Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Sirius Huang and Version 1 by Dirk W. Lachenmeier.

Coffee bean harvesting incurs various by-products known for their long traditional use. However, they often still end up being a waste instead of being used to their full potential. On the European market, coffee cherry (cascara) products are not yet common, and a novel food approval for beverages made from coffee cherry pulp was issued only recently.

- coffee cherry pulp

- cascara

- coffee by-products

- coffee bean processing

1. Introduction

Cascara (i.e., Spanish: husk) is the term typically used to describe the fruity bittersweet layers with unique flavors that cover the coffee bean. Coffee is widely consumed around the world and ranks among the most traded agricultural products [1]. Despite the traditional use of cascara as a beverage prepared with hot water in some coffee processing cultures such as Ethiopia (hashara) or Yemen (qishr) [2], this application is rather unknown in the Western world [3]. About 30% of the dry matter of the coffee cherry is due to the exocarp and mesocarp, which together are generally referred to as pulp [4]. Dry processing produces about 1 kg of coffee husk for every kg of coffee bean produced [5]. Considering that approximately one-third of the world’s population consumes coffee and it is an important export commodity, coffee by-products offer not only great potential but also a large market [6]. Recently, the way to more sustainability was paved, as dried coffee cherry pulp was granted novel food approval in the EU. However, the approval of coffee cherry pulp has so far been limited to its use in non-alcoholic beverages [7,8][7][8]. Commercial EU trade in other processed by-products is hindered by the lack of novel food approvals [9] due to the still missing information and risk assessments on bioactive substances.

The cascara pulp obtained during wet processing after harvesting (Figure 1) still has a high moisture and sugar content and therefore spoils quickly [10]. It requires food-safe working steps and equipment for further processing of the pulp. Until now, coffee by-products have been used as fertilizers [11] or animal feed [12]. However, these by-products are suitable only as an admixture to animal feed and not for exclusive feeding, since bioactive substances such as caffeine, tannins, and polyphenols can have undesirable effects in cattle [13]. Bressani et al. showed that an admixture of more than 10% leads to a reduced feed intake, poorer nutrient usage, and reduced weight gain among animals [14]. The high caffeine and tannin contents also represent anti-nutritional factors for plants, for which reason the use of coffee by-products as fertilizers is limited as well [15]. Furthermore, chlorogenic acid has a negative influence on the germination of plant seeds and plant growth [16]. Nevertheless, a large part of the coffee by-products is still inappropriately disposed of in the environment, where the products contaminate soil and water to a high degree. Due to the rapid onset of the fermentation and degradation processes of the coffee cherry pulp and its high biochemical oxygen demand in water, the pH value decreases [17]. Beyene et al. described the change in measured parameters in river water upstream and downstream of coffee plantations in Ethiopia. In summary, the results show significant water degradation during coffee processing: the pH decreased from 7 to 6.2, the amount of oxygen dissolved in the water was reduced, and the load of organic substances was strongly increased. These changes in water quality, as well as the bioactive substances dissolved from the coffee plant, reduced the biodiversity of macroinvertebrates in the river water [7].

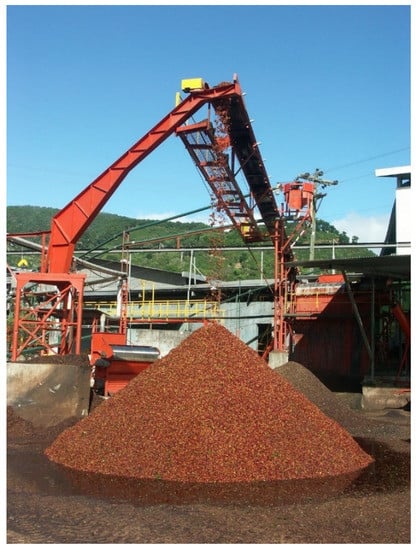

Figure 1.

Coffee pulp from wet processing collected in a heap.

