Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Biodiesel, a mixture of fatty acids alkyl esters shows properties, which make it a feasible substitute for fossil diesel. Biodiesel can be produced using different processes and different raw materials. The most common, first generation, biodiesel is produced by methanolysis of vegetable oils using basic or acid homogeneous catalysts. The use of vegetable oils for biodiesel production raises serious questions about biodiesel sustainability. Used cooking oils and animal fats can replace the vegetable oils in biodiesel production thus allowing to produce a more sustainable biofuel.

- biodiesel

- vegetable oils

- animal fats

1. Biodiesel

Biodiesel, a mixture of alkyl esters produced of fatty acids is highlighted out as a feasible renewable and low carbon substitute of fossil diesel for the transportation sector [1]. Biodiesel can be used pure or blended with petroleum diesel due to its complete miscibility. Biodiesel blends are referred to as Bxx, where the xx indicates the amount of blend. Thus, B100 corresponds to pure biodiesel, and a B80 blend is 80% biodiesel and 20% petroleum diesel by volume.

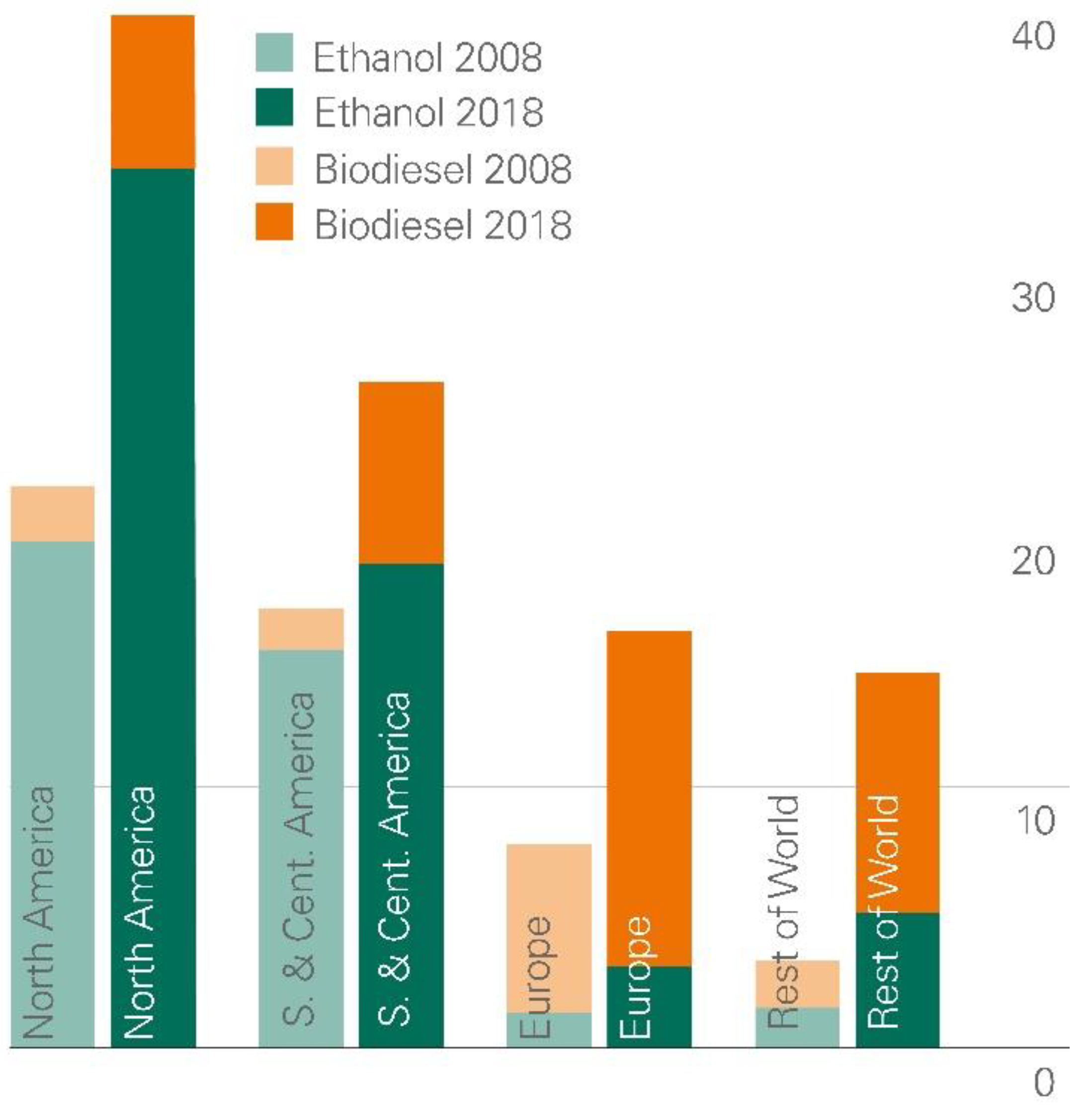

Worldwide Europe is the main producer of biodiesel as a result of the environmental policy (Figure 1). Diverse feedstocks can be employed in biodiesel production. Nowadays biodiesel worldwide production is still dominated by vegetable oils: soybean, rapeseed, and palm oil. In the USA the main raw material used is soybean oi, with a 52% share of total biodiesel feedstocks, followed by canola oil and corn oil with 13% each [2]. In Europe, rapeseed oil was the major feedstock used, with 45% of the total production in 2017, followed by used cooking oil (UCO) with 21% and palm oil with 18% [3]. For example, in Portugal, rapeseed is the main vegetable oil used, followed by soybean oil.

