This research tackles issues such as the reliability and efficiency of real-time control systems based on commercial off-the-shelf (COTS) components. A strong emphasis is placed on finding novel efficient solutions based on standardized and commercially available off-the-shelf hardware/software components. In this direction, this research applies credible and feasible methodologies (e.g., model-based design, component-based design, formal verification, real-time scheduling, prototyping, and validation) in an innovative enhanced way. As an important outcome, a versatile integrative design approach and architectural framework (VIDAF) is proposed, which supports the development and implementation of reliable real-time control systems and applications using commercial off-the-shelf components. The feasibility and applicability of the proposed system’s architecture are evaluated and validated through a system application in embedded real-time control in manufacturing. The research outcomes are expected to have a positive impact on emerging areas such as the Industrial Internet of Things (IIoT).

- control systems

- real-time

- commercial off-the-shelf

- reliability

- availability

- low-cost

1. Introduction

The advances of computer technologies and the continuous growth of their applications bring new challenges (e.g., tasks concurrency in multicore processors) in building reliable real-time control systems. The complexity of such systems continues to increase, by integrating various computing and networking components and devices, particularly wireless communication equipment and other structures and services that rely on the physical world as well as on the virtual world e.g., cloud computing and the Internet-of-Things (IoT) [1][2]. The drastic increase in the versatility of computing devices and their deployment in key sectors, such as health-care, energy, and the military raises several issues regarding the reliability, availability, and adaptability of their operation. Many sectors rely on the reliable, on-schedule, and cost-efficient operation of such computer-based systems in order to provide appropriate and time effective services. Such essential aspects are a necessity for critical systems deployed in key sectors. In these environments, the architectural framework of such systems is based primarily on specialized or custom-built hardware/software (HW/SW) components, which impose extra undesirable costs, slow down the development and maintenance process, and limit the reusability and versatility of the final product or service [3].

2. COTS-Based Architectural Framework for Reliable Real-Time Control Applications

The challenge of keeping the development and implementation of real-time control systems reliable and efficient, and at the same time, low-cost is getting harder. This is because system designers and developers are faced with the dependability, inflexibility, and often high-cost of the specialized hardware/software components [4][5]. In addition, building systems based on specialized hardware/software imposes extra costs which are not desirable. Developers would prefer to utilize primarily general-purpose, reconfigurable/reprogrammable hardware/software components, in order to lower the cost, speed up the development process, and make the final product more versatile. Such components are commercial off-the-shelf (COTS) items sold in substantial quantities in the commercial marketplace. For example, commercial off-the-shelf components have become the preferred way of designers in military and aerospace applications for the development of unmanned aerial vehicles [6][7].

The market of reliable real-time systems is rapidly expanding due to the increasing number of applications in several domains and sectors (e.g., health services, industrial robotics, unmanned aviation, smart cities, etc.). In such critical real-time systems, typically, the more severe the consequence of potential system failure, the more specialized the control system needs to be. Usually, such specialized solutions impose significant costs. The new market applications, particularly of reliable embedded systems in critical applications in IoT and cloud computing, are seeking to use low-cost COTS-based components and devices in building real-time control systems due to their immediate availability, rapid utilization, ease of reconfiguration, and versatility. Low-cost COTS components are expected also to affect the reliability of many systems, as reduced costs could improve the threshold for introducing reliable solutions in real-time systems too, for which reliability is not a strict prerequisite (e.g., in soft real-time systems). In this direction, several companies report the development of such systems based on COTS components. Just recently, companies such as Abaco Systems, Real-Time Innovations (RTI), and Wind River Co. announced the joint development of the first hardware, operating system, and communications framework with commercial-off-the-shelf (COTS) components for Airborne Systems [8]. Systems built on COTS-based components provide increased reliability and quality over custom-built components as these are utilized and validated by various independent developers and organizations, due to their large scale utilization in various applications and implementations. However, despite the continuous increase in the utilization of COTS-based components, their reliable performance in real-time systems still remains under further research, which is an objective of this work too.

An important motivation for this research into reliable real-time systems based on COTS components, particularly for control applications in manufacturing, is the continuous increase of the demand for rapid, low-cost, low-consumption, and short-time development. Additionally, there is also a need for the immediate availability of versatile and general-purpose hardware/software components (e.g., cloud computing is the on-demand availability of computer system resources). For this reason, a strong emphasis of this research is to find efficient solutions to relevant open questions and issues, regarding the reliability and efficiency of real-time control systems based on general-purpose hardware/software components, such as:

-

How to ensure availability and reliability through a warehouse of general-purpose hardware/software components?

