Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is an old version of this entry, which may differ significantly from the current revision.

Subjects:

Chemistry, Analytical

Metal oxides, because of their remarkable properties including high electrical capacity and mixed ion-electron conductivity, have found applications as both sensing layers (e.g., of screen-printing pH sensors) or solid-contact layers and paste components in solid-contact and paste-ion-selective electrodes.

- metal oxides

- constructions of sensors

- solid-contact electrodes

1. Metal Oxides

1.1. Characterization of Metal Oxides as Electrode Materials

One of the most known constructions of a potentiometric sensor is the solid-contact electrode. When choosing the material for solid-contact layers in potentiometric sensors, some key aspects must be taken into careful consideration.

Firstly, the material must enable an efficient ion-electron exchange process at the electrode | ion-selective membrane interface. Those processes are associated with either high redox capacitance or high double-layer capacitance. Redox capacitance is associated with the electron and ionic conductivity of materials in which exchange processes occur through reversible redox reactions, while double-layer capacitance surface development results from the nanometric size of particles or pores in the material structure.

Due to the nanometric size of its particles, nanostructured metal oxides are characterized by a high surface area. Besides its favorable morphology, some metal oxide nanomaterials such as ruthenium or iridium dioxide exhibit excellent redox properties. One of the mechanisms proposed by Fog et al. in [49] is that in contact with hydrogen ions, the oxide undergoes a redox reaction in which ions and protons are exchanged. This mechanism decides the ability of the oxide to transduce both ions and electrons through the layer, which simplifies the processes on the interface between the ion-selective membrane and the electronic conductor. The combination of those two properties—high surface area and high redox capacitance [4]—in one material makes it a great choice for the solid-contact layer.

In addition to the basic criterion of the presence of mixed ion-electron conductivity and high electrical capacitance, materials for solid-contact layers must meet a number of other requirements, including high hydrophobicity, chemical stability of the material, and the absence of side reactions occurring during the electron-ion exchange process [22,27,72,73].

The wettability of the solid-contact material is of particular importance in the context of the formation of an undesirable aqueous layer between the ion-selective membrane and the electron conductor. In the literature, hydrophilic materials (characterized by low values of the wetting angle below 90°) introduced into the electrode design did not prevent the formation of a water layer, unlike hydrophobic materials (with wetting angles above 90°), which have been repeatedly proven to protect sensors from the unwanted water layer and susceptibility to drop off of the ion-selective membrane [35,74,75]. Metal oxides, especially hydrous forms of oxides, are characterized by low wetting angle values and are defined as a hydrophilic material. Besides this property, even after prolonged use and conditioning of the electrodes in aqueous solutions, an aqueous layer did not form. This may be due to a specific reaction occurring on the surface of the ruthenium oxide layer [49] and/or large surface development that conditions the solid-contact layer to adhere strongly to the membrane, preventing it from peeling off the electrode surface.

The opposite requirements concerning wettability relate to electrodes without an ion-selective membrane. In this construction of an electrode, the metal oxide nanoparticle layer contacts the analyzed fluid and must be easily wettable by aqueous solutions. Taking this into account, hydrophilic metal oxides with contact angles below 30 degrees are perfect for the sensing layer in potentiometric sensors for pH measurement.

In the context of the design of paste electrodes, the material used as a paste should meet certain requirements. These include providing a quick and reversible transition from ionic to electronic conductivity and having a nonpolarizable surface between the paste and the high-capacity red-ox or double-layer ISM. In addition, the paste should be hydrophobic and characterized by low water absorption, which prevents the formation of a water layer. Moreover, the materials for the paste should be readily available and non-toxic. Similar to the case of solid-contact electrodes, metal oxides were proven to be great materials for paste electrode modification and production [76].

In addition, metal oxides exhibit a combination of unique properties, such as high thermal and chemical stability and low resistivity [11].