Figure 1. World ethanol and biodiesel production from 2008 to 2018 (vertical axis in million tonnes oil equivalent) [4].

2. Advantages and Disadvantages

- ⬬

-

Biodegradability;

- ⬬

-

Non-flammable and low toxicity;

- ⬬

-

Safer to handle;

- ⬬

-

Higher combustion efficiency, portability, availability, and renewability;

- ⬬

-

Higher cetane number and flash point;

- ⬬

-

Lower emissions such as CO2, CO, SO2, particulate matter (PM) and hydrocarbons (HC) compared to diesel;

- ⬬

-

May be blended with diesel fuel at any proportion;

- ⬬

-

No required engine modification up to B20;

- ⬬

-

Excellent properties as a lubricant.

There are also some disadvantages of using biodiesel that must be taken into consideration:

- ⬬

-

Lower calorific value;

- ⬬

-

Higher pour and cloud point fuel;

- ⬬

-

Higher nitrous oxide (NOx) emissions (in some cases);

- ⬬

-

Higher viscosity and less oxidative stability;

- ⬬

-

Biodiesel is corrosive to copper and brass;

- ⬬

-

May degrade plastic and natural rubber gaskets and hoses when used in pure form;

- ⬬

-

Biodiesel causes excessive engine wear.

The main restriction for biodiesel commercialization is its higher cost in comparison to petroleum fuel. Raw materials price represents 70–95% of the total production cost [9].

3. Transesterification

Biodiesel is produced by transesterification of triglycerides with short-chain alcohols in the presence of a catalyst. Due to the reversibility of the reaction, it is necessary to use an excess of alcohol to drive the reaction equilibrium [10]. However, the transesterification reaction can be done without a catalyst through supercritical process reactions [11]. This process consists of three consecutive reversible reactions where triglycerides are converted into diglycerides, diglycerides are converted into monoglycerides and finally, monoglycerides are converted into glycerol. In addition, for each glyceride that reacts the formation of an ester (biodiesel) molecule occurs [12].

Various parameters affect the transesterification reaction. In order to produce biodiesel that meets the standard quality parameters, production processes must be optimized [13]. The most relevant, processual and quality, parameters are [13][14][15]:

- (1)

-

Free fatty acids, moisture and water content.

- (2)

-

Type of alcohol and molar ratio employed.

- (3)

-

Type and concentration of catalysts.

- (4)

-

Reaction temperature and time.

- (5)

-

Rate and mode of stirring.

- (6)

-

Purification process of the final product.

- (7)

-

Mixing intensity.

- (8)

-

Effect of using organic co-solvents.

- (9)

-

Specific gravity

Glycerol, also known as glycerin (commercial term, purity > 95%), is a by-product of transesterification reactions. About 1 kg is produced for each 10 kg of biodiesel [16]. Glycerol is a nontoxic, edible and biodegradable compound used as a raw material in different industries, such as pharmaceuticals, cosmetics, tobacco, textiles or foods [16][17]. Due to its commercial value, in transesterification reaction beyond the biodiesel quality it is also important to obtain glycerol with high purity.

4. Alcohol Used

In biodiesel production, different alcohols can be used, such as methanol, ethanol, propanol or butanol [18]. The most commonly used are methanol and ethanol, and the reaction product produced when methanol is used is called a fatty acid methyl ester mixture (FAME) whereas if the alcohol is ethanol, the product obtained is a fatty acid ethyl ester mixture (FAEE) [18].

The mild reaction conditions needed, the fast reaction time and the easy phase separation combined with its low-cost and industrial availability make the methanol the most used alcohol in biodiesel production [18][19]. However, the use of this alcohol presents some drawbacks. Methanol is more toxic, volatile and has a lower oil dissolving capacity than ethanol. Although methanol can be obtained from biomass gasification, this alcohol is majorly produced from a fossil sources, about 90% from natural gas. Thus, the biofuel produced by methanolysis is not considered fully renewable biodiesel [20].

Besides, ethanol is made from agricultural products such as potatoes, grain, and corn, allowing this way the production of a renewable fuel [21]. Due to the extra carbon atom, the FAEE produced has a cloud and pour point lower than FAME, which allows the engine to start low temperatures [22]. The combustion heat and the cetane number are higher and the storage properties of FAEE fuel are also improved [19]. The main drawbacks of ethanolysis in biodiesel production are its lower reactivity, compared with methanol, as well as the more difficult separation of FAEE from the coproduced glycerin due to their higher miscibility [23].

Many studies have been carried out to compare the effect of methanol and ethanol on biodiesel production from different feedstocks [24][25][26][27]. All achieved results reported that the yield obtained by ethanolysis is lower and more time is needed to complete the reaction than for methanolysis. The separation of FAEE from glycerin is also more difficult. Nevertheless, it allows achieving a completely renewable biodiesel. Although several alcohols can be used to produce biodiesel, so far European Union legislation only covers FAME.