-

How to integrate and synthesize complex general-purpose hardware/software components into real-time systems applications?

-

How to assess and measure the reliability of real-time systems applications based on general-purpose hardware/software components?

-

How to evaluate the overall performance of real-time systems based on a versatile range of general-purpose components and devices?

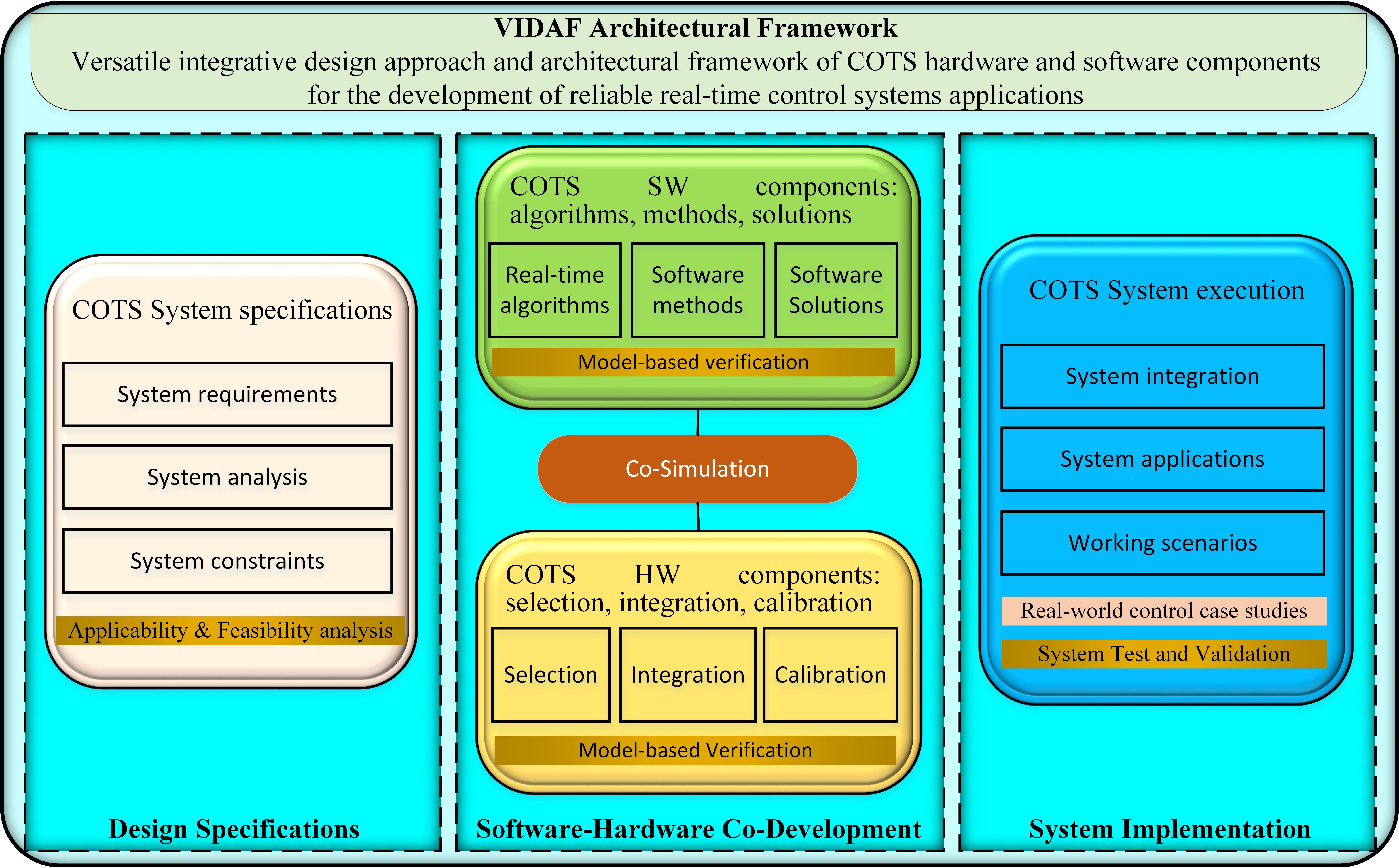

This research work proposes a versatile integrative design approach and architectural framework (VIDAF) that addresses these challenging issues and open questions, with credible methodologies and approaches that lead to novel efficient solutions, validated in real-world cases. The overall structure of the proposed framework is illustrated in Figure 1.

