

- Huang, J.; Gong, Y.; Liu, Y.; Suo, X.; Li, H. Developing titania-hydroxyapatite-reduced graphene oxide nanocomposite coatings by liquid flame spray deposition for photocatalytic applications. J. Eur. Ceram. Soc. 2017, 37, 3705–3711.

- Pawłowski, L. Technology of thermally sprayed anilox rolls: State of art, problems, and perspectives. J. Therm. Spray Technol. 1996, 5, 317–334.

- Kozerski, S.; Białucki, P; Kaczmarek, M.; Ambroziak, A. Properties of Weld Overlays on Regenerated Wheel Hub of a Mining Vehicle. Ph.D. Thesis, Wrocław University of Science and Technology, Wrocław, Poland, Unpublished data.

- Oerlikon Metco. TriplexPro-210 Plasma Spay Gun. Available online: https://www.oerlikon.com/metco/en/products-services/coating-equipment/thermal-spray/spray-guns/coating-equipment-plasma/triplexpro-210/ (accessed on 20 June 2020).

- Tomaszek, R.; Pawłowski, L.; Zdanowski, J.; Grimblot, J.; Laurens, J. Microstructural transformations of TiO2, Al2O3 + 13TiO2 and Al2O3 + 40TiO2 at plasma spraying and laser engraving. Surf. Coat. Technol. 2004, 185, 137–149.

- Kiilakoski, J.; Trache, R.; Bjorklund, S.; Joshi, S.; Vuoristo, P. Process parameter impact on suspension‑HVOF‑sprayed Cr2O3 J. Therm. Spray Technol. 2019, 28, 1933–1944.

- Pawłowski, L. Strategic oxides for thermal spraying: Problems of availability and evolution of prices. Surf. Coat. Technol. 2013, 220, 14–19.

- Tanaka, M.; Takatani, Y. Evaluation of sealants on Al–Zn alloy sprayed coating by galvanostatic technique. In Thermal Spray 2001: New Surfaces for a New Millenium; Berndt, C.C., Khor, K.A., Lugscheider, E.F., Eds.; ASM International: Materials Parks, OH, USA, 2001; pp. 621–625.

- Praxair Surface Technologies. Get the Best Possible Treatment. Available online: https://www.praxairsurfacetechnologies.com/en/solutions-for-your-industry/printing-and-converting/corona-treating (accessed on 20 June 2020).

- Feng, Y.; Li, Y.; Luo, Z.; Ling, Z.; Wang, Z. Resistance spot welding of Mg to electro-galvanized steel with hot-dip galvanized steel interlayer. J. Mater. Process. Technol. 2016, 236, 114–122.

- Patel, V.K.; Bhole, S.D.; Chen, D.L. Characterization of ultrasonic spot-welded joints of Mg-to-galvanized and ungalvanized steel with a tin interlayer. J. Mater. Process. Technol. 2014, 214, 811–817.

- Gu, X.; Sui Ch., Liu, J.; Li, D.; Meng, Z.; Zhu, K. Microstructure and mechanical properties of Mg/Al joints welded byultrasonic spot welding with Zn interlayer. Mater. Des. 2019, 181, 108103.

- Winnicki, M.; Małachowska, A.; Korzeniowski, M.; Jasiorski, M.; Baszczuk, A. Aluminium to steel resistance spot welding with cold sprayed interlayer. Surf. Eng. 2017, 34, 235–242.

- Wojdat, T.; Winnicki, M.; Rutkowska-Gorczyca, M.; Krupiński, S.; Kubica, K. Soldering aluminium to copper with the use of interlayers deposited by cold spraying. Arch. Civ. Mech. Eng. 2016, 16, 835–844.

- Li, J.F.; Agyakwa, P.A.; Johnson, C.M.; Zhang, D.; Hussain, T.; McCartney, D.G. Characterization and solderability of cold sprayed Sn–Cu coatings on Al and Cu substrates. Surf. Coat. Technol. 2010, 204, 1395–1404.

- Wojdat, T.; Winnicki, M.; Łamasz, S.; Żuk, A. Application of interlayers in the soldering process of graphite composite to aluminium alloy 6060. Arch. Civ. Mech. Eng. 2019, 19, 91–99.

- Yang, K.; Li, W.; Huang Ch., Yang, X.; Xu, Y. Optimization of cold-sprayed AA2024/Al2O3 metal matrix composites via friction stir processing: Effect of rotation speeds. J. Mater. Sci. Technol. 2018, 34, 2167–2177.

- Peat, T.; Galloway, A.; Toumpis, A.; McNutt, P.; Iqbal, N. The erosion performance of cold spray deposited metal matrix composite coatings with subsequent friction stir processing. Appl. Surf. Sci. 2017, 396, 1635–1648.

- Huang Ch., Li, W.; Zhang, Z.; Fu, M.; Planche, M.P.; Liao, H.; Montavon, G. Modification of a cold sprayed SiC p/Al5056 composite coating by friction stir processing. Surf. Coat. Technol. 2016, 296, 69–75.

