Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Construction & Building Technology

Every year, the human impact on the world’s water sources becomes more pronounced. One of the triggers to this increase is the use of ineffective wastewater and sludge treatment systems. Recently, the number of studies of microwave processing in handling liquid municipal and industrial waste has increased. This paper discusses heat treatment, change in properties, decomposition of substances, removal of metals, demulsification, pyrolysis, biogas processing, disinfection, and other topics.

- microwave irradiation (MW)

- wastewater (WW)

- wastewater/sewage sludge (WWS)

- treatment technology

- MW installations/devices/reactors

1. Introduction

The size of global urban water consumption can be estimated based on the total population of Earth living in urban environments, which is more than 3.4 billion people, and the average water consumption per human of 499 m3 per year [1]. While accurate data on the amount of wastewater (WW) generated around the world is not available, using a calculated method based on the standard of water use and the percentage of irreversible losses (roughly 30–35 per cent) can help us assume that more than 1100 billion m3 of wastewater and 0.1–0.05% of that amount—wastewater sludge (WWS)—is treated and disposed of annually in urbanised settlements. Solving high-quality WW and WWS treatment issues leads to a decrease in the anthropogenic impact on water and land resources. New methods and technologies, such as electromagnetic microwave irradiation (MW), may help make a breakthrough in this field.

Microwave radiation is electromagnetic ultrahigh-frequency radiation, including decimeter, centimetre, and millimetre ranges of radio waves with a frequency of 0.3 GHz to 300 GHz, corresponding to a wavelength from 1 m to 1 mm [2,3]. High-intensity microwaves are commonly used for contactless heating of objects, including stoves for cooking food, metallurgical industry heat treatment installations, and medical devices for treating veins. People actively involve microwaves of a particular range (frequency from 1 to 100 GHz) in radiolocation. MW reactors are increasingly adopted to neutralise various solid and liquid wastes produced by people and industrial enterprises [4,5,6].

Microwave irradiation is confidently entering the wastewater (WW) and sludge (WWS) treatment technology in the twenty-first century, primarily as an alternative to conditional heating [4]. MW is a well-known heating and drying process used both for domestic and industrial purposes.

This method has several advantages over conventional electric heating, including non-contact heating, instant and rapid process with a high degree of uniformity, and precise heating, which induces dipolar oscillations and ionic conductivity in the medium [7,8]. In 2011, researchers conducted a comprehensive study of the existing state of MW technology for WW treatment [9]. According to this report, using MW to decompose contaminants has numerous advantages. For example, selectivity and reaction rate increase while reaction time, activation energy, equipment size, and waste parameters decrease.

These benefits are primarily due to the thermal and nonthermal effects of microwave irradiation. Many transformations with a beneficial impact on the structure and properties of water occur in the aquatic environment under the thermal influence of MW: increased dissolution of substances, coagulation and demulsification of pollution, activation of various chemical reactions (including oxidation of organic matter), and degradation of toxins; the disinfecting effect of MW is well known [10].

2. Heating and Thermal Treatment

MW has become increasingly common as a thermal method for treating wastewater and sediments in recent years, owing to its rapid and selective heating [9,10,11,12,13,14,15]. The thermal effect of MW [16] describes how ultrahigh-frequency energy can be consumed by microwave absorbers and dissipated as thermal energy. For many environments, including water solutions, microwave heating with dielectric losses is typical [13].

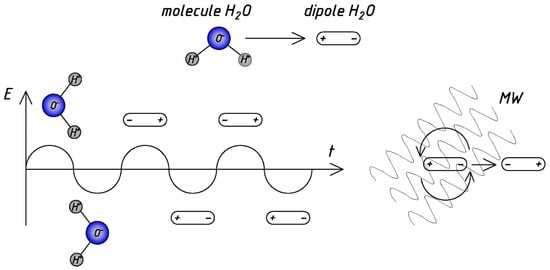

Water is a positive-charged molecule (or dipole) with a negative-charged opposite end. Dipolar polarization occurs due to intermolecular inertia, responsible for most of the microwave heating observed in liquids. The rapid change in the electric field of microwave radiation causes a rotation of dipoles. At the same time, the rate at which the dipole rotates (reverses) cannot accurately correlate to the rate at which the electric field shifts direction. It induces “internal friction” between water molecules, which leads to direct and very uniform heating of the reaction mixture. However, reflections and refractions at local boundaries between phases lead to the appearance of so-called “hot spots” and the effect of “overheating”, which has been extensively discussed by researchers [15,17,18,19,20,21].