1.2. The Action Mechanism of Metal Oxides

The action mechanism is described based on the behavior of ruthenium oxide after contacting the electrolyte. According to the reaction mechanism proposed by Fog and Buck [49], ruthenium oxide in contact with hydrogen ions undergoes redox reactions, in which both ions and charged elementary parts are exchanged. The action mechanism of metal oxides is based on the redox reactions. These processes are initiated by electrons (e−) and protons (H+) introduced to the surface of the dioxide from the electrolyte, as presented in the following reaction [77]:

RuO2 + xH + xe = RuO2 − x(OH)x, where 0 ≤ x ≤ 2

This mechanism is used indirectly when designing sensors for pH determination with metal oxides acting both as a sensing layer and as a solid-contact layer.

In the literature [78], it was noted that the insertion of other cations, for example, potassium ions, into the porous dioxide layer also participates in the mentioned mechanism. As presented by Wen et al. [79], monovalent cations may act as hydrogen ions in the presented reaction and, as protons, lead to faradaic reactions. This feature was used when designing potentiometric sensors with an ion-selective membrane based on metal oxides for potassium determination [80].

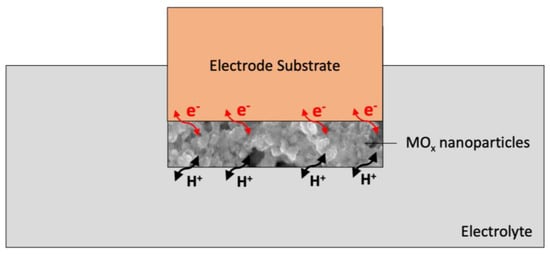

The schematic representation of the charge storage mechanism that occurs via the proton-electron transfer for the metal oxide (MOx) layer is presented in Figure 5.

Figure 5. Mechanism of ion-electron exchange at phase boundaries using a metal oxide (MOx) layer.

2. Metal Oxide Nanoparticles as a Sensing Material

Metal oxides as sensing materials are mostly used in pH sensors. Historically, the use of metal oxides in potentiometric sensors began in the 1980s when Fog and Buck introduced them for the first time as a sensing material for pH detection [49]. Some of the metal oxides were successfully applied as pH sensor materials and showed a near-Nernstian response in the pH range of 2–12. This research was followed by many publications by scientists searching for a replacement for the glass-membrane electrode.

Among the oxides used for the fabrication of pH sensors, the most commonly known and used are ruthenium oxide RuO2 and iridium oxide IrO2, characterized by remarkable sensitivity to hydrogen ions and high accuracy. Furthermore, the researchers can distinguish tantalum(V) oxide Ta2O5, titanium dioxide TiO2, tin(IV) oxide SnO2, cerium dioxide CeO2, tungsten trioxide WO3, lead dioxide PbO2, and mixed oxides: Bi2O3-Nb2O5, IrO2-TiO2, and RuO2-TiO2 for pH sensor applications. In addition to this, some work has been conducted in the area of metal/MOx-based pH sensors such as those based on antimony and bismuth. In these couples, the redox equilibrium between the metal/MOx phases (e.g., Sb-Sb2O3) is attributed to the origin of their pH sensitivity [81,82,83]. The sensitivity of the MOx pH sensor significantly depends on the type of material composition and the deposition method since both factors can influence the microstructure, porosity, surface homogeneity, and crystalline structure of the material. This leads to variation in the sensitivity of the electrodes. The sensitivity of the pH sensors is expressed in terms of the Nernstian response (the sensor is expected to show 59.14 mV/pH at 25 °C derived from the Nernst equation). Table 1 presents the comparison of analytical parameters of MOx-based sensors such as pH measurement range, slope of calibration curve, and time of response.

