1. Electrochromic Evacuated Glazing (ECEVG)

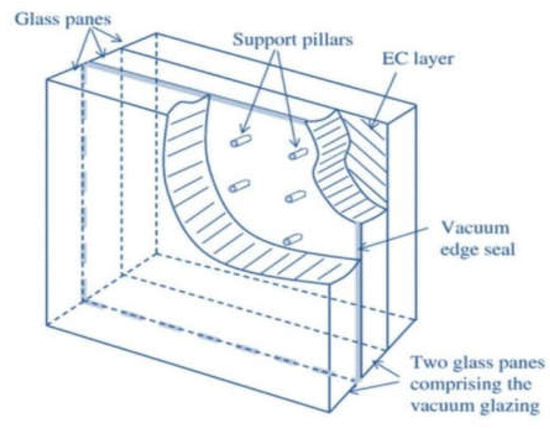

Recently, a combination of electrochromic and vacuum glazing in a single unit has been investigated [

25,

104]. To show the potential of this technology, [

105] examined and evaluated ECEVG prototypes with VT of 0.63, in the transparent state, and U-values of 0.86 W/m

2K.

Figure 24 illustrates the layout of an ECEVG.

Figure 24. Schematic illustration of an ECEVG (retrieved from [

104]).

According to [

10], an ECEVG glazing system can be switched between clear and opaque states by applying a DC voltage. This occurs since the applied voltage modifies the density of the electrochromic layer’s electrons, leading to a change in the optical properties and state of the system, and consequently, entering solar energy can be modulated. A significant advantage of ECEVG is that it combines the transmittance of electrochromic glazing, which varies with the low heat loss characteristics of evacuated glazing. Therefore, optimal thermal comfort is achieved while energy consumption is reduced. Work on the energy performance of ECEVG showed that, due to the EC layer, about 10% of incident solar energy in the transparent state and 60–80% in the opaque state is absorbed [

104]. Investigation of the energy performance of ECEVG was performed with EC layer facing outdoor or indoor environment. This investigation revealed that the temperature difference between the inside and outside glass pane, when the electrochromic layer was facing the indoor environment, was dangerously high, resulting in the breakdown of the glazing system. In the case of an ECEVG, the electrochromic layer must be placed facing the outdoor instead of the indoor environment.

2. Integrated Micro-Blinds and Nanocrystals EC

An emerging dynamic glazing technology with incorporated micro-blinds and nanocrystals-based electrochromic materials promises possible future applications in architecture. Integrated micro-blinds consist of inorganic prestressed curling electrodes with a size of the order of 100 µm. They are invisible to the naked eye being able to unwind when they are triggered by a weak electrostatic stimulus [

106]. Light passes through when no voltage is applied because the blinds are curled. However, when a voltage is applied, the micro-blinds are stretched under the electrostatic forces induced by the applied voltage, and light is blocked. The performance of this glazing is comparable to that of conventional dynamic electric control glazing [

12]. Currently, a few institutions, such as the University of Kassel, Germany [

107], the University of Tokyo, Japan, and the Institut National d’Optique, Canada [

108] are working on developing this technology.

The main advantages of this glazing technology are: (i) conductive layers of expensive indium-tin oxide are not required, (ii) very small (in the order of milliseconds) activation and deactivation times, and (iii) for further performance improvement in the unwound state, highly reflective materials are used [

14]. Current development aims to create market-sized glazing that can independently modulate visible light and infrared solar radiation.

3. Localised Plasmon Resonance (LPR)

For energy-saving purposes, the reflection of solar radiation at near-infrared wavelengths is vital to prevent heat transfer into space and decrease cooling energy consumption. Therefore, for near-infrared light, reflecting coatings attached to glazing are important [

109,

110,

111]. On the other hand, achieving high light transmission in the visible range is also significant to ensure good visibility and decrease electricity consumption for lighting the space. According to [

112], Fujifilm Co. Ltd. has developed a spectrally selective film ( Nano Silver Pavement, NASIP), which satisfies the above requirements. It consists of randomly distributed silver nanoparticles with disk shapes that reflect near-infrared light. The physical principle of its operation is attributed to plasmon resonances between the nanostructured matter and the incoming light [

109].