2. Coffee Cherry Structure and Processing

In the literature, the reported contents of components vary significantly in some cases. The reason for this situation, apart from geographical and biological conditions, is also the different understanding of what cascara is. Depending on the processing method, different parts of the fruit are included in the final product. The processing methods and the structure of the coffee cherry will be briefly outlined in the following.

2.1. Coffee Cherry Structure

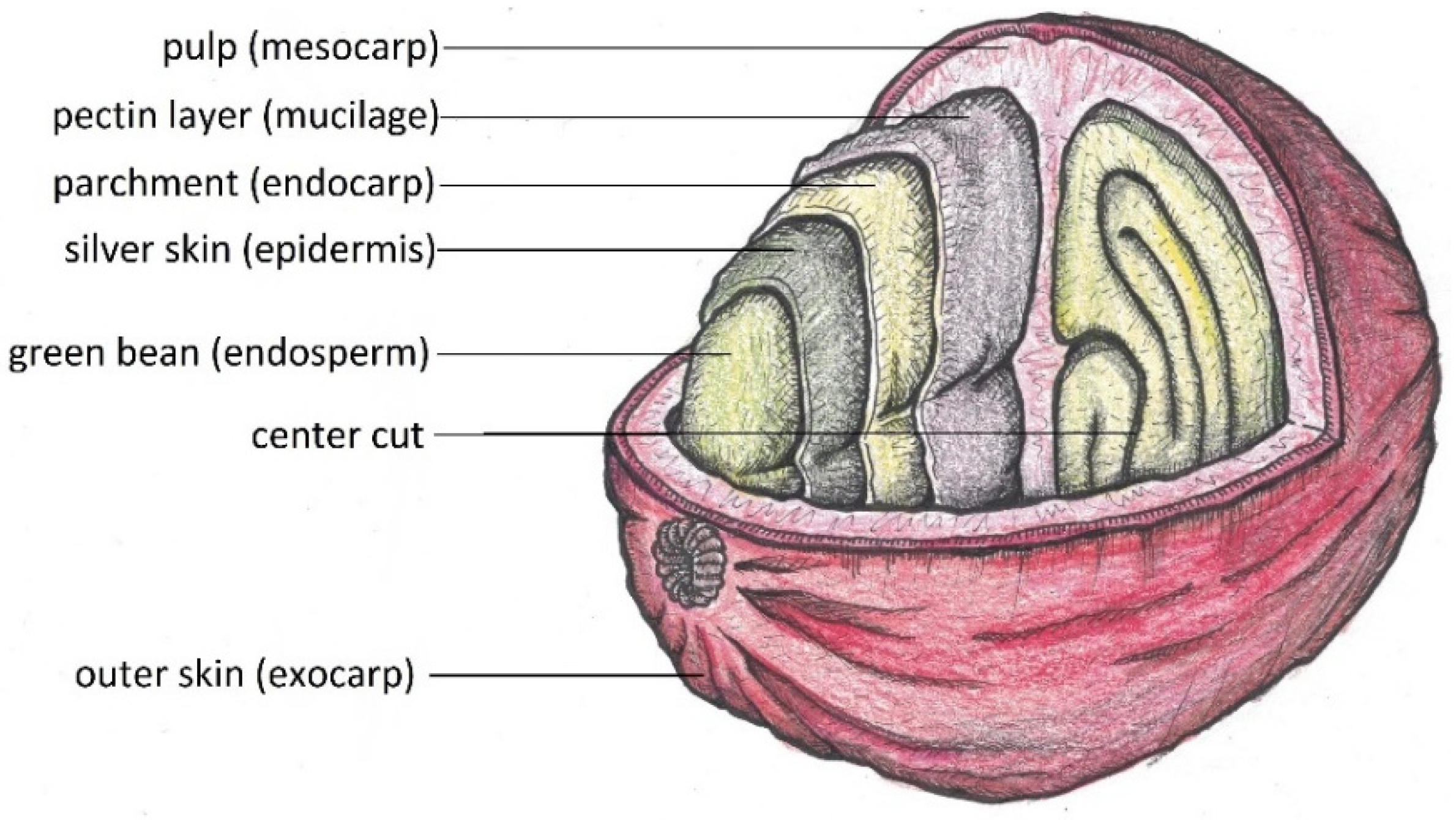

Coffee cherries are drupes that grow to an average diameter of 1.5 cm (Figure 2). The two main species that are grown are Coffea canephora and Coffea arabica [11]. Between the parchment and the outer skin lies the sweet-tasting mesocarp. The two coffee beans themselves are coated with silver skin and parchment (Figure 3).

Figure 2.

Ripe (red) and unripe (green) coffee cherries on a branch.

Figure 3.

Different layers of a coffee cherry (drawing by the authors).