Table 1. pH sensors based on metal oxides—metal oxides as sensing materials.

| Material | pH Range | Slope [mV/pH] | Response Time | Reference |

|---|---|---|---|---|

| RuO2 | 1–13 | 55.64 | - | [60] |

| RuO2-TiO2 | 2–12 | 56.03 | - | [90] |

| RuO2-Ni | 1.5–12.5 | 52 | - | [86] |

| RuO2-NT | 2–12 | 55 | <40 s | [87] |

| RuO2-Ta2O5 | 2–12 | 56 | <8 s | [58] |

| RuO2-SnO2 | 2–12 | 56.5 | <5 s | [88] |

| IrO2 | 2–10 | 63.5 | ~1 min | [84] |

| IrO2-TiO2 | 1–13 | 59.1 | 120 s | [85] |

| Ta2O5 | 2–12 | 58–59 | <0.3 s | [61] |

| SnO2 | 2–12 | 58.1 | - | [91] |

| TiO2 | 1–11 | 58.73 | - | [89] |

| WO3 | 1–7 | 44.85 | - | [92] |

| WO3-NT | 2–12 | 41 | <90 s | [93] |

| CeO2 | 7.2–10.8 | 38 | - | [94] |

| PbO2 | 1.5–12.5 | 64.82 | <1 s | [95] |

| MnO2 | 2–12 | 78.3 | few seconds | [96] |

| CoO2 | 1–12 | 54.9 | <1 min | [97] |

List of abbreviations: NT—nanotubes, IrO2—iridium dioxide, RuO2—ruthenium dioxide, MnO2—manganium dioxide, CeO2—cerium dioxide, TiO2—titanium dioxide, Ta2O5—tantalum(V) oxide, SnO2—tin(IV) oxide, WO3—tungsten trioxide, PbO2—lead dioxide, CoO2—cobalt(II) oxide.

3. Metal Oxide Nanoparticles as Solid-Contact Layers

One of the observed trends in the development of potentiometric sensors is the search for new functional materials for the construction of solid-contact electrodes. These electrodes are characterized by sandwich-like construction with a solid-contact layer between the substrate electrode and the ion-selective membrane. The properties of the solid-contact layer directly translate into the properties of the sensors, allowing them to achieve lower and lower limits of determination, higher potential stability, and lower response times.

As already mentioned, one of the trends in modern potentiometry is the search for new materials for solid-contact layers, which, because of their properties, will improve the analytical and performance of solid-contact ion-selective electrodes. Since the 1990s, when conductive polymers were first introduced as a solid-contact layer, up to the present day, various types of materials have been introduced into electrode design with varying results [4,13].

A group of metal oxides can be classified as high redox capacity and high double-layer capacity materials, as they exhibit both high redox sensitivity and high surface area [49]. The implementation of metal oxide macro/nanomaterials as solid-contact layers, to support the ion-to-electron transduction processes, relies on two strategies: High specific surface area and high redox activity. Some of the tested metal oxides also appeared to meet all the other requirements for solid-contact layers; hence, they were considered promising materials for solid-contact electrode design.

The mechanism of the selective response to hydrogen ions, described and applied by Fog and Buck [49], was later implemented by many research groups in the design of ion-selective electrodes with solid-contact layers based on metal oxide.

The first implementation of metal oxide in membrane-based potentiometric sensors dates back to 2013 when the Khun group introduced ZnO nanorods as solid-contact material for Cr2+-ISEs and ZnO nanotubes in I-ISEs [98]. The hollow structures of ZnO nanotubes can provide a larger surface area than ZnO nanorods. Later, the same group presented the use of CuO nanoflowers in Cd2+-ISEs [99]. These electrodes exhibit a very advantageous LOD (level of detection) at the nanomolar level. In other studies, the Qin group proposed MoO2 microspheres as an ion-to-electron transducer (2017) [100]. Compared to the coated-disc electrodes, the introduction of MoO2 microspheres improves the sensor performance to some extent as a result of the enhanced double-layer capacitance. In 2019, Yang et al. manufactured solid-contact K+-ISEs based on MnO2 nanosheets for the determination of K+ in the blood [101]. The MnO2 nanosheets turned out to have a wrinkled morphology, thereby preventing their dense accumulation and maintaining the advantage of a large surface area, which is advantageous for achieving a large double-layer capacitance. Also in 2019, the Paczosa-Bator group introduced hydrous RuO2 nanoparticles into solid-contact H+—and K+-ISEs as ion-to-electron transducers. Remarkably, these RuO2 nanoparticle-based sensors exhibit a large redox capacitance at the millifarad level. Other oxides introduced by the Paczosa-Bator group in the construction of ion-selective electrodes were hydrous IrO2 (2021) [102], and a year later, hydrous CeO2 (2022) [103]. In 2022, Wardak’s group presented a paper on the use of ZnO, CuO, and Fe2O3 in potassium-sensitive electrodes [104].