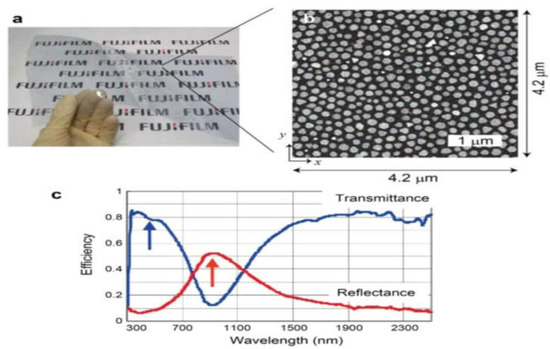

An LPR film with silver nanoparticles is shown in

Figure 25a, whereas

Figure 25b depicts a scanning electron microscope (SEM) image of disk-shaped silver nanoparticles [

110]. The nanoparticles, which are in disc shape have an average diameter in the range of 100–120 nm, and their thickness is about 10 nm. Furthermore, from

Figure 25b, the shape and layout of nanoparticles vary randomly. The fabricated film’s spectral properties (reflectance and transmittance), which were observed experimentally, are depicted in

Figure 25c.

Figure 25. (

a) LPR film (

b) image indicating the silver nanoparticles (

c) measured transmittance and reflectance of the LPR film (retrieved from [

112]).

It can be shown that the reflectance is high for near-infrared light whereas, in the visible and far-infrared regions, the transmittance maintains high. In Figure 25c, particles resonate at frequencies of light with wavelengths of about 900 nm. At this wavelength, light is reflected and scattered, whereas, at the other values of the light wavelength, it is transmitted. The reflectivity and transparency of the film can be modulated by tuning the resonant frequency by controlling the size and shape of nanoparticles.

4. Electrically Tunable Glazing

According to [

113], a device has been designed to control the light transmitted through significant areas, such as glazing surfaces. The main feature of this device is that without affecting its colour its transparency is tunable. Its operation is based on the distortion of the soft dielectrics caused by a voltage applied between the two electrodes on either side of the elastomer [

4].

5. Nanocrystal in-Glass Composites Glazing (NCCG)

Among electrochromic glazing, nanocrystal in-glass composites (NCCG) are the most promising emerging technology for improving the glazing’s overall performance (thermal and visual). It allows separate and independent regulation of the transparency of visible light (VL) and near-infrared (NIR) wavelengths, and, therefore, it is characterised as dual-band dynamic glazing technology [

13].

NCCGs technology was initially developed by the University of California, Berkeley, using nanocrystals of Indium-tin-oxide (ITO) in a niobium oxide (NbOx) matrix called NIR-switching electrochromic glazing [

114]. This technology, without blocking visible light transmission, allows controlling NIR radiation from a bright mode (fully transparent) to a cool mode (state without VL control), and finally, a no-tinted state (dark mode) controlling both heat and natural light.

The energy performance of this glazing technology has been investigated using simulations for various types of buildings and weather conditions in the USA and compared to electrochromic glazing [

115]. This investigation/comparison shows that dual-band dynamic glazings are the best energy savers for cooling and heating-dominated climates.

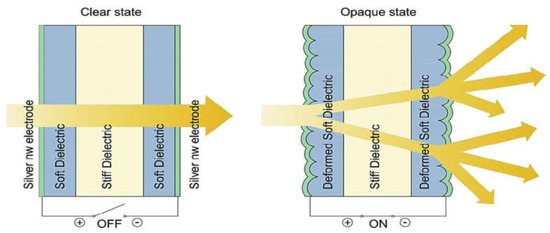

6. Elastomer-Deformation Tunable Glazing

This emerging dynamic glazing technology can vary from a clear to an opaque state, able to diffuse light similarly to LCD glazing. It has different properties and uses from electrochromic. It is based on a mechanical rather than an electrochemical approach to light control [

113]. A schematic illustration of the composition and principle of operation of an elastomer-deformation tunable glazing is illustrated in

Figure 28. The glass pane is located between two transparent soft dielectrics on which electrically conducting silver nanowires are sprayed. These nanowires do not significantly affect light transmission. They are invisible to the naked eye, and they react to electromagnetic stimuli.

Figure 28. Schematic illustration of composition and principle of operation of elastomer-deformation tunable glazing (retrieved from [

13]).

The basis of the operation of this glazing technology is the geometric alteration of the glazed surface, which leads to control light scattering. Thus, the optical state of the glazing changes to any state between transparent and opaque. According to [

13], without voltage applied to the system, the glazing is at the clear state, as shown in

Figure 28 as nanowires are not energised. On the contrary, by applying a voltage to the system, the nanowires are energised, become electrodes, and, due to Coulomb forces, they move toward each other. Under this movement, the two layers are squeezed and deformed, leading to an irregular surface roughness since nanowires are unevenly distributed. This results in light refraction reducing the glazing VT [

116].