- Hodder, K.J.; Izadi, H.; McDonald, A.G.; Gerlich, A.P. Fabrication of aluminum–alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. A 2012, 556, 114–121.

- Peat, T.; Galloway, A.; Toumpis, A.; Steel, R.; Zhu, W.; Iqbal, N. Enhanced erosion performance of cold spray co-deposited AISI316 MMCs modified by friction stir processing. Mater. Des. 2017, 120, 22–35.

- Yang, K.; Li, W.; Xu, Y.; Yang, X. Using friction stir processing to augment corrosion resistance of cold sprayed AA2024/Al2O3 composite coatings. J. Alloys Compd. 2019, 774, 1223–1232.

- Gupta, N.; Doddamani, M. Polymer matrix composites. J. Met. 2018, 70, 1282–1283.

- Afshar, A.; Mihut, D.; Hill, S.; Baqersad, J. Synergistic effects of environmental exposures on polymer matrix with or without metallic coating protection. J. Compos. Mater. 2018, 52, 3773–3784.

- Che, H.; Chu, X.; Vo, P.; Yue, S. Metallization of various polymers by cold spray. J. Therm. Spray Technol. 2018, 27, 169–178.

- Khalkhali, Z.; Rothstein, J.P. Characterization of the cold spray deposition of a wide variety of polymeric powders. Surf. Coat. Technol. 2020, 383, 125251.

- Małachowska, A.; Winnicki, M.; Konat, Ł.; Piwowarczyk, T.; Pawłowski, L.; Ambroziak, A.; Stachowicz, M. Possibility of spraying of copper coatings on polyamide 6 with low pressure cold spray method. Surf. Coat. Technol. 2017, 318, 82–89.

- Yang, S.-Y.; Ji, M. Polyimide matrices for carbon fiber composites. In Advanced Polyimide Materials; Yang, S.-Y., Ed.; Elsevier: Amsterdam, The Netherlands, 2018; pp. 93–136.

- Huang, W.; Zhao, Y.; Fan, X.; Meng, X.; Wang, Y.; Cai, X.; Cao, X.; Wang, Z. Effect of bond coats on thermal shock resistance of thermal barrier coatings deposited onto polymer matrix composites via air plasma spray process. J.Therm. Spray Technol. 2013, 22, 918–925.

- Huang, W.; Gan, X.; Zhu, L. Fabrication and property of novel double-layer coating deposited on polyimide matrix composites by atmospheric plasma spraying. Ceram. Int. 2018, 44, 5473–5485.

- Zhu, L.; Huang, W.; Cheng, H.; Cao, X. Thermal shock resistance of stabilized zirconia/metal coat on polymer matrix composites by thermal spraying process. J. Therm. Spray Technol. 2014, 23, 1312–1322.

- Abedi, H.R.; Salehi, M.; Shafyei, A. Microstructure, tensile adhesion strength and thermal shock resistance of TBCs with different flame-sprayed bond coat materials onto BMI polyimide matrix composite. J. Therm. Spray Technol. 2017, 26, 1669–1684.

- Ivosevic, M.; Knight, R.; Kalidindi, S.R.; Palmese, G.R.; Sutter, J.K. Solid particle erosion resistance of thermally sprayed functionally graded coatings for polymer matrix composites. Surf. Coat. Technol. 2006, 200, 5145–5151.

- Ivosevic, M.; Gupta, V.; Baldoni, J.A.; Cairncross, R.A.; Twardowski, T.E.; Knight, R. Effect of substrate roughness on splatting behavior of HVOF sprayed polymer particles: Modeling and experiments. J. Therm. Spray Technol. 2006, 15, 725–730.

- Ivosevic, M.; Knight, R.; Kalidindi, S.R.; Palmese, G.R.; Sutter, J.K. Erosion/oxidation resistant coatings for high temperature polymer composites. High Perform. Polym. 2003, 15, 503–517.

- Liu, A.; Guo, M.; Zhao, M.; Ma, H.; Hu, S. Arc sprayed erosion-resistant coating for carbon fiber reinforced polymer matrix composite substrates. Surf. Coat. Technol. 2006, 200, 3073–3077.

- Cui, Y.; Guo, M.; Wang, C.; Tang, Z. Adhesion enhancement of a metallic al coating fabricated by detonation gun spray on a modified polymer matrix composite. J. Therm. Spray Technol. 2019, 28, 1730–1738.

- Rezzoug, A.; Abdi, S.; Kaci, A.; Yandouzi, M. Thermal spray metallisation of carbon fibre reinforced polymer composites: Effect of top surface modification on coating adhesion and mechanical properties. Surf. Coat. Technol. 2018, 333, 13–23.

- Chen, W.R.; Irissou, E.; Wu, X.; Legoux, J.G.; Marple, B.R. The oxidation behavior of TBC with cold spray CoNiCrAlY bond coat. J. Therm. Spray Technol. 2011, 20, 132–138.