5. Feedstocks

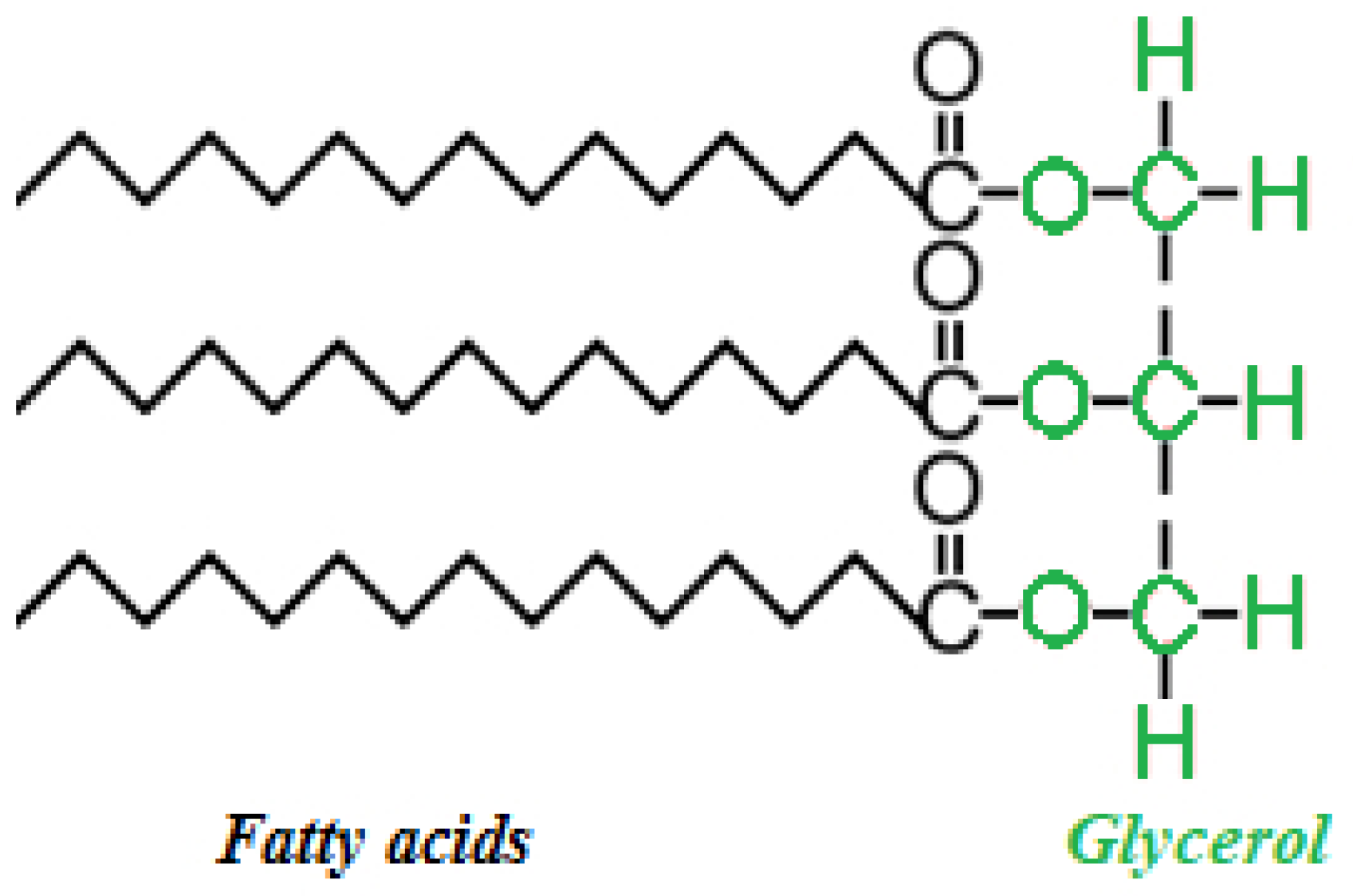

As mentioned before several feedstocks can be employed in biodiesel production such as vegetable oils (edible and non-edible), waste cooking oils, animal fats and algae oils [28]. The chemical structure is similar in vegetable oils and animal fats, mainly composed by triglycerides with a smaller fraction of diglycerides and monoglycerides [9]. Triglycerides (Figure 2) are formed by one molecule of glycerol combined with three molecules of saturated or unsaturated fatty acid.

Figure 2. Triglyceride [29].

Both feedstocks are water-insoluble, hydrophobic and soluble in nonpolar organics solvents [9]. The main differences between them are the varied distributions of fatty acids and the high free fatty acids (FFA) content in the fats.

Animal fats and greases, at room temperature, tend to be solid due to their high content of saturated fatty acid (carbon-carbon single bond), oils are generally liquids. Refined oils have less FFA, lower acid value, than animal fats, waste grease and waste oils [9].

Based on their feedstock, biodiesel can be classified into three categories: first, second and third generation:

First generation refers to biodiesel derived from edible vegetable oils. The most commonly used are rapeseed, palm, soybean, coconut, peanut, and sunflower [30]. The vegetable oils are widely available and relatively easier to convert into biodiesel. However, the use of edible vegetable oils in the production of biofuel raises several ethical issues. Edible vegetable oils come from food crops. The use of arable land, water, and fertilizer in “growing fuel” instead of food not only affects the food price but also sustainability issues [30].

Furthermore, even if the total amount of edible oils available was used in the production of biodiesel, it was not enough to meet today’s diesel requirements. These concerns ally with the double counting of biofuels produced from wastes, which have led to an increasing search for more sustainable feedstocks.