2.2. Coffee Cherry Processing

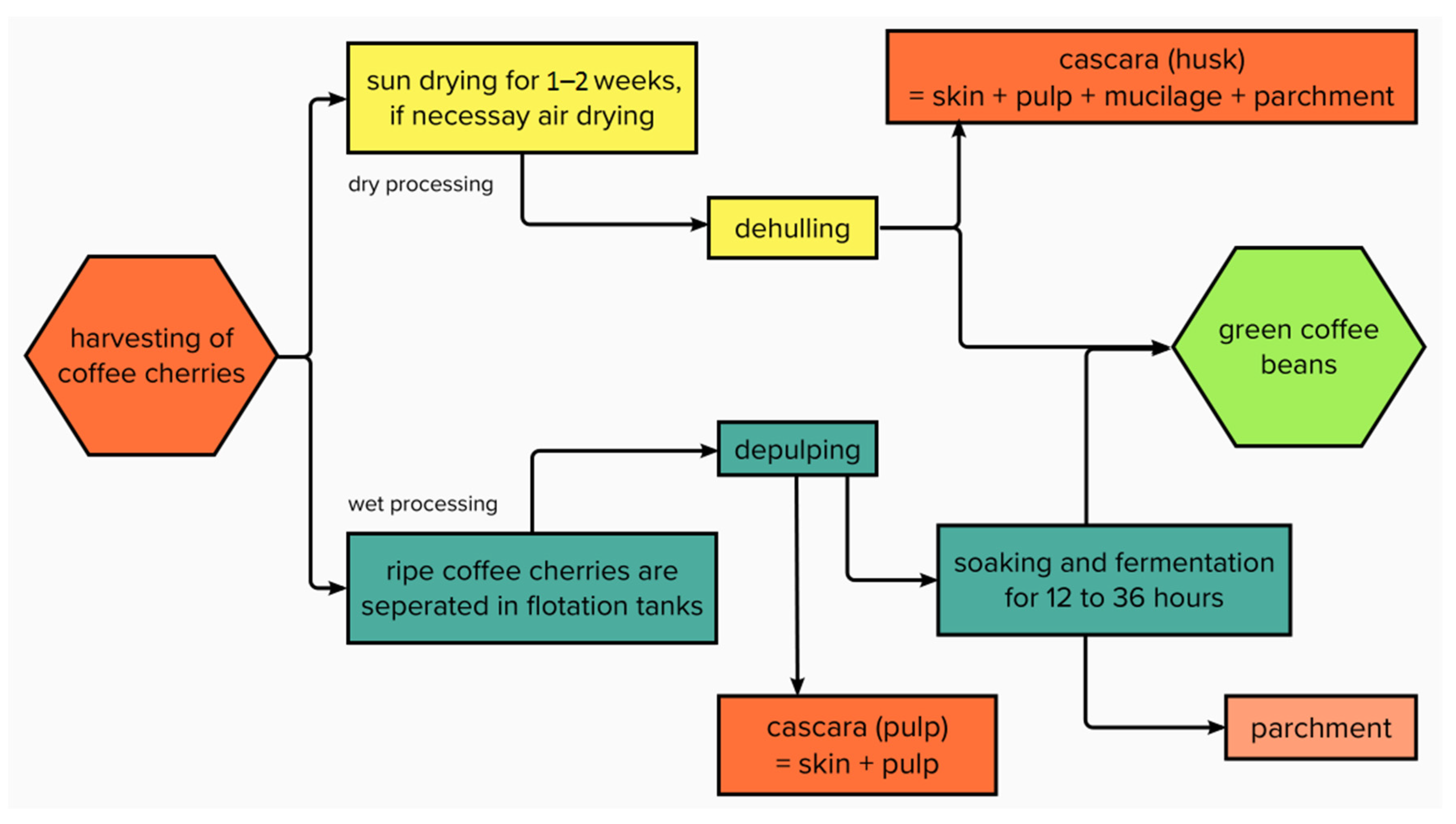

When processing, a distinction is made between the dry method, the wet method, and the semi-dry or semi-washed method (Figure 4).

Figure 4.

Dry and wet processing of coffee cherries.

The dry method is often used to process C. canephora, but also for C. arabica (as the main processing method in countries such as Brazil or Ethiopia) [24][18]. During this process, the coffee cherries are spread on fields, terraces, or beams to be dried in the sun (Figure 5), if necessary, with the help of heated air dryers, until the moisture content has been reduced to approximately 10–12% [25][19]. This takes, depending on the local climate, about 1 to 2 weeks. Subsequently, a dehulling machine separates the green coffee bean from the dried outer layers of the fruit, thus obtaining coffee husks (Figure 6). By definition, coffee husks or cherry husks consist of the exocarp (outer skin), the mesocarp (pulp), and the endocarp (parchment). In the more sophisticated wet method, ripe coffee cherries are separated in flotation tanks, after which a mechanical depulper separates the skin and pulp from the green coffee bean (Figure 7) as well as from the green (unripe) cherries which cannot be depulped. The coffee bean is still covered with parchment and mucilage layer and is now soaked and fermented for 12–36 h. Fermentation is performed using existing or added microorganisms or enzymes [25][19]. The microbial community during depulping is mainly composed of lactic acid bacteria, acetic acid bacteria, enterobacteria, and yeasts. During fermentation, the proportion of lactic acid bacteria increases, such as Leuconostoc pseudomesenteroides, Lactobacillus vaccinostercus, Lactobacillus brevis, and Lactobacillus plantarum [26][20]. Before finally drying the beans, they must undergo intensive cleaning with water. Coffee beans obtained using this method often have a higher market value due to the higher acidity created during the fermentation process [11,25][11][19]. The by-product separated during the depulping process is called coffee pulp or cherry pulp, which consists of exocarp and mesocarp. During the wet method, the parchment remains attached to the green coffee bean and is degraded by fermentation processes.

Figure 5.

Coffee cherries are spread on beams to be dried in the sun.

Figure 6.

Coffee cherry husks obtained after dry processing.