Figure 1. Versatile integrative design approach and architectural framework (VIDAF).

VIDAF defines an open architectural framework in building reliable, real-time, and cost-effective systems and applications, based on general-purpose hardware/software components, and minimizing the use of specialized ones. In resolving these challenges, the research targets the following objectives:

-

Define a novel system architectural framework that uses general-purpose hardware and software components for building reliable real-time and cost-efficient control systems.

-

Propose a novel system application infrastructure that enables efficient and reliable functionality and implementation of such systems in real-time applications.

-

Demonstrate the efficient and reliable development and exploitation of such systems based on general-purpose hardware/software, in real-time embedded applications in manufacturing.

This research paper presents the approaches and methodology to achieve these objectives and goals in an innovative way, proposes an architectural framework that enables the development and implementation of reliable real-time control systems, and demonstrates its feasibility and applicability through a system application in manufacturing. A COTS-based development process is proposed, upon which a system architecture is implemented into the control of a lime mash/slurry (milk-of-lime) storage and delivery machine. In this case study, a custom-built (80C188EB-based and assembly driven) controller was substituted successfully with COTS-based hardware components (RaspberryPi-based microcontroller board, referred from now on as RPi3) and open-source control software modules (written in standard C and Python). The experimental results of the architectural working prototype provide evidence that the system performs reasonably well and correctly.

Overall, this research work presents a framework with its own structure specifications and constraints, upon which COTS-based systems could be developed, and further on, based on the architectural framework proposed, a case study demonstrates the development of such a COTS-based system in real-time control in manufacturing, verifying its validity and applicability. The proposed architectural framework is just a prototype architecture that could not be generally applied as a roadmap or as a standard in developing real-time COTS-based systems in the manufacturing domain. However, it constitutes a successful architectural attempt in developing COTS-based systems for specific manufacturing cases where real-time reliable control is also essential among low-cost, rapid development, and other desired requirements.

References

- Yuanqing Xia; Cloud control systems. IEEE/CAA Journal of Automatica Sinica 2015, 2, 134-142, 10.1109/jas.2015.7081652.

- Buyya, R.; Dastjerdi, A. . Internet of Things, Principles and Paradigms.; Morgan Kaufmann: Cambridge, MA, USA, 2016; pp. 1-378.

- Wolf, M.. Computers as Components, Principles of Embedded Computing System Design; Morgan Kaufmann: Cambridge, MA, USA, 2012.

- Gan, J. Tradeoff Analysis for Dependable Real-Time Embedded Systems during the Early Design Phases. Ph.D. Thesis, Technical University of Denmark, Copenhagen, Denmark, 2014.

- Wei Pan; Zhanhuai Li; Yansong Zhang; Chuliang Weng; The New Hardware Development Trend and the Challenges in Data Management and Analysis. Data Science and Engineering 2018, 3, 263-276, 10.1007/s41019-018-0072-6.

- Elias Berra; Rachel Gaulton; Stuart Barr; Commercial Off-the-Shelf Digital Cameras on Unmanned Aerial Vehicles for Multitemporal Monitoring of Vegetation Reflectance and NDVI. IEEE Transactions on Geoscience and Remote Sensing 2017, 55, 4878-4886, 10.1109/tgrs.2017.2655365.

- Chiabrando, F.; Teppati Losè, L. Performance evaluation of COTS UAV for architectural heritage documentation. A test on S. Giuliano Chapel in Savigliano (CN) Italy. In Proceedings of the International Conference on Unmanned Aerial Vehicles in Geomatics, Bonn, Germany, 4–7 September 2017.

- Real-Time Innovations Co. COTS DO-254 and DO-178C Solution for Airborne Systems. Available online: www.rti.com/news/abaco-rti-and-wind-river-partner-to-deliver-first-cots-do-254-and-do-178c-solution-for-airborne-systems (accessed on 4 April 2020).