Second generation biofuels are biodiesels derived from non-edible crops or feedstocks that have already fulfilled their food purpose such as waste oily streams from the oil refinery, waste cooking oils (WCOs), greases and waste animal fats (WAFs) [31]. The non-edible crops can be grown on lands that cannot be used for arable crops that have a lower necessity of water or fertilizer to grow, making their plantation more economic [31]. The WCO refers to vegetable oils or animal fats that had been heated and used for cooking different types of food. During this process, various chemical reactions occur such as hydrolysis, polymerization, and oxidation modifying the physical and chemical properties of oil/fat [32]. Recycled fats, based on their FFA level, can be divided as yellow or brown grease. The yellow greases have a FFA level of less than 15% while, brown has more than 15% [32]. The second generation also includes WAFs or rendered animal fats, this topic will be explored in the next chapter. The use of these less expensive feedstocks reduces the production costs and reuse wastes, without competing with the food market [33]. The prices of feedstocks are unstable.

Third generation are the biodiesels derived from algal biomass.

Independently of the feedstock category used, the physical and chemical properties of the biodiesel are the same [34].

Animal Fats

Biodiesel production can be also done with animal fats as raw materials such as tallow, lard, poultry fat and fish oils (Figure 3) [9]. Animal fats are wastes or by-products that came from animal meat processing industry and carcasses of livestock, with relatively low prices.

Figure 3. Tallow, lard, fish oil, and poultry fats.

In the European Union the regulation (EC) No 1069/2009 and No 142/2011 lays down health rules as regards animal by-products and derived products not intended for human consumption. These materials can be categorized into three specific categories considering the perceived level of risk to public and animal health [35]:

Category 1 (high risk):

- ✓

-

Specified Risk Material (SRM) linked with the transmission of TSEs (Transmissible Spongiform Encephalopathies), this includes the spinal cord and brain.

- ✓

-

Fallen stock with SRM

- ✓

-

Catering waste

- ✓

-

Anything handled with Category 1

Category 2:

- ✓

-

Material not fit for human consumption and posing a risk to animals and humans

- ✓

-

Fallen stock without SRM

Category 3 (lowest risk):

- ✓

-

Fit for human consumption at the point of slaughter

Fats are recovered from waste fat tissues by the rendering process. This process depends on the risk category and to prevent contamination between different categories of waste and different species, all processing is done on separated lines [35].