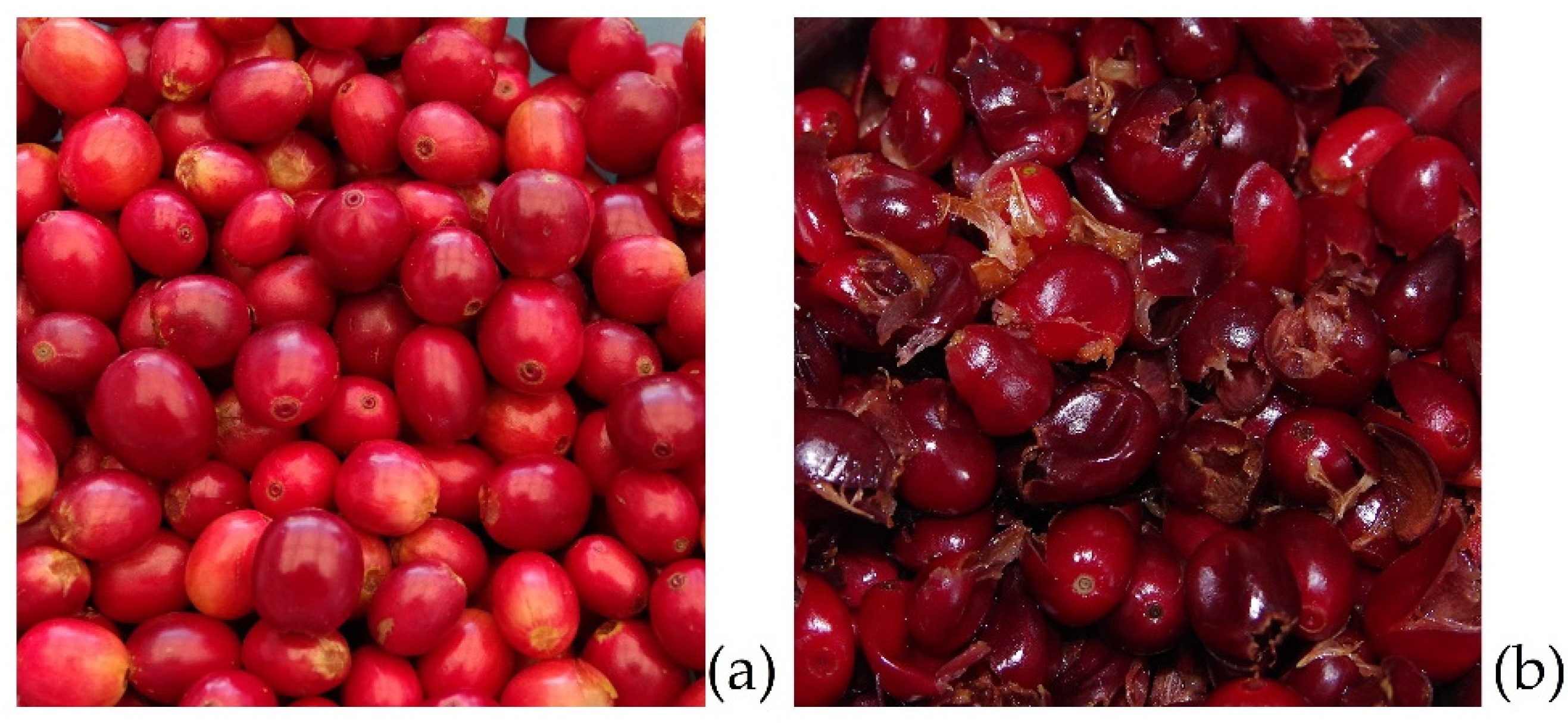

Figure 7.

(

a

) Ripe coffee cherries before processing; (

b

) coffee cherry pulp obtained after wet processing.

During the semi-dry method (often also referred to as “pulped natural”), as during the wet method, the ripe coffee cherries are sorted in flotation tanks, and the pulp is removed from the green coffee bean. However, no fermentation occurs after this process; instead, the mucilage remains on the bean and is dried along with it [27][21]. This method was developed in Brazil [25][19]. Coffee beans processed this way are claimed to have a particularly flavorful body due to the remaining layers rich in polysaccharides and give the beverage a certain sweetness [28][22].

References

- Arpi, N.; Muzaifa, M.; Sulaiman, M.I.; Andini, R.; Kesuma, S.I. Chemical characteristics of cascara, coffee cherry tea, made of various coffee pulp treatments. IOP Conf. Ser. Earth Environ. Sci. 2021, 709, 012030.

- Maxwell, G.W. Poor mans coffee? Yemeni qishr, qahwa and qat. Tea Coffee Trade J. 1996, 168, 64–69.

- Zeckel, S.; Susanto, P.C.; Erfiani, N.M.D. Market potential of cascara tea from Catur village Kintamani Bali. 2019. International Conference on Fundamental and Applied Research (I-CFAR). Available online: https://jurnal.undhirabali.ac.id/index.php/icfar/article/view/1061 (accessed on 30 November 2022).