Metal Oxide Nanoparticles-Based Hybrid Materials as Solid-Contact Layers

Metal oxides were also used as components of hybrid materials with remarkable success. In 2019, Zeng et al. introduced TiO2-PANI material into the Pb2+- selective electrodes. This material possessed a large specific capacitance, thereby effectively promoting ion-to-electron transduction and enhancing the potential response stability of electrodes [105].

Later, the Paczosa-Bator group presented composite materials containing RuO2 nanoparticles and conducting polymers POT (RuO2–POT) [106] and PEDOT:PSS [107] and composite material containing ruthenium dioxide and carbon nanomaterials [108]. All the mentioned hybrids were applied as solid-contact layers in K+- selective electrodes.

The RuO2–POT composite exhibits superhydrophobic properties (a contact angle of 149°). The results of electrochemical techniques demonstrate that these solid-contact electrodes possess a large capacitance of approximately 1.2 mF, which is much larger than that of the coated-disc electrode. Compared to single-component counterparts, K+-ISE based on the RuO2-POT composite exhibits a shorter equilibration time and better potential stability and reproducibility.

The RuO2-PEDOT:PSS composite allowed the acquisition of electrodes with an electrical capacitance of as much as 7 mF. It is worth mentioning that the value of 7.2 mF is one of the highest values presented in the literature for this type of electrode.

The addition of graphene, the representative of the carbon materials group, to ruthenium dioxide allowed the capacitance to increase to 2.6 mF, which is 2.5 times higher compared to the oxide alone.

In 2021, Su et al. designed electrodes with MoS2-Fe3O4 as an ion-electron transduction layer for the determination of serum potassium [109]. These sensors present high performance in potential reproducibility and long-term stability.

In 2022, Lenar et al. presented a composite material based on iridium dioxide, creating a hybrid material of not two but three different components. The layer of IrO2-POT-MWCNT turned out to be superhydrophobic with a contact angle of 178°, which resulted in great stability in potentiometric response and long lifetime. This layer was introduced in K+ [110] and H+ [111] selective electrodes.

A year later, the group of Wardak presented the CuO-MWCNT material, applied as a solid-contact layer in Cu2+-selective electrodes [112]. These electrodes were characterized by a low detection limit (1.5 × 10–8 mol L–1) and very good potential stability.

4. Metal Oxides Nanoparticles in Paste Electrodes

Both metal oxides and their composites were used as a component in the paste electrodes. Niemiec et al. designed carbon black paste electrodes modified with poly(3-octylthiophene-2,5-diyl) and transition metal oxides: Ruthenium and iridium dioxide [77].

In this research, electrodes with carbon paste based on carbon black and modified with hydrated transition metal oxides, namely hydrous ruthenium dioxide and hydrous iridium dioxide, were presented. The paste with hydrous ruthenium dioxide, characterized by the best capacitance (470 μF), was extra modified by poly(3-octylthiophene-2,5-diyl). This modification results in a PVC-based electrode with the highest capacitance (130 μF) and, consequently, the lowest drift of the potentiometric response. The developed electrodes can be used to determine nitrate ions in liquid samples and soil samples [77].

This entry is adapted from the peer-reviewed paper 10.3390/membranes13110876

This entry is offline, you can click here to edit this entry!