A brief overview of the main photovoltaic technologies is chronologically presented. Single-crystal and multi-crystalline, epitaxial and thin film inorganic materials are widely used as absorbers in high efficiency solar cells and modules. A schematic representation of the principal devices developed in more then 70 years of research will be displayed and commented. Among thin-film technology, cadmium telluride (CdTe) has achieved a truly impressive development that can commercially compete with silicon, which is still the king of the market. Solar cells made on a laboratory scale have reached efficiencies close to 22%, while modules made with fully automated in-line machines show efficiencies above 18%. Based on the research developed in our laboratory, the fabrication processes of both CdTe polycrystalline thin-film solar cells and photovoltaic modules are critically discussed. The most common substrates, the constituent layers and their interaction, the interfaces and the different “tricks” commonly used for obtaining highly efficient devices will be analyzed. A realistic industrial production process will be analytically described.

Solar cells and photovoltaic (PV) modules have been intensively studied since the 1950s, when a Si-based p/n junction, able to convert sunlight into electrical energy, was made for the first time. Since then, many steps for obtaining more and more efficient devices have been made, both with laboratory-scale solar cells and with commercial PV modules.

Many different materials were studied, which gave rise to their respective technologies. Others have been abandoned due to the inability to obtain power conversion efficiencies (PCE) high enough to be used in large-scale industrial production, or because they did not produce devices that were sufficiently stable over time [

1,

2]. Among the most successfully technologies are certainly those based on single- and multi-crystalline Si [

3,

4], widely used in terrestrial PV generators and multi-junctions based on GaAs technology, which are essentially used for space applications [

3].

In addition to Si technology, alternative materials and production processes have been developed in order to easily realize solar devices. The research was pushed towards the optimization of the PCE/cost ratio, decreasing the amount of constituent materials and using easily available low-cost substrates, such as soda-lime glass, polymers or thin metallic foils. This was the beginning of the thin-film technology, which demonstrated its potential when a fully automated in-line machine produced the first PV module based on amorphous Si (a-Si) [

5]. The success of this technology is mainly due to two other materials: CdTe and Cu(In, Ga)Se

2 (CIGS) which, thanks to the high efficiency obtained in recent years both on laboratory scale and in large modules [

3], have completely replaced a-Si. Currently, a-Si finds its principal use in consumer electronics, such as calculators, watches, toys and gadgets, while the PV market is almost completely governed by multicrystalline silicon (mc-Si), relegating thin film technology to a small percentage of the market. This is firstly due to the fact that Si technology was the first implemented at an industrial level, secondly thin film technology developed high-efficiency modules only in the last ten years, when the PV market was already well-established. However, thin film technology, with its CdTe and CIGS diamond tips, is gaining more and more space in the PV market due to its excellent performance and the over-time stability achieved in recent years.

Nowadays, the increasing demand for environmentally friendly technologies pushes research towards new absorber materials made of non-polluting and abundant elements on the earth’s crust such as: Cu2ZnSnS4 (CZTS), SnS and Sb2Se3 between inorganics and perovskites and polymers among organic substances. The research on these systems is still young; for this reason, the final performance and the over-time stability of the solar cells based on these absorbers have certainly improved.

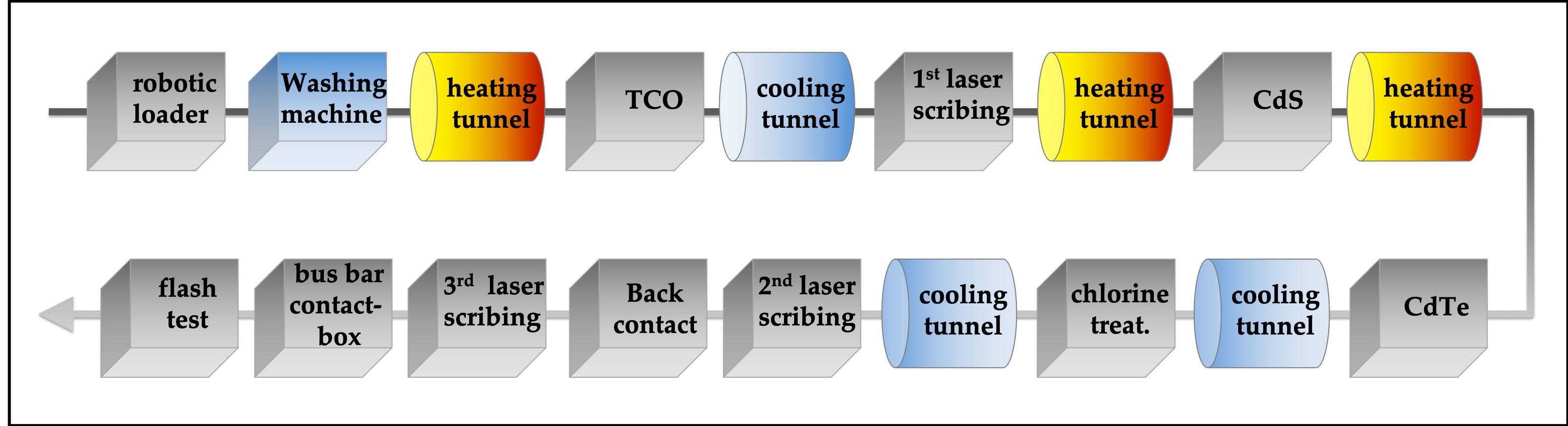

Schematic of the in-line machine for the production of large PV modules based on CdTe technology.

This entry is adapted from the peer-reviewed paper 10.3390/coatings10040344