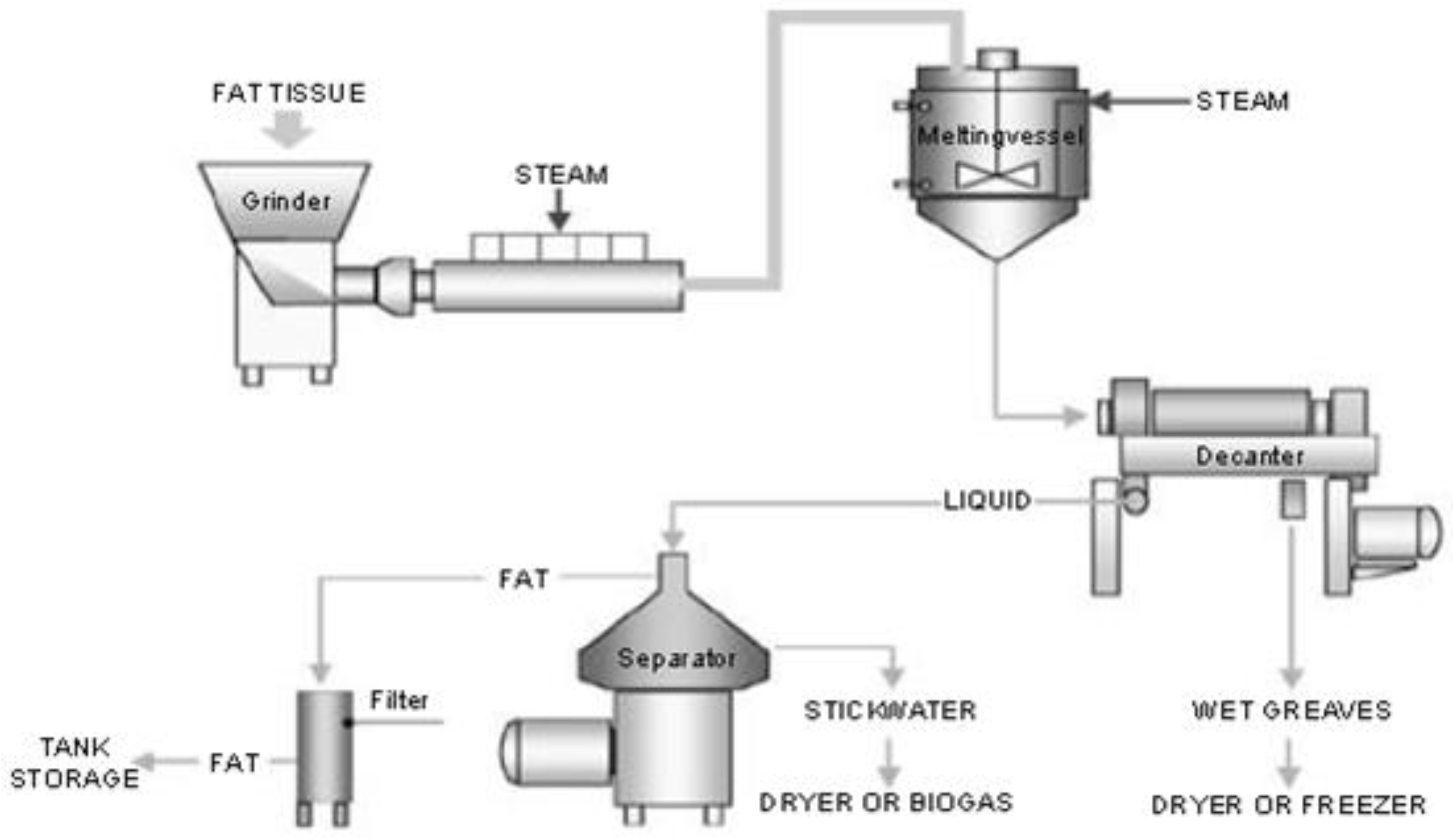

Many types of rendering are used in the industry. All of them involve the application of heat, the extraction of moisture, and the separation of fat [36]. The fat can mainly be recovered from wet or dry rendering. In wet rendering (Figure 4), the fat is recovered by heating in the presence of water. Boiling in water and/or steam at a high temperature can be employed [36][37]. The color of the fat produced by this process is clearer. The free fatty acid content increases due to the long contact with water [36].

Figure 4. Wet rendering [37].

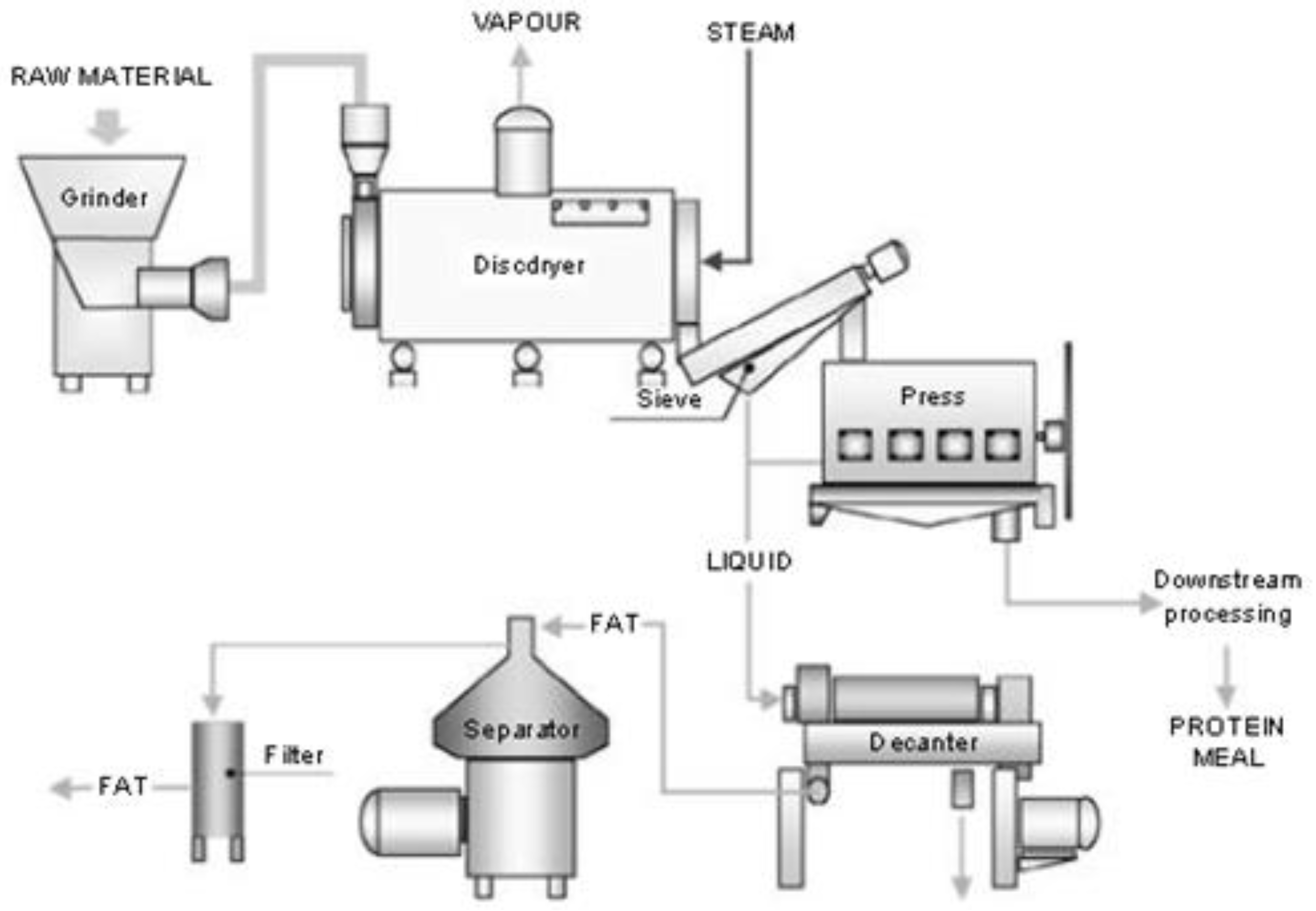

In dry rendering (Figure 5), in either batch or continuous processes, the fat tissues are cooked in their “own juices” with dry heat [37].

Figure 5. Dry rendering [38].

There is no rule when and where wet or dry rendering is ideal, but it can be observed that the lard and tallow from wet rendering are better than from dry rendering [37]. The rendering process may also be done using an organic solvent.