Figure 1 presents the schematic diagram of microwave action [3,17], illustrating the advantages and scope of application of microwave processing. Microwave heating penetrates the liquid and creates the rapidly changing field: dipoles (water molecules) continuously react attempting to align in the field, which generates heat; heat is uniformly distributed throughout the water.

Figure 1. The scheme of mechanism of the MW water heating.

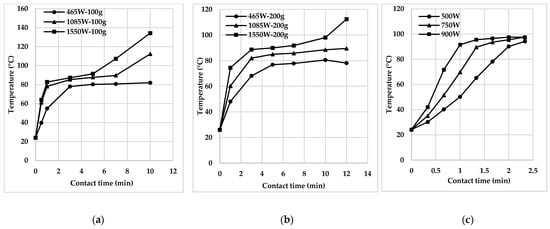

Under the influence of MW, several parameters such as strength, frequency, duration, treatment temperature, and sample volumes [9,14,22,23,24,25,26,27] can influence the efficiency of pollutant decomposition and mineralisation of wastewater and sediments. It is confirmed in the materials [25,26,27], which use the Netherlands, Kenya, China, and other countries as examples of MW-heating of faecal sludge (Figure 2).

As a rule, the efficiency of the MW system tends to rise with the increase of power and time of microwave irradiation [22]. It is due to the release of extra heat, contributing to the rapid movement of water molecules. In addition, increased time and power of irradiation amplify the decomposition of various contaminants in the water environment [9].

In some cases, the efficiency of the MW system is reduced at very high temperatures by evaporating water and increased viscosity of the substance by overheating. Thus, it is necessary to determine the optimal power and reaction temperature for decomposing a particular target pollutant [9,14,17,18,19,20,21].

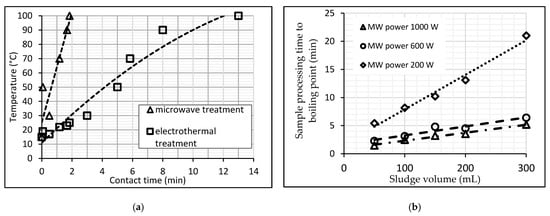

It should be noted that the technological and economic efficiency of MW heating for the water environment is currently actively explored by contrasting it to other methods of heating and processing [14,23,24]. The Department of Water Supply and Sanitation (Industrial University of Tyumen, Russia) laboratory has carried out several experiments related to the MW-heating of wastewater sludge [14,24]. Firstly, a comparison is made between microwave and electric heating. The distinctive feature of microwave heating is its thermal effect, which is volumetric and does not involve thermal diffusion from the surface into the material, as conventional heating does, which explains its high thermoset reaction rates. According to observations, ultrahigh-frequency irradiation of liquid sewage sludge has a rapid thermal effect: samples of sludge with a 50–300 mL volume started to boil within one to two minutes (Figure 3) [14].

Figure 3. (a) Comparison of two methods of WWS-heating. (b) Boiling time dependence of the WWS on the sample volume at a constant power MW.

Figure 3a compares the heating curves of sewage sludge (mixture of the raw sludge and activated sludge) in two different ways, with the rate of heating the sludge to a given temperature using microwaves being four to six times faster than the usual heating on an electric stove. In addition, in the process of microwave irradiation, an improvement in the sedimentation and compaction of WWS was obtained by 13–15% compared to traditional convective heating to the same temperature [14].

Secondly, the maximum time for MW treatment of WWS samples to reach boiling point [24] was determined experimentally. Figure 3b illustrates dependency t = f (V) at constant power MW based on the experience data. Obviously, the higher the microwave processing power, the faster the sludge samples reach the boiling point. At MW 200 W, the heating rate of sewage sludge is 3.7–4.0 times lower than at MW 1000 W and 3–2.8 times lower than at MW 600 W. Heating sludge with a power of 1000 W is 1.2 times more effective than heating with 600 W. Rapid and voluminous MW-heating of wastewater and sediments entails other positive effects discussed below.

3. Decontamination (Disinfection)

In the last century, the biophysical impact of the MW field on the viability and other properties of bacteria was discovered [43,44]. The sterilising efficiency of the MW field produced by the GZ–10A generator when irradiated for 10 min, for example, was used to assess the biological effect of microwaves on microorganisms [45]. The bacteria’s viability was determined by the number of colonies developed within two days on the breeding ground. As a result, researchers discovered a bactericidal effect of pulsed and continuous microwaves on Escherichia coli and staphylococcus cultures.