Remarkably, the time required for the complete process is less than a second, while the value of the applied voltage can control the irregular surface roughness of the elastomer, and thus, according to this value, tuning of VT is achievable. This is an advantage compared to conventional LCD glazing, which allows only altering from a transparent to an opaque state. The manufacturing process of the subject glazing technology uses elastomer sheets available in large rolls; therefore, it is cheaper compared to the more expensive vacuum deposition process used by chemical-based dynamic glazing technologies currently used. The best potential of this technology is the possibility of glare control while maintaining an adequate level of diffused light indoors. However, the energy performance of this technology in real-time has not been defined yet.

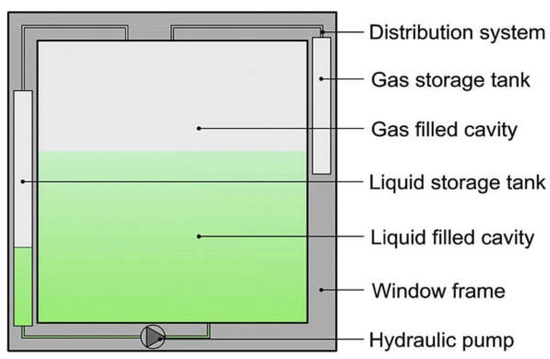

7. Liquid Infill Tunable Glazing Technology

Liquid infill tunable glazing technology belongs to purely mechanical systems in contrast to the electrochemical systems to which most dynamic glazing technologies belong. For this technology, the use of a liquid for shading purposes is employed. The liquid is pumped in or out of the cavity/cavities of insulated glazing systems. The principle of its operation is schematically illustrated in

Figure 29 [

13]. The liquid-based technology was developed at the Universita Politecnica delle Marche [

117] and includes a triple glazing unit, with one 12 mm cavity used for thermal insulation purposes and a second cavity of 1.5 mm used for the storage tanks of the shading fluid and gas. These tanks are enclosed in the glazing frame, and the circulation of shading fluid is achieved by a pump which, when it is needed, fills the narrow cavity with the shading fluid, whereas the gas is extracted and pumped to the gas tank. Thus, the glazing unit can block unwanted light and heat. Further to the main components described above, the system also employs overflow sensors and valves required for the monitoring of liquid infill.

Figure 29. Schematic illustration of the principle of operation of liquid infill tunable window (retrieved from [

13]).

Regarding the system’s performance, experimental work revealed that the visual and thermal transmittance, at its clear and filled state, is: 68.3% with 47.2% and 16.0% with 18.3%, respectively [

13].

The main disadvantage of this technology is the bulky frames needed for the accommodation of piping, pump, and liquid and gas storage tanks. Furthermore, another disadvantage may be the uneven appearance of the glazing in its partly filled state due to the fluid pumping from the bottom of the panes.

8. Electrokinetic Pixel Glazing Technology

Electrokinetic pixel glazing technology is a polarised particle technology, such as LCD technology, that aims to modulate the colour and temperature of the visible light passing through electrochromic glazing. According to [

118], by controlling the movement of coloured particles via an applied voltage, it is possible to modulate separately the transmission and colour of the light entering the glazing.

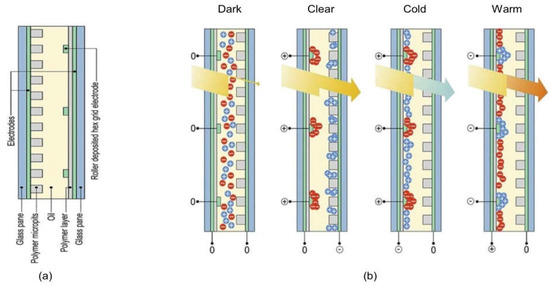

Figure 30a shows that the glazing consists of two planar electrodes to control how the particles of 2 complementary colours (Blue-Yellow or Red-Cyan or Green-Magenta) carrying opposite electrical charges are dispersed. The principle of operation is schematically illustrated in Figure 30b. Each electrode can be separately charged, positively or negatively, triggering the coloured particles’ movement towards another electrode.

Figure 30. Schematic illustration of: (

a) composition and (

b) operation principle of electrokinetic pixel glazing technology (redrawn from [

13]).