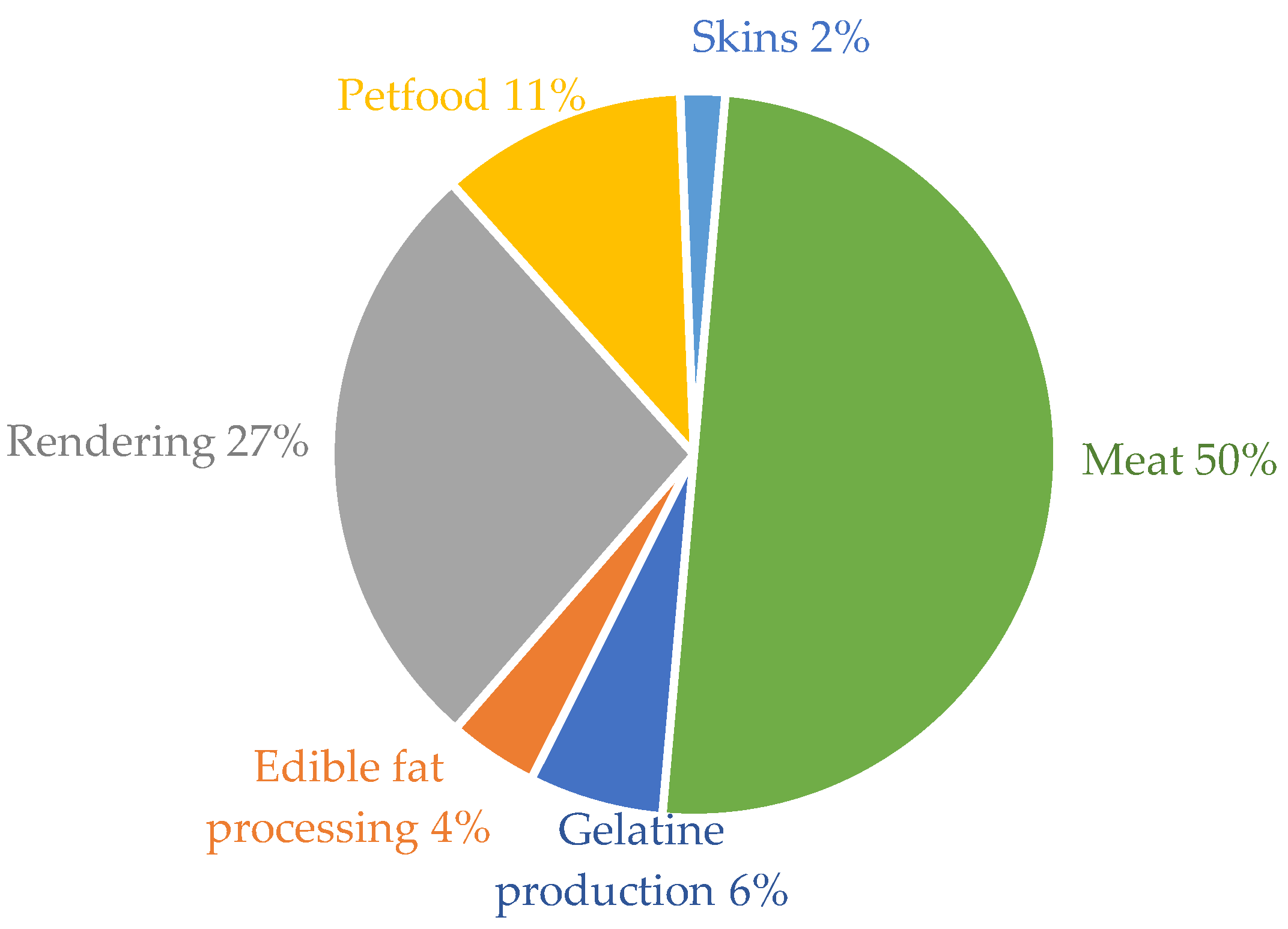

Usually, fats are further used in food, pet foods, feed applications but can also be transformed into soaps and oleochemicals (Figure 6), depending on the risk category [39]. All fats can be employed as feedstocks in biodiesel production.

Figure 6. Estimated utilization of slaughtered animal (by % weight) [38].

6. Biodiesel Production from Animal Fats Versus Vegetable Oils

In terms of emission of pollutant gases, the advantages of replacing diesel with biodiesel produced from animal fats or obtained from vegetable oils are similar, since the emissions from burning generate similar results. However, Wyatt et al. have reported that three animal fats-based B20 biodiesel blends obtained from lard, beef tallow and chicken fat had lower nitrogen oxide (NOx) emission levels than B20 blend produced from soy oil [40].

In comparison with biodiesel from vegetable origin, biodiesel from animal fats has several advantages. Due to its lower content of unsaturated fatty acids, biodiesel produced from animal fats has a higher cetane number than biodiesel from the most vegetable oils and diesel fuel [9][28]. The cetane number increases with the increment of fatty acid carbon chains and the increase in degree of saturation [41]. A higher cetane number is recognized to lower NOx emissions [28]. Biofuel from animal fats has also a higher calorific value [28]. A nonconsensual issue is the oxidative stability of animal-based biodiesel. Some authors claim that animal fat-based biodiesel is less stable for oxidation due to the absence of natural oxidants as compared to biodiesel from vegetable oil [42][43][44]. On the other hand, others, claim that from the content of saturated fatty acid, the addition of animal fat improves the oxidative stability of biofuel [28][45][46]. Feedstocks rich in polyunsaturated fatty acids are more susceptible to oxidation, due to the presence of double bonds in the chains, than feedstocks rich in saturated or monounsaturated fatty acids [47].