- Murthy, P.S.; Madhava Naidu, M. Sustainable management of coffee industry by-products and value addition—A review. Res. Conserv. Recyc. 2012, 66, 45–58.

- Franca, A.S.; Oliveira, L.S. Coffee Processing Solid Wastes: Current Uses and Future Perspectives; Nova Science Publishers, Inc.: New York, NY, USA, 2009; ISBN 978-1-60741-305-9.

- International Coffee Organization. International Coffee Organization—Trade Statistics Tables. Available online: https://www.ico.org/trade_statistics.asp (accessed on 26 August 2022).

- Beyene, A.; Kassahun, Y.; Addis, T.; Assefa, F.; Amsalu, A.; Legesse, W.; Kloos, H.; Triest, L. The impact of traditional coffee processing on river water quality in Ethiopia and the urgency of adopting sound environmental practices. Environ. Monit. Assess. 2012, 184, 7053–7063.

- European Food Safety Authority. Technical Report on the notification of dried cherry pulp from Coffea arabica L. and Coffea canephora Pierre ex A. Froehner as a traditional food from a third country pursuant to Article 14 of Regulation (EU) 2015/2283. EFSA J. 2021, 18, 6808E.

- Klingel, T.; Kremer, J.I.; Gottstein, V.; Rajcic de Rezende, T.; Schwarz, S.; Lachenmeier, D.W. A review of coffee by-products including leaf, flower, cherry, husk, silver skin, and spent grounds as novel foods within the European Union. Foods 2020, 9, 665.

- Devoney, M. Cascara Jelly Production Potential for Smallholder Farms in Huehuetenango, Guatemala; University of California, Davis: Davis, CA, USA, 2021.

- Belitz, H.-D.; Grosch, W.; Schieberle, P. Food Chemistry, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-540-69933-0.

- Bondesson, E. A nutritional Analysis on the by-Product Coffee Husk and Its Potential Utilization in Food Production; Swedish University of Agricultural Science: Uppsala, Sweden, 2015.

- Arya, S.S.; Venkatram, R.; More, P.R.; Vijayan, P. The wastes of coffee bean processing for utilization in food: A review. J. Food. Sci. Technol. 2022, 59, 429–444.

- Bressani, R.; Braham, J.E. Utilization of coffee pulp as animal feed. In Proceedings of the Neuvieme Colloque Scientifique International sur le Cafe, Londres, UK, 16–20 June 1980; pp. 303–323, 799–800.

- Galanakis, C.M. Handbook of Coffee Processing by-Products: Sustainable Applications; Academic Press: London, UK, 2017; ISBN 9780128112915.

- Janissen, B.; Huynh, T. Chemical composition and value-adding applications of coffee industry by-products: A review. Res. Conserv. Recyc. 2018, 128, 110–117.

- Otalora, A.F.B. Coffee Pulp Preservation and Extraction Process. U.S. Patent No. 10,066,089 B2, 4 September 2018.

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, composition, and application of coffee and its industrial residues. Food. Bioprocess. Technol. 2011, 4, 661–672.

- Das, S. Review Post-harvest processing of coffee: An overview. Coffee Sci. 2021, 16, e161976.

- Zhang, S.J.; de Bruyn, F.; Pothakos, V.; Torres, J.; Falconi, C.; Moccand, C.; Weckx, S.; de Vuyst, L. Following coffee production from cherries to cup: Microbiological and metabolomic analysis of wet processing of Coffea arabica. Appl. Environ. Microbiol. 2019, 85, e02635-18.

- Duarte, G.S.; Pereira, A.A.; Farah, A. Chlorogenic acids and other relevant compounds in Brazilian coffees processed by semi-dry and wet post-harvesting methods. Food Chem. 2010, 118, 851–855.

- Farah, A. Coffee as a speciality and functional beverage. In Functional and Speciality Beverage Technology; Woodhead Publishing: Sawston, UK, 2009; pp. 370–395.

More