Experiments on the influence of centimetre waves on the growth of Escherichia coli M–17 in a continuous mode (frequency 10.6 GHz, PPM = 0.1–5.5 MW/cm2) are presented in the paper [46]. According to the material results, microwave radiation has a harmful effect on escherichia coli (n = 10) at a power of 130 W for five minutes [47]. Water heating and disinfection systems were invented and patented in the 1970s and 1980s [48,49].

The modern use of MW for wastewater disinfection is based on earlier studies [50,51]. Less often it is mentioned that sewage sludge is also disinfected during microwave irradiation [14,26,27,31,33,34,37,42,52]. Water disinfection usually occurs at a power of MW from 300 W and higher (frequency 2.45 GHz) when heated from 45 to 100 °C. Therefore, the processing time depends on the sample volume and the MW heating power. This knowledge is very relevant concerning the further disposal of such liquid municipal waste. For example, faecal sludge formed in public toilets was treated using a laboratory microwave installation (MW) [26,27].

Total bacterial inactivation was achieved in 30–240 min after sewage sludge treatment in a special MW reactor [42]. According to findings in [52], high–level disinfection for enterococci and salmonella is possible to achieve in 9.5 min at MW energy consumption of 580 W∙s/g and temperature 72 °C. In some studies [53,54], microwave irradiation proved to effectively reduce the bacterial content of sewage sludge prior to anaerobic digestion. In addition, a high degree of removal of faecal coliforms in the sediment is recorded in [55] (the content of 2.66 logs or less).

Similarly, researchers [56] confirmed that a single pretreatment with microwaves resulted in a 50% reduction of bacteria C.Perfringens. Furthermore, according to the article [14], the microwave treatment of a mixture of sewage sludge can achieve 99% decontamination from all pathogenic bacteria subject to control.

The MW technology can be further investigated for potential expansion as a rapid treatment alternative for faecal effluents and sediments in emergencies [26,27], such as a pandemic.

4. Decomposition of Organic Substances

Organic pollution of natural and wastewater is a source of concern for scientists and environmentalists worldwide, as these contaminants have a detrimental impact on the natural environment, human life, and health. Approximately 3000 different organic contaminants have been identified [57,58] and classified into three groups: (1) organic substances of natural origin, (2) synthetic organic pollutants, and (3) chemicals reformed in water as a result of its purification. Many organic pollutants of the second and third groups are toxins and carcinogens [59]. Therefore, the international community is looking for creative, highly efficient advanced oxidative water treatment technologies that involve various pollutant exposure processes to address this problem.

In order to increase the performance of WW treatment from different contaminants and minimise reaction time, microwave exposure should be combined with oxidising agents OX (MW + OX), adsorbents activated carbon AC (MW + OX + AC), catalysts carbon C (MW + OX + C), and advanced oxidation processes with the addition of UV irradiation such as photo-Fenton (MW + OX + C + UV), direct photolysis using an electrodeless discharge lamp EDL (MW+OX+EDL), and photocatalysis using TiO2 photocatalyst (MW + OX + UV + TiO2) [60,61,62,63,64,65,66,67,68,69,70,71,72].

The review data were summarised reasonably well in the papers [9,73]. Other studies of the efficacy of MW oxidation of organic compounds under various treatment conditions are seen in Table 6 [22,61,62,63,64,65,66,67,68,69,70,71,72].

Table 6. The efficiency of MW oxidation of organic substances in WW.

| Type of an Organic Substance | Sample Volume | Concentration | Oxidizing Agent, Catalyst, pH | MW Power | MW Duration, Temperature | Effect | [Ref./No] |

|---|---|---|---|---|---|---|---|

| Sample was only MW-treated | |||||||

| Ammonia (laboratory installation) | 100 mL | 0.5–12 g/L | Air 1 L/min pH = 11 |

750 W | 3 min 80 °C |

D * 98.4–96.1% | [63] |

| Ammonia (pilot plant) | 28,000 mL | 2.4–11 g/L | Air 30 L/min pH = 11.6–12 |

4.8 kW | 60 min 80–100 °C |

D * 80% | [63] |

| With an addition of the oxidizer: MW + OX | |||||||

| Naphthalene Disulfonic Acid | 10 mL | 1.0 mmol/L | H2O2 | 300 W | 20 min 30 min 80 °C |

D * 90% M ** 50% | [64] |

| Dimethoate (phosphoric compound) | No Data | 0.1 mmol/L | K2S2O8 pH = 6.8 |

750 W | 4 min 100 °C |

D * 100% | [22] |

| Perflurooctanic acid | 50 mL | 0.25 mmol/L | Na2S2O8 | 800 W | 240 min 60–130 °C |