According to [

13], the movement and final concentration/position of the coloured particles determine the various states/modes characterised by different VT and light colour, as shown in

Figure 30b: (i) Dark when electrodes are not charged, and both colour particles are mixed and uniformly dispersed, (ii) Clear state, when outer perimeter electrode is not charged, inner perimeter electrode is negatively charged, hexagonal grid electrode is positively charged and thus colour particles are compacted at the perimeter electrode and the micro-pits without colour dispersion. (iii) Cold hue, when the outer perimeter electrode is negatively charged, the inner perimeter electrode is not charged, hexagonal grid electrode is positively charged, and thus blue particles dispersed. In contrast, yellow particles compacted around the perimeter electrode and, (iv) Warm hue, when the outer perimeter electrode is positively charged, the inner perimeter electrode is not charged, hexagonal grid electrode is negatively charged and thus yellow particles dispersed and blue particles accumulated around the perimeter electrode. A 25 V voltage is required for switching between control states, whereas each state can be maintained with a voltage of ±10 V [

13].

9. Optofluidic Glazing

The three optical properties, transmission, reflection, and absorption, can be adapted by utilizing the concept of refractive index matching. The optofluidic glazing consists of two transparent layers and an air cavity between the two layers [

14]. One of the transparent layers is roughened from the inside. The light rays are reflected and scattered due to the roughened surface, and thus, the light transmittance is reduced. The working mechanism of the optofluidic glazing utilizes the total internal reflection between the material-air interfaces. The cube reflectors reflect the light incident upon them back to the source, whereas the light transmittance increases when the intermediate space is filled with fluid. As the fluid’s refractive index increases compared to that of the surrounding material, the refraction decreases, and the transmittance increases.

It is worth mentioning that optofluidic glazing has various maintenance problems. For instance, leakage and low air temperature (less than the freezing point of the liquid) are reported [

14]. However, recently, sealed modules have been manufactured using Vero Clear photopolymer [

119]. Due to the capability to modulate reflectance and transmittance, solar loads can be controlled, and consequently, the efficiency of heating, ventilation, and air conditioning increases. Furthermore, privacy panels, dynamic camouflage, and architecture are reported as additional applications of optofluidic glazing [

119].

The main advantages and disadvantages of emerging glazing technologies are tabulated and presented in Table 6.

Table 6. Features/Advantages and Limitations/Disadvantages of emerging glazing technologies.

| Glazing Technology |

Features/Advantages |

Limitations/Disadvantages |

References |

| Static |

Air Sandwich |

|

-

It has lower thermal performance currently

-

It has not been used for a long time

-

Vulnerable to degradation due to solar radiation

|

[89,90,91] |

| Suspended films |

|

|

[11] |

| Heat Insulation Solar Glass (HISG) |

-

It provides thermal insulation, power generation, self-cleaning, and acoustic insulation ( Multi-functional glazing)

-

Lower U-value compared to conventional PV

|

|

[92,93] |

| Transparent Insulation Material (TIM) |

|

-

Imperfection in the manufacturing process

-

Very high production cost

-

Overheating may occur due to high levels of solar radiation absorption

|

[27,87] |

| Solar absorbing |

-

Reduction of inner pane temperature

-

Room heat gain is decreased

-

Air-conditioning electricity reduction

-

Enhanced thermal and visual comfort

|

|

[94] |

| Transparent PV |

|

|

[95,96,97,98,99,101,102,103] |

| Dynamic |

Electrochro-mic evacuated |

|

|

[10,25,104,105] |

| Micro-blinds and nanocrystals electrochro- mic |

-

Small activation and deactivation times

-

Expensive indium-tin oxide is not needed

-

Independent control of visible light and infrared radiation

|

|

[12,14,106,107,108] |

| Electrically tunable |

-

Tunable transparency without affecting the glazing colour

-

Control of transmittance of light incident

-

Reduction of lighting energy consumption

|

|

[4,113] |

| Nanocrystal in-glass composites |

|

|

[13,114,115] |

| Electrokine-tic pixel |

|

|

[13,118] |

| Elastomer- deformation tunable |

|

|

[13,113,116] |

| Liquid infill tunable |

-

Short switching times

-

Lower cost

-

Shading modulation

|

-

VL and IR radiation at a lower control range

-

Uneven appearance at partly filled state

-

Bulky frames are needed for tanks

|

[13,117] |

| Localised Plasmon Resonance |

-

High light transmission in the visible range

-

High reflectance for NIR light

-

Cooling energy consumption is reduced

-

Transparency and reflectivity are modulated

|

|

[109,110,111,112] |

This entry is adapted from the peer-reviewed paper 10.3390/en16145357