Pereira et al. evaluated the effect of blending vegetable with animal-based biodiesel on the oxidative degradation of this biofuel. The authors reported that blends of soybean/beef tallow biodiesel presented a higher oxidative stabilities in comparison with soybean biodiesel [46]. Wyatt et al. also reported that the oxidative stability of biofuel from lard, beef tallow, and chicken fat is equivalent or better than soybean biodiesel [40]. However, Sendzikiene et al. [48] showed that biofuel from animal fats such as lard and tallow is less stable for oxidation than rapeseed and linseed oil. Fuel produced from fats has also some disadvantages, such as the higher cold filter plugging point (CFPP) due to a significant content of saturated fatty acids [42][43][44]. The CFPP refers to the lowest temperature at which a given volume of liquid fuel will still flow through a specific filter in a specified time when cooled under certain conditions [49]. This is an important property to cold temperature countries.

This entry is adapted from the peer-reviewed paper 10.3390/en12234408

References

- European Union Directive (EU) 2009/28. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2009:140:0016:0062:EN:PDF (accessed on 12 February 2019).

- Biodiesel Explained—U.S. Energy Information Administration (EIA). Available online: https://www.eia.gov/energyexplained/biofuels/biodiesel.php (accessed on 14 April 2019).

- Phillips, S.; Flach, B.; Lieberz, S.; Lappin, J.; Bolla, S. EU Biofuels Annual 2018. Available online: https://apps.fas.usda.gov/newgainapi/api/report/downloadreportbyfilename?filename=Biofuels%20Annual_The%20Hague_EU-28_7-3-2018.pdf (accessed on 14 April 2019).

- BP Statistical Review of World Energy 2019, 68th ed.; BP: London, UK, 2019.

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Adam, A.A.; Ishak, W.F.W.; Alenezi, R. Production, characterization and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–509.

- Romano, S.D.; Sorichetti, P.A. Dielectric Spectroscopy in Biodiesel Production and Characterization; Springer: London, UK, 2011.

- Islam, A.; Ravindra, P. Biodiesel Production with Green Technologies; Springer: Basel, Switzerland, 2016; ISBN 9783319452722.

- Moser, B.R. Biodiesel production, properties, and feedstocks. Vitr. Cell. Dev. Biol. Plant 2009, 45, 229–266.

- Banković-Ilić, I.B.; Stojković, I.J.; Stamenković, O.S.; Veljkovic, V.B.; Hung, Y.T. Waste animal fats as feedstocks for biodiesel production. Renew. Sustain. Energy Rev. 2014, 32, 238–254.

- Banerjee, A.; Chakraborty, R. Parametric sensitivity in transesterification of waste cooking oil for biodiesel production—A review. Resour. Conserv. Recycl. 2009, 53, 490–497.

- Shahid, E.M.; Jamal, Y. Production of biodiesel: A technical review. Renew. Sustain. Energy Rev. 2011, 15, 4732–4745.

- Avhad, M.R.; Marchetti, J.M. Innovation in solid heterogeneous catalysis for the generation of economically viable and ecofriendly biodiesel: A review. Catal. Rev. 2016, 58, 157–208.

- Atabani, A.E.; Silitonga, A.S.; Badruddin, I.A.; Mahlia, T.M.I.; Masjuki, H.H.; Mekhilef, S. A comprehensive review on biodiesel as an alternative energy resource and its characteristics. Renew. Sustain. Energy Rev. 2012, 16, 2070–2093.

- Ajala, O.E.; Aberuagba, F.; Odetoye, T.E.; Ajala, A.M. Biodiesel: Sustainable energy replacement to petroleum-based diesel fuel—A review. Chembioeng Rev. 2015, 2, 145–156.

- Mathiyazhagan, M.; Ganapathi, A. Factors affecting biodiesel production. Res. Plant Biol. 2011, 1, 1–5.

- Tan, H.W.; Abdul Aziz, A.R.; Aroua, M.K. Glycerol production and its applications as a raw material: A review. Renew. Sustain. Energy Rev. 2013, 27, 118–127.

- Luo, X.; Ge, X.; Cui, S.; Li, Y. Value-added processing of crude glycerol into chemicals and polymers. Bioresour. Technol. 2016, 215, 144–154.

- Borges, M.E.; Díaz, L. Recent developments on heterogeneous catalysts for biodiesel production by oil esterification and transesterification reactions: A review. Renew. Sustain. Energy Rev. 2012, 16, 2839–2849.

- Avramović, J.M.; Veličković, A.V.; Stamenković, O.S.; Rajković, K.M.; Milić, P.S.; Veljković, V.B. Optimization of sunflower oil ethanolysis catalyzed by calcium oxide: RSM versus ANN-GA. Energy Convers. Manag. 2015, 105, 1149–1156.

- Dalena, F.; Senatore, A.; Marino, A.; Gordano, A.; Basile, M.; Basile, A. Methanol production and applications: An overview. In Methanol: Science and Engineering; Elsevier: Amsterdam, The Netherlands, 2017; pp. 3–28.

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol production from agricultural wastes: An overview. Renew. Energy 2012, 37, 19–27.

- Watcharathamrongkul, K. Calcium oxide based catalysts for ethanolysis of soybean oil. Songklanakarin J. Sci. Technol. 2010, 32, 627–634.

- Velickovic, A.; Avramovic, J.; Stamenkovic, O.; Veljkovic, V. Kinetics of the sunflower oil ethanolysis using CaO as catalyst. Chem. Ind. Chem. Eng. Q. 2016, 22, 409–418.