D * 99.3% M ** 74.3% |

[66] |

| The photo-Fenton process: MW + OX + C + UV | |||||||

| Polyacrylamide (PAA) | No Data | 150 mg/L | H2O2/AC pH = 3 |

70 W 490 W |

6 min | D * 20% D * 80% |

[61] |

| Pesticides (dimethoate, triazophos, malathion) | 1000 mL | 6.11–31.65 mg/L | H2O2 Fe2+; pH = 5 |

80 W | 120 min 25 °C |

M ** 72.1% | [62] |

| Direct photolysis: MW + OX + EDL | |||||||

| Phenol | 50 mL | 200 mg/L | H2O2 | 1000 W | 9 min 30 min 50 °C |

D * 90% M ** 95% |

[67] |

| Atrazine | 50 mL | 50 mg/L | pH = 6.3 | 900 W | 30 min 30 °C |

D * 100% | [68] |

| Photocatalysis: MW + OX + UV + TiO2 | |||||||

| Methylene Blue (aromatic compound) | 50 mL | 100 mg/L | TiO2 load pH = 7 |

900 W | 15 min 100 °C |

D * 96% M ** 50% |

[69] |

| 2,4–D chlorophenoxyacetic herbicide | 10 mL | 0.04 mmol/L | TiO2 load pH = 4.9 |

700 W | 20 min 200 °C |

D * 100% | [70] |

| Bisphenol A (Endocrine disruptor) | 30 mL | 0.1 mM | TiO2 load pH = 6.7 |

1500 W | 90 min 150 °C |

M ** 100% | [71] |

| Phenol | 50 mL | 10 mg/L | TiO2/AC | 900 W | 30 min 1000 °C |

D * 87% | [72] |

| Atrazine | 50 mL | 20 mg/L | TiO2 nanotubes pH = 8.1 |

900 W | 5 min 20 min |

D * 100% M ** 98.5% |

[72] |

D *—destruction efficiency; M **—mineralisation efficiency.

The addition of microwaves to oxidising agents accelerates the oxidation of organic compounds due to dipolar polarisation. For each pollutant, the form of oxidising agents, necessary doses, and reaction conditions (including temperature, strength, and treatment period MW) are calculated separately [64,66]. Microwave capacity ranges from 300 W to 900 W, temperature ranges from 20 °C to 130 °C, and processing time ranges from three minutes to one hour, depending on sample volume. Thus, the pollutant characteristics and their resistance to temperature and chemical factors affect the variance of parameter values.

Various catalysts, such as ferromagnetic metal, transition metal oxides, various types of activated carbons, and others, are applied to the water to increase the MW oxidation of organic compounds. The catalysts can be added to the water in two different ways: a suspension accompanied by sedimentation or a fixed filter plate. At the same time, the removal efficiency for a wide range of organic pollutants is about 85–100% [9].

A promising technology for the degradation of organic pollutants, even from the stage of mineralisation, is considered to be catalytic oxidation by moist air (CWAO) under conditions of high temperature (180–315 °C) and pressure (2–25 MPa), with the addition of catalysts [9]. The photo-Fenton process is based on the use of the Fenton reagent, that is, a mixture of Fe2+ salt (catalyst) and hydrogen peroxide (oxidiser) in combination with ultraviolet irradiation (UV). The study [9] provides research on the decomposition and mineralisation of different organic pollutants and reveals that compared to Fenton and photo-Fenton processes without MW, the decomposition rate of various pollutants increases by at least 50 times.

Electrodeless discharge lamp (EDL) use eliminates the issue of electrode destruction in a conventional mercury-based UV lamp. EDL consists of a glass tube—a plasma chamber filled under reduced pressure with argon and excitable matter (Hg, HgI2, Cd, I2, KI, P, Se, and S) and generating UV radiation under the action of MW (direct photolysis–MWDP). Together with microwaves and oxidising agents, MWDP is considered the most effective by many authors [9,67,68,74,75].

Microwave photocatalysis emerged to speed up and deepen organic carbon oxidation and mineralisation reactions, preventing secondary corrosion and iron-containing sediment production. The TiO2 semiconductor photocatalyst is commonly used in this method in grains, nanoporous films, and nanotubes. In addition, the TiO2 composite catalyst supported on activated carbon TiO2/AC shows good results [9].

The authors [9,13,65,76] consider the most critical factors influencing the efficiency of decomposition and mineralisation of organic pollutants based on comprehensive experimental experience with microwaves for the removal of organic pollutants: microwave power (W), irradiation time (min), and exposure temperature (°C).