- Karaoglanli, A.C.; Turk, A. Isothermal oxidation behavior and kinetics of thermal barrier coatings produced by cold gas dynamic spray technique. Surf. Coat. Technol. 2017, 318, 72–81.

- Khanna, A.S.; Rathod, W.S. Development of CoNiCrAlY oxidation resistant hard coatings using high velocity oxy fuel and cold spray techniques. J. Refract. Hard Met. 2015, 49, 374–382.

- Go, T.; Sohn, Y.J.; Mauer, G.; Vassen, R.; Gonzalez-Julian, J. Cold spray deposition of Cr2AlC MAX phase for coatings and bond-coat layers. J. Eur. Ceram. Soc. 2019, 39, 860–867.

- Gardon, M.; Melero, H.; Garcia-Giralt, N.; Dosta, S.; Cano, I.G.; Guilemany, J.M. Enhancing the bioactivity of polymeric implants by means of cold gas spray coatings. J. Biomed. Mater. Res. Part B 2014, 102B, 1537–1543.

- Arcos, D.; Vallet-Regi, M. Substituted hydroxyapatite coatings of bone implants. J. Mater. Chem. B 2020, 8, 1781–1800.

- Ullah, I.; Siddiqui, M.A.; Liu, H.; Kolawole, S.K.; Zhang, J.; Zhang, S.; Ren, L.; Yang, K. Mechanical, biological, and antibacterial characteristics of plasma-sprayed (Sr, Zn) substituted hydroxyapatite coating. ACS Biomater. Sci. Eng. 2020, 6, 1355–1366.

- Lyasnikova, A.V.; Markelova, O.A.; Dudareva, O.A.; Lyasnikov, V.N.; Barabash, A.P.; Shpinyak, S.P. Comprehensive characterization of plasma-sprayed coatings-based silver- and cooper-substituted hydroxyapatite, Powder Metall. Ceram. 2016, 55, 328–333.

- Unabia, R.B.; Bonebeau, S.; Candidato, R.T., Jr.; Pawłowski, L. Preliminary study on copper-doped hydroxyapatite coatings obtained using solution precursor plasma spray process. Surf. Coat. Technol. 2018, 353, 370–377.

- Bose, S.; Vu, A.A.; Emshadi, K.; Bandyopadhyay, A. Effects of polycaprolactone on alendronate drug release from Mg-doped hydroxyapatite coating on titanium. Mater. Sci. Eng. C 2018, 88, 166–171.

- Cao, L.; Ullah, I.; Li, N.; Niu, S.; Sun, R.; Xia, D.; Yang, R.; Zhang, X.; Plasma spray of biofunctional (Mg, Sr)-substituted hydroxyapatite coatings for titanium alloy implants. J. Mater. Sci. Technol. 2019, 35, 719–726.

- Chen, Y.; Zheng, X.; Xie, Y.; Ding, C.; Ruan, H.; Fan, C. Anti-bacterial and cytotoxic properties of plasma sprayed silver-containing HA coatings. J. Mater. Sci.: Mater. Med. 2008, 19, 3603–3609.

- Chen, Y.; Zheng, X.; Xie, Y.; Ji, H.; Ding, C.; Li, H.; Dai, K. Silver release from silver-containing hydroxyapatite coatings. Surf. Coat. Technol. 2010, 205, 1892–1896.

- Shimazaki, T.; Miyamoto, H.; Ando, Y.; Noda, I.; Yonekura, Y.; Kawano, S.; Miyazaki, M.; Mawatari, M.; Hotokebuchi, T. In vivo antibacterial and silver-releasing properties of novel thermal sprayed silver-containing hydroxyapatite coating. J. Biomed. Mater. Res. B 2010, 92, 386–389.

- Fielding, G.A.; Roy, M.; Bandyopadhyay, A.; Bose, S. Antibacterial and biological characteristics of silver containing and strontium doped plasma sprayed hydroxyapatite coatings. Acta Biomater. 2012, 8, 3144–3152.

- Cizek, J.; Brozek, V.; Chraska, T.; Lukac, F.; Medricky, J.; Musalek, R.; Tesar, T.; Siska, F.; Antos, Z.; Cupera, J.; et al. Silver-doped hydroxyapatite coatings deposited by suspension plasma spraying. J. Therm. Spray Technol. 2018, 27, 1333–1343.

- Singh, B.; Singh, G.; Sidhu, B.S.; Bhatia, N. In-vitro assessment of HA-Nb coating on Mg alloy ZK60 for biomedical applications. Mater. Chem. Phys. 2019, 231, 138–149.

- Heimann, R.B.; Kleiman, J.I.; Litovsky, E.; Marx, S.N.R.; Petrov, S.; Shagalov, M.; Sodhi, R.N. S.; Tang, A. High-pressure cold gas dynamic (CGD)-sprayed alumina-reinforced aluminum coatings for potential application as space construction material. Surf. Coat. Technol. 2014, 252, 113–119.

This entry is adapted from the peer-reviewed paper 10.3390/app10155153