- Rashid, U.; Ibrahim, M.; Ali, S.; Adil, M.; Hina, S.; Bukhari, I.H.; Yunus, R. Comparative study of the methanolysis and ethanolysis of Maize oil using alkaline catalysts. Grasas Aceites 2012, 63, 35–43.

- Verma, P.; Sharma, M.P. Comparative analysis of effect of methanol and ethanol on Karanja biodiesel production and its optimisation. Fuel 2016, 180, 164–174.

- García, M.; Gonzalo, A.; Sánchez, J.L.; Arauzo, J.; Simoes, C. Metanolysis and ethanolysis of animal fats: A comparative study of the influence of alcohols. Chem. Ind. Chem. Eng. Q. 2011, 17, 91–97.

- Meneghetti, S.M.P.; Meneghetti, M.R.; Wolf, C.R.; Silva, E.C.; Lima, G.E.S.; de Lira Silva, L.; Serra, T.M.; Cauduro, F.; de Oliveira, L.G. Biodiesel from castor oil: A comparison of ethanolysis versus methanolysis. Energy Fuels 2006, 20, 2262–2265.

- Adewale, P.; Dumont, M.J.; Ngadi, M. Recent trends of biodiesel production from animal fat wastes and associated production techniques. Renew. Sustain. Energy Rev. 2015, 45, 574–588.

- Fat Minami-Nutrition. Available online: https://socratic.org/questions/how-do-lipids-affect-the-digestive-systemhttp://www.minami-nutrition.co.uk/website/absorption.php (accessed on August 2006).

- Knothe, G.; Razon, L.F. Biodiesel fuels. Prog. Energy Combust. Sci. 2017, 58, 36–59.

- Živković, S.B.; Veljković, M.V.; Banković-Ilić, I.B.; Krstić, I.M.; Konstantinović, S.S.; Ilić, S.B.; Avramović, J.M.; Stamenković, O.S.; Veljković, V.B. Technological, technical, economic, environmental, social, human health risk, toxicological and policy considerations of biodiesel production and use. Renew. Sustain. Energy Rev. 2017, 79, 222–247.

- Canakci, M. The potential of restaurant waste lipids as biodiesel feedstocks. Bioresour. Technol. 2007, 98, 183–190.

- Dias, J.M.; Ferraz, C.A.; Almeida, M.F. Using mixtures of waste frying oil and pork lard to produce biodiesel. Energy Fuels 2008, 22, 3889–3893.

- Dias, J.M.; Alvim-ferraz, M.C.M.; Almeida, M.F. Mixtures of vegetable oils and animal fat for biodiesel production: Influence on product composition and quality. Energy Fuels 2008, 20, 3889–3893.

- EFPRA. What are the Three Categories? Available online: http://efpra.eu/which-byproducts-rendered/ (accessed on 22 November 2018).

- Meeker, D.L. Essential Rendering, All About The Animal By-Products Industry; The National Renderers Association: Alexandria, VA, USA, 2006; ISBN 0965466035.

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293.

- Woodgate, S.; van der Veen, J. The role of fat processing and rendering in the European Union animal production industry. Biotechnol. Agron. Soc. Environ. 2004, 8, 283–294.

- Giriprasad, R.; Sharma, H.; Goswami, M. Animal fat-processing and its quality control. J. Food Process. Technol. 2013, 4, 252.

- Wyatt, V.T.; Hess, M.A.; Dunn, R.O.; Foglia, T.A.; Haas, M.J.; Marmer, W.N. Fuel properties and nitrogen oxide emission levels of biodiesel produced from animal fats. J. Amer Oil Chem Soc. 2005, 82, 585–591.

- Knothe, G.; Krahl, J.; Van Gerpen, J. The Biodiesel Handbook; AOCS Press: Urbana, IL, USA, 2005; Volume 1.

- Encinar, J.M.; Sánchez, N.; Martínez, G.; García, L. Study of biodiesel production from animal fats with high free fatty acid content. Bioresour. Technol. 2011, 102, 10907–10914.

- Dias, J.M.; Alvim-Ferraz, M.C.M.; Almeida, M.F.; Méndez Díaz, J.D.; Polo, M.S.; Utrilla, J.R. Selection of heterogeneous catalysts for biodiesel production from animal fat. Fuel 2012, 94, 418–425.

- Avhad, M.R.; Marchetti, J.M. A review on recent advancement in catalytic materials for biodiesel production. Renew. Sustain. Energy Rev. 2015, 50, 696–718.

- Pinzi, S.; Leiva-Candia, D.; López-García, I.; Redel-Macías, M.; Dorado, M. Latest trends in feedstocks for bioidesel production. Biofuels Bioprod. Biorefin. 2014, 8, 126–143.

- Pereira, G.G.; Garcia, R.K.A.; Ferreira, L.L.; Barrera-Arellano, D. Soybean and soybean/beef-tallow biodiesel: A comparative study on oxidative degradation during long-term storage. J. Am. Oil Chem. Soc. 2017, 94, 587–593.

- Canakci, M.; Sanli, H. Biodiesel production from various feedstocks and their effects on the fuel properties. J. Ind. Microbiol. Biotechnol. 2008, 35, 431–441.

- Sendzikiene, E.; Makareviciene, V.; Janulis, P. Oxidation stability of biodiesel fuel produced from fatty wastes. Pol. J. Environ. Stud. 2005, 14, 335–339.

- Kumar, M.; Sharma, M.P. Selection of potential oils for biodiesel production. Renew. Sustain. Energy Rev. 2016, 56, 1129–1138.

This entry is offline, you can click here to edit this entry!