In complex treatment, the optimum dosages of oxidising agents and catalysts, pH values, and air supply parameters to the device must be determined. In addition to the influencing factors mentioned above, the light intensity and amount of oxygen in the solution are applied to photocatalysis and microwave photolysis reactions [70]. Thus, each specific organic contamination must determine the optimal values of these parameters of microwave exposure, depending on the required efficiency of destruction and mineralisation.

One urgent task of applying innovative oxidation methods is to optimise energy consumption, particularly when using microwaves. Hence, according to the authors [9], the least energy-intensive methods are MW+K and MW+UV+TiO2; the most energy–intensive is water treatment using only microwaves [60]. On the other hand, MW radiation in the pulsed mode significantly saves energy [9,60].

The prospect of using MW in wastewater treatment is more justified in the presence of challenging organic substances that are not biodegradable.

Microwave irradiation has several practical uses, including the oxidation of synthetic dyes in the wastewater of industrial establishments in the textile, leather, cosmetic, food, paper, pharmaceutical, and other industries. In the presence of oxidants and catalysts, a 65–100% reduction in dye concentration can be achieved in 1.5–210 min at MW power of 150–900 W [73,74,75,77,78,79,80].

There is confirmation of successful MW oxidation of naphthenic acid, typical for industrial wastewater of oil-producing enterprises [81]. MW can be used for complex oxidation of wastewater containing ammonia [63], phosphorous compounds [65], phenols [9,62], pesticides [61], PAA [62], medical preparations [9], and other elements.

5. Biogas Processing

European and Asian experience in managing liquid municipal waste gives preference to the anaerobic treatment of wastewater and sediments to produce biogas. The maximum number of biogas plants operate in China—approximately fifteen million, and India—about ten million. The construction of biogas plants is actively developing in Europe, especially in Germany, with more than 9000 stations. Only 7% of the biogas produced by these enterprises goes to the gas pipelines. The rest is used for the manufacturer’s needs. In the future, 10–20% of the natural gas used in the country can be replaced with biogas [93,94,95].

The biogas market is growing much more slowly in countries with natural gas resources. For example, only about 200 biogas plants operate on agricultural waste in the United States [95]. In Russia, the production of biogas is implemented in only a few WWTP [96].

Today, the anaerobic treatment of wastewater and sediments to produce biogas guarantees fuel and energy savings. However, there are problems related to the quality of the treated material, the provision of conditions for the stability of the biodegradation of organic matter, and the explosion hazard of biogas production [97,98].

Microwaving is a novel thermal pretreatment process for sludges that improves digestion efficiency and, under certain conditions, can intensify the gas output by 15–32% due to the solubilisation and hydrolysis of organic substances [99,100,101,102,103,104,105]. Previous studies have shown that MW pretreatment is more effective for sludge with a high concentration of solid particles [101,102]. It is also proved that in the thermophilic fermentation mode, the yield of biogas from the MW-treated sediment is higher than in the mesophilic mode [99]. The results of modern studies based on [99,106] are presented in Table 9.

Table 9. Intensification of the biogas output during the MW treatment of WWS.

| Sediment | MW Power and Frequency | Temperature | Sample Processing Conditions | Description of Results | [Ref./No] |

|---|---|---|---|---|---|

| Domestic wastewater sludge mixture, ratio 48:52 | 1250 W 2.45 GHz |

96 °C | 500 mL samples heated in a home MW furnace to the boiling point, then subjected to anaerobic digestion in laboratory reactors for 5–18 days; biogas output recorded. | With thermophilic fermentation, the gas output increased by 17–26%. |

[99] |

| Dehydrated WWS | 1200 W 2.45 GHz |

80–160 °C | Samples heated and kept at a set temperature for 1 min, then cooled for 25 min. Heating speed 7.5 °C/min. Further, the samples were subjected to anaerobic digestion in laboratory reactors for 5–20 days; biogas output was recorded. | Maximal biogas output: At 160 °C- on the fifth day of the fermentation process. At 120 °C on the tenth day. | [105] |

| Sludge mixture | 300–600 W 2.45 GHz |

no data | Microwave pre-treatments were carried out in a semi–pilot MW unit in which the flow rate varied in the range of 5–60 L/h. Next, anaerobic digestion of the nitrogen-treated sludge mixture was carried out at a temperature of 37 degrees. | The biogas production improved by 174–210% (depending on the MW power and irradiated energy) | [106] |

This entry is adapted from the peer-reviewed paper 10.3390/w13131784

This entry is offline, you can click here to